Gas welding hoses are used to transmit pressurized media used in the welding process. They are designed to perform welding work in different climatic regions at air temperatures at the work site from – 55.0 to + 70.0 C. In the welding process, hoses are used for gas welding of 2 types of fuel, while one is used for oxygen and the other for liquefied gas . The rules for safe welding work limit the length of use of hoses - above 9.0 and no more than 30.0 m.

Purpose and scope

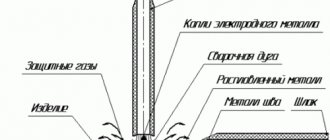

Welding technology is in demand, especially when performing large-scale installations, for example, the construction of hydroelectric and nuclear power plants. This is due to the reliable and efficient technology. The gas provides a high melting temperature at which the edges of the material melt, forming a weld pool. The welding kit is quite simple, it includes a hose for gas welding and cutting metals, gas cylinders, a torch device or cutter. A special load lies on the hoses through which the fuel mixture and O2 are transported. They are produced not only with high quality, but also with state standards.

The product for gas welding work is made in the form of a multilayer structure. The main material is elastic rubber or rubber. A thread frame is installed between the outer and inner layers of rubber, which is responsible for ensuring the design strength of the structure. Reinforcement is done with thread or fiberglass.

What do gas welding sleeves look like?

All rubber hoses for gas welding are assigned to the following classes according to their intended purpose:

- 1 – used for transporting propane-butane and acetylene gases under high pressure.

- 2 – used to move gasoline or other energy carriers in the liquid phase.

- 3 – mounted in schemes for organizing the welding process for the movement of oxygen with high pressure up to 20 atm.

Technical characteristics of hoses by class:

| Allowable diameter (mm) | Allowable pressure (atm) | Classification | Length in bay (m) | Color | |

| 6.30 | 6.30 | 1 | 50.0 | Black + red stripe | |

| 9.0 | 6.30 | 1 | 50.0 | Black + red stripe | |

| 12.0 | 6.30 | 1 | 50.0 | Black + red stripe | |

| 6.30 | 6.30 | 2 | 50.0 | Black + yellow stripe | |

| 9.0 | 6.30 | 2 | 50.0 | Black + yellow stripe | |

| 12.0 | 6.30 | 2 | 50.0 | Black + yellow stripe | |

| 6.30 | 20.0 | 3 | 50.0 | Black + blue stripe | |

| 9.0 | 20.0 | 3 | 50.0 | Black + blue stripe | |

| 12.0 | 20.0 | 3 | 50.0 | Black + blue stripe | |

| 16.0 | 20.0 | 3 | 50.0 | Black + blue stripe | |

Gas welding hoses

Sort by: by popularity cheap first by name

Gas welding uses propane, butane, acetylene, liquid fuel and oxygen under pressure. Special sleeves are used to transfer them to welding equipment. The admissibility of using a particular hose is determined by the substance being transferred. Based on this condition, gas welding hoses are divided into three classes:

- Class I includes a hose for transmitting gas (butane, propane, acetylene, city gas) under a working pressure of 6.3 kgf/sq.m. cm (0.63 MPa);

- Ko II - for supplying liquid fuel such as gasoline or kerosene and their mixture under a pressure of 0.63 MPa;

- to III – for supplying oxygen pressure up to 2 MPa.

Rubber hoses for welding are a type of rubber products that can withstand enormous loads and not lose their consumer qualities under conditions of high and low temperatures. Technical characteristics indicate that the hoses do not lose their technical qualities in the temperature range from - 55 to + 70 degrees Celsius.

An important feature of the product is a high safety margin, which when ruptured by pressure exceeds three times.

No less important properties of welding hoses are their elasticity and resistance to aggressive environments.

Structurally, welding sleeves have 3 layers: inner and outer rubber layers, separated by a thread frame. The frame is made of cotton fibers or based on (un)impregnated chemical fiber.

In this case, the color of the outer layer must comply with GOST, which determines the relationship of color with the purpose of the sleeve. Thus, the red color of the hose suggests its use for gas transmission, yellow for liquid fuel, and blue for oxygen.

