Spot welding is one of the most common in everyday life. It allows you to connect metal parts quickly and reliably, and there is no need for any special welding skills. Another important advantage is its simple equipment, which is quite possible to make yourself. Considering the fairly high cost of such units, the issue of independent production of this device becomes very relevant.

What is spot welding

Spot welding is a common welding method based on connecting two products by heating using electric current.

The properties of the weld depend on several factors:

- Properties of electrode wire;

- Welding current;

- Surface cleanliness of welded structures;

- The force of compression between products.

High-quality welding is highly valued and equally highly paid. It features high performance and a wide range of applications.

Successfully used in the following industries:

- Automotive industry;

- Shipbuilding;

- Aircraft manufacturing;

- Mechanical engineering.

Homemade welding device

The resistance welding machine is an indispensable device. Such units should be in the “arms” of every master. In the garage, at the dacha, in the workshop and even at home, there is always a use for such units.

The resistance welding machine is quite expensive, so its production looks very attractive. Firstly, you can be proud and show off this device in the future. Secondly, homemade manual resistance welding is much cheaper.

It is also important that it is quite possible to assemble such a device yourself from scrap materials, which will further reduce the cost of the unit. In addition, the assembly is not very difficult and almost anyone can handle it. In this matter, it is important to strictly follow the instructions.

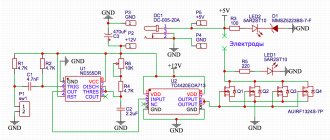

Schematic diagram of a spot welding machine.

It is worth noting the following: the manufacturing task is greatly simplified if you make a spotter from a welding machine that has stopped standing. In this case, there will be almost all the necessary details. As a result, assembling a new unit will not cause any difficulties.

Another common method is to create a device based on a microwave oven. In this case, the main thing is to correctly connect the transformers, especially if there are several of them.

It is enough to understand the basic diagram of resistance welding, as well as understand the principles of its operation, in order to be able to manufacture a device not only according to ready-made drawings, but also according to your own. In the latter case, it becomes possible to create equipment that fully satisfies all the requirements of the master.

With the right approach, you can make welding better than models sold in stores. This is due to the fact that your own product will take into account many parameters that are important to the master. We are talking about the design of the pliers, the size of the body, as well as the power and weight of the device.

At home, resistance welding is used for welding cars, metal sheets, wires, small household appliances and much more.

How spot welding works

This type of welding has characteristic features that must be taken into account when operating the equipment. When current is passed through electrodes through overlap welded metal structures, heat is generated, which rapidly heats and melts the parts.

The metal parts are pressed tightly with the electrode wire, due to which they are tightly connected to each other.

Features of the welding process

When spot welding, a short-term pulse of electric current is applied to the junction of metal parts, the duration of which varies within 0.01-0.1 seconds.

In this case, in the area where the electrodes are applied, the edges of the products melt and acquire a common core. After applying current, the parts are cooled under pressure to crystallize this core, as well as to cool it completely.

Technical data of resistance welding machines.

Main methods of resistance welding:

- point method;

- suture or roller method;

- butt contact welding.

The peculiarities of this type of welding are that it does not require increased safety measures. Pressing the parts against each other leads to the formation of a sealing belt between them without a splash of molten metal.

But the pressure should be removed from the parts with some delay in order to ensure better crystallization, forging and elimination of inhomogeneities.

The advantages of spot welding are cost-effectiveness, high mechanical strength of seams, and the ability to automate work processes. The disadvantages of resistance welding are the lack of tightness of the created welding seams.

Preliminary preparation will ensure high quality welds. Parts are cleaned of all types of contaminants using special brushes, sandblasting, acid etching, and other methods.

It is important to perform the assembly before welding in such a way that it ensures an accurate and tight fit of the metal products to each other.

Otherwise, the gap between the parts will reduce and absorb part of the pressure on them, the sedimentary pressure will decrease, and a scatter in the strength of the weld points will appear. In general, this will reduce the strength characteristics of the weld and make it vulnerable to negative external factors.

