The invention of the sword had a huge impact on our civilization. A sword is not just a piercing weapon, it is a symbol of the Middle Ages, a sign of status and a symbol of honor. Swords were given proper names, they were known by their characteristics, and it was believed that a sword could have its own character. The life of the blade was long and difficult, as was its manufacture.

We must understand that at all times the sword was not just a weapon, it was a sign of a professional warrior-knight, the elite of the army. Mastering a sword required long periods of practice and the strength of the owner's hand. The sword itself was practically a work of art. Its production took a lot of time and resources. And the craftsmen who made such blades have always been valued at their weight in gold, or even more. It is worth noting that in those days it was impossible to control the temperature and maintain the hardening time, everything was done by eye and touch, however, ancient swords still surprise us today with the quality of their metal, thanks to the incredible skill of the blacksmith.

Evolution of the sword

Legends speak of the widespread use of swords by warriors of antiquity and the Middle Ages. But in reality everything was different. The main material for the manufacture of weapons then was copper and its alloys, such as bronze. Despite its low hardness, bronze was widely used to make weapons.

The next step in metallurgy was the use of iron, its forging and the production of low-carbon steels based on it. The main weapons of the infantryman were the sword, spear and ax.

Short swords made of soft iron became widespread already in ancient times.

Roman maniples and Greek hoplites went into battle armed with short one-handed swords. The quality of the metal of these swords left much to be desired, but they were mass produced and the legionnaires' gladiuses were not required to cut through iron armor.

But metallurgy improved, and new methods of iron processing and steel smelting gradually appeared. In the IV-III century BC. Forge welding technology appeared, then still copper, but later it began to be used for welding strips of low-carbon steel.

Already in the 12th-9th centuries, craftsmen learned to weld strips of metal into one strip, and then subjecting its edges to thermochemical treatment to obtain sword blades.

There were no high-quality iron deposits on the territory of Rus', so Russian craftsmen used high-quality metal purchased in Sweden. Well, or they repeatedly forged the metal obtained from the swamp ore, even from it the Slavic blacksmiths made magnificent steel products.

Characteristics

| LEVEL | BASE ATK | ENERGY RESTORATION |

| 20 | 109 | 17,7% |

| 40 | 205 | 25,8% |

| 50 | 266 | 29,8% |

| 60 | 327 | 33,8% |

| 70 | 388 | 37,9% |

| 80 | 449 | 41,9% |

| 90 | 510 | 45,9% |

Viking swords

The famous Vikings are known to come from Scandinavia. And, in modern terms, these were highly armed and trained small units of the Marine Corps that caused terror throughout Europe. From their campaigns they brought with them looted treasures.

The area of modern Norway, Sweden, Iceland and Denmark, as the main places of their settlement, had a fairly harsh climate. Which accordingly left its mark on the formation of a power and hierarchical structure among the Vikings.

At the head of the tribe or clan was a military leader, possessing the “right of the strong.”

Subordinate to him were separate clans, which in turn were united into clans. The head of the tribe had a military squad and ships - drakkars - under his command.

The economy developed only through the extraction and sale of iron ore and products made from it, as well as meager hunting and fishing, since farming in those parts was quite inconvenient and dangerous, from the point of view of crop failure. The main path of economic development was trade, piracy and raids on the coastal cities of other peoples for the purpose of robbery.

Due to the clan way of life, metal mining, weapon production, and even individual technological operations for its decoration were in the hands of several separate clans or clans. This is how the Ulfberht family is known, one of the famous blacksmith families of the Franks and Danes.

The armament of the squads of the Scandinavian kings did not stand out in any way compared to the weapons of the Frankish or ancient German troops. Usually for the senior warrior it was a sword, shield and armor; for ordinary warriors, axes and shields made of wood with stuffed umbons and a metal edge of the shield.

The Scandinavian sword originates from the Frankish straight sword, also called Carolingian.

This is a long, straight, double-edged blade with a cross. The handle was round or oval in cross-section and fitted onto the shank of the blade. An apple pommel was placed on top of the handle.

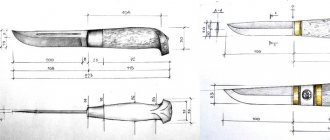

Swords created by Scandinavian blacksmiths are designed for slashing. Length, usually 70...90 cm. Thickness - 4..4.2 mm. Width - 5...6 cm. The end, as a rule, is blunt or even rounded. The thing is that it is inconvenient to thrust with a sword. According to Oshcott's classification, these swords are a subtype of the European "Carolingian swords".