You can get competent advice regarding the suitability of the welding hoses presented on the website to your needs from our managers by phone. 290-10-12. You can place an order directly through the website or by telephone.

vsyasvarka.ru

Design features

The most highly resistant O2 hose complies with the parameters of GOST 9356-75 and consists of an external and internal rubber coating that ensures an integral structure of the cotton base. According to the parameters of GOST 9356-75, all hoses must, in addition to markings, have a colored stripe; for O2 it is blue. There are also differences for use in climatic conditions in order to ensure their frost resistance at the minimum design outdoor temperature. Oxygen hoses are made with special tightness, guaranteeing the integrity of the structure even when the medium pressure is higher than permissible. In the event of a rupture, the hose design provides a 3-fold reserve of protection that prevents the movement of gas in the area of work.

Requirements for all classes of gas welding products have tolerances and specified flexibility. But there are general requirements - the outer coating must be free of cracks, folds, and any bubbles, which subsequently cause a rupture in the structure of the material. Subject to compliance with state requirements, the service life of gas hoses according to GOSTs is set at 1.5 years. After this, experts in Moscow advise replacing it, even if outwardly they look acceptable.

The hoses supplying O2 and propane to the burner are made of vulcanized rubber, protected by paper or linen gaskets. To pump kerosene or gasoline fuel, a 4.0 mm durite hose made of special rubber that is resistant to these substances is used.

All hoses are subject to control and special measurement methods in accordance with the requirements of GOST 8.051.

Types of measurement:

- Frost resistance, the hose is measured after cooling at the design T for 4 hours, with a double bend of 180 degrees around an installation of a certain diameter, while there should be no cracks on the surface.

- Tightness with pressure testing higher than calculated.

- Gasoline resistance of the inner layer according to GOST 9.030 on hose samples cleared of glue and threads.

- Strength and tensile strength according to GOST 6768. After testing, the deformation of the samples is checked.

All hoses for gas welding are subject to control and special measurement methods in accordance with the requirements of GOST 8.051.

Sleeves for gas welding GOST 9356-75 with a diameter of 16 mm in the online store mtrservis.ru

The gas welding hose can be used in areas where it is necessary to supply liquid or gaseous fuel under pressure.

The flexible gas hose has two distinctive color stripes on the outside, indicating that it belongs to one of three classes. With a red stripe - I class, with a yellow stripe - II class, with a blue stripe - III class.

GOST 9356-75 Download GOST 9356-75 in pdf

LLC PP "MTR-Service" offers to buy hoses for gas welding with delivery to Moscow at a competitive price.

- Price

- Characteristics

- Detailed description

Hose I class

Internal diameter, mm. Outer diameter, mm. Working pressure, atm. Length, lm Weight, kg. / p.m.

| 6.3 atm | 100, 150 | 0.14 | |

| 9 | 18 | 50, 100, 150 | 0.24 |

| 12 | 22 | 75, 150 | 0.36 |

Hose II class

Internal diameter, mm. Outer diameter, mm. Working pressure, atm. Length, lm Weight, kg. / p.m.

| 6.3 | 13 | 6.3 atm | 100 | 0.14 |

| 9 | 18 | 100 | 0.24 | |

| 12 | 22 | 75 | 0.36 |

Hose III class

Internal diameter, mm. Outer diameter, mm. Working pressure, atm. Length, lm Weight, kg. / p.m.

| 6.3 | 13 | 20 atm | 50, 100, 150 | 0.14 |

| 9 | 18 | 50, 100 | 0.24 | |

| 12 | 22 | 50, 150 | 0.36 | |

| 16 | 26 | 50, 100 | 0.43 |

Example of a symbol: Sleeve class. III oxygen f 9 mm (20 atm) GOST 9356-75 class 3 - hose class 9 - internal diameter (mm) 20 atm. — working pressure (atm)

GOST 9356-75 - State standard

All three types of hoses comply with GOST 9356-75 and can be used in areas where it is necessary to supply liquid or gaseous fuel under pressure.

The flexible gas hose consists of a thread frame and a rubber layer; on the outside it has two distinctive color stripes, indicating that it belongs to one of three classes.

At MTP-service you can buy an oxygen, gas hose or a hose for liquid fuel.

The hoses are used in temperature conditions from -35C to +70C for temperate climates and from -55C to +70C in cold climates.

