by Alexey | Tools | Wednesday, December 15, 2021

| Follow Make-Self.net on Facebook and be the first to read our articles. |

A router is a very useful tool in woodworking. It can be used for shaping wood, drilling various holes, cutting grooves, finishing edges and much more. It's hard to imagine any complex project without it.

A router table may be the most important tool a carpenter can use.

Most people use routers as portable tools. While this is a viable option, a table-mounted router is safer to use and can perform its functions on a whole different level. If you're looking to build your own router table yourself, you've come to the right place. We've rounded up 13 of the best DIY table designs.

Folding milling table

This briefcase-sized design transforms into a fully functional router in minutes and folds up for storage just as quickly.

A full-size router table can be a great solution—if you have the space. But if you only use the router occasionally or need a mobile solution, this might be a good solution. This benchtop tool provides all the precision and stability you'd expect from a full-size router table.

What material

The milling table drawings should definitely help you make a comfortable and strong structure. But the material from which the tabletop is made will correspond to the service life of the surface and the quality of the cuts made on the profile.

There are 3 options that allow you to choose the material to suit your taste, but they will differ in their physical and operational characteristics.

Note!

Do-it-yourself electric scooter - a master class with step-by-step instructions for doing it yourself. Tips and simple patterns for beginners + the best photo reviews

DIY rocking chair: TOP-120 photos of the best manufacturing options. Master class on creating a rocking chair at home

Smokehouse from a gas cylinder - the best master class on making a homemade smokehouse with step-by-step photo diagrams for beginners

Now there are several types of tables that are suitable for milling wood:

- Plywood;

- metal;

- combined.

It is strictly prohibited to create a durable canvas by connecting ordinary wooden blocks together. During the finishing process, the workpiece will sway from side to side, which will affect the quality of the cut contours.

The first option is perfect for those who do not want to spend a lot of money on creation. You just need to buy special plywood, which is joined together with strong polymer compounds. It is not used in the production of sofas, because there is a strong emission of formaldehyde, but it is perfect for a carpentry workshop.

The metal frame and blade are more reliable, but to obtain the necessary parts they need to be sharpened using a lathe. If it is not there, then you will have to contact specialized companies.

Spacious milling table on wheels

If you're a fan of Ana White, then you know that she has everything you could ever want to build.

It's no surprise that she has a great plan for helping you build a great router table. It has ample storage and work space. I hope you enjoy it as much as we do.

Other characteristics

The number of revolutions of the cutter is of great importance - the higher the speed, the cleaner the processing. Models of high-quality and reliable brands develop 25,000-28,000 rpm. There are models whose specifications indicate 30,000 - 33,000 rpm. You should not choose a router based on this indicator alone for the following reasons:

- revolutions over 20,000 rpm are sufficient for high-quality processing;

- winning in speed, the model loses in power due to the gear ratio (analogous to 4 and 5 gears in a car gearbox);

- extremely high speeds quickly wear out the bearings and gears of the mechanism. At the slightest imbalance in the weight of rotating parts, vibrations occur;

- the indicated record turnovers may simply be a marketing ploy to increase sales.

Optimal performance is from 20,000 to 28,000 rpm, for edge trimmers - 30,000 - 33,000 rpm.

We are talking about maximum speed. During operation, the speed can be significantly lower, as indicated in the characteristics. For example, from 11,000 rpm to 28,000 rpm.

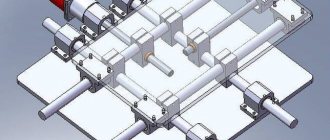

Professional milling table at half the price

This table includes all the best features found in store bought router tables at half the price! We have had the opportunity to study and use most of the router tables available on the market. Based on this experience, we developed our own fully functional and easy to assemble desk. The detailed project can be viewed here.

Makita RP2301FCX

Frame

The power unit of this router is enclosed in a vertical housing made of industrial plastic. The unit weighs 6.1 kg, which is not a hindrance for stationary installation and reduces vibration in mobile mode. Convenience of work is facilitated by a transparent protective shield, spot LED lighting and a flexible standard cable 4 meters long.