Swords were worn as convenient for the warrior, usually on the hip. But contrary to the films, carrying swords on your back is not very convenient and, moreover, extremely dangerous; it will not be possible to quickly remove it if necessary. For this reason, it is a purely cinematic technique.

The blade was made using layer-by-layer forging, alternating soft and hard iron, thereby achieving high ductility and elasticity of the blade.

Later, Scandinavian blacksmiths also mastered the method of layer-by-layer forging, making swords using a method similar to Damascus steel, but unlike the East, this tradition did not take root among the Scandinavians.

First of all, this is due to the presence of iron ore deposits, from which high-quality steel was produced, which is valued to this day; the second factor was time. Making an expensive sword could take up to six months; the Vikings did not have that kind of time; raids had to be carried out much more often.

For this reason, Carolingian Viking style swords are more likely to be weapons for a senior warrior or chieftain. In the Scandinavian squad, axes and hammers were considered more convenient, due to their fighting style.

Making a wooden shield

Based on the preferences of Scandinavians and modern materials, the simplest thing is to make a board from plywood 6 mm thick. Using the markings, cut out a circle of the diameter you need. Cut a hole in the center for the fist. Using a wood knife or paint, you can imitate boards. For durability and a better look, coat the shield with stain.

Depending on the size of your hand, make a metal umbon to cover the hole. The shield handle is attached to two strips, which are attached to the entire diameter of the product. The handle is made of oak, birch or ash. They are fastened with nails, and the protruding parts are removed with pliers and riveted.

At the next stage, the shield is glued with leather or burlap. After this, the umbon is mounted. The shield is framed either with metal or leather. The metal is from 1 to 1.5 mm thick, and the leather when forging should be thicker, from 5 mm.

For ease of wearing, you need to make a leather strap. This addition will allow you to carry the shield on your shoulder or throw it over your back over your head.

The final stage - decoration - is left to your discretion. The shield was often depicted with a coat of arms, a unit sign, or simply a drawing aimed at intimidating the enemy.

Metallurgy in Japanese

Iron came to Japan later, but despite this, Japanese swords are known for their deadly characteristics. The “master of swords” in Japan in class society was on the same level as the samurai. His skill gave him this right.

Blacksmiths-gunsmiths - kaji, were outside the rank of artisans and were part of 80...120 blacksmith schools, their number changed at different times.

Iron ore was mined from river sand; smelting steel from such ore was a labor-intensive and time-consuming process. After smelting, the resulting steel was forged many times until a homogeneous dense mass was obtained. Strips of such material were combined by forge welding into a package and forged again.

It is necessary to distinguish the Japanese technology for producing a composite from layers of metal from the European technology for producing Damascus steel. If in Japan it was customary to weld layers of steel onto the base, then in the manufacture of Damascus a monolithic package was used, united by forge welding.

Making Japanese swords was a complex process. There were two main types of sword forging:

- itame - a repeatedly folded package of high-hard metal was welded onto a steel strip of mild steel, which formed the blade;

- masame - also a strip of soft steel was used as a base, but a rolled strip of hard metal was forge welded onto the blade area and a blade made of hagane - a very hard alloy - was welded onto it.

The blade itself had a wedge shape, which simplified its processing and repeated welding.

The production of a samurai sword differed in technology and quality from the products of European masters. Although it had some common features.

Determining optimal sizes and parts

Trying to make a weapon, even a wooden one, without knowing anything about it is the height of frivolity. The simplest straight Slavic sword consists of two parts - a hilt and a blade. The components of the hilt are the pommel, the handle and the guard, and the blade has a blade and a point.

When making a wooden copy of a sword, you may not take into account all the nuances that were known to the true masters of damask steel of yesteryear, but you need to know something to make the weapon as convenient as possible.

Before making a wooden sword, you should figure out which hand is the dominant one and this is not necessarily the one with which a person writes or cuts.

You can do a small test:

- Take a stick in your right hand, the length of which matches the length of your forearm.

- Transfer it to your left hand.

- Whichever one is more convenient to hold is the leading one.

After determining the leading hand, you should take the stick approximately in the same way as the sword will be held and freely lower it along the body. Then grab the stick so that its tip touches the ground: the distance from the end of the stick to the hand is the optimal length of the blade plus the thickness of the guard.

Based on these values, all other dimensions are calculated. For example, if the measurements result in a value of 102.5 cm, and you are going to make the guard 2.5 cm thick, then the length of the blade is 1 m, the length of the handle is taken as 1/10 of the length of the blade (that is, 10 cm). A slight inaccuracy in size does not matter.