Gas hose acetylene, propane (Class I)

A gas hose with a red stripe is very often used in residential buildings to connect gas equipment to cylinders, pumps, gas pipelines and is more often used as a hose for:

- gas stove, cylinder,

- geyser, burner, boiler,

- propane tank, cutter,

- welding machine,

- gas welding, cutting,

- semi-automatic,

- metal cutting,

- oxygen cylinder,

- gas stove, cylinder.

The working medium used for the gas hose is all types of gas fuel: acetylene, city gas, propane, butane. Hence it is often called propane, acetylene or butane hose.

Hose for liquid fuel (Class II)

The yellow stripe hose is used for welding and metal cutting equipment that uses liquid fuels:

- diesel fuel,

- petrol,

- kerosene,

- White Spirit

- and other mixtures.

Oxygen hose (III class)

Blue stripe oxygen hose is very commonly used and well in demand as a welding hose or metal cutting hose.

The oxygen hose is used as a hose for:

When using an oxygen hose, you can use a working medium in the form of oxygen, gas and liquid fuel, so it is universal.

Frequently asked questions about gas hoses

Our manufacturing enterprise MTP-service has been in the rubber products market for more than 7 years. We have extensive experience in communicating with clients and are always ready to help make a choice.

What is the diameter of the gas hose?

Determined by the internal diameter and measured in millimeters. MTP-service supplies gas (oxygen) hose 6.3mm, 9mm, 12.5mm.

What is the length of the gas hoses? What is the maximum length of the gas hose?

The hose is packed in coils of 50 meters. In our company you can buy a gas hose from 1 to 50 meters.

Where to buy a gas hose?

You can order a sleeve on our website or by calling +7. The MTP-service warehouse is located at Chelyabinsk, st. 2nd basic 37.

How much does a gas (oxygen) hose cost?

Oxygen hose, the price depends on the required diameter and manufacturer, so it ranges from 30.9. up to 80.6 rub. per meter

Gas hose, price also varies from 25.1. up to 47.9 rub. per meter

The price of a hose for liquid fuel is from 47.3 to 73.5 rubles. per meter

Gas hose, which is better?

It all depends on what purpose you are purchasing it for. The oxygen hose with the blue stripe is universal.

What pressure is applied to the oxygen hose?

The pressure for oxygen hoses is increased and is 2MPa. For class I and II hoses, the pressure is much lower - 0.63 MPa.

Classification of classes, parameters and sizes of oxygen hoses

Currently, 2 classes of special products are produced, in the form of a simple sleeve or as a multifunctional cable complete with a gas burner. The latter are universal in purpose and are equipped with: a hose with a built-in welding gun-torch and a special connecting connector. This kit is suitable for a semi-automatic process that requires the wire to be fed to the processing site along a guide channel with a compressed spiral. The inner surface of which is usually strengthened to protect the structure with a special tube made of wear-resistant materials, such as Teflon.

In addition to the traditional single-channel transmission method, the hoses can also operate according to the parallel supply principle. In this case, several channels are placed simultaneously in one coaxial cable. The permissible length of welding hoses is from 8.0 to 20.0 m; it is prohibited to use hoses shorter than 9.0 and longer than 30.0 meters during work. Certain tolerances for increasing the length are allowed for large slip structures up to 40 m, and above 40 m, a special permit for work will be required in the presence of the person responsible for safety.

It is permissible to lengthen the sleeves with nipples made of steel or brass, while in order to avoid breakdown and leaks, the sleeves with nipples are additionally secured with soft types of wire. The length of the connecting sections cannot be less than 3 m. It is prohibited to use smooth-bore tubes to connect structures.

Before connecting the hoses with the cutter, they must be purged with working media: oxygen, respectively, O2, and propane, with propane. During the welding process, it is prohibited to pull the hoses or step on their sections and place them near an open fire or a high-temperature source. They must also be protected from sparks. Upon completion of the process, the hoses are carefully collected onto the reel and placed on fastenings or placed in a place specially prepared for storage.

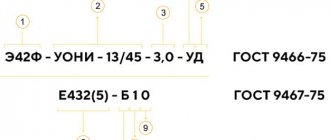

Symbols and markings

On each hose, the manufacturer encrypts information containing the technical capabilities of the product:

- Purpose and approvals for use;

- cross-sectional diameter of the internal free space;

- permissible maximum medium pressure.