Pros and cons of spot welding

Spot welding, like any other type of welding “art,” has a number of advantages and disadvantages.

About the pros:

- Smooth and precise seam;

- At the welding site, deformations are insignificant;

- There is a possibility of automatic operation;

- Welding using this method does not have a detrimental effect on human health;

- Speed of work;

- Thick material can be joined;

- Ease of use.

With such significant advantages, there are also disadvantages. Briefly about them:

- Area of application – joining of overlapping sheet parts and core materials (e.g. wire)

- Low tightness compared to welds using electrode wire;

- The metal must be cleaned before welding;

- Experience setting up equipment is required.

Resistance welding equipment

All units for contact welding are conventionally classified according to the following criteria:

- appointment;

- power supply;

- electrode location;

- method of movement;

- automation method.

According to their intended purpose, welded equipment is divided into general-purpose models and specialized units used for specific work.

Precision equipment for spot welding for a wide range of purposes is suitable for welding various types of microelectronic devices and metal products, depending on their design features and current requirements.

Welding machine for spot welding.

But in the case of most metal products and alloys, it is necessary to use specialized units for resistance spot welding:

- installations operating on the principle of one-sided contact welding;

- units for welding conductors in insulating material.

Various types of power sources are used in flash butt welding equipment in production.

- capacitors, including those with voltage maintenance and automatic control of the operating mode during the welding process;

- power supplies with alternating current, including high frequency with the ability to automatically regulate current or voltage.

The flash butt welding diagram should describe the type of equipment used, which will simplify the welder’s task and allow him to achieve the highest possible quality of welded joints.

Electrodes for contact welding can be positioned in different ways:

- opposite each other;

- parallel.

In the first version, the electrodes simultaneously compress the parts on both sides. In the second, the welded wire rests on the parts on one side.

Flash butt welding involves the use of different types of welding heads:

- for double-sided spot welding;

- for welding and soldering with split and V-shaped electrodes;

- heads for one-sided welding and soldering with the ability to separately regulate the force on each electrode.

Construction of a flash butt welding machine.

According to the method of movement, welding units for the contact method of joining metal products into a single structure can be:

- stationary;

- hanging;

- mobile.

In the first case, the welded parts are moved to a specific unit, and in the second and third cases, the apparatus is mounted in the welding position.

According to the automation method, welding units are:

- manual;

- automatic.

Manual units are more affordable, however, they require more skill on the part of the welder: absolutely all operations must be carried out manually under the strict control of a person.

Automated equipment for spot welding deprives the master of the need to carry out a number of processes, and therefore makes the work easier for an inexperienced welder.

The main parameters when choosing a welding machine are the strength of the welding current, as well as the length of the arms with welding electrodes. They will determine the possible thickness of the parts to be welded, the type of metal and the dimensions of the structures that can be worked with.

Manufacturers often indicate them in the passport of a specific device model. A simple do-it-yourself welding machine for turning technology can be made with your own hands.

welding equipment

Let's talk about equipment, what you should look for when choosing, and a number of other subtleties.

How to choose

When choosing welding equipment for spot welding, 7 important parameters are taken into account that affect the goals and acceptable limits of the welding machine:

- Welding method

- Operating mode

- Voltage

- Maximum Incoming Current

- Allowable material thickness

- Control method

- Additional options

Welding defects and quality control

Defects that occur during resistance welding are of two types:

- Defective welded joints. There may be several reasons for this: excessive heating of the docking area, excessive mechanical pressure, malfunctions of the device itself. The dimensions of the weld point are controlled using special templates and measuring instruments;

- Weld defect. This happens if the area where the parts are joined is too narrow, or, conversely, wide, if it contains irregularities, burrs, and gaps. Such defects can be determined by visual inspection - with the naked eye, through a magnifying glass, using a probe or probe. If necessary, the seam is x-rayed.

Prevention of defects is competent work not only during welding, but also before it, which includes leveling and cleaning the contact edge.

Types

Portable equipment is small in size, no more than 18,000 cm3. Small equipment equals small power.

