Metallurgy produces a huge number of steel grades. To perform different tasks, specific characteristics of the metal are often required, which factories are not able to provide. Then, at processing enterprises, the raw materials are refined to the required standard. Annealing steel is one of the most common operations to impart the desired qualities.

History and technology of steel annealing

Annealing steel involves the use of variable temperatures: heating to high values without loss of shape and cooling at a given temperature conditions leads to structural changes in the crystal lattice, the alloy receives new qualities needed to solve specific problems.

Annealing steel improves the technological characteristics of metals. It is customary to distinguish between 2 types of annealing - 1st and 2nd kind.

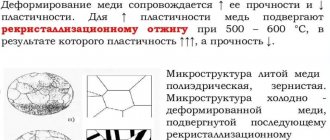

In the first case, the impact is carried out by cold hardening, which reduces internal stresses by recrystallization. This eliminates the effects of pressure treatment, reducing strength characteristics and increasing ductility. Products acquire increased reliability and durability.

The second type of impact includes heating the rolled product to a level exceeding critical points in special cooling modes in terms of duration and temperature. The result is a qualitative change in the structural lattices and obtaining the specified characteristics of the material. Annealing carries a risk of burnout. The occurrence of irreversible negative changes in the structure leads to the remelting of rolled products and products.

Chernov points

Calculation of temperature regimes is carried out using the ones discovered in 1868 by the Russian scientist D.K. Chernov critical points, depending on the temperature and % carbon content, at which the phase states and structural structure of metals change. Chernov’s discovery is the foundation for the creation of the science of metals: for the first time, a connection has been established between the processing mode, the structural appearance and characteristics of alloys. The use of critical points makes it possible to construct various modes of metal heat treatment. Chernov points are designated by the letter A with the addition of an index indicating the correspondence of the point to the influence:

- “c” - heating, from the French chauffage - heating;

- "r" - cooling, refroidissement - in French.

Diagram built on Chernov points:

Section “I” in the diagram corresponds to hypoeutectoid steel. The intersection of the diagram line, horizontally temperature and vertically, corresponding to the % carbon content in the alloy, determines the required critical values.

During the heating process, section “I” passes the following critical points:

- At a temperature of 210°C, the dotted line passing along the QP line intersects the point Ac 0, which marks the loss of cementite’s magnetic properties.

- t=727°C on line PG there is point Ac 1 of transformation of pearlite into austenite.

- t = 768 ° C on the PG line there is a point Ac 2 of loss of magnetic properties - magnetic iron turns into non-magnetic.

- A subsequent increase in t° until it intersects with the GS line indicates the transition of the steel alloy to a single-phase austenitic state (recrystallization ends. The temperature of this point depends on the composition of the particular metal.

Cooling does not change the point numbers and does not cause a reverse restructuring of the material.

Line “II” is built for eutectoid steels.

In industry, for heat treatment of rolled products and products, the following structures are used in furnaces:

- chamber - for small-volume workpieces;

- mines - run on gas and electricity, perform various technological tasks;

- furnaces with retractable floors - processing of large-sized rolled products and components;

- vacuum - for fast-flowing alloys, refractory metals, titanium, copper.

Application of U10 steel

Alloys U10 and U10A are used for the manufacture of tools and devices that experience loads without overheating the tip. Such tools include taps for cutting internal threads, wood saw blades, rasps, axes, and cold-action die stampers.

Cold-rolled steel strip is used for the manufacture of various springs, probes, valves, bifurcating blades, lamella contacts, and parts for the watch industry. The thickness of the tape ranges from 20 microns to 2.5 mm, the difference is quite noticeable.

U10 steel is used to make saw blades for drives, cores, cross saws, needle wire, conventional drilling cutters and cold forming dies. Simplified gauges, scrapers, rolling rollers and files are also produced from the alloy.

Alloy U10A is used for the manufacture of knives for general utility and special purposes. They are used in home life and catering establishments. The stamping of U10 steel should be no wider than 3 cm, then the product will be of decent quality.

Examples of knives made of steel U10 and U10A.

What does annealing of metals do?