For products capable of operating in environments with negative temperatures, the marking will contain the designation “HL”.

Example: III-9-2.0-U GOST 9357-76:

- Hose 3rd class, diameter 9.0 mm;

- gas pressure 20 atm (2.0 mPa);

- “U” for the central zone of the Russian Federation, with an ambient temperature range of -36 C: +72 C.

Marking must be applied to each hose at certain intervals by embossing, color marking or other visible and durable method. The designation must contain the following information:

- Information about the manufacturer;

- hose classification;

- internal diameter size, mm;

- product release date, in month and year format, indicating the last two digits;

- maximum permissible medium pressure, MPa;

- current standard.

The designation of hoses for gas welding contains information about the manufacturer, production date.

Then color marking is applied, the color is white on colored hoses, or color stripes are simply indicated. Hoses that will be used in conditions of high outdoor temperatures, for example, tropical climates, are designated according to the requirements of GOST 15152, and in northern conditions according to NTD. Markings are marked on the corrugated surface of the sleeves using the embossing method, including for “HL” and “T”.

All hoses are collected into coils with an external diameter of at least 0.300 m and tied in three places with a wide 40mm calico tape, guaranteeing the safety of the coil. Each one has a label with mandatory technical information:

- Manufacturer's data;

- hose length in coil, m;

- batch numbers and release date;

- letter for products made from unimpregnated threads;

- Responsible for packaging and quality control stamp.

Length of gas cutting and welding hoses

Oxygen hoses GOST 9356-75 are used for supplying under pressure acetylene, urban natural gas, propane, butane, liquid fuel and oxygen to devices used for gas welding and metal cutting.

According to GOST 9356-75, oxygen hoses can be used in areas with temperate and tropical climates at ambient temperatures from -35 o C to +70 o C, and in areas with cold climates - from; -55 o C to +70 o C.

Gas hose classes

Depending on the purpose and area of application, oxygen hoses according to GOST 9356-75 are divided into the following classes:

- I – oxygen hoses designed for supplying acetylene, city gas, propane and butane under pressure. The working pressure for which the first class oxygen hose is designed is 6.3 kgf/cm2 (0.63 MPa).

- II – oxygen hoses used for supplying liquid fuel: A-72 gasoline, white spirit, kerosene or mixtures of these liquids at an operating pressure of 6.3 kgf/cm2 (0.63 MPa).

- III – oxygen hoses, operated to supply oxygen at a pressure of 20 kgf/cm2 (2.0 MPa) and 40 kgf/cm2 (4.0 MPa).

Symbols on gas hoses

The symbol for an oxygen hose according to GOST 9356-75 contains:

- product name,

- class indication,

- internal diameter value in millimeters,

- value of the design pressure in MPa,

- if necessary, climatic version,

- as well as instructions from GOST 356-75.

An example of a symbol for a class I oxygen hose with an internal diameter of 16 mm, designed for a working pressure of 0.63 MPa, operable in areas with a tropical climate: Hose I-16-0.63-T GOST 9356-75.

Oxygen hoses intended for use in areas with cold climates have the symbol “HL” in their designation . The design of oxygen hoses for temperate climates, according to GOST 9356-75, does not require an additional marking symbol.

Composition of gas hoses

- inner rubber layer,

- thread frame made of cotton fiber or based on unimpregnated and impregnated chemical fibers

- outer rubber layer.

Gas hose colors

Depending on the purpose and area of application, oxygen hoses have different colors.

- The red color of the sleeve indicates that the product belongs to class I, and is intended for supplying acetylene, city gas, propane or butane

- Yellow – class II hoses, for supplying liquid fuels

- Blue – Class III products for oxygen supply.

- Black color of the outer surface of the oxygen hose is allowed, and the product class designation is applied in the form of two colored stripes.

Gas hose quality assessment

Oxygen hoses are flexible products, and with a minimum bending radius, the change in the outer diameter of the product does not exceed 10%.

Criteria for visual quality control of an oxygen hose

- Oxygen hoses manufactured in accordance with the requirements of GOST 9356-75 should not have folds, porosities, bubbles or cracks on the surface of the internal rubber layer.

