Recently, corrugated sheeting has been so widely used in construction that it is difficult to come up with a more universal roofing covering. And such qualities as strength, durability, and ease of installation helped him win his place in the building materials market. The designation MP 20 has the following meaning: MP – mounting corrugated sheet, 20 – wave height 20 mm (in fact, this value is 18 mm, and 20 is a rounded number).

Description of the material. Types and scope of application

The advantages of MP 20 corrugated sheets include:

- Flexibility. Thanks to this quality, this material is used to cover any roof, including “irregular” ones - broken, hipped, attic.

- Long service life. Under normal conditions and care it can last up to 50 years.

- Budgeting. Compared to other coatings, corrugated sheets really have an affordable price.

- The relative lightness of the material does not give the foundation excessive load.

MP 20 corrugated sheet is used:

- during the construction of internal partitions;

- for the construction of light metal buildings, for example, garages and pavilions, kiosks;

- for covering the walls of permanent buildings;

- for the manufacture of roofing;

- for the construction of fences, gates and fences;

- for the construction of all-metal structures with a small area;

- As a basis for sandwich panels.

The material also has some disadvantages:

- If you do not periodically clean structures from snow and dirt, this can lead to damage to the coatings.

- If the material is used to cover flat roofs, water may accumulate, which has a detrimental effect on it. The same picture will be observed in cases where there is no drainage system.

- It is problematic to use this material to cover complex roofs, since the profile height is not always convenient.

Still, despite minor shortcomings, corrugated sheets are used everywhere and have good reviews.

Price overview

The price of MP 20 corrugated sheeting depends on the city in which you want to buy it and the specific manufacturer. Let's consider prices in different localities of Belarus and Russia:

| City | Cost per square meter. | City | Cost per square meter. |

| Belgorod | 230 | Bryansk | 233 |

| Volgograd | 230 | Voronezh | 250 |

| Ekaterinburg | 240 | Kazan | 250 |

| Krasnodar | 230 | Krasnoyarsk | 230 |

| Lipetsk | 230 | Minsk | 250 |

| Moscow | 250 | Nizhny Novgorod | 240 |

| Omsk | 240 | Permian | 240 |

| Rostov-on-Don | 230 | Saint Petersburg | 250 |

| Tyumen | 230 | Chelyabinsk | 230 |

Recommendations on many forums say that you should check the compliance of characteristics, GOSTs, and certificates. If you do not know how to properly install corrugated sheets, then many companies provide clients with services such as installation, dismantling, transportation and much more.

13 October 2014 Author: Vladimir Bakaev

Production of MP 20 corrugated sheets

MP 20 is made from galvanized metal sheets. The metal arrives at the plant in rolls, and then it is unwound using specialized equipment. After this, the metal is placed on a rolling table, the main function of which is to move it to special rollers, giving the smooth surface of the metal a corrugated structure.

Depending on the scale of production, such a machine can be automatic, semi-automatic or manual. The use of automatic equipment significantly reduces the cost of the finished material. When using a manual device, the cost will be significantly higher.

After this procedure, all that remains is to cut it into the necessary sheets. When ordering profiled sheets from the manufacturer, it is possible to order sheets of the required length. If the metal was initially received in rolls in a non-galvanized form, then it undergoes a galvanizing procedure after cutting. Upon completion of all these activities, the sheets are sent for painting. This processing can be carried out in two ways:

- — painting using high-frequency electric current (this method is considered the most reliable);

- - painting by powder coating applied under pressure.

Manufacturers offer various color options for this material. Painted corrugated sheeting looks more beautiful, in addition, it better resists corrosion and temperature changes. But at the same time, the painted material is somewhat more expensive than usual. After painting, the corrugated sheet is covered with a special protective film, which promotes even longer color retention and better corrosion resistance.

Side S

Where is it used?

Corrugated sheeting with the front side S is only suitable for facades and fences .

Characteristics

Side S is one of the front sides of the C-10 profile. It is produced only in Siberia (it is also sold there).

The S-face S-10 has wide cambers and narrow wave crests. It would seem to fit the roof. But for roofs they use corrugated sheets with a wave of at least 18 mm . Therefore, S-10 is chosen only for wall cladding and installation of fences.

Labeling example

Profiled sheet S-10x1100-S.

Some recommendations for installing corrugated sheets:

- It is necessary to lay the sheets overlapping; this technique helps to obtain a more rigid connection;

- During installation, the use of screws is mandatory; the use of nails is not allowed;

- To calculate the required amount of material required, you must first make drawings. The presence of diagrams is also desirable - they will help calculate the rigidity of the structure being built;

- It is not necessary to use screws too frequently, as this reduces rigidity.

MP 20 corrugated sheet has its own classification:

- type A and B have a trapezoid shape, which allows you to get a variety of shapes. The shorter base of the trapezoid is usually located at the bottom. This technique helps to achieve special stability. These types of corrugated sheets are perfect for building fences. Depending on the color of the profiled sheet, it can be coated with either a polymer or paint coating. This must be taken into account, because the properties of these coatings are different.