- The maximum thickness of the metal sheet material being welded is no more than 5 mm. Such devices are suitable for welding body parts or large metal structures. Such equipment should weigh no more than 16 kilograms.

- Stationary equipment is used in production. Compared to portable welding machines, they are large in size (up to 300,000 cm3) and weigh up to 1 quintal. High power allows you to weld sheet metal with a cross-section of no more than 10 mm.

Welding of small parts

Sometimes it can be problematic to attach small contacts: a regular soldering iron is not suitable for this; the connection obtained by tinning is very fragile and cannot withstand high dynamic loads.

You can spot weld two small contacts using a low-power mini-welder. It is made according to the same principle as pliers, only the lower handle of the clamping device is permanently fixed, only the upper one moves.

The current source is fixed on a dielectric base, it can be:

- tree;

- plywood;

- non-flammable plastic;

- textolite

A transformer from a microwave oven or a ready-made TR1 is suitable as a current rectifier. If a transformer from a microwave oven is used, a wire with a cross-section of at least 8 mm2 in a durable heat-resistant braid is used as an additional winding.

When selecting electrodes, it is important to compare their thickness with the size of the wire. D The ends of the electrodes are sharpened to the required size. The smaller the contact area, the stronger the connection.

- DIY fan: how to make a homemade powerful fan. Basic parameters and properties of fans (130 photos)

- Why do you need a security alarm, what functions does it perform?

How to choose winter workwear and not make a mistake - recommendations from the pros

The following is used as an electrode for spot welding:

- soldering iron tips;

- solid brass products (rods, hexagons, capillary tube);

- rods made of cadmium chrome bronze.

When choosing a lever, take into account the length of the working area - this is the depth to which the welded metal can be inserted into the welding device. To attach the tip to the handle, terminals are used: current is supplied to one end, the other part is secured with a self-tapping screw.

To select the correct pulse time, a resistor is included in the electrical circuit of the power supply. The power button is located on the handle or fixed on the power supply box. The wires and housing can be hidden in a single electrical insulator housing.

Spot welding methods

Welding equipment is divided into two welding methods.

Welding on one side. Spotters are used for this operation; they have several fundamental differences from other devices. There is a manual device used for welding. The one-sided option of welding metal structures is justified if the reverse side of the welded products is difficult to access.

It is more convenient to use the type of welding when it is possible to weld the seam on both sides. This method is used to join sheet materials.

Control circuit with indicator block for spot welding spotter

Figure 2. Diagram of the control unit for the spotter.

The appearance of the control unit board with the controller is shown in photo 2.

The photo shows the appearance of the indicator block with control buttons without a decorative panel. The indicator panel with buttons and installed decorative panel is shown in another photo 3.

The control circuit has a minimum of auxiliary elements. All processes are controlled by an AtMega 16 microcontroller installed in the DIP version. The element from the manufacturer Atmel has a low cost and a large number of pins. The controller device allows the use of input and output signals on any legs of the microcircuit, so the board is as simplified as possible. In addition to configuration capabilities, the controller is equipped with high-capacity RAM and non-volatile memory, etc. In the spotter control circuit, its capabilities are used by approximately 20%.

Operating mode

Divided into soft and hard. In gentle operating mode, little electrical energy is used, but the welding process takes longer - 2-5 seconds. Thanks to this, electrode rods of a smaller cross-section are used and it is not necessary to press very hard with them.

The hard operating mode uses increased energy, and the process is faster - 0.2-1.5 seconds. High productivity is ensured, but strong compression of the workpieces with electrode rods is necessary. A rod of large cross-section is also required, which exceeds the cross-section of the products being connected.