Annealing is performed to impart the desired qualities to the steel:

- relieving internal stresses obtained by primary processing of the metal - a structural imbalance appears, which can be removed by a certain method of heat treatment, obtaining the necessary characteristics of the alloy for solving specific problems;

- increase in strength and mechanical characteristics - products after annealing are more durable and stronger;

- changes in the internal structure - under the influence of high temperature, the molecular structure of the metal changes and becomes homogeneous (homogeneous), which simplifies subsequent processing;

- improving ductility, resistance level, impact toughness - improving quality characteristics after annealing reduces the cost of final finishing of metal products to the required parameters.

The method and mode of heat treatment is determined by the composition of the alloy.

Vickers method

When measuring hardness using the Vickers method, a pyramid-shaped tip is used as an indenter, the edges of which converge at an angle of 136 degrees. To ensure the accuracy of the test, it is important to observe several points:

- the load must be placed strictly in the center of the diamond tip;

- the load application vector must be strictly perpendicular to the surface of the test sample.

Measurements take place according to the following algorithm: the sample being tested is placed on a special table, and the indenter is pressed into the sample from above immediately with the required load level (the maximum possible value is up to 100 kgf). Next, the indenter is held under load for 10-15 seconds. After removing the indenter, the indentation depth and indentation diagonal are measured.

Next, a calculation takes place according to the form, which takes into account the ratio of the applied load to the diagonal of the indentation and the time during which the test took place. Hardness is indicated in kgf/mm2 format, display format HV. The Vickers method, due to the use of a diamond tip, allows for more accurate measurements than the Brinell method.

Types of annealing

Let's consider what the term “annealing of metals” means. The heat treatment of a metal, consisting of heating above the temperature of the Chernov critical points and cooling, in professional language is called annealing. The procedure is applied to various metals and their alloys.

Industrial enterprises use the following heat treatment modes:

- complete, incomplete;

- recrystallization;

- diffusion;

- isothermal;

- spheroidization;

- normalization.

Complete annealing of steel

Full firing is carried out on products made of hypoeutectoid alloys or steels containing carbon in an amount of ≤ 0.8%. The purpose of the operation is to refine the grain and improve the quality of processing using a cutting tool, relieving internal stresses of the material. Heating occurs 30..50°C above point Ac3, then the part is gradually cooled without removing it from the oven. As it cools, austenite releases fine-grained, homogeneous (uniform structure) ferrites and pearlites (French - pearls). The heating temperature is selected according to the type of steel and the state diagram; the data is recorded in reference materials. The cooling duration is determined according to the composition and structure of the metal:

- carbon alloys - 180...200°C/hour;

- low-alloy - 90°C/hour;

- highly alloyed - 50°C/hour.

Chemical composition of steel

U10 steel is used for the production of cutting tools. It refers to alloys with low hardenability and not characterized by high heat resistance. Cutting tools made from this alloy are small in size. Let's look at the chemical composition of steels in the tables:

Steel U10

| C,% | Si,% | Mn,% | Ni,% | S,% | P,% | Cr,% | Cu,% |

| 0,96 — 1,03 | 0,17 — 0,33 | 0,17 — 0,33 | up to 0.25 | up to 0.028 | up to 0.03 | up to 0.2 | up to 0.25 |

Steel U10A

| C,% | Si,% | Mn,% | Ni,% | S,% | P,% | Cr,% | Cu,% |

| 0,96 — 1,03 | 0,17 — 0,33 | 0,17 — 0,28 | up to 0.2 | up to 0.018 | up to 0.025 | up to 0.2 | up to 0.2 |

U10 steel occupies an average value in the group of carbon steels. They have value as a structural and instrumental material. In accordance with the customer's specifications, the content of some alloying elements may vary in hundredths of the total volume of metal.