— type R is most often used to cover the roofs of low buildings. With this type of profiled sheet, the base of the trapezoid is larger than its top. This corrugated sheet is coated with a protective agent on only one side. If it becomes clear to the buyer that he himself will not be able to install the corrugated sheet, then the manufacturer’s warehouses and factories provide additional services for the transportation, installation or laying of the corrugated sheet. Their cost will be minimal if you order services in addition to purchasing professional sheets.

What is a profiled sheet

Profiled sheet is a construction sheet material made from thin sheet steel. A relief is formed on the workpiece by cold stamping, and then a protective coating is applied. The relief is called a profile. This is where the name of the material came from - corrugated sheet. That is, a sheet with a profile. You can also find such a name as corrugated sheeting. Some people think that corrugated sheets and corrugated sheets are different materials and there is a difference between them. But no. No difference. It’s just that GOST describes two brands as “for flooring.” This is apparently where the name corrugated sheet came from.

“Bent steel sheet profiles with trapezoidal corrugations for construction” - name according to GOST 24045-2016. Conventionally, we can say that if it is necessary to cover the roof, we choose roofing profiles (corrugated sheeting), and if it is necessary to sheathe the walls, we choose wall profiles (corrugated sheeting).

In general, this material has many names. You can find a “sheet profile”, a metal profile. Less common is a “profile sheet”. There is also a name from the catalogs - profiled steel sheet. It's all about the same material.

This is what a corrugated sheet with a colored coating looks like

So, a profiled sheet is a steel sheet with a formed relief. A protective multilayer coating is applied to it. The number of layers and types of coatings differ and affect the final characteristics of the product. For durability, resistance to fading, high or low temperatures, chemical and mechanical influences. In general, many important properties depend on the coating and the quality of its application.

What is a professional sheet? This is sheet metal with a protective coating and a specially shaped profile

There are corrugated sheets for different purposes and they differ in relief. In the sense that the height and width of the wave, the distance between the peaks are different, and the shape is always trapezoidal. This is stated in GOST 24045-94. Only in some types (with increased load-bearing capacity) protrusions - shelves - are added on the side faces, and additional grooves are formed in the ridge and recess. However, the profile shape is trapezoidal.

Technical characteristics and quality standards

This material is made from thin-sheet cold-rolled steel with hot-dip galvanizing or galvanized steel with a polymer coating.

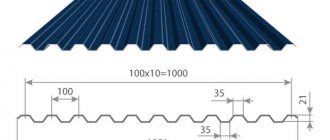

Characteristics of MP20:

- standard width is 1150 mm, but, as a rule, a useful width of 1100 mm is used in calculations;

- The height of the profile is the indicator that determines the strength of the material. In this case, it is equal to rounded 2 cm;

- length. The length options for corrugated sheets can be different and range from 1.2-1.6 m. The length usually depends on the manufacturer’s equipment, as well as on the personal wishes of the customer. When ordering a batch of corrugated sheets, the customer can choose the length he needs;

- the weight of MP20 profiled sheet ranges from 3.8 – 7.3 kg per square meter.

When choosing a material, you need to remember: the thicker the steel sheet was initially, the better technical characteristics the profiled sheet will have. But in this regard, its cost will also increase.

The protective coating is also of great importance. Paint coating is cheaper, but polymer coating is considered more durable.

When purchasing profiled sheets, be sure to check the relevant documents and note that MP20 profiled sheets are produced in accordance with TU 5285-002-78099614-2008. This will serve as a guarantee of the quality of the material.

The meaning of the numbers in the marking of corrugated sheets

As you already understand, the letter in the marking (it usually comes first) means the type of sheet. The second number following the letter is the sheet height in millimeters. For example, C20 corrugated sheet is a wall sheet with a profile height of 20 millimeters, and H75 corrugated sheet is a sheet with a profile height of 75 millimeters.

The third figure is the thickness of the steel that was used to stamp the sheet; the figure is also given in millimeters.

The number following it indicates the installation width of the profile in millimeters.

The last number is the maximum sheet length in millimeters. It is quite natural that the length of the sheets may differ, because when ordering a batch, the profile is cut to the required length.

Thus, it turns out that, for example, the marking of corrugated sheet C20-0.55-750-12000 means that this sheet is intended for wall fencing, has a height of 20 mm, is made of metal 0.55 mm thick, and is supplied in profiles 0. 75x12 m.

Selecting a material will be a simple matter for anyone who knows how to correctly read its markings, because it contains almost all the information necessary for a real master.

Dimensions and weight of MP 20 sheets

The initial metal blank is usually 0.4-0.8 mm. According to the technical characteristics of MP 20 profiled sheets, the following types can be divided:

- MP-20 1100 0.4 – 4.45 kg; 3.87kg;

- MP-20 1100 0.45 – 4.93kg;4.2kg;

- MP-20 1100 0.5 – 5.42kg;4.72kg;

- MP-20 1100 0.55 – 5.91kg;5.15kg;

- MP-20 1100 0.6 – 6.41kg;5.57kg;

- MP-20 1100 0.7 – 7.4kg;6.44kg;

- MP-20 1100 0.8 – 8.4 kg; 7.3 kg.

Where (using the example of the first type) 0.4 is the thickness of the metal, 4.45 is the weight of one linear meter of MP20 corrugated sheet, and 3.87 is the weight of one square meter of corrugated sheet.

Conclusion

We talked about the front sides of corrugated sheets: what they are like and how they differ.