Consumables

Electrodes that are subject to the greatest wear in welding machines are constantly subject to mechanical and thermal loads. They are made from pure copper, or from copper alloys with aluminum, zinc, cadmium and other metals that increase the strength and elasticity of the product. Such alloys are divided into several types:

- To operate at high temperatures (about 500 degrees Celsius) and continuous current supply, such electrodes are made of bronze with the addition of nickel, silicon, zirconium or chromium;

- To work at temperatures up to 300 degrees, welding non-ferrous alloys, low-alloy steels, MS (alloyed with silver) and MK alloys are used;

- Alloys of bronze with chromium and cadmium are suitable for working at low temperatures (up to 200 degrees Celsius).

Conical and cylindrical electrodes wear out the fastest, while flat and wide ones, used in projection welding machines, wear out the slowest.

Voltage

Welding installations are powered by 220V and 380V. This is indicated in the documents included with the welding machine.

Important! It is not recommended to connect devices with a power of more than 5 kW to a household network.

Necessary equipment

Depending on the mode in which the work is planned, the appropriate equipment is selected. Today, stores have a wide range of spot welding machines.

Large enterprises install expensive machines for this type of welding. This machine has high functionality and can work with a wide variety of metals. The price may vary depending on the type of transformer installed on the machine.

There are lightweight compact devices for home use. Their kit includes a low-power transformer, as well as pliers.

The most popular device is the spotter . It has the lowest price, but does not come with special pliers. In this case, the current is transmitted through the terminal, which is connected to the part and the electrode.

Approximate cost of spotters on Yandex.market

The spotter has a fairly simple operating scheme, and the quality of work meets all requirements.

Allowable material thickness

A parameter indicating the maximum thickness of a part that welding equipment can weld. Ignoring this parameter, the welding quality deteriorates significantly. It is indicated either by a common section, for example “2 mm”, or by two numbers, “1+1 mm”.

Industrial machines have the ability to weld three metal sheets together, then the cross-section is designated “1+1+1 mm”.

Control method

The cheaper the device, the less functionality and the more difficult it is to control the device. The cheapest versions do not have the ability to adjust the current strength - it is the same and always maximum.

Needless to say, you have to work manually. Before working on such a welding machine, it is advisable to “break in” it on rough sheets, and then start working.

Numerical control makes the job much easier. The operator indicates the type of connection to be processed, and the “brains” of the equipment independently select the necessary operating modes. The welder only needs to bring the electrodes to the welding site. Of course, you have to pay extra for such convenient functionality.

Device designs

It was said earlier that do-it-yourself spot welding can be assembled by any craftsman. At the moment, there are a large number of examples on the Internet dedicated to the manufacture of such equipment.

Do-it-yourself welding will allow you to solve a large number of problems related to the repair and manufacture of various products and mechanisms. This device will be indispensable in almost any workshop or garage.

The most important fact is this: making a unit with your own hands from a welding device is not difficult. As a result, with this device, creating high-quality and reliable connections of various metal products will become commonplace.

Depending on the characteristics of the workpieces being welded, such as their size, thermal conductivity, etc., the welding process should be carried out with the following parameters:

- the power circuit voltage ranges from one to ten volts;

- the process time should last from 0.01 to several seconds;

- the welding pulse current exceeds a thousand amperes;

- the melting zone of the surface of the parts is minimal;

- the pressure applied to the welding site must reach tens and sometimes hundreds of kilograms.

It is enough to comply with all the above parameters, and then the quality of the connection will not raise any doubts. You can do resistance welding with your own hands in accordance with one of the diagrams presented on the Internet.

Electrical circuit of the welding machine.

The most common option is microwave welding. This is due to the fact that getting this device in our time is not difficult. The assembly process itself is quite simple and only requires careful adherence to the instructions.

Also common are devices based on laboratory autotransformers, inverters, etc.

Let's look at one of the options on how to make spot welding.

For these purposes we will need:

- variable resistance element, nominal 100 Ohm;

- a capacitor with a capacity of one thousand microfarads, designed for a voltage of at least 25 V;

- thyristor;

- diodes;

- five amp fuse.

Blueprints

Do-it-yourself contact-type welding can only be done if the drawing is chosen correctly. Here preference should be given to the simplest schemes with the least number of components and parts.

