Inverter welding at home is a universal tool for which practically nothing is impossible. You need to weld a wicket, gate, greenhouse frame or foundation piping - no problem. A compact, easy-to-use inverter will cope with all tasks. It can be used by both an experienced welder and a beginner in this matter.

To do this, it is enough to provide the equipment with a power supply of 220 Volts. It is good when a single-phase network is connected to the site. What to do when there is no electricity? How to perform work on a new building or in the field? A generator designed for welding equipment will help out.

Design and principle of operation

DC welding generators operate on the following principle: an internal combustion engine through a gearbox or directly transmits the energy of shaft rotation to an alternating or direct current electric generator.

It produces electricity that is fed to the input of a voltage conversion circuit. Models of such devices differ from each other in details, but have common design elements:

- frame on which other components and parts are attached;

- internal combustion engine , with fuel tank, ignition systems; preparing the fuel mixture and removing exhaust gases;

- gearbox that transmits torque to the shaft of the electric generator;

- AC or DC electric generator

- power supply unit , which converts the output voltage of the electric generator into welding current of the required voltage, strength and polarity;

- control system .

The low power engine is started manually using a starter cord. For powerful devices, an electric starter and battery are provided.

Is it possible to combine them in one device?

Such a merger is possible and profitable . If you have to use such a unit often or it must be constantly ready (like repairmen or rescuers), then both money and time are saved. Using a single design provides the following advantages:

- compactness, use of a single frame and control unit;

- ease of transportation and carrying;

- low energy losses and energy efficiency;

- high degree of device availability;

- saving time on connecting and adjusting individual devices.

Amangeldy Kurbanaliev, foreman of the repair team at Tatneft-Transservice: “Without a welding gas generator in a repair workshop it’s like being without hands. We arrived on site to fix the problem - no need to unwind the wires and connect the welding to the generator, saving both time and space.”

The most significant argument in favor is the price. A single unit will, in principle, cost less than two separate devices.

How is it different from usual?

The main difference lies in the specifics of the consumer. An ordinary, universal unit is designed for use under household load .

These consumers are switched on for a long time and consume constant power. The simplest generators supply voltage to the output directly from the windings of the electric generator or through a transformer. Welding has a different type of energy consumption. It is turned on by long or short pulses, and the welding generator produces a peak current. In the intervals between pulses there is practically no consumption. If you apply voltage to the welding machine directly from the windings, then

- a large power reserve will be required;

- during periods when welding is not carried out, there will be unproductive fuel consumption.

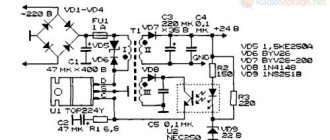

Therefore, modern welding electric generators are equipped with an inverter power supply. During double voltage conversion, its parameters are stabilized and adapted to the needs of the welding process. The control system of such a device is capable of controlling engine speed (and fuel consumption) depending on the load.

The best generators in an affordable price segment

To simplify as much as possible the task of choosing a generator with optimal characteristics for a specific inverter, below are descriptions of the four models most in demand among different categories of buyers for use in domestic conditions. This is in no way a review or rating of models. This is most likely a small list of installations that have been tested and shown to work well as household equipment.

Electric generator Huter DY6500L

A very good assistant for the amateur welder. A power of 5 kW is enough to connect a small inverter that generates a current of up to 150 Amps. The synchronous model runs on gasoline. For normal operation and safe long-term operation, it is recommended to fill with gasoline of at least grade AI-92. In addition to gasoline, the unit can also operate on propane. The filling tank capacity is 22 liters.

The Huter DY6500L starts with a manual starter. Forced air cooling of the engine is provided. If you need to move the generator, the effort of one person is not enough: its weight is 80 kg.

Petrol generator Brima LT 8000 B

To provide electricity to the inverter, it is recommended to purchase this model from a well-known German brand. Its rated power is slightly higher than that of the model discussed above, and is 6 kW. At peak loads it will be able to produce more - 6.5 kW. But do not forget that the generator can only be operated at maximum performance for a short period of time. The model is suitable for those welders who have a welding inverter in their household that produces up to 180 Amperes.