Together we figured out which side to put the corrugated sheet on the roof, and which side to mount on the facade or fence.

- If you need roofing material , choose corrugated sheeting with face A or R (except for profiles C-8, C-10, MP-10 - they are not suitable for roofing, because they have low waves). Also, MP-18 is not used for roofing.

- If you are looking for cladding for a fence or facade , order corrugated sheeting with front side A, B, S. This will not affect anything. It doesn’t matter how the sheets are joined, there will be no leaks. Just see which option looks better - with narrow or wide combs. For example, a fence made of corrugated sheets with wide corrugations is similar to a wooden one - it seems to be assembled from slats. To make the fence look more impressive, order corrugated sheets in Ecosteel® wood-look coating.

Comparison of galvanized corrugated sheets and polymer-coated sheets

Galvanized corrugated sheet

It is widely used in civil and industrial construction; it is used to cover roofs and perform finishing work, make fences and use it to build formwork for monolithic structures.

During the production process, the galvanized sheet passes through special rolling equipment, where it is given the required rigidity by profiling. In this way, a certain shape is obtained for the waves of the sheet; it can be trapezoidal, U-shaped and sinusoidal.

This type of corrugated sheet has an attractive appearance, long service life, and undeniable ease of installation. When covering roofs, this material is indispensable, because it is very flexible, light and airtight.

Since coloring is not used in the manufacture of such profiled sheets, the price will be significantly lower, which can also be an advantage in some cases. However, zinc coating effectively protects the product from corrosion and extends its service life several times. Also, zinc coating is fireproof; flames do not spread across it in the event of a fire.

Galvanized corrugated sheeting has the following markings:

- C – wall corrugated sheeting;

- N – load-bearing or roofing corrugated sheeting;

- CH – universal.

Galvanized sheet can be mounted horizontally and vertically, and it is equally good for both external and internal installation.

Due to its compactness, this material is convenient for transportation.

This material is indispensable as facade insulation: the building frame is first covered with a layer of any insulation, and then sheathed with corrugated sheets, which will reliably protect the insulation from exposure to precipitation and sunlight.

Corrugated sheeting with polymer coating

This coating is applied to ordinary galvanized steel sheet in the form of a primer, protective varnish and polymer material. The method of using corrugated sheeting directly depends on the resulting color. But the coating not only gives it an aesthetic appearance, but also reduces its sensitivity to ultraviolet radiation and makes it more resistant to temperature changes.

Acrylic coating (a mixture of varnish and paint) is widely used. But this particular coating is not the most durable and can be damaged during installation.

The glossy polyester coating of corrugated sheets is also not very durable, as it quickly loses its presentation due to mechanical damage and dust. Unlike glossy, matte polyester coating is more reliable. Such corrugated sheeting does not create glare and fades less in the sun.

There is also a coating called pural. Its thickness is 50 microns and is most often used to cover roofing corrugated sheets. This is due to the fact that pural is little susceptible to ultraviolet radiation and low temperatures.

The most durable coating for corrugated sheets can be called PVC-based plastisol. The protective layer has a thickness of 200 microns, which allows the sheets to be successfully used under the most difficult climatic conditions and for a very long period. It is also extremely resistant to mechanical damage.

The most aesthetically pleasing appearance is provided by corrugated sheeting coated on both sides. For example, when building a fence, this is a very useful quality: the fence will look the same both outside and inside. But double-sided corrugated sheeting is the most expensive of all available types.

A colorful coating is an excellent means of attracting customers to an already finished building - it is difficult to pass by a beautiful, bright kiosk or supermarket.

Which corrugated roofing sheet to choose: the best option in terms of thickness

Metal roofing of private houses is becoming increasingly popular, especially since the material is produced in various variations and, thanks to modern technologies, is constantly being modernized. Therefore, many consumers have a fair question - which corrugated roofing sheet to choose? This roofing material has excellent aesthetic and performance characteristics and can not only reliably protect a building from precipitation and wind, but also transform its appearance.

Corrugated sheeting is produced in different colors, and can also have different thicknesses and sheet configurations. Due to the fact that roofing sheets are given dimensions that allow them to completely cover the length of the roof slope, from the ridge to the overhang, they are much easier to install on the rafter system than, for example, the familiar traditional slate. In addition, the material is not too heavy, and thanks to special protective coatings and a polymer film applied on top, it will last quite a long time.

What are the advantages of corrugated sheeting over other roofing coverings?

High-quality corrugated sheeting is increasingly preferred when choosing a material for roofing residential buildings, since it has a large number of positive qualities that other coatings cannot boast of. These advantages include:

- The first thing that always worries many buyers is the price of the material. Precisely because corrugated sheeting is available to almost any family, it is increasingly the choice when choosing a roofing material.

- The extensive color range of sheets produced allows you to choose exactly the shade of coating that will be perfect for the harmonious design of the exterior of a private home.

- Corrugated sheeting is produced in sheets up to twelve meters in length, which allows, when installing it on the roof, to make a minimum number of joints along the slope or even completely abandon the transverse joint.

- The low specific gravity of the material, simplicity and clarity of installation allows you to carry out roofing work yourself with the involvement of just one assistant who will feed the sheets to the height of the roof.

- The consumer is given the opportunity to choose the height of the sheet relief - depending on the planned slope angle.