Engine

The tool's motor consumes 2.1 kW of electricity, which is sufficient for processing any hardwood, most plastics and a number of soft alloys based on copper or aluminum.

It is equipped with a brake and an electronic soft start system that maintains the selected speed regardless of the resistance of the material. When the brushes wear out, they can be replaced without resorting to service. The spindle is securely fixed while the cutter is installed.

Controls and support sole

This model is equipped with a wheel installed in the body for setting one of six speeds in the range from 9000 to 22000 rpm with final adjustment using a button on the control handle. The cutter stroke is 70 mm, and you can simultaneously set up to three points of the required immersion. The maximum deviations in milling accuracy do not exceed 0.1 mm, which satisfies the requirements of most carpentry work.

Pros of Makita RP2301FCX

- High performance.

- Milling precision.

- Long lasting resource.

- Reliable electronics.

- Professional ergonomics.

Cons of Makita RP2301FCX

- The parallel fence develops play over time.

- It is inconvenient to use the adapter sleeve for an 8 mm shank.

Wall cabinet for router

This compact storage cabinet does double duty as a top-notch router table while also holding all your accessories.

With plenty of storage and a built-in desk, this cabinet allows you to knock two important items off your list. And here's what's interesting: it takes up very little space. The secret to its compactness is that it folds out when you need it and retracts when you're done.

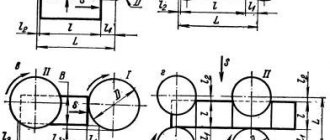

How to make a mounting plate

The mounting plate should be wider than the torch diameter if you plan to work with multiple cutting attachments. It is more profitable or cheaper to form this element from 20 mm birch plywood.

But it is more practical to work on a homemade machine with cast polycarbonate as a mounting plate. The essence of the work is this:

- Remove the base from the power tool, making sure to place the mounting plate side up.

- Temporarily connect the plate and sole with double-sided tape.

- Drills are selected to match the diameter of the factory fasteners, and the correct holes for fastening are drilled in the plate.

- Then they connect the home plate with the router and place it on the table for adjustment.

- An 8mm drill is inserted into the caliper and the engine is lowered. It is necessary to tap the plate with a drill and mark the center.

- Then, according to the markings, a hole of the required diameter is made.

Milling small parts

Several router table accessories make it easy to achieve safe and accurate results.

The problem with small workpieces is that there are large holes in the tabletop, and the stops can cause small parts to get stuck. This can ruin the project and be unsafe. This router table attachment holds small parts and allows the workpiece to be pushed past the router bit for precise and safe cutting.

Follow us on Pinterest for more interesting articles.

Useful short videos from Make-Self.net

Making a countertop

If you watch a video on creating a milling machine, the first step is to take a piece of plywood and mark on it the dimensions that fit the shape of the table. It is recommended to mark a minimum of 80x80 cm.

If you make a small table, the wooden elements will constantly fall. Then you need to hold the ruler with your left hand, and cut off the excess part with your right hand.

The second step is to take a pencil and make a mark where the hole for the cutter will be located. Most recommend making the hole one-third the width from the longitudinal edge. Then drill a hole using a crown of the same diameter.

The third step is to attach the tool to the hole and trace its base with a pencil. You need to make sure that the router does not wobble to the side.

There will be another 3 steps allocated to the seat. To create it, you need to use a router to make a cutout 5 mm deep according to the dimensions drawn in pencil.

Be sure to check the fit so that the machine does not wobble. Later, repeat the manipulation only on another piece of plywood, only with a difference of 15-20 cm from the base of the router. When you have 2 holes on your hands, you need to connect them together, place them on the table, then insert the router into them.

The seventh step is to make small grooves so that the fonts can be placed in them, keeping the router in balance. The eighth step is to connect the elements and check that they are securely fastened. After adjustment, tighten with self-tapping screws using a drill. The last step is to take 2 pieces of plywood and place them at the level of the font so that the router stands securely.