- The outer surface of the oxygen hose should not contain bubbles, peeling or exposed areas of the load-bearing frame.

- To clarify the criteria for visual rejection of products, a control sample approved in the prescribed manner is used.

Reception of gas hoses

Oxygen hoses are accepted in batches. A batch is understood as products of the same class and size in quantities with a total length of no more than 2000 meters. Each batch of oxygen hoses is accompanied by a quality document containing the following information:

- trademark or trademark and name of the manufacturer

- name of oxygen hoses,

- Class,

- inner diameter

- working pressure and overall length

- batch number

- month and year of manufacture

- designation GOST 9356-75

- stamp of the technical control section confirming the compliance of the quality of oxygen hoses with the requirements of GOST 9356-75.

To check the compliance of the quality of oxygen hoses with the requirements of GOST 9356-75, the products are subjected to acceptance tests in appearance (design, color, size), a leak test under hydraulic pressure, a tensile strength test under hydraulic pressure, a gasoline resistance test of the inner layer (for hoses) oxygen class II), testing the strength of bonds between the elements of the product, monitoring the condition of the internal surface.

Marking

Each oxygen hose must be marked. Each product along its entire length, or at intervals, must be applied by embossing, indelible paint or another method that guarantees the clarity and safety of the designation and marking. The oxygen hose marking contains:

- name or trademark of the manufacturer,

- product class,

- designation of the internal diameter, date of manufacture (month and last two digits of the year),

- the value of the design pressure,

- designation GOST 9356-75.

GOST 9356-75 allows marking on the label for oxygen hoses with a diameter of 6.3 mm. For colored oxygen hoses, the paint color for marking must be white; on oxygen hoses with a black surface, the color of the marking must correspond to the class of the product.

Transportation of gas hoses

Oxygen hoses are subject to transportation by all types of covered vehicles in accordance with the cargo transportation rules in force for each type of transport. Moreover, each batch of oxygen hoses is accompanied by transport markings indicating the class of hoses, diameter, total length and designation GOST 9356-75.

Transportation and storage

Transportation of products packaged in a bay is carried out by any covered vehicles in compliance with the requirements of cargo transportation that apply to road and rail transport. If there is a special agreement between the plant and the buyer of the cargo, it can be packed in soft containers or transported in bags.

For the transportation of hoses, a transport designation is used indicating additional data on the class of hose products, packaging length and the current standard.

Hoses are stored in rooms with ambient temperatures from – 20.0 C to +25.0 C. They are placed in coils with a maximum height of up to 1.5 m or in unfolded form. Hoses should not be exposed to direct sunlight or open flame. They must be protected from oil or gasoline solvents, as well as aggressive chemical solutions in the form of acids and alkalis, which can destroy rubber and the protective frame.

It is prohibited to store products near functioning radio-electronic or other equipment capable of producing ozone, as well as light sources that emit ultraviolet rays.

Oxygen hose for gas cutting and welding GOST 9356-75 (76)

Oxygen hose for gas cutting and welding GOST 9356-75

A rubber pressure hose, intended for gas cutting and gas welding work, is manufactured in accordance with the requirements of GOST 9356-75 and is often called an oxygen hose.

The product is designed to supply working gas under pressure (this can be acetylene, natural gas, butane, propane, oxygen, and liquid fuel) to equipment used for gas cutting and welding. According to GOST 9356-75, the operation of oxygen hoses is possible in cold, temperate and tropical areas.

The operating temperature range is determined by the climatic version - from –55 to +70 °C (cold and moderate) and from –35 to +70 °C (tropical).

The classification of oxygen gas welding hoses is based on their purpose and scope of application:

Oxygen hose marked GOST 9356-75

- class I - a series of oxygen hoses used to supply various gases or their mixtures (propane, butane, natural gas) under pressure up to 0.63 MPa;

- class II - hoses that are designed to supply liquid (A-72 gasoline, kerosene, white spirit or mixtures thereof) under pressure up to 0.63 MPa;

- class III - a series of pressure oxygen hoses used exclusively for supplying oxygen at high pressure (working pressure can be 2 and 4 MPa).

- The class of the product is indicated in the labeling.