- In addition, it is possible to choose a finishing coating for corrugated sheets of different composition. The coating can be applied using different technologies and, accordingly, differ in quality, service life and, of course, the cost of the material.

- Another important advantage of corrugated sheeting is the environmental friendliness of the entire range of materials used in its production. Roofs made of corrugated sheets, regardless of the duration of operation, are not capable of causing harm to the environment. It is also important that the material is non-flammable.

Classification of corrugated sheets

Nowadays, manufacturers offer various types of corrugated sheets designed for specific areas of application in construction practice. However, some of the types, due to their qualities, can be considered almost universal and can be used for a variety of purposes.

To decide on the choice of material that is well suited for roofing work, it is necessary to consider all the main types of corrugated sheeting, since they are very often interchangeable.

When considering a specific type of profiled sheet, you should pay attention to its marking - it consists of several digital and alphabetic symbols indicating its purpose and main parameters.

Letter designations in markings

The first letter in the marking determines the strength qualities of the material and its main area of application:

- “N” is the most durable profiled sheets. In this case, the letter “N” indicates that this is a load-bearing type of corrugated sheet. This material has the highest wave height (corrugations) with additional grooves in its lower part - they give the sheets increased rigidity.

In addition, the load-bearing corrugated sheet differs from other varieties in the greater thickness of the metal sheet. Therefore, it is used for roofing of residential buildings, construction of walls and roofs of large hangars, fences, manufacturing of heavy-duty containers, construction of production workshops, warehouses, garages, gates and other structures that must have high mechanical strength, reliability, and durability.

- “NS” is a “load-bearing wall” profile material, and it can safely be called almost universal, since it is used for a variety of purposes. This type of corrugated sheet differs in the average level of metal thickness and wave height.

This material is used for the construction and cladding of walls, for roofing work, fences, sheds, and other domestic, industrial and utility buildings are erected from it, and wickets and gates are made from it. In terms of its operational characteristics, this type of corrugated sheeting can be called intermediate between load-bearing and wall materials, but its cost is much lower than that of load-bearing.

- “C” - wall corrugated sheeting. It is used for the construction of light outbuildings, cladding the walls of residential buildings over a thermal insulation layer, for the manufacture of frame gates, fences and other structures.

Its wave height is low, therefore, its strength properties for transverse bending are also low. For the manufacture of many models, the thinnest steel is used, and it is not surprising that the cost of such material is also low.

However, many of the corrugated sheet models of category “C” are also quite suitable for roofing work.

- “MP” is another common type of corrugated sheeting, which is characterized by good versatility and is ideal for roofing and for the construction of walls of outbuildings, and in addition, it is used in the production of sandwich panels. What each of its modifications is intended for can be found out from the digital and letter markings.

MP galvanized corrugated sheets are used to cover pitched roofs, partitions in industrial premises, as well as for suspended ceilings. This type of material is produced not only in galvanized form, but also with a polymer coating.

“MP”-profiled sheet is produced in three variations – these are types “A”, “B” and “R”.

For example, “MP-R” corrugated sheeting is intended specifically for roofing, while types “A” and “B” are more suitable for fencing and wall cladding. Type “R” differs from “A” and “B” in the dimensions of the corrugation, in particular, in that the base of the wave towards it is smaller and the distance between the waves is wider, while for wall sheets the situation is the opposite. This profile will make it easier for storm water to flow.

In addition, thanks to these parameters, roofing type “R” surpasses corrugated wall sheets in bending strength and is able to withstand high static loads. Types “A” and “B”, in turn, resist wind dynamic influences better than it.

The wall types of this corrugated sheet differ from each other in that “A” is produced with a protective coating only on the front side, and the “B” type coating is specified at the time of order. Therefore, in the second option, color layers may be completely absent, or applied on one or both sides of the sheet.

MP corrugated sheeting is manufactured with a corrugation wave height of 18 or 20 mm.

Digital designations in markings

So, in the product labeling, the letter designation is followed by numerical values that provide the necessary information:

- The first number indicates the height of the wave in millimeters.

- The second digital value indicates the thickness of the sheet steel from which the corrugated sheet is made - this parameter is also given in millimeters.

- The third group of numbers gives information about the useful width of the sheet in millimeters, that is, taking into account the overlap of waves when laying the coating. This parameter is always slightly smaller than the actual dimensions of the sheets, which should be remembered, for example, when organizing transportation or storage of material.

- The length of the sheet may not be indicated, since when ordering material for specific needs, it can be any, at the request of the customer and according to the capabilities of the manufacturer. However, price lists often still give a maximum length value, also in millimeters. For example, the last group of numbers could be 12000.

Thus, the marking of corrugated sheets may look, for example, like this:

C10-0.5-1100 - this means that wall-type corrugated sheeting, having a wave height of 10 mm, is made of a sheet 0.5 mm thick, with a useful width of 1100 mm.

Another example of marking:

MP-18-0.7-1000V is a corrugated sheet with a wave height of 18 mm, made of steel sheet 0.7 mm thick, usable width 1000 mm, made of galvanized steel without coating, but it can be applied at the customer’s request with one or both sides.

Knowing how to read these values, it will be much easier to find the corrugated sheeting of the required modification.