It is worth keeping in mind: DIY welding does not have too much power. However, it is quite sufficient to perform almost all everyday tasks that arise when working in the country, in a workshop or in a garage.

Before you understand the assembly of such a device, you should remember the school physics course, namely the Joule-Lenz law. The essence of the law is as follows: current passing through a conductor creates thermal energy. Its value is proportional to resistance, time and the square of the current.

The conclusion from the above law is as follows: if the current is large, for example, on the order of a thousand amperes, then in the case of poor contact and the use of thin wires, the energy consumption will become too large and will be several thousand times higher than the consumption corresponding to a current of ten amperes.

In this regard, the quality of the assembled electrical circuit is very important.

Required Parts

To assemble a spot welding machine with your own hands, you should make sure that you have certain parts. Such a device, made at home, can have any shape and dimensions. There are two main types of implementation of the unit: in the form of a portable structure or in the form of a large-sized stationary version.

The most practical is tabletop resistance spot welding. It will cope perfectly with the simplest tasks of joining thin sheet metal. It can also be easily transported or simply moved around the workshop.

Processes during spot welding.

So, we will need:

- a transformer that you can make yourself from microwave spare parts; an LATr or a transformer from a TV is also an excellent option;

- cable with a cross-section of ten millimeters;

- copper electrodes;

- timer;

- tips;

- bolts;

- various available materials for making the body, mass, etc.

Spot welding with a spotter is done both using a ready-made diagram and on the basis of drawings developed independently. All necessary parts are purchased in the appropriate stores or taken from “donor equipment”.

When manufacturing this device, it is important to select the right components based on the parameters and characteristics of the transformer.

Only use wires with the correct size for the current flowing through them. When contacts are poorly made, they will experience large energy losses. As a result, the connections will spark and heat up, and the welding process will simply become impossible.

Transformer assembly process

Many people are interested in the question: how to properly weld from a microwave?

So, to assemble a homemade spot welding machine, you need a transformer. This element is the heart of the device and the parameters of the device as a whole will depend on its characteristics. Taking a transformer for spot welding, as noted above, follows from the microwave.

Any microwave oven is equipped with a magnetron, which provides the necessary electromagnetic radiation necessary for heating food. This node requires a fairly high voltage.

The microwave transformer connected to the magnetron is a step-up transformer. Its primary winding has fewer turns than its secondary winding. Thanks to this, a voltage of up to two kilovolts is formed on it. Due to the doubler, this value is then multiplied by 2 times.

It is necessary to carefully and carefully remove the transformer from the microwave oven. The microwave should be disassembled by removing the base and removing the fasteners. In the case of making spot welding from a transformer, only two of its components will be needed from the furnace.

Structural elements of a welded joint.

The first is the primary winding, the mains voltage is supplied to it, the second is the magnetic circuit. It needs to be improved so that it can provide the necessary parameters of the transformer.

The secondary winding is not needed, so it is dismantled using a hammer, chisel or chisel. The main thing is not to damage the primary winding. If during dismantling you find shunts designed to limit the current, they should be removed.

In a microwave oven, two options for implementing a magnetic core are possible: adhesive and welded. In the first case, it is best to remove the winding using a hacksaw or chisel. But in the second case it needs to be drilled out. Such operations should be performed with the utmost care to avoid damaging the magnetic circuit.

After the transformer is removed from the microwave, you need to wind the secondary winding. For these purposes, a wire with a diameter of at least one centimeter is perfect. If the farm does not have one, it will have to be purchased.

It is not necessary to buy a solid single-core wire; you can get by with a bundle of several individual wires with a total diameter corresponding to the required one. Once the secondary winding is complete, the resulting upgraded transformer will provide up to a thousand amps of current.

This value is quite enough for a do-it-yourself device to allow you to easily connect small parts, repair body work, and much more.

If it is necessary to manufacture a more powerful device, the parameters of one transformer may not be enough. In this case, you can use two such elements.

In this type of welding, it is necessary to obtain 2 V at the output, which will provide a current of more than eight hundred amperes. This result can be achieved by winding two or three turns on the core of the secondary winding.