The fuel consumed is gasoline. Equipped with a 25 liter filling tank. The 190F's reliable four-stroke powerplant features forced air cooling. It starts with a starter and can operate continuously for up to 8 hours. After this, a short break is required to cool the case. Otherwise, overheating is inevitable.

The generator has standard dimensions for installations of this level. His weight is 83 kg. But moving it is not difficult at all, since the body is mounted on a wheelbase.

Gasoline generator Ergomax ER 5400

Low-power model with a performance of up to 4.5 kW. It will be the best option for those who have simple welding up to 140 Amps. For operation, gasoline of at least grade AI-92 is used. The better quality gasoline is poured into the tank, the longer the generator will operate without repairs. It is characterized by efficiency: it uses approximately 2 liters of gasoline per hour.

It starts with a kick starter, autostart is not provided. Among the advantages are compact sizes. This is the smallest generator of all those discussed here.

The dimensions of the installation are 82x54x58 cm, and the weight is 70 kg. It can be stored in an unheated room, well protected from moisture and dust.

Can it be used as usual?

Such use is quite acceptable if the device is equipped with a separate 220 volt output . Working for home consumers will not overload the unit, which is accustomed to possible peak loads.

Cheap models of welding generators can tolerate voltage surges, pulsed high-frequency interference, etc. They do not interfere with the welding process, but can damage sensitive household, media and medical equipment. Therefore, it is better to connect such a device through a voltage stabilizer with a built-in surge filter.

An inverter generator usually produces high-quality voltage without impulse noise.

What if I buy both devices separately?

This solution is justified if a generator is needed constantly for household or construction needs, and welding is only needed occasionally and in small volumes.

In this case, you can even save a little by purchasing a portable portable welding inverter. It is very important that the gas generator and welding machine match each other in terms of parameters . You cannot select devices based on their characteristics “back to back”; there must be a good margin (from 20%) in terms of power and operating current. Otherwise, the device will begin to work with overload and will quickly fail.

Important: Be sure to read the user manual carefully. If it states that the device is not intended for use with welding, it is better not to experiment.

If it is planned to connect other consumers in parallel with welding, then, accordingly, the power of the device must support them all.

How to choose generator power for a welding inverter

A prerequisite is the fact that the power of the electricity source must be 20-30% greater than that of the inverter. This is important not only for stable operation of the arc, but also for optimal use of the resources of the generating plant. It is undesirable to operate a source of electricity at the limit of its potential. That is why it is necessary to make a power reserve so that the equipment generates energy in a gentle mode. In this case, the welder will receive a stable arc, and the generator will last for a long time without problems.

For clarity, let's look at a simple example. Let's say there is an inverter that can generate current up to 180 Amps. In this case, taking into account the required power reserve of up to 30%, it is recommended to buy a 6-6.5 kW generator. Using this information as a source, you can independently determine the desired equipment performance.

Criterias of choice

To choose the right unit, you need to take into account a number of criteria. The most important of these is power.

Power. Differences in designation

To make the right choice, you must distinguish between the power of the internal combustion engine and the generated power of the generator. The mechanical energy of crankshaft rotation is converted into electrical energy with a certain coefficient of efficiency (efficiency). For modern devices it is close to 85%. The passport indicates both meanings.

Important! Some manufacturers designate power in kilowatts ( kW ), some in kilovolt-amperes (kVA).

These values depend on each other according to the formula 1 kW = 1 kVA * Km, where Km is the power factor, taken equal to 0.65 - 0.7.

The generated power must be sufficient to provide the specified welding current.

Fuel

Currently, most manufacturers have focused on two types of engines:

- gasoline;

- diesel

What type of fuel is better to choose? The choice depends on the availability of a particular type of fuel, as well as on what the existing engines of vehicles and construction equipment run on.

Gas engines are used much less frequently.

Engine

Gasoline engines are divided according to their type into

- two-stroke, running on a 5:1 mixture of gasoline and oil

- four-stroke, running on pure gasoline.