Sheet thickness, wave height, corrugated sheet weight

It is necessary to highlight the question of what the minimum and maximum thickness of the metal sheet from which the corrugated sheeting is made can be, as well as what weight the sheets of roofing material can have - this is extremely important for the roof structure.

- The thickness of the metal sheet is:

- for varieties “H”, “NS” and “C” it can vary from 0.4 mm to 1.2 mm;

— “MP-R” – from 0.4 to 0.8 mm;

- “MP-A” and “MP-B” - about 0.4 to 0.7 mm.

The strength of the material and its resistance to typical roof loads – wind and snow – directly depend on this parameter.

- It is necessary to choose the correct wave height of the corrugated sheeting, since the rigidity of the material and the reliability of its fit and fastening to the sheathing of the roofing system also depend on this parameter. Typically, corrugated sheeting with a wave height of at least 18 mm and up to 60 ÷ 75 mm is used for roofing work. True, the upper value cannot be considered the limit; higher material can be used, but the only question is the feasibility of such an approach.

The height of the wave affects not only the strength of the material, but also the quality of water drainage from the roof during rain. Profiled sheets “NS” and “N”, which have grooves in the lower part of the wave, are more resistant to various loads, therefore, when choosing a roofing material, it is recommended to give preference to them.

We must not forget that during the winter period an accumulation of snow may form on the roof, which the coating must withstand. In addition, the roof must withstand the weight of a person, since it will have to be climbed more than once for various reasons.

The table below shows the main types of corrugated sheets indicating their typical areas of application:

| Type of corrugated sheeting | Typical applications of the material | ||||

| Wall covering | Roof covering | Load-bearing wall structures | Permanent formwork | Fence construction | |

| C8 | ˅ | — | — | — | ˅ |

| MP18 (A) | — | ˅ | — | — | ˅ |

| MP18 (V) | ˅ | — | — | — | ˅ |

| MP20 (A,B) | ˅ | — | — | — | ˅ |

| MP20 (R) | — | ˅ | — | — | — |

| C21 (A) | — | ˅ | — | — | ˅ |

| S21 (B) | ˅ | — | — | — | ˅ |

| NS35 (A) | — | ˅ | — | — | ˅ |

| NS35 (B) | — | — | — | — | ˅ |

| MP35 (A) | ˅ | — | — | — | ˅ |

| MP35 (V) | — | ˅ | — | — | ˅ |

| MP40 (A) | ˅ | — | — | — | ˅ |

| C44 (A) | — | ˅ | — | — | ˅ |

| C44 (B) | ˅ | — | — | — | ˅ |

| H60 (A) | — | ˅ | — | — | ˅ |

| H60 (B) | — | — | ˅ | ˅ | ˅ |

| H75 (A, B) | — | — | ˅ | ˅ | ˅ |

| H114 (A, B) | — | — | ˅ | ˅ | — |

The design of the sheathing created under the roofing also depends on the type of material and wave height. Approximate values for the pitch of the transverse sheathing are indicated in the following table:

| Type of corrugated sheet | Roof sheathing pitch |

| C8 | It is better not to use it for roofing. In exceptional cases - only with the use of continuous sheathing |

| C10 | It is better not to use it for roofing. Can be used with a lathing pitch of no more than 300 mm |

| S18 (MP18) | no more than 400 mm |

| MP20 | 400 – 500 mm |

| S21 | 350 - 600 mm, depending on the steepness of the roof slope |

| NS35 | 1200 – 1500 mm |

| C44 | 500 - 1000 mm, depending on the steepness of the roof slope |

| NS44 | up to 2600 mm |

| H57 | up to 3000 mm |

| H60 | up to 3000 mm |

| H75 | up to 4000 mm |

corrugated sheet

- An important parameter, both for organizing the delivery of material to the construction site, and for assessing the possibility of performing roofing work manually, without the use of special lifting equipment, is the weight of corrugated sheets, which depends on the thickness of the metal, the features of the profile configuration and its coating. This parameter can vary significantly - in the range from 5.4 to 17.2 kg/m².

The table of weight parameters of the load-bearing “H” corrugated sheet is given below:

| Marking of corrugated sheets | Thickness of metal sheet, mm. | Weight of 1 linear meter of material, kg | Weight of 1 m² of coverage, kg |

| H57-750 | 0.7 | 6.5 | 8.67 |

| H57-750 | 0.8 | 7.4 | 9.87 |

| H60-845 | 0.7 | 7.4 | 8.76 |

| H60-845 | 0.8 | 8.4 | 9.94 |

| H60-845 | 0.9 | 9.3 | 11.01 |

| H75-750 | 0.7 | 7.4 | 9.87 |

| H75-750 | 0.8 | 8.4 | 11.2 |

| H75-750 | 0.9 | 9.3 | 12.4 |

| H114-600 | 0.8 | 8.4 | 14 |

| H114-600 | 0.9 | 9.3 | 15.5 |

| H114-600 | 1.0 | 10.3 | 17.17 |

And one more table showing similar parameters, but for universal sheets of the “NS” type:

| Marking of corrugated sheets | Metal sheet thickness, mm | Weight of 1 linear meter of material, kg | Weight of 1 m² of coverage, kg |

| NS35-1000 | 0.5 | 5.4 | 5.4 |

| NS35-1000 | 0.55 | 5.9 | 5.9 |

| NS35-1000 | 0.7 | 7.4 | 7.4 |

| NS44-1000 | 0.5 | 5.4 | 5.4 |

| NS44-1000 | 0.55 | 5.9 | 5.9 |

| NS44-1000 | 0.7 | 7.4 | 7.4 |

What type of protective and decorative coating for corrugated sheets should I choose?