Forming the required number of turns can cause certain difficulties if the insulation on the wire is too thick. This problem can be solved quite simply: the insulation is removed from the wire and another one is made instead using fabric insulating tape.

The shortest length of wire used in the secondary winding is important. This is necessary to minimize electrical resistance.

If it is necessary to weld metal workpieces with a thickness of more than five millimeters, you will need a device with high power. In the manufacture of such a device, two transformers should be used, connected into one electrical circuit.

In this matter, it is important to follow all the rules of such a connection. An error in connection and incorrect assembly will lead not only to the inoperability of the device, but also to a short circuit.

After connecting the terminals of the same name, the current generated by the windings is measured. Typically, such devices are capable of providing a current of two thousand amperes. If this value is exceeded, then malfunctions may occur in the electrical circuit not only of your home, but also of your neighbors.

So, what results can be achieved if two transformers of equal power and parameters are connected to each other?

Let's say there are two identical devices with a power of half a kilowatt, the input voltage corresponds to the network value and is 220 V, and at the output the transformer produces two volts and provides a current of 250 amperes.

Scheme of capacitor spot welding.

If two such devices are connected in series with each other, then they can provide a rated current of five hundred amperes. However, during its formation, significant losses will occur due to the significant electrical resistance of the circuit.

Homemade pliers for resistance welding are subsequently connected to both ends of the winding.

If there are 2 transformers with sufficiently high power, but their output voltage is still not enough, then their secondary windings are connected in series to each other.

In this case, the essential point is the number of turns wound on both windings. This method turns out to be especially useful when it is simply impossible to rewind the turns due to the insufficient size of the magnetic circuit.

When making such a connection, it is important to carefully monitor the coordinated direction of the turns on the windings connected to each other. Otherwise, the output voltage from the two windings will be in opposite phases. After summation it will be equal to zero.

If the transformer terminals are not marked, then you should determine which of them are of the same name and connect them to each other. This problem is solved as follows: the secondary and primary windings of the transformers are connected in series, voltage is applied to the input, and a voltmeter is connected to the output.

Depending on how the devices are connected, the voltmeter will either show some number or nothing. The first case is realized when there are different terminals in the connection circuit.

This connection is incorrect. In such a case, the following processes will occur in the windings: the voltage arriving at the input of the device will decrease by half on each of the primary windings, since they have the same transformation ratio.

As a result, a voltmeter installed at the output will show twice the input voltage.

In the second case, when the voltmeter shows 0, the following situation occurs: the voltages coming out of the windings of each transformer connected to the circuit are equal in magnitude. However, the signs of the stresses will be different, which means they compensate each other.

Electrodes

Welding spotter is equipped with copper tongs. They will subsequently be used in connecting metal workpieces to each other.

Electrodes for spot welding can have several design options. They are installed directly into the body of the device itself, or a remote device in the form of scissors is implemented.

A simpler option in the case of self-manufacturing of a resistance welding machine is electrodes built into the body. The disadvantage of the design is the insignificant clamping pressure corresponding to the force of the welder if the distance from the device to the end of the pliers is not increased.

Remote electrodes are easier to use. They can be used even at some distance from the spot welding device. The pressure generated by this design depends on the length of the lever between the movable joint and the ends of the pliers.

It is very important to insulate the moving connection well. Textolite bushings and washers are used for these purposes.

The issue related to the length of the lever should be thought through in advance, even at the stage of manufacturing the pliers. Welding machines, as noted above, require significant compressive forces to be applied to metal workpieces during welding.

Spot welding machine design.

Another important point is the length of the handles. It determines the maximum distance from the edge of the parts being welded to the joint.

Typically, the most common material from which electrodes are made is copper, but beryllium bronze can also be used. Soldering iron tips are perfect for a simple and ready-made option. The important thing is the diameter of the clamps, which is no less than the diameter of the wires connected to them.

At the same time, the tips of the electrodes are made small, almost sharp. This will allow you to obtain kernels of sufficiently high quality.

