Shaped products made of cast iron and steel are widely used in the process of pipe installation. Without these elements, it is unlikely that it will be possible to design any sewerage or water supply system. It should be noted that the range of styles is so wide that almost any configuration can be made from pipes.

Today there are companies that provide customers with all the necessary shaped products. To get acquainted with the assortment, just visit several specialized stores and pay attention to product catalogs.

What materials are suitable for production

Any shaped parts of the pipeline are made of steel (ductile iron is also often used). Much depends on what specific pipes are used - made from the first or the last material. It’s simple: if it’s made of steel, then the shaped products must be steel.

As practice shows, cast iron fittings are made mainly with sockets, which is why it is believed that this is the most popular type of connecting pipes to each other. Although flanged cast iron products also exist. If we talk about shaped steel parts, they can only be flanged.

Purpose and device

The main purpose of shut-off valves is to reliably isolate a section of a pipeline or other pipelines and devices associated with it from the flow of the medium transported through them, thereby ensuring the safety of the planned work. In addition to shutting off (cutting off) the medium circulating in the system, the valves have other purposes. With its help you can regulate, distribute, mix and remove the used medium.

In accordance with the design of the pipe, the type and parameters of the medium flow, the necessary shut-off, control and discharge devices are selected. For example, they must correspond to the pressure in the system, the type and temperature of the medium, the design features of the pipelines (diameter, type of connections) and meet all safety requirements. Depending on their purpose, locking devices are divided into several groups.

- General purpose. It is used on water and steam pipelines, in gas lines of city networks and heating systems.

- Special purpose. Used at high pressure, as well as in cases of low or high temperatures, toxicity, viscosity, corrosivity, radioactivity and abrasiveness of the transported substances.

- Target reinforcement. Intended for individual cases provided for by technical regulations.

- Plumbing. Small diameter fittings for household devices.

- Ship's. It is equipped with sea and river vessels and is manufactured taking into account specific operating conditions.

- Unique. Manufactured to special orders for industrial and experimental installations.

The following types of locking devices are available:

- valves with cast iron and steel bodies;

- shut-off or shut-off and control valves;

- cranes of various types and devices;

- butterfly valves;

- control valves;

- safety and protective products.

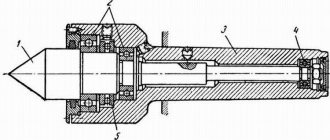

All of the locking devices listed are similar in design. They are a hermetically sealed housing with a locking unit located in it. This unit must hermetically seal the pipeline on which it is installed, dividing it into parts - sections before the valve along the flow of the medium and after it. The locking assembly includes two main working elements: the seat and the locking mechanism. These two devices, when their sealing surfaces come into contact, create an obstacle to the movement of the medium used in the pipeline. In addition to the shut-off part, the fittings have parts for connecting to the pipeline: flanges, threaded pipes, smooth pipes for welded joints.

What do modern companies offer?

As a rule, any company with a good reputation has in its arsenal a production department where shaped products are made. To obtain a mold from cast iron, material of the VChShG brand (high strength, with admixtures of spherical graphite) is used. The parameters of products made from such raw materials are so good that the products can be used for a very long time - at least fifty years.

The top of the shaped parts is coated with different compounds. If the products are made of steel, then on the outside they are treated with a layer of primer, and enamel is used, which is resistant to corrosion. The surface is not treated from the inside - this is prohibited by SNiP in order to avoid a negative impact on the quality of water that the population needs. If we consider cast iron products, then everything is different - from the inside they are treated with a cement-sand composition, from the outside - with zinc paint or paint coating.

It should be noted that the dimensions of the sockets and flanges of shaped products fully comply not only with GOST 5525-88, but also with ISO 2531. Thanks to this, the products can be used even for installation work where pipes from foreign manufacturers are involved.

Chimney options

Smoke and ventilation industrial pipes are divided into the following categories:

- metal column;

- self-supporting made of metal;

- façade;

- on stretch marks;

- truss

Industrial chimney pipes are designed individually, although they all have the same function, but the location in a particular production imposes certain features. The chimney pipe design project is carried out only by professionals, observing the following factors:

- gases must pass along the entire height of the structure and be discharged into the atmosphere along a smooth surface;

- the features of the equipment dictate the calculation and diameter of industrial pipes so that “gravity” is created in them;

- the concentration and dispersion of emissions must be within acceptable limits.

Chimney pipes are subject to special requirements not only during production, but also during installation.

Classification of fittings

We have figured out what shaped products are, now we should talk about internal classification - it is found in every type of product. That is, the common name “tee” combines several types of fashion, “release” - two, “transition” - four.

Let's look at the main groups - it all depends on the purpose of the connecting parts:

- Bends, elbows, corners.

- Manifolds and tees.

- Transitions.

- Plugs.

- Flanges.

- Cast iron couplings.

- Other elements.

Process pipelines

Industrial process pipelines include pipelines located on the territory of an industrial facility, as well as those on the balance sheet of an institution that are intended for pumping water, steam, various raw materials, chemical reagents, fuel, semi-finished products, production waste and other materials (a similar definition can be found in GOST 32569 -2013).

Pipelines are also classified depending on their location: inter-shop, intra-shop, piping - necessary for the operation of a separate unit (compressor, pump, tank piping, etc.)