The durability of roofing material largely depends on what kind of coating is applied to it and how high quality it is. Therefore, it is necessary to consider the main types of such coatings.

Galvanized corrugated sheet

Galvanized roofing corrugated sheeting is made from cold-rolled steel with a zinc coating, sheet thickness 0.4÷1.3 mm.

- The first step is to coat the “black” steel with zinc - this layer is the main barrier in protecting the metal from corrosion.

- After galvanizing, the zinc layer is passivated, that is, it is covered with an oxide film, which also effectively prevents the development of corrosion.

- Next, the sheets enter a profile bending machine, where they are given a trapezoidal or wavy profile with a wave height of 8 to 180 mm, depending on the purpose of the corrugated sheet. The result is a finished sheet made in accordance with GOST. After this, the material can be sent for sale, or a protective polymer coating can be applied to it.

Today you can purchase roofing material coated with a modified anti-corrosion compound - aluminum zinc or aluzinc, consisting of 43% zinc, 55% aluminum and 1.6% silicon. Corrugated sheeting with such a coating does not differ much in price from conventional sheeting coated only with zinc, however, it is much more resistant to various aggressive influences, and therefore more durable.

Simple galvanized corrugated sheeting is rarely used for roofs of residential buildings - as a rule, it is used for garages and various outbuildings, since in these cases issues of economy usually come to the fore, prevailing over decorativeness. For houses and cottages, materials with protective polymer coatings are often chosen.

Previously, many owners, when purchasing galvanized corrugated sheets, independently tried to apply coloring compounds to it. Today there is no need for this - you can choose its color to suit every taste, depending on the overall facade design of the house.

Corrugated sheeting with a protective and decorative polymer coating

Roofing material protected by one of the high-quality polymer coatings dramatically increases its “longevity” - its service life ranges from 25 to 60 years or more.

Polymer coating technology

The polymer coating is designed to protect the roofing material from external natural, chemical and mechanical influences.

Maximum service life is ensured by a protective coating consisting of several layers and applied using modern technological processes.

The performance qualities of the corrugated sheeting will directly depend on the method by which one of the polymer coatings is applied to the metal. Polymers can be applied in various ways, but the stages of this process are approximately the same:

- Galvanized sheets are degreased and dried.

- Next, the metal undergoes a priming process, which significantly increases the adhesion of the galvanized layer to the polymer.

- Then, a polymer colored coating is applied. Its thickness can vary from 25 to 200 microns. This layer is usually applied to the front side of the profiled sheet, and its lower side is often covered only with a layer of protective varnish.

- At the next stage, the sheets enter special chambers, where, under the influence of high temperatures, the processes of final polymerization and strengthening of the protective coating take place.

The most common method of applying a polymer layer is powder. The painting process takes place in a special chamber. At this stage, a positive charge of direct electric current is passed through the metal, after which a fine powder of a certain color is sprayed onto its surface, which is given a negative charge. Under the influence of the created electromagnetic field, powder particles are attracted to the metal sheets. Then, the sheets enter thermal chambers for the final polymerization of the coating.

This coating method helps create a more durable layer on the metal surface compared to liquid painting. This is due to the fact that the coloring composition is very evenly distributed on the surface of the metal, which significantly reduces the risk of receiving defective corrugated sheets.

Corrugated sheets with a polymer-powder coating are highly resistant to all kinds of negative influences, so their service life is much longer than that of corrugated sheets coated with liquid compounds.

By the way, another fact speaks about the strength of the polymer coating.

galvanized corrugated sheet

After painting, sheets are usually immediately shipped to consumers - companies that are already producing corrugated sheets locally. Of course, protective packaging for this purpose is usually provided.

But already during the production of corrugated sheets, the material is passed through the rollers of machines that form the desired profile, that is, the metal experiences considerable loads and internal stresses. However, the high-quality protective coating is not damaged at all from such exposure.

Types of polymer coatings

Since polymer decorative and protective coatings can be different, it makes sense to consider their features. So, what are they like and what qualities do they have?

So, the following polymer coatings can be applied to roofing corrugated sheets: polyester, pural, matte polyester, PVDF and plastisol.

- Polyester

Profiled sheets with a similar coating have the most affordable price, and therefore have become the most popular material, both for roofing and for the construction of fences and gates. Polyester is resistant to ultraviolet rays, so it practically does not change its original color for many years. The material is resistant to corrosion processes and temperature changes, but its disadvantage is the small thickness of the applied polyester, which is easily damaged by mechanical action - the same as scratching.

Before purchasing this material, it is recommended to conduct an experiment to check the quality of the coating. To do this, you can try to bend the edge of the corrugated sheet - from such an impact the polyester should not become covered with cracks or small folds.