It is also worth not forgetting about degradation processes. Over time, the electrodes can wear out. In this case, they will sometimes have to be sharpened. Nevertheless, sooner or later the electrodes will have to be replaced.

If you use copper rods as the electrode material, then replacing them will not cause any particular difficulties. On the other hand, a better welding result is achieved when using tips from professional soldering irons, but their price is higher than that of simple rods.

Which design option to choose is up to everyone to decide for themselves. It all depends on what tasks are to be solved with the help of this device, as well as on the financial capabilities of the person.

Do not forget that in wires, in any case, there will be losses of electricity due to heating, because any conductor has resistance.

The principle of operation of the welding device was already mentioned above and the Joule-Lenz law was discussed. It is also applicable in the case of simple conductors, since their resistance is not zero. This means that when current flows through the copper wires, heating will occur.

From the above it follows: the length of the wires connecting the electrodes and the device must be minimal. Only in this case will it be possible to realize the full potential of the unit.

Control

To make a welding machine an easy-to-use device, you need to take care of the controls. Its implementation is not too difficult. For these purposes, you will need only two main elements: a lever and a switch.

As you can see, the control circuit in ordinary homemade spot welding does not require the presence of any complex parts or their purchase. After all, with a high degree of probability, they are already in the household of almost any master.

The role of the lever is to ensure reliable contact between the parts being welded. It is possible to increase the compressive force of this unit through the use of screw elements. Of course, this part must be highly reliable, otherwise homemade spot welding will not last long.

In large and critical industries, the compression force between two connected parts reaches thousands of kilograms. Spot welding at home, intended for occasional work, does not require industrial loads.

Usually in everyday life a pressure of thirty kilograms is sufficient. The welder can provide it independently, but increasing the length of the lever will significantly simplify this task.

Drawing of spot welding of metal products.

More specifically, a handle length of 60 centimeters is quite enough. Such a lever is capable of increasing the force applied to its shoulder by approximately ten times. As a result, to achieve a force of 30 kilograms, it is enough to press on the shoulder with a force equivalent to 3 kg.

The resistance welding spotter switch is connected directly to the transformer. The connection must be made to the primary winding, where the current strength is negligible.

If you connect it to the secondary winding, it will not only increase losses by creating additional resistance, but will also be tightly welded to the leads of the welding transformer.

The design with the switch located directly on the handle of the lever is very convenient. This option allows you to leave one hand free, which will simplify the task of supporting the parts being welded.

It is also worth considering the heating to which a homemade spotter made from a welding transformer is exposed. In this regard, it is necessary to provide a cooling system. A simple fan is suitable for its implementation.

In addition, short breaks should be taken so that the resistance welding machine does not overheat. You should monitor the duration of welding of products visually, or use a controller for this purpose.

In case of short-term operations, such as welding wire, there is no need to worry about heating. But in longer processes, this point is extremely important and should not be forgotten.

Additional options

If the device performs regular, long-term work, the presence of a cooling system should be taken into account. Devices with water cooling and a radiator last much longer than their counterparts without cooling.

For full operation, the spotter requires a gun and a reverse hammer. Also, all welding machines require copper electrodes as consumables. If the equipment weighs more than 13 kg, then it should purchase a trolley for easy transportation on wheels.

Power supply and its circuit

Transformer winding diagram.

The power supply diagram is shown in Fig. 1. Conventionally, it can be divided into three components:

- power circuit of the primary winding of the step-down transformer;

- a step-down transformer;

- secondary winding with diode bridge and voltage stabilizer.

A surge filter, usually used in switching power supplies, is installed in the primary winding circuit of the transformer. Here it is used to protect the controller chip from impulses created in the mains voltage during operation of the spotter.

Any transformer with a voltage of 220 V/24 V can be used when operating from a 220 V network. When operating from a 380 V network, you need to use an appropriate transformer and a surge filter.