European sword

Technologies for obtaining metal were constantly evolving, but initially the same technologies were used almost everywhere. In order to understand the essence of the sword, you will have to delve into the technology of its creation from the very beginning. From receiving ore.

From ore to iron

Iron was initially mined from swamps, from the so-called bog ore, but already at the beginning of the Middle Ages, mining from closed deposits began to be used.

The resulting ore was smelted into metal using the cheese-blowing method, which got its name due to the use of air at atmospheric temperature to support combustion.

The efficiency of metal production was extremely low. The resulting steel had an unstable structure, interspersed with slag. In order to bring it to an acceptable condition, repeated forging of the workpiece and its subsequent carburization were required.

Making swords in Rus' was a rather expensive and complex process precisely because of the swamp ore; almost all high-quality weapons were made from iron imported from Sweden.

It should be noted that steel is an alloy of iron and carbon. The more carbon in iron, the harder the metal, but at the same time, with a significant amount of carbon, the material becomes excessively brittle. When oversaturated, it turns into cast iron, which at that time was considered a useless material due to the impossibility of processing it by forging.

Smelting was carried out in a furnace into which iron ore mixed with charcoal was poured and burned for a certain time.

Air was supplied to the house by bellows. The process is quite slow and expensive, especially considering that the coal also required long-term burning from certain types of wood.

After the coal burned out, metal ingots called kritsy were taken out of the furnace. It was an alloy of slag, steel and cast iron. The kritsa was broken into smaller parts, the steel was separated, and then forged, removing voids and slag particles. After this, the blanks were sold to gunsmiths.

Forging a sword

After obtaining the iron, many more operations were required. The technology of forging military weapons from such ore is a delicate matter and requires experience, accuracy and skill. The blade was created in several stages:

- production of packages from metal of different hardness, repeated forging with forge welding;

- forge welding of packages to create a sword blade;

- shaping;

- thermochemical treatment of cutting surfaces;

- final hardening;

- blade polishing;

- sharpening and fitting of the handle.

Forge welding of metal packages of varying hardness was used to ensure that the sword blade had sufficient elasticity (soft core), strength (medium-hard side packages) and hardness (blade area).

Thermochemical treatment usually consisted of surface cementation; a hot workpiece was lowered into a vessel with finely ground coal and heated in it. At this time, the surface layers of the steel were saturated with carbon, which increased the hardness of the blade surface.

It should be noted that the surface cementation did not cover the depth and therefore, after a cycle of sharpening, the sword required repeating this procedure, since sharpening removed the cemented layer.

This is how the famous Carolingian swords were made; the production of Scandinavian swords was practically no different from this process.

The process of obtaining such products has now been mastered by blacksmithing enthusiasts, using independently created sketches and drawings of medieval weapons, but even now, using relatively modern technologies, it takes up to six months to create a high-quality sword.

How to forge a blade with your own hands?

Forging involves the formation of a metal product by striking a hot material, which, due to exposure to high temperature, becomes plastic and soft. To make a sword using the forging method, you will need:

- low-carbon steel (rod or strip);

- hammer;

- anvil and forge

If you start forging from a rod, then the first step is to forge it into a square or rectangle along its entire length. Then a strip is cut from this blank, the thickness of which corresponds to the thickness of the intended product plus excess, which will be removed during further processing.

You should try not to cool the metal too much, since the inevitable bending during forging is better to straighten before the next heating of the workpiece.

A distance is set back from the end of the strip that will be slightly less than the required length of the handle, taking into account that when this part is thinned, it will lengthen. Heat the workpiece until the metal glows red and break the shank. To do this, at the required distance on the edge of the anvil or on the backing tool, use the sharp end of a hammer to form a “step” - the shoulders of the blade body. The thinner part is called the shank. Pull the shank to a cone.

The body of the blade is given the desired contour. Slopes from the middle to the edges can be formed using sandpaper or forged by striking at a strictly defined angle from the edges to the center of the strip. The forger's elbow pressed to the body will help maintain a constant position of the hammer during forging. This way the blows will be delivered strictly vertically, and the inclination of the striker to the plane of the anvil will be controlled by fixing the hand in a certain position. The fullers on the blade are traditionally forged using a template.

Scale particles remaining on the metal make its surface uneven, covered with dents of varying depths. To remove scale during the forging process, the hammer and anvil are periodically moistened with water.

After the final finishing of the blade, it is annealed to eliminate internal stresses: it is heated to red and left to cool in the forge. Then start hardening:

- The blade is heated to a barely noticeable red glow as evenly and slowly as possible. The air flow from the blast should not hit the product. At the quenching temperature, it is kept for some time, which is calculated by a coefficient of 0.2 from the heating time.