| Chemical elements and their significance in the composition of knife steel: | |

| Carbon (C) | Without enough carbon it is very difficult to obtain a suitable hardness. This is the most important element in steel, it increases its strength. |

| Chromium (Cr) | gives the alloy increased anti-corrosion properties, chromium carbides increase wear resistance and hardenability. The high chromium content in the alloy affects its brittleness. |

| Manganese (Mn) | increases wear resistance and strength. Its content has a positive effect on the grain structure of the alloy and also contributes to excellent hardenability. |

| Molybdenum (Mo) | prevents steel from becoming brittle and allows it to maintain strength at high temperatures. Also increases corrosion resistance, strength, toughness. |

| Silicon (Si) | increases the strength and wear resistance of steel, like manganese, it makes steel more stable and reliable. |

| Vanadium (V) | forms the structure of carbides in such a way as to increase wear resistance, survivability and hardenability. |

| Nickel (Ni) | increases corrosion resistance and prevents steel from rotting. Increases the strength of steel. |

| Niobium (Nb) | the best carbide former, which provides corrosion resistance, ductility, and wear resistance. |

| Tungsten (W) | increases the wear resistance of steel, increases its stability during hardening and resistance to high temperatures. |

| Cobalt (Co) | enhances the effects of other individual elements in more complex alloys. Increases strength and hardness. |

| Sulfur (S) | is a harmful impurity, leading to the formation of cracks and tears. Typically, the sulfur content of high-quality steel is limited. The presence of sulfides is unacceptable for critical parts. |

| Phosphorus (P) | worsens the plastic properties of the alloy, causing the phenomenon of cold brittleness. In steels, phosphorus content is allowed in very small quantities. |

Features of annealing various alloys

When assigning a method and mode of heat treatment, the percentage of carbon and other impurities in it is important. To accurately adhere to the regime, it is recommended to use two furnaces: in the 1st, the product is heated at t=max, in the 2nd, it undergoes a holding period, ensuring the completion of the structural transformations of the metal. Stainless steel is processed in the first furnace at t=1000°С, then held for several hours in the second furnace at t=900, completes cooling to t=300° at a speed of 50...100 degrees/hour, final cooling is carried out in an open space.

Analogs

Substitutes for the alloy can be called Russian steel grades U11 and U12. According to the markings, it becomes clear that the alloys contain slightly more carbon. Oddly enough, U10A steel has quite a lot of analogues. Let's look at them in more detail:

- Hungarian: S-101/102;

- Italian: ABN/C-100-KN;

- Spanish: C-102;

- French: C-105-E2U;

- British alloy: 1645;

- Romanian: OSC-10;

- Swedish: 1880;

- Czechoslovakian: 19191;

- Pan-European: AFNOR-NF;

- Japanese: SK-3;

- American: T-72301;

- Spanish: F. 515;

- Polish: N-10 (E);

- Chinese: T10 (A).

Annealing at home

In everyday life, to reduce strength and simplify subsequent metal processing, it is possible to perform the annealing procedure using a simplified method of incomplete annealing. Using a gas burner for heating does not make it possible to control the temperature, so the temperature is determined “by eye”, in a shaded place. The product consistently acquires the color of frying depending on the temperature (in degrees):

- dark brown - t=530...580;

- brown-red - t=580...650;

- dark red - t=650...730;

- dark cherry -t= 730…770;

- cherry red - t=770...800;

- light cherry - t=800...830;

- light red - t=830...900;

- orange - t=900...1050;

- dark yellow -t= 1050…1150;

- light yellow - t=1150...1250;

- light white - t=1250...1350.

U10, U10A carbon tool steel

The concept of metal hardness was previously known only to graduates of technical universities, workers of machine-building plants and blacksmiths.

This term came into use with the modern knifeman with the adoption of the law on weapons and GOST standards, which provide signs on the basis of which a knife can be classified as a bladed weapon. One of the mandatory characteristics by which a particular product is classified as a bladed weapon is the hardness of the steel from which the knife blade is made (or, as it is called in GOST, the warhead of a bladed weapon). And starting from this moment, the nyfomaniacs in Russia began to slowly read reference books that provide the characteristics of different steels, explanations of the differences between powder and laminated steels, and of course the steel hardness indicators, those very noticeable HRC.

If one car enthusiast can ask another about how many “cubes are in the engine,” then an advanced knifomaniac, looking at the characteristics of a field knife that says “57-59 HRC,” can seriously determine that this is a flimsy model for bushcraft and it belongs on kitchen.

This article will tell you in a simple and understandable form what kind of beast this HRC is, where it came from and why it is needed at all.

Interesting fact : On American and European websites, among the parameters indicated by sellers or manufacturers, it is extremely rare to find such a parameter as steel hardness. This issue is not regulated in any way by law, so the average inexperienced buyer does not need this parameter.