- Matte polyester

Matte polyester is slightly different in composition from the glossy version. Since the coating is rough, it diffuses light and does not produce glare. The technology is such that the composition is applied unevenly, so it is quite difficult to determine the exact thickness of the layer. But in any case, it turns out to be quite large, and such a coating is significantly superior in surface and anti-abrasive strength to its glossy counterpart.

This quality of the coating allows us to hope for a longer service life of the roofing covering.

Quite often, it is with the use of matte polyester that the textured patterns of stone, wood or brickwork are imitated on the surface of the corrugated sheet.

- Pural

Pural is a protective multipolymer composite, which is made from a polyurethane-based composition with the addition of polyamide and acrylic. It makes the roofing material more durable, suitable for use for 50 years without losing its basic protective and decorative qualities.

Pural is applied with a thickness of 50 microns and has excellent adhesion to metal, so it is quite difficult to damage, since it is resistant not only to mechanical loads, but also to chemicals, temperature changes, and various external influences of a natural or man-made nature. Therefore, it is well suited for use in areas with an aggressive environment for metal, such as high humidity or air pollution from industrial emissions.

The disadvantage of pural-coated corrugated sheets is its high price, which is several times higher than the cost of sheets protected with regular or matte polyester. Most often, corrugated sheets coated with pural are used specifically for roofing or facade finishing of residential buildings.

There are two options for pural coating - smooth glossy and matte.

- Plastisol coating

Plastisol is made from polyvinyl chloride with the addition of plasticizers. It is applied in a layer of about 200 microns. Due to this thickness, this material is highly resistant to mechanical and chemical influences, as well as some natural phenomena.

However, plastisol has a significant drawback - it reacts poorly to elevated temperatures, so it is not recommended for use in climate zones with hot summer climates. In addition, this protective coating is not resistant to ultraviolet rays, therefore, under their influence, it quickly loses its original color. If you purchase corrugated sheets with this coating, it is recommended to choose light colors, since they fade less in the sun under the influence of ultraviolet rays and do not heat up as much.

Many people choose corrugated sheeting with this protective coating because it is produced with a relief surface that imitates the textured pattern of various natural materials, such as wood, a cut of stone or the surface of leather. This design usually has a matte surface that does not give glare, so the color appears deeper and richer, which gives the material a respectable appearance.

Corrugated sheeting coated with plastisol is most often used in cold regions with an aggressive climate or in industrial areas, as well as where there is a high probability of mechanical damage to the roof from natural phenomena, for example, in areas where dust storms or hail often occur.

- PVDF coating

PVDF is also a composite coating, as it consists of 20% acrylic and 80% polyvinyl fluoride. Thanks to the complex of these materials, the metal is provided with the highest degree of protection from all types of influences, including ultraviolet rays. Such corrugated sheeting is used for finishing facades and roofing, as it retains its original appearance for 45–50 years. Metal sheet coated with PVDF can be used in areas with any climate, regardless of environmental conditions, since it is inert to industrial air pollution, as well as humid, including “salty” marine climate.

As is clear from the presentation, all types of coatings mentioned above are capable of performing the functions of protecting a metal sheet, but to varying degrees. The table below allows you to more clearly compare the qualities of protective and decorative coatings, so that it is easier for the consumer to make a choice:

| Coating properties | Polyester | Matte polyester | Pural | Plastisol (PVC) | PVDF |

| Nominal coating thickness, microns. | 25 | 35 | 50 | 200 | 27 |

| Thickness of metal polymer coating, microns | 19 | 23 | 30 | 192 | 20 |

| Primer thickness, microns | 6 | 12 | 20 | 8 | 7 |

| Maximum operating temperature, °C | 90 | 90 | 100 | 70 | 110 |

| Surface | Smooth | Embossed | Smooth | Embossed | Smooth |

| Service life, years | 20-30 | 30-40 | 40-50 | 30-50 | 30-40 |

| Compositions of polymer coatings | Polyester | Polyester | Polyurethane, polyamide and acrylic | Polyvinyl chloride and various plasticizers | Polyvinyl fluoride - 80%, acrylic - 20% |

| The table below shows comparative assessment indicators of the resistance of coatings to various influences (ratings are indicated on a 5-point system). Points are assigned based on the results of testing in the laboratories of companies producing similar materials. | |||||

| UV resistance | 3 | 3 | 4 | 1 | 5 |

| Mechanical resistance | 2 | 3 | 4 | 5 | 3 |

| Chemical resistance | 2 | 3 | 4 | 4 | 5 |

| Resistance to aggressive climatic conditions | 3 | 4 | 5 | 5 | 4 |

Basic criteria for choosing corrugated sheets

As a generalization of all of the above, it makes sense to highlight the points that you need to pay special attention to when choosing corrugated sheets for arranging the roof of your home.

corrugated sheeting with protective coating

- The material must be marked “N”, “NS” or “MP-R”, and if it is selected for a residential building, then an average sheet thickness of 0.5 ÷ 0.8 mm will be sufficient.

- It is recommended to purchase roofing material with powder coating. The polymer used for the coating is selected independently, taking into account those features that were emphasized above, taking into account the climatic and other conditions of the region or even a specific locality.

- Particular attention should be paid to the quality of the corrugated sheet covering:

— the surface of the roofing sheets must be smooth, without dents or scratches;

— the edges of the sheets must have smooth cuts, without burrs;

— the protective colored polymer layer must be uniform, without chips or sagging;

— when a profiled sheet is bent, its coating should not crack, break or fold, and the sheet itself, when unbent, should easily return to its original shape.

