Everyone had to observe spark discharges, including people who were far from knowledge of electrical engineering. Thunderstorms are accompanied by giant spark discharges. The release of enormous energy concentrated in the electrical discharge of lightning (see Fig. 1) is accompanied by a blinding flash of a hot barrel. One of the types of spark discharges created by humanity is an arc discharge, or simply, an electric arc.

Rice. 1. Lightning discharge

To date, the reasons for the occurrence and properties of an electric arc have been studied in detail by science. Physicists have found that in the area of its combustion there is a huge concentration of charges that form the plasma of the barrel. The temperature of the column reaches several thousand degrees.

What is an electric arc?

This mysterious phenomenon was first described by the Russian scientist V. Petrov. He created an electric arc using a battery consisting of thousands of copper and zinc plates. Studying the process of igniting an arc with direct current, the scientist came to the conclusion that the air gap between the electrodes under certain conditions becomes electrically conductive.

One of the conditions for the occurrence of electrical breakdown is a sufficiently high potential difference at the ends of the electrodes. The higher the voltage, the larger the gas gap the discharge can bridge. In this case, an electrically conductive gas column is formed, which becomes very hot during the burning of the arc.

Rice. 2. Electric arc

A reasonable question arises : “Why does air, which is an excellent insulator in its normal state, suddenly become a conductor?”

There can be only one explanation - charge carriers are formed in the arc barrel, capable of moving under the influence of an electric field. Since there are no free electrons in air, unlike metals, only one conclusion suggests itself - ionization of gases (see Fig. 3). That is, starting the process of gas saturation with ions that are carriers of electric charge.

Rice. 3. Physics of the electric arc

Air ionization occurs under the influence of various types of radiation, including X-ray and cosmic irradiation. Therefore, there are always small amounts of ions in the air. But since the ions almost immediately recombine (turn into neutral atoms and molecules), the concentration of charged particles is always tiny. It is impossible to produce an arc flash at such a concentration.

For an arc discharge to occur, an avalanche-like ionization process is required. It can be caused by the strong heating of the gas that occurs during ignition.

When the contacts open, electrons are emitted and accumulate in a very small space. Under the influence of electric field strength, negative charges rush towards the electrode with a positive sign.

When the breakdown voltage is reached, a spark discharge occurs between the electrodes, heating the area between the electrodes. If the current is large enough, then the amount of heat will be sufficient to trigger an avalanche-like process of air ionization.

In an area called the arc gap, a barrel is formed, called an arc column, consisting of hot conductive plasma. A current flows through this barrel, maintaining the heating of the plasma. This is how the arc discharge ignites.

Saturation of the plasma barrel with ions of different signs leads to a significant increase in the current density, as well as to the recombination of some of the ions. Warming up the plasma also leads to an increase in pressure in the barrel. Therefore, some of the ions escape into the surrounding space.

If the formation of new charges is not maintained, the arc will be extinguished. As we have already found out, stable combustion is accompanied by 2 factors: the presence of voltage between the electrodes and maintaining a high plasma temperature. Excluding one of them will lead to arc extinguishing.

Thus, we can formulate the definition of an electric arc . Namely, an electric arc is a type of spark discharge, accompanied by a high current density, burning duration, and a small voltage drop across the barrel, characterized by increased gas pressure in which a high temperature is maintained.

An electric arc differs from a conventional discharge in that it burns longer.

Why does it happen?

According to the theory, under normal conditions gases are dielectrics. Given the right conditions, they can be ionized, giving their elements positive or negative charges.

An external electric field with specified parameters and high temperature affect the gas, transforming it into plasma, which has all the properties of a conductor of electricity.

This property has become widespread in industry, using the arc as a gas conductor.

The algorithm for generating an electric welding arc is as follows:

- Contact . It connects the electrode and the metal.

- Breaking contact . Under the influence of current, the surface of the electrode and metal begins to melt, forming a layer of liquid metal. Over a period of time, as the melt layer increases, the contact breaks.

- Excitation of the arc . The space between the anode and cathode is filled with ions and electrons of molten metal vapors, which, under the influence of voltage, are attracted to opposite poles, exciting an arc.

- Arc stabilization . As the concentration of charged particles increases, the arc connection undergoes intense ionization; at this point, complete combustion stabilization is achieved.

- Formation of a weld pool . Under the action of the arc, the metals of the electrode and surface pass into a liquid state of aggregation, forming a mixture.

- Crystallization . After the welding power source is turned off, the surface cools to form a welded joint.

Phenomena of ionization and deionization

Internal processes that contribute to the initiation and extinction of the arc are ionization and deionization. Studying these phenomena allows us to understand the factors influencing external processes. The predominance of ionization processes is characteristic of the causes of arc occurrence. When it stabilizes, the phenomena occur with equal frequency. With the prevalence of deionization phenomena, the arc will go out.