So, what do we need to know about the hardness of metals?

Since ancient times, man has encountered the concept of hardness of materials. I also quickly realized that different materials differ from each other in hardness and strength. If you hit a stone with a stick, the stick will either break or bounce off. If you hit a stick with a stone, the stick will break. If a coconut falls from a tree onto a pebble beach, it will break. And if you hit a softer stone with flint for a long time and diligently, then you can quite easily make a head for a stone axe.

Gradually, in the process of evolution, our ancestors realized that different materials have different hardness, and depending on this hardness, they do or do not have the desired properties. Thus was born a method for determining the hardness of a material by comparing it with a certain standard.

Thus, a good carpenter can determine the degree of shrinkage of a log by tapping it with a mallet made of a harder type of wood. Using a special hammer, a potter can determine the degree of readiness of pottery. Willingly or unwittingly, each of us at least once in our lives has resorted to a similar method of determining the hardness of an object.

However, until recently, the most common method for determining the hardness of a material was the sclerometric method. Sclerometry is a physical process where the material being tested scratches (or scratches) a reference sample. If the material being tested scratches the standard, it means the material being tested is harder.

If the material being tested cannot leave a mark on the standard and is easily scratched by the standard, then the material being tested has a hardness less than that of the standard. Now this procedure seems ridiculous to us, but until recently, this was the only way to determine the hardness of a material. How else could the ancient Sumerians determine that it was possible to write inscriptions with a sharp stick on almost dried clay?

The issue of determining the hardness of materials (especially stones and metals) became acute at the end of the 18th and beginning of the 19th centuries, with the development of geology and the beginning of the flowering of mechanical engineering.

It was at this time that the “Mohs scale”, known to all physicists and archaeologists, appeared. However, the first to propose measuring the hardness of metals by comparing them with a standard was the French naturalist of the mid-18th century, Rene Antoine Reaumur.

Reaumur actively conducted experiments related to the melting and processing of metals and therefore he was faced with the acute question of determining the various characteristics of the alloys that he obtained in the process of his research.

His ideas were picked up and developed by the German naturalist and geologist Karl Friedrich Christian Mohs. In 1811, he came up with a system for standard comparison of minerals, which now bears his name. Until about the middle of the 20th century, this scale was actively used by geological exploration parties around the world.

The Mohs scale is a comparative table in which known minerals of different hardness are indicated and their hardness is measured in the following criteria:

- Scratched with a fingernail;

- Scratched by copper;

- Scratched by glass;

- Scratches glass;

- Processed only with diamond.

The softest reference mineral is talc, and the hardest mineral is diamond. The hardness of talc on the Mohs scale is “1”, the hardness of diamond is “10”. Between talc and diamond, as hardness increases, there are: gypsum (hardness 2), calcite (hardness 3), fluorite (hardness 4), apatite (hardness 5), orthoclase (hardness 6), quartz (hardness 7), topaz (hardness 8 ), corundum (hardness 9). This simple method of determining the hardness of minerals turned out to be indispensable in field conditions.

In addition to the Mohs scale, there are other methods for determining the hardness of materials, which were actively developed at the end of the 19th and beginning of the 20th centuries. There are usually four most well-known methods for determining the hardness of metals:

- Brinell method;

- Vickers method;

- Shore method;

- Rockwell method.

Looking ahead , we note: all these methods are similar to each other, since they are based on pressing a reference sample into the surface of the metal. Only the shape of the standard, the pressure force, and the formula for calculating the value differ.

The element that is pressed into the surface of the metal is called an “indenter”. A steel ball (Brinell method), a diamond cone (Rockwell method), or a diamond pyramid (Vickers and Shore methods) can be used as an indenter.

The demand for these methods of measuring metal hardness is explained by their following features:

- all the methods described make it possible to measure each finished sample separately, which undoubtedly improves the quality of serial products;

- there is no destruction of the finished product (for example, a knife) and in the future it can be used for its intended purpose;

- high measurement speed, which means high productivity of the method.

Important : Test results using different methods are not comparable.

Let's consider each method separately, paying special attention to the Rockwell method.