- To quickly cool a heated blade, you need a large volume of cold water. It is completely immersed in the container vertically or at an angle.

- The blade section is cleaned to a shine and the blade is again placed in the forge for tempering after hardening. Heating is carried out until the cleaned area acquires a golden color. The sword is cooled in air.

Steel named after the bazaar in Damascus and damask steel, and their differences

Damascus steel, despite its name, is in no way connected with the city; it received its name in the Middle Ages because of the large arms bazaar located there. And it appeared in antiquity.

A Damascus steel blade is a blade made from several packages of steel with different carbon content.

The most famous is the so-called “charal” steel. In this case, the blacksmith welded several rods of metal with different carbon contents into one package, after which he twisted it into a braid and forged it into a bar; several such bars were also welded, twisted and forged.

With successful selection of temperatures, a flexible and hard blade was obtained.

After forging, the blade was hardened and sharpened. A characteristic ordered pattern on its surface was etched.

The second option for making Damascus was to repeatedly forge a package of steel plates, constantly folding and bending it. The result was a “puff pastry” of more than a hundred microlayers of material of varying hardness and viscosity.

But this option also took a huge amount of time. For such forging, it was necessary to use the labor of hammerers, since a blacksmith alone would clearly not have been able to cope with such work.

This produced a magnificent weapon; legends christened it after the eastern city of Damascus, but in fact, haraluzh blades appeared in Europe at the beginning of the Middle Ages, as evidenced by numerous archaeological finds. So bastards, that is, one-handed European swords made of Damascus steel, appeared earlier than kiliches and shamshirs from the East.

Damascus steel differed from the composite blades of Japanese and European masters. But, despite the excellent characteristics, the manufacture of such swords was too labor-intensive. They did not gain much popularity, but they became legendary.

It should be noted that the qualities of Damascus blades are greatly exaggerated. The blade could not cut through plate armor on its own or cut through a pillow; these were all inventions of novelists of the 18th and 19th centuries. Damascus blades were distinguished only by increased strength, sharpening sharpness and increased cutting properties, due to the multi-layer structure of the blade.

At the end of the 19th century, Damascus steel and damask steel were obtained by the Russian metallurgist Anosov. But if damask blades were mass-produced at the Zlatoust plant, the production of Damascus steel was considered economically unprofitable due to its complexity.

Bulat, unlike Damascus, is a cast metal, and not produced by forge welding.

It just came to Europe from the East, under the name wootz it was made in India, in Afghanistan and Iran it is also known under the name horoshan. Externally, it is relatively simple to distinguish Damascus steel from damask steel. Damask steel has a chaotic, disorderly pattern, while on damascus obtained by forging the pattern is more stable and orderly.

Damascus steel was produced from high-carbon steel, almost cast iron, by adding particles of low-carbon metal to it during melting; not completely melted particles of a low-carbon structure gave the damask steel its characteristic patterns.

In general, the ancient masters knew not only this secret, there were many options for smelting, but the main one and the easiest to master was still this one.

Like damascus, damask steel did not have supernatural powers. High-strength blade steel, good toughness and hardness - this is a damask steel blade. But compared to contemporary composite swords, often made with technological violations, damask steel had excellent characteristics.

With the end of the Middle Ages, which included wars and the invasion of the Tatars, the secret of obtaining damascus and damask steel was lost. It was restored in 1881 by the Russian metallurgist Anosov.

Reenactors

The movement of role-players and re-enactors is popular in our world. Some use plots from fantasy books for their games, others reconstruct battles from our history. If the former can get away with not playing a very active role and not participating in mass battles, then the latter are better off having fencing skills, good physical fitness and dexterity, and also being able to fight in formation.

It’s always easier to buy a sword in a special workshop; it’s not difficult to find one among roleplayers, but if you decide to make a wooden sword with your own hands, then be patient.

Guards (crosspieces, also called “armchair”)

Sword guards

Sword guard - this element of the sword hilt is designed to protect the hand during fencing, from blows from the enemy’s sword blade. Different countries and peoples have created guards of different shapes. In addition, the guard performs the function of balancing the sword.

Shank

may or may not be present on the guard. It is believed that the presence of a tang on the sword allows the blade to better absorb impact energy and thereby protect the blade from vibration and loosening in the hilt.

2) Let's take a closer look at the individual parts of the blade:

Indian subcontinent

The region of India and adjacent areas is rich in various types of swords. The best steel blades in the world with luxurious decorations were made in India. In some cases, it is difficult to give the correct name to some samples of blades, to determine the time and place of their manufacture, so a thorough study of them is still ahead. Dates shown apply to examples shown only.