Types of ionization:

- Thermal . The most common process that helps maintain the arc after it has formed. Due to the significant temperature effect, the number and speed of elements increases, which has a beneficial effect on ionization.

- Percussion . When moving at high speed, an electron inevitably collides with a neutral particle. After the interaction, a new charged particle is formed - an ion.

- Field electron emission . Under the influence of an external high-intensity electric field, electrons leave the surface without prior excitation.

- Edison effect or thermionic emission . When exposed to high temperature, the energy level of electrons increases. Upon reaching a certain indicator, they are able to overcome the potential barrier at the border with the metal.

Deionization phenomena include:

- Recombination . The process of interaction of particles with opposite charges is accompanied by the formation of neutrally charged elements.

- Diffusion . The process of transfer of charged particles into the environment, accompanied by the release of thermal energy.

Structure

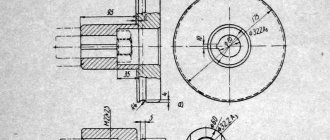

The electric arc consists of three main zones:

- cathode;

- anodic;

- plasma column.

In welding arcs, the dimensions of the cathode and anode zones are small compared to the length of the column. The thickness of these zones is thousandths of a millimeter. In the area of the cathode voltage drop (at the end of the negative electrode), the presence of cathode spots is observed, which are formed as a result of strong heating.

Figure 4 shows a diagram of the structure of the arc created by the welding machine.

Rice. 4. Welding arc structure

Please note: for the purpose of clarity, the electrode zones are greatly exaggerated in the picture. In reality, their thickness is measured in microns.

Thermal imaging methods

Methods for thermal imaging (infrared) inspection of electrical equipment up to NFPA 70e standard:

Thermal imaging cameras (infrared cameras, IR cameras) have been used for many years to identify problems in electrical systems. Problems in electrical systems manifest themselves through heat. A thermal imager can easily identify such problems in the form of a thermal image. This is an excellent method for identifying faulty or problematic components before they fail. A failure could result in shutdown of the entire electrical system, resulting in significant loss of productivity, equipment damage, and personal injury.

Thermal imaging inspection of electrical equipment has been used by insurance companies for many years to determine insurance eligibility and rates in the industry. More recently, users of thermal imaging equipment have discovered that they can use infrared radiation to predict and prevent problems. This reduced downtime due to equipment failure and improved overall safety.

Thermal imagers are based on digital camera technology, requiring line of sight to record an accurate image. In most cases, examinations are hampered by equipment enclosures that hide the target components being imaged, and thermography technicians are at risk because they must open covers or doors in an attempt to gain access to the internal components being examined. Thermal imaging results from electrical systems are most valuable when the system is under severe or even peak electrical load. This requires a specialist to inspect or work around live electrical components.

Typically, electrical system covers are secured with bolts that must be removed during the inspection and then reinstalled. This method of operation is contrary to NFPA 70.

NFPA 70e Recommendations for Thermal Imaging Surveys

One of the ways NFPA 70 E determines hazards and risks is by analyzing activities on and around the equipment. Scale from zero to 4, with 4 representing the greatest potential risk. For example, removing a bolted cover on 600V equipment has a hazard/risk classification of Level 3, but increases to Level 4 for equipment above 600V.

Because this work is performed within the limits of arc flash protection, appropriate personal protective equipment is required.

The required minimum personal protective equipment for working with the third level of hazard/risk classification must withstand 104.6 J/cm, and the required minimum set of personal protective equipment for working with the fourth level of hazard/risk classification must withstand 167.36 J/cm.

Most thermal imaging work requires the removal of bolted covers, which requires the use of personal protective equipment. Additionally, NFPA 70e recommends that only qualified personnel be allowed to work within arc flash boundaries. The thermographer must be accompanied by a qualified person to remove the covers. They must both have full personal protective equipment.

Useful Application

Oddly enough, physicists found application for this electrical phenomenon even at the stage of development of the science of electricity. An example of this is the Yablochkov light bulb . It consisted of two carbon electrodes, between which an electric arc was ignited.

This lamp had two drawbacks. The electrodes quickly wore out (burned out), and the light spectrum shifted to the ultraviolet zone, which negatively affected vision. For these reasons, arc lamps did not find widespread use and were quickly replaced by incandescent lamps, which exist to this day.

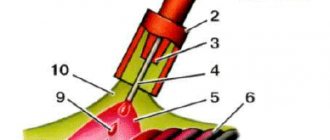

The exception is arc-discharge lamps, as well as high-power spotlights used primarily for military purposes. The arc discharge has been widely used in practice since the invention of the welding machine. Arc welding is used for welding metals. (see Fig. 5)

Rice. 5. Arc welding

Using plasma conductivity, including special welding electrodes in the welding circuit, a high temperature is achieved in a concentrated spot. By adjusting the welding current, the welder has the opportunity to adjust the machine to the desired temperature of the arc discharge. To protect the barrel from heat loss, the metal electrodes are coated with a special mixture that ensures combustion stability.