Classification according to the danger of the transported environment

Depending on the classification of the transported substance, process pipelines are grouped into three main groups (A, B, C) and five categories (I, II, III, IV, V). Table 1, according to GOST 32569-2013.

Categories divide substances according to parameters such as temperature and pressure.

- The group is determined based on the hazard class of harmful substances according to GOST 12.1.005-88 and GOST 12.1.007-76 when determining the degree of fire and explosion hazard, one should be guided by GOST 12.1.044-89 (ISO 4589-84).

- The category is selected based on the parameters of the transported medium (pressure and temperature).

An example of a pipeline designation: “Pipeline IV group B (c)” means that the pipeline transports a substance of group “B”, subgroup “c” and the parameters of category IV.

Industrial hot water and steam pipelines

This type of pipeline refers to energy pipelines, designed to move hot water, saturated steam and superheated steam.

This type of industrial pipelines includes pipes with working environment parameters at temperatures above 115°C and excess pressures (working) of more than 0.7 kgf/cm2 (0.07 MPa).

According to the rules (NP-045-03), steam and hot water pipelines, depending on operating temperature and pressure, are divided into categories and groups, which are shown in Table 2.

Fasonina: etymology

In general, connecting parts have many different names. It is worth noting several phrases that refer to the same product.

- Shaped products for installation (it is assumed that we are talking about the components from which, for example, a water supply system is made).

- Fitting - this concept comes from the English language and can be translated as “fastening, installation, installation.”

- Fashion is the most laconic and capacious designation for the range of products that are in demand during pipeline installation.

The term “cast iron” also exists - this word is used to refer to connecting elements made of cast iron, but the concept cannot be called completely correct. This has long been the name given to decorative decorations for fences and gates, as well as castings for Russian stoves. Shaped elements are not cast entirely from cast iron, since their surface is quite complex.

How to choose fittings for polypropylene pipes for soldering

To correctly select polypropylene fittings, you must follow the following rules. If you plan to hide a polypropylene pipe in concrete after installation, then you must take into account that stray currents destroy metal connections within 15–20 years. Therefore, in areas of contact with concrete, it is necessary to choose solder fittings.

When installing your own water supply system, choose fittings for soldering. The cost of a soldering iron and fittings is small, so buy plenty of fittings and practice before installation.

Polypropylene fittings are available in the following sizes: 20, 25, 32, 40, 50, 63, 75 and 90 mm. The connection is made according to the socket principle - when soldering, the pipe is inserted into the fitting.

By the diameter of the pipe you can determine where it will be installed. In buildings where there are a large number of people, polypropylene pipes with a diameter of 200 mm are used. It is better to purchase such pipes in bulk, as this will save your money.

How to choose fittings for polypropylene pipes in individual construction? Polypropylene pipes and fittings with a diameter of up to 30 mm are often used here. But when choosing, it is worth remembering that each heating branch performs certain functions, and the material must be selected in accordance with them. Buy polypropylene pipes in specialized stores and be sure to consult with sellers.

For use in hot water supply systems, polypropylene pipes and fittings with a diameter of 20 mm are usually chosen. Pipes with a diameter of 25 mm are suitable for risers. This diameter is also used in central heating. In autonomous systems, you can choose pipes of a different diameter. In the photo you can see polypropylene pipes, which are in greatest demand. For heated floors, polypropylene pipes with a diameter of 16 mm are preferred.

The fitting is connected to a polypropylene pipe only after the walls of the contacting parts have been heated and melted. It is impossible to connect a cold pipe and fitting due to insufficient clearance. If you still manage to connect the parts in a cold state, then this indicates their poor quality. Such parts will not be able to guarantee the reliability and tightness of the connection.

The material from which the fittings are made is the same as that used for other pipeline elements. The characteristics of such products are determined by its brand. The method of manufacturing polypropylene products divides them into:

- Cast - products that do not have joints (solid).

- Segmental - elements created by soldering sections of polypropylene pipes. Due to the large number of seams, they are less reliable and their cost is lower.

Polypropylene is installed using a low-temperature soldering iron. A special nozzle melts the polypropylene pipe and fitting at the junction. After cooling, such a connection is strong and airtight.

When soldering, you should adhere to the following recommendations:

- soldering iron temperature – no higher than +260 °C;

- For an even connection, the movement of the elements at the moment of connection must be carried out along one axis.

To connect pipes with fittings, you need a soldering iron and nozzles in accordance with the diameter of the products being connected.

The sequence of operations is as follows:

- We cut the polypropylene pipe with special scissors (pipe cutter) strictly at a right angle.

- Using a file, remove burrs from the cut area.

- We heat the soldering iron to a temperature of +250…+260 °C, and insert the pipe and fitting onto the heated nozzles.

- Keep it in this position for some time (depending on the diameter of the fitting and pipe).

- After this, we remove the elements from the nozzles and connect them by inserting the pipe into the fitting until it stops.

- We fix the connection for the time specified in the table. We do not allow movement along the axis of the product. Cool at room temperature and use a rag to remove the plastic buildup.

Read material on the topic: Wholesale of polypropylene pipes

Read also

- Production of sandwich panels - details about the service.

- What are the dimensions of sandwich panels - plan the size of your building.

- What you will need for installation of sandwich panels - select self-tapping screws for installation.

- How to bring sandwich panels correctly - details on the rules for transporting sandwich panels.

- Current prices for sandwich panels - + price list in PDF.