- Chora (Khyber), a heavy single-edged sword of the Afghan and Pashtun tribes. Afghanistan-Pakistan borderland.

- Tulwar (talwar). Sword with a curved blade and a hilt with a disc-shaped pommel, India. This specimen was discovered in Northern India, 17th century.

- Tulwar (talwar) with a wide blade. Was the executioner's weapon. This specimen originates from Northern India, XVIII-XIX centuries.

- Tulwar (talwar).Punjabi style steel handle with safety bail. Indore, India. End of the 18th century

- Khanda, steel handle with gilding in the “Old Indian” style. Double-edged straight blade. Nepal. XVIII century

- Khanda. The handle is made in the style of “Indian basket” with an appendage for gripping with both hands. Marathi people. XVIII century

- Sucker pattah. The handle is made in the Indian basket style. Forward curved reinforced blade with one blade. Central India. XVIII century

- South Indian sword. Steel handle, square wooden pommel. The blade is curved forward. Madras. XVI century

- Sword from the temple of the Nayar people. Brass handle, double-edged steel blade. Thanjavur, South India. XVIII century

- South Indian sword. Steel handle, double-edged wavy blade. Madras. XVIII century

- Pata. An Indian sword with a gauntlet - a steel guard that protected the hand up to the forearm. Decorated with engraving and gilding. Oudh (now Uttar Pradesh). XVIII century

- Adyar katti is of typical shape. A short, heavy blade curved forward. The handle is made of silver. Coorg, South West India.

- Zafar Takeh, India. Attribute of a ruler at audiences. The top of the handle is made in the shape of an armrest.

- Firangi (“stranger”). This name was used by the Indians for European blades with Indian handles. Shown here is a Maratha sword with a 17th century German blade.

- A double-edged two-handed sword with hollow iron pommel. Central India. XVII century

- Bark. The blade is curved forward, has one blade with a “pulled” apex. Nepal. XVIII century

- Kukri. Long narrow blade. It was widespread in the 19th century. Nepal, around 1850

- Kukri. Iron handle, elegant blade. Nepal, approximately 19th century.

- Kukri. Was in service with the Indian Army in World War II. Manufactured by a contractor in North India. 1943

- Ram dao. A sword used for animal sacrifice in Nepal and Northern India.

What difficulties may arise during work?

The most difficult thing when making a sword yourself will be to correctly observe the heating temperatures, as well as to properly harden the blade. These processes are extremely important for obtaining sufficiently high-quality weapons. Overheating the metal will result in a very fragile product, and poorly hardened material will be too soft.

It should be remembered that the lower limit of ductility of low-carbon steels is in the temperature range of 800-850 degrees. Without instruments, you can determine the heating of the material in two ways:

- At a certain heating temperature, steel acquires the corresponding color. At 800-830 degrees - light red and light cherry tones;

- When steel is heated to temperatures of 768 degrees Celsius or more, it loses its magnetic properties. After cooling they are restored. You can check the presence or absence of these properties with a regular magnet.

Hardening is done when the metal becomes barely red. After this, you need to “release” (stabilize) the metal again. To do this, the blade is first cleaned and heated to a golden color, and cooling is carried out in the open air.

Far East

- Tao. Sword of the Kachin tribe, Assam. The example shown shows the most common blade shape of many known in this region.

- Dao (noklang). Two-handed sword, Khasi people, Assam. The hilt of the sword is iron, the trim is made of brass.

- Dha. Single-edged sword, Myanmar. The cylindrical hilt of the sword is covered with white metal. Blade inlay with silver and copper.

- Castanet. The sword has a carved wooden hilt and a steel safety guard. Decorated with silver and brass inlay. Sri Lanka.

- Single-edged Chinese iron sword. The handle is a blade stalk wrapped in cord.

- Talibon. Short sword of Filipino Christians. The hilt of the sword is made of wood and braided with reed.

- Barong. Short sword of the Moro people, Philippines.

- Mandau (parang ihlang). Sword of the Dayak headhunter tribe, Kalimantan.

- Parang pandit (pandat). Sword of the Sea Dayak tribe, Southeast Asia. The sword has a single-edged, forward-curved blade.

- Kampilan. Single-edged sword of the Moro and Sea Dayak tribes. The handle is made of wood and decorated with carvings.

- Klewang. Sword from Sula Vesi Island, Indonesia. The sword has a single-edged blade. The handle is made of wood and decorated with carvings.