An electric arc is used in blast furnaces for melting metals. Arc melting is convenient in that you can regulate its temperature by changing the current parameters.

Along with useful applications, in electrical engineering we often have to deal with arc discharges. An uncontrolled arc discharge can cause significant damage on power lines, industrial and domestic networks.

Rice. 6. Arc discharge on power lines

Discharge duration

In practical applications, continuous discharge mode is more often used. However, pulse mode is also common. It is used for contact welding.

Welding of workpieces is not carried out in a continuous seam, but at several points. Such a connection does not provide tightness, but is strong enough to make thin-walled structures, such as housings for household appliances, various devices and installations, and car bodies.

The process is carried out by a non-consumable massive electrode, which is pressed against the workpiece with great force. A short-term current of very high strength is passed through the electrode - up to several thousand amperes. At the point of contact, the metal of both workpieces melts, and at the end of the pulse it cools and crystallizes as a single whole.

Next, the electrode (or workpiece) moves along the seam line to a new point, is pressed against it and a new impulse is applied.

Roller electrodes for resistance welding

There is a variation of this method that allows you to obtain tight connections. In this case, the electrode is made in the form of a roller rolling along the surface of the workpiece. The pulses are supplied at short intervals; the guiding zones along the rolling line partially overlap and form a continuous weld material. This technology is used for automatic welding of pipelines.

Causes

Based on the definition, we can name the conditions for the occurrence of an electric arc:

- the presence of multipolar electrodes with high currents;

- creation of a spark discharge;

- maintaining voltage on the electrodes;

- providing conditions for maintaining the temperature of the barrel.

A spark discharge occurs in two cases: during short-term contact of the electrodes or when approaching breakdown parameters. A powerful electrical breakdown always ignites the barrel.

While maintaining the optimal arc length, the plasma temperature is maintained independently. However, as the gap between the electrodes increases, intense heat exchange occurs between the barrel and the surrounding air. Eventually, in the barrel, due to a drop in temperature, the formation of ions will stop like an avalanche, resulting in the extinguishing of the flame.

Breakdowns often occur on high-voltage power lines. They can lead to the destruction of insulators and other negative consequences. A long electric arc goes out quite quickly, but even in a short burning time its destructive power is enormous.

An arc tends to form when contacts open. In this case, the switch contacts quickly burn out, the electrical circuit remains closed until the barrel disappears. This is dangerous not only for networks, but also for humans.

Combustion conditions

Under normal conditions, at normal pressure and temperature of 20 ° C, gases, and above all air, are not conductors. In order for them to conduct electricity, special conditions must be created: a large number of ions must be released from atomic orbits. This process is called ionization.

The work required to release one electron is called the ionization potential. For various materials it ranges from 3.5 to 20 electron volts. The lowest potential is typical for alkaline elements: potassium, calcium and their compounds. These substances are added to the electrode coating or welding wire in order to maintain stable discharge parameters. They are also added to the composition of flux powder for closed type welding.

To ensure high quality welded joints, it is necessary to maintain stable electric arc parameters, such as current, voltage, and temperature.

Temperature is determined by the following factors:

- Cathode material.

- Cathode dimensions.

- Environmental conditions.

Arc temperature distribution

The constancy of the current parameters - voltage and strength - is ensured by the current source. A large number of designs of such sources have been developed for welding work - from outdated bulky welding transformers and rectifiers to modern inverters and semi-automatic machines.

Extinguishing methods

It should be noted that arc extinction occurs for various reasons. For example, as a result of cooling of the column, a voltage drop, or when the air between the electrodes is displaced by external vapors that prevent ionization.

In order to prevent the formation of arcs on high-voltage power line wires, they are spaced over a long distance, which eliminates the possibility of breakdown. If a breakdown between the wires does occur, the long barrel will quickly cool and extinguishment will occur.

To cool the barrel, it is sometimes divided into several components. This principle is often used in the designs of air circuit breakers designed for voltages up to 1 kV.

Some circuit breaker models contain multiple arc chutes to promote rapid cooling.

Rapid ionization can be achieved by evaporating certain materials surrounding the space of the moving knives. High-pressure evaporation blows away the plasma of the barrel, resulting in extinguishing.

There are other methods: placing contacts in oil, auto-blowing, using electromagnetic damping, etc.

Recommendations

- A. Anders (2003). “Tracing the Origins of Arc Plasma Science-II. Early continuous discharges" (PDF). IEEE Transactions on Plasma Science

.