Symbols and markings

Each oxygen hose GOST 9356-75 has a marking applied using indelible paint or in relief. Marking technology must ensure the safety and readability of markings throughout the entire service life of rubber products. For gas welding hoses having a diameter of 6.3 mm, designations can be applied to the tag rather than the hose itself.

The marking of rubber products contains the following information:

Welding sleeve with longitudinal markings

- symbols;

- brand mark or name of the manufacturer;

- batch number and release date;

- stamp of the technical control department confirming compliance with the requirements of state standards.

Colored oxygen hoses are marked using white paint. Black products are marked with color, depending on their class. Application is carried out in the form of a longitudinal line along the entire length (possibly at intervals).

The designation of the main technical and operational characteristics of oxygen hoses is encrypted in the marking. It contains:

- full name of the rubber product;

- belonging to a class;

- bore diameter (mm);

- climatic version - HL (cold climate) and T (tropical);

- GOST number, according to the requirements of which the hose is manufactured.

Thus, oxygen hoses GOST 9356-75 class II with a diameter of 16 mm, designed to supply gasoline under pressure up to 0.63 MPa and intended for use in cold areas, will be designated as follows: “Hose II 16-0.63-HL GOST 9356- 75".

Design features

Welding hose structure

The oxygen hose has a multi-layer design. The inner and outer layers are made of elastic rubber. The intermediate one performs a reinforcing function and can be made from either cotton fibers or synthetic fibers.

The basis of the rubber layer is natural or synthetic rubber with modifiers that change its physical and chemical characteristics depending on the operating environment.

The outer rubber layer of the welding sleeve can be modified to provide resistance to abrasion, ultraviolet radiation and heat.

To visually distinguish products for different purposes, the outer rubber layer can be painted in different colors:

- red - class I oxygen hoses;

- yellow - for rubber products of class II;

- blue - for class III hoses.

According to GOST 9356-75, it is allowed not to paint the outer rubber layer. In such cases, the hoses are black, but colored stripes are applied along the entire length of the product, which correspond to the class.

Gas welding hoses are flexible products. Provided that the minimum bending radius is observed, the deformation of the internal section should not exceed 10% of the nominal values.

Quality control

Oxygen hoses are produced and subject to acceptance by technical control departments in batches. Each contains hoses of the same class and size with a total length of no more than 2000 m.

In appearance, rubber products are accepted visually; optical control devices do not need to be used. The main criteria by which the quality of hoses is determined:

- internal rubber layer - bubbles, porosity, cracks and folds are not allowed on its surface;

- outer layer - bubbles are not allowed on its surface, as well as peeling from the load-bearing frame or its bare zones.

To visually control the quality of an oxygen hose, a method is used to compare actual products with control samples.

In addition to acceptance by appearance (design, color, size), the welding hose is subjected to tests for tightness under hydrostatic pressure, tensile strength from hydraulic pressure, tests for resistance to gasoline (rubber products of class II), as well as tests for the bond strength of the rubber layer with textile reinforcement.

Transportation and storage

Gas welding sleeve (hose) in packaged form

To transport oxygen welding hoses, the products are tied into coils (in three or four places) and covered with plastic film. Transportation is possible using all types of covered transport, subject to compliance with the delivery rules in force for each of them. Each package contains markings indicating the designation of the products and the total footage.

According to GOST 9356-75, storage of gas welding hoses is allowed in closed warehouses at temperatures from –20 to +25 °C. Products can be stored in coils with a maximum height of 1.5 m or in a straightened form at a distance from heat and ozone-emitting equipment.

In addition, it is necessary to protect rubber products from sunlight or exposure to light from artificial sources that can emit ultraviolet radiation.

Contact with substances that are aggressive to rubber or thread frames - gasoline, kerosene, alkalis, acids, etc. is not allowed.

When storing oxygen hoses at subzero temperatures, the products must be kept at room temperature for at least 1 day before installation. Warming up cannot be accelerated by increasing the temperature.

Manufacturer's Warranty

Subject to compliance with transportation and storage requirements, the manufacturer establishes the following guarantees:

- The shelf life of the gas welding hose is two years from the date of manufacture;

- The service life of the gas welding hose (subject to the conditions of correct installation and subject to intended use) is one year within the warranty period for storage.

The manufacturing plant guarantees full compliance of gas welding hoses with the requirements of State Standard 9356-75.