Two-stroke engines are simpler to design and handle, but are limited in power . Four-stroke engines are more complex in design and require more maintenance time, but have higher power and efficiency.

Versatility

Universal units have a separate 220V output for connecting lighting, construction electric tools or household equipment.

Generator

Modern devices more often use brushless alternators . They have smaller dimensions and higher efficiency. Both single-phase and 3-phase high-power devices are used. DC generators are more often found in past models and in homemade designs.

The best welding generators

Huter DY6500LXW

The gasoline generator is suitable for creating a backup power source and for use in welding equipment..

Equipped with a Huter 188F piston engine with 1 cylinder and 4 strokes, air cooling.

The control panel includes a voltmeter, control indicators, ignition switches, activation protection and 12 V terminals plus a ground terminal.

The unit is mounted on a steel frame, complemented by handles and wheels. Operation and maintenance are carried out without special operator skills.

Characteristics:

- voltage - 220 V;

- engine power - 15 l. With.;

- tank volume - 22 l;

- active power - 5 kW, max. — 5.5 kW;

- Max. welding current - 200A;

- noise level - 71 dB;

- sockets - 2 for 220 V, 1 for 12 V;

- dimensions - 70x57x53.5 cm;

- weight - 72 kg.

Advantages:

- stable power supply;

- welding function;

- overload protection;

- quick manual or electric start of the system;

- suitable for welding all types of metals;

- ability to connect 7 mm electrodes;

- quiet work.

Flaws:

- No.

Fubag WS 230 DC ES

Single-phase generator with Fubag GF 460 engine . Presented in the form of a gasoline power station with a built-in welding machine.

The user can carry out arc welding with electrodes with a diameter of 5 mm, and at the same time evaluate the high quality of the connection at the joint. The electric starter allows you to quickly start the unit, despite the surrounding weather.

The generator additionally has an on-board battery, built-in overload protection, and low oil level indicators.

You can use additional options - a DX50 grounding cable, an electrical holder with a DX50 cable.

Characteristics:

- engine capacity - 458 cubic meters. cm, power - 13.4 l. With.;

- tank volume - 25 l;

- active power - 5 kW;

- welding current - 50-230 A;

- sockets - 2 x 220 V;

- electrode diameter - from 1.6 to 5 mm;

- dimensions - 73x59x53.5 cm;

- weight - 94 kg.

Advantages:

- 9 hours of battery life;

- spacious fuel tank;

- easy to operate electric starter;

- high-quality welding seam;

- quiet operation;

- clear control panel;

- economical fuel consumption;

- versatility;

- durability.

Flaws:

- No.

Fubag WHS 210 DDC

Three-phase, gasoline, direct current (DC) welding generator, professional air-cooled Honda GX 390 engine.

Designed to perform complex tasks in the construction and installation field, in cases of emergency.

Allows the connection of rutile electrodes up to 5 mm, as well as a wide range of three-phase and single-phase users.

The unit is located on a reinforced frame, which protects it from various negative influences.

Characteristics:

- engine capacity - 389 cubic meters. cm, power - 13 l. With.;

- tank volume - 25 l;

- active power - 5 kW, total - 7 kW;

- current - 9.1 A, welding current - 50-210 A;

- sockets - 1 for 220 V, 1 for 380 V;

- dimensions - 73x59x53.5 cm;

- weight - 87 kg.

Advantages:

- battery life up to 9 hours;

- sufficient strength of direct welding current;

- intuitive display;

- economical OHV engine;

- bayonet connectors for quick connection of welding cables;

- socket protection;

- additional options in the form of a handle and wheels.

Flaws:

- No.

EUROPOWER EP200X2

Gasoline welding generator based on the Huter 188F engine with an air cooling system, manual and electric start type.

It is actively used in welding, construction and installation work in places with regular power outages.

Operates in two modes - power plant with synchronous alternator, welding with direct current.

You can connect various electrodes, but with a diameter of up to 4 mm. This is a single-phase model with several sockets for connecting equipment, instruments, and tools.