A diode bridge with smoothing capacitors and a voltage stabilizer on the LM2574 chip are connected to the secondary winding. From the output of the microcircuit, a nominal voltage of 5 V is supplied to the output connector X1 through an LC filter chain to eliminate high-frequency interference. The connecting lines marked with a dotted line should be of a minimum length and located as close as possible to the second leg of the IC1 chip.

Figure 1. Power supply diagram.

The voltage at terminal 1 of connector X1 is used by the controller to determine the zero level.

The voltage from terminal 7 of connector X1 is used to start the controller at a positive half-wave of the mains voltage.

A self-made circuit, if there are no errors in the assembly, starts working without additional settings. The presence of a voltage of 5 V will control LED1.

Starter K1 is designed to connect mains voltage when switch S1 is closed.

Instead, you can use a circuit breaker with protection of the required rating or connect the voltage directly, if there are fuses in the supply network.

Best models

According to many people who work closely with welding equipment, the following models should be noted.

| Name | Description | Price | Advantages | Flaws |

| Caliber SVA-1.5 AK | The best price/power option, but not for “garage use” | 13890 rub. | The welding process goes smoothly No machining required Powerful return spring | The overhead console is overheating Heavy Heavily loads the 220V network |

| FoxWeld KTP-8 3098 | Popular when working with large metal structures | 15560 rub. | Large carrying handle Small-sized Increased current power when welding | Backlash Loads the network Heavy Unregulated power |

| Spotter FUBAG TS 2600 38 666 | Suitable for car body repair | 32620 rub. | Overheat warning Four different operating modes | Heavy Expensive Unregulated current |

| Spotter RedHotDot HAMMER IT 275116 | Notable for the presence of numerical control. Suitable for use in garage conditions. | RUR 30,168 | Does not load the home network Small-sized Large melting and welding depth | High price Heavy - weighs more than 16 kg |

| FoxWeld MTP-25 3373 | An excellent option for production conditions. | 67900 rub. | Easy to operate Durable The pliers are compressed using a pedal | Very expensive Special installation required Constant sharpening of electrodes is required |

| WIEDER KRAFT WDK-6000 | An acceptable option for auto repair shops. | 65273 rub. | Availability of trolley Powered by 220V Increased reliability Can weld in eight different modes Microprocessor control | Very expensive No fan or cooling mechanism Overall (60x50x95 cm) |

Application of technology in practice

Electric spot welding allows you to create a permanent connection between the edges of metal parts using high temperature from the passing electric current from the inverter and plastic deformation of their contact zone during compression.

It provides the welder with a unique opportunity to work with a wide range of welded thicknesses: from 1-2 micrometers to 30 millimeters.

An extremely important role in this method of performing welding operations is assigned to the electrical resistance of the joint zone, which is why it is also called electric resistance welding. The rules for carrying out welding operations using the contact method are described by state standards 15878-79.

Contact welding technology.

The advantages of using spot welding technology are very wide.

Let us describe the most significant of them:

- making connections between metal parts requires an extremely short period of time;

- technology allows operations with high power consumption;

- the welding process can be automated, which makes it possible to integrate welding units for resistance welding into production lines at large enterprises;

- welds created by this method are distinguished by high performance parameters, regardless of the skill level of the craftsman;

- during operation, no special materials or special components are required: filler welding wire, flux, shielding gas, etc.;

- electrodes for point technology are affordable and can be found in many specialized stores.

In addition to spot welding, other types of resistance welding are characterized by a large list of advantages: butt welding, seam welding, etc. But it is spot welding that is most common today.

It is relevant in the manufacture of large-sized building structures, space units, miniature semiconductor devices, and microcircuits. This state of affairs is explained by the universality of the contact method of welding metal parts.

Almost all structural materials known to mankind can be combined using this technology into a single product: various types of low-carbon, alloy steel, heat-resistant, corrosion-resistant alloys, alloys of aluminum with other metals, magnesium and titanium, etc.

Do-it-yourself spot welding is also relevant for performing repair operations in small workshops, service stations, etc. With its help, cars, railway cars, airplanes are assembled, reinforced concrete structures are erected, and radio-electronic units are created.