- In addition, it is worth paying attention to the warranty provided for the material by the manufacturer. For example, the certificate may indicate a service life of corrugated sheets of 30 years or more, but the warranty is given for only a year or even completely absent - in this case it is recommended to refuse to purchase such products.

- If such an opportunity is given, then the best option is to purchase corrugated sheets directly from its manufacturer or from official dealers - this moment will significantly reduce the likelihood of purchasing low-quality material.

- In addition, it is worth considering the reputation of the manufacturer and seller. You should not purchase corrugated roofing in a small store on the construction market, since in this case the risk of running into products from an unscrupulous manufacturer is quite high.

- According to the rating of manufacturers, several domestic and foreign companies can be identified that have earned positive reviews - these are Russian enterprises producing high-quality sheet steel, such as Novolipetsk NLMK, Severstal and Magnitogorsk MMK, as well as European manufacturers of roofing materials that represent its products on the Russian market - “RUUKKI”, “Thyssen Krupp”, “Arcelor”, “Galvex”.

When choosing corrugated sheeting, you must remember that roofing work is a rather labor-intensive and expensive process, and it is usually carried out once every few decades. Therefore, it will be very unpleasant if you have to do this again and spend a lot of money in a year or two due to poor-quality corrugated sheeting, which can crack and peel under the influence of natural or other factors.

At the end of the article, there is an informative video about the types of corrugated sheeting and its installation as a roofing covering:

Video: corrugated sheeting is an excellent solution for roofing a house

Universal flooring

It is more convenient and cheaper to use universal flooring. These are sheets of the NS, NPC, MP20 series. Broad-spectrum materials are more in demand than highly specialized ones. Because they can be purchased in large quantities, which is much more economical, and used on different objects (say, a fence and a roof of the same color).

NS combines the properties of both types of sheet coating. It is light and flexible, like roofing, but at the same time quite durable, like wall covering. In addition, almost every plant produces flooring with stiffeners and painted either with special paint under pressure or using electrolysis. In addition, it is considered a variable material, if desired, change the roof at least every year once a month.

Using universal profiled sheets, it is much easier to carry out the process of covering a roof or fence. This is explained by the fact that self-tapping screws, rivets and screws can be used as mounting parts (it is best to use threaded options, as the fastening is stronger and more reliable, and it is also not necessary to buy a special tool). Its marking looks like this - NS45-1200-0.8:

- 1200 – sheet length;

- 0.8 its thickness;

- NS 45 – brand type.

Sometimes it is marked as follows: MP45-1000-0.8. Why MP? This is a designation according to specifications; most likely the marker is simply using old instructions.

The only requirement for the installation of such profile sheets is the need to install drain grooves. Despite all the positive qualities, universal corrugated sheeting does not tolerate standing water very well. Moisture must be removed from the roof, for example, otherwise the sheets will begin to rust.

Video: how to choose the right corrugated sheet

The main features of universal corrugated sheeting:

- installed on any surface (but again, take into account either the presence or absence of stiffeners);

- used for covering greenhouses, roofs, fences and much more;

- Corrosion-resistant paints are used to cover it.

Side R

Such profiled sheets are the best choice for roofing.

Features and differences

The front side R is present only in profiled sheets marked MP-20-R.

The differences between this corrugated sheet are:

• the presence of a capillary groove on the side of the lock, which helps to avoid leaks; • side edges that are curved downwards. This allows you to get tight joints; • narrow ridges, as well as fairly wide troughs. This ensures uniform load distribution.

Dimensions of corrugated sheeting for a fence

If you are planning to create a classic fence from corrugated board, then first of all you should focus on the dimensions from the table above. The number of pillars and the length of the guides will depend on the width of the sheet. The height of the fence is limited only by your wishes. Unless, of course, you are going to install a fence over 12 m.

Wickets and gates made of corrugated sheets

When arranging gates and gates from corrugated sheets, you first need to purchase or make your own base, onto which the corrugated sheeting will subsequently be attached. The height of wickets and gates made of corrugated sheets directly depends on the base. We recommend using the ready-made Economy subsystem. It includes the necessary posts and guides for mounting the corrugated sheet. In addition, you can order subsystems for wickets and swing gates. Height – 2.03 m. Gate width – 3.45 m, wicket width – 1 m.

Recommendations for purchasing

When purchasing a metal profile, you need to pay attention to the GOST rolled steel from which the profiled sheet is made.

If this is GOST R 52246−2004, then the sheet is galvanized. In other cases, it is necessary to check the presence of zinc or similar coating. It is important that the manufacturer provides a guarantee for its products for at least 10-15 years. This is interesting: the colors of the corrugated board.

In the case where corrugated sheeting is planned to be used for roofing, the following should be taken into account:

- presence of the letter “R” in the marking;

- the presence of a capillary groove on one edge of each sheet;

- The protective and decorative coating must be one-sided.

If trees grow near the roof, then their branches, when touched, can scratch the insufficiently durable coating, which will entail a significant reduction in the service life of the roof. In this case, it is better to choose a more durable type of coating, despite its higher cost. Because frequent roof repairs during operation will cost much more.