31

(5):1060–9. doi:10.1109/TPS.2003.815477. - Ayrton, Herta (2015). Electric arc (CLASSIC REPINT)

. S.L.: FORGOTTEN BOOKS. paragraph 94. ISBN 978-1330187593. - The Electric Arc

, Hertha Ayrton, p.20 - Lakiesh, Matthew (1920). "Artificial light, its influence on civilization." Nature

.

107

(2694): 112. Bibcode:1921Natura.107..486.. Doi:10.1038 / 107486b0. HDL:2027/chi.14153449. OCLC 1446711. S2CID 4135392. - "Arc". Columbia Encyclopedia

(3rd ed.). New York: Columbia University Press. 1963. LCCN 63020205. - Davy, Humphrey (1812). Elements of Chemical Philosophy

.

paragraph 85. ISBN 978-0-217-88947-6. This is the probable origin of the term " arc

". - ^ a b

“Elucidation of the origin of arc plasma Nauka-II.

Early continuous discharges." Author: André ANDERS. IEEE. Xplore

, ieee.org.

IEEE Transactions on Plasma Science

. Volume 31, Issue 5, October 2003 - Kartsev, V. (1983). Shea, William R. (ed.). Mathematical nature

. Boston, MA: Kluwer Academic. p. 279. ISBN 978-90-277-1402-2. - Mason, Joan. "Sarah Ayrton." Oxford Dictionary of National Biography

(online ed.). Oxford University Press. Doi:10.1093 / link: odnb / 37136. (Subscription or UK Public Library Membership required.) - ^ a b c d

Howatson, A. (1965).

"Introduction to Gas Discharges". Science and Technology of Plasma Sources

.

9

(4): 47–101. Bibcode:2000PSST…. 9..517B. Doi:10.1088/0963-0252/9/4/307. ISBN 978-0-08-020575-5. S2CID 37226480. - Mehta, V. (2005). Principles of Electronics: For Diploma, AMIE, Degree and other Engineering Examinations

(9th, Colourful, Illustrative Ed.). New Delhi: S. Chand. pp. 101–107. ISBN 978-81-219-2450-4. - "Laser beams create tunnels for lightning." Retrieved 2015-06-20.

- Clerici, Matteo; Hu, Yi; Lassonde, Philip; Milian, Carles; Quiron, Arnaud; Christodoulides, Demetrios N.; Chen, Zhigang; Razzari, Luca; Vidal, Francois (06/01/2015). "Laser guidance of electrical discharges around objects." Science achievements

.

1

(5): e1400111. Bibcode:2015SciA…. 1E0111C. Doi:10.1126/sciadv.1400111. ISSN 2375-2548. PMC 4640611. PMID 26601188. - "Arc Suppression" Retrieved December 6, 2013.

- Harper, Charles A.; Petrie, Edward M. (2003). Plastics Materials and Processes: A Concise Encyclopedia

. John Wiley and Sons. item 565. ISBN 9780471456032. - Harper and Petrie 2003, p. ???[ page needed

] - “Laboratory note No. 106 Impact of arc extinguishing on the environment

.” Arc extinguishing technologies. April 2011. Retrieved October 10, 2011.

Exposure to humans and electrical equipment

An electric arc poses a danger to humans due to its thermal effects, as well as the ultraviolet effect of the emitting light. High AC voltage poses a huge danger. If an unprotected person is at a critically close distance from live parts of devices, an electrical breakdown may occur with the formation of an arc. Then, in addition to the effect of current, the body will be affected by a thermal component.

The spread of an arc discharge through structural parts of equipment threatens to burn out electronic elements, boards and connections.

Varieties

There are several classifications of the element in question, which have different current supply schemes and the environment where it appears.

Welding

- With direct action. In this case, the equipment is installed parallel to the metal product that needs to be welded. The arc, in turn, becomes at right angles towards the electrodes and the metal surface.

- With indirect action. Appears when using two electrodes that are located at an angle of 50 degrees from the work being welded. An arc appears between the electrode and the material being welded.

The appearance of a welding arc.

In addition, it can be divided according to the principle of the atmosphere where the welding arc appears:

- Open sphere. The arc can burn in an open space with the formation of a gas phase, which contains vapor of the metal, electrode and surfaces after processing with a welding tool.

- Closed sphere. The arc burns under flux. In the gas phase near the arc, vapor from the material, electrodes and the flux layer itself enters.

- With supply of gas mixture. The arc may contain compressed gas such as helium, carbon dioxide, hydrogen, argon and other gaseous impurities. They are necessary so that the welded surface of the product is not subject to oxidation. Thanks to their supply, the environment is restored or becomes neutral to external factors. The gas supplied for operation, steam from the product being welded and the electrodes enter the arc.

In addition to the listed classifications, we can also distinguish types by duration of action:

- classic is used for constant use;

- pulse – for one-time use.

One of the most popular parts is steel, i.e. consumable electrode. However, today most professionals prefer non-melting, from which we can conclude that the types of elements under consideration are quite different from each other.