Characteristics:

- engine power - 15 l. With.;

- specific fuel consumption - 374 g/h;

- tank volume - 22 l;

- active power - 5 kW, max. — 5.5 kW;

- Max. current strength - 200 A;

- sockets - 2 for 220 V, 1 for 12 V;

- dimensions - 70x57x53.5 cm;

- weight - 72 kg.

Advantages:

- quick start in any weather;

- high level of reliability;

- suitable for welding any metals;

- smooth, neat welding seam;

- good protection of sockets and the unit itself;

- mobility;

- versatility.

Flaws:

- No.

Kronwerk LK 210E

Petrol model with synchronous alternator, electric and manual start . Designed to provide electricity to users, as well as to serve as full-fledged welding equipment.

The single-phase generator has several key features - protective function against overload and system overheating, AVR, DC, fuel and oil sensor.

The power plant is equipped with wheels to increase mobility and a muffler to reduce noise during operation.

Characteristics:

- engine capacity - 420 cubic meters. cm, power - 15 l. With.;

- fuel consumption - 2.6 l/h;

- tank volume - 25 l;

- protection class - IP23;

- active power - 4.5 kW, max. — 5 kW;

- sockets - 2 for 220 V, 1 for 12 V;

- dimensions - 70x58x54 cm;

- weight - 73 kg.

Advantages:

- functional;

- economical fuel consumption;

- spacious fuel tank;

- intuitive settings management;

- welding function;

- overload protection;

- smooth execution of the weld.

Flaws:

- No.

TSS SGW-4000 EH

Single-phase gasoline generator with built-in arc welding function . Designed for use in construction and other installation work.

The rated welding current is 190 A, which defines the unit as professional equipment.

Various electrodes with a diameter from 1.6 to 5 mm are used for welding.

In the role of a power plant, the model showed itself on the positive side: it allows you to connect single-phase users, solves problems with lack of electricity, and is equipped with a voltmeter for assessing operating parameters.

Characteristics:

- electric and manual start;

- fuel consumption - 2.4 l/h;

- tank volume - 25 l;

- active power - 4 kW;

- sockets - 1 for 220 V, 1 for 12 V;

- dimensions - 73x59x53 cm;

- weight - 82 kg.

Advantages:

- reliable four-stroke air-cooled engine;

- spacious fuel tank;

- economical fuel consumption;

- welding function;

- neat welding seam due to high-quality DC;

- durability;

- mobility;

- multifunctionality.

Flaws:

- No.

TCC DGW-200ES

This is a single-phase diesel welding generator in a noise-proof casing . Designed to perform manual arc welding, to create an autonomous source of electricity.

It features a powerful 188F series engine (1 cylinder, 4 strokes) with air cooling.

To perform welding, it is necessary to connect electrodes with a diameter from 1.6 to 4 mm . The power plant also has a built-in AVR system for automatic voltage control.

Starting occurs with an electric starter, while the injector instantly injects fuel into the system, facilitating starting.

Characteristics:

- engine capacity - 456 cubic meters. cm, power - 8.2 l. With.;

- fuel consumption - 1.9 l/h;

- tank volume - 12.5 l;

- active power - 3 kW, max. — 3.5 kW;

- welding current strength - 50-190 A;

- noise level - 72 dB;

- sockets - 2 for 220 V, 1 for 12 V;

- weight - 145 kg.

Advantages:

- durable soundproof casing;

- overload protection system;

- welding function;

- wide choice of electrode diameters;

- neat welding seam;

- continuous arc supply;

- mobility.

Flaws:

- No.

TCC DGW-200E

Single-phase, diesel, welding generator based on a 188F air-cooled engine . Equipped with an electric starter and manual system start.

Acts as an efficient power station for supplying stable current, DC welding structure for welding seams on various metals.

The unit is located on a reinforced frame with wheels.

This allows you to easily move it around the work area and protect it from adverse external factors.

Characteristics:

- engine capacity - 456 cubic meters. cm, power - 8.2 l. With.;

- fuel consumption - 1.9 l/h;

- tank volume - 12.5 l;

- active power - 3 kW, max. — 3.5 kW;

- welding current - 50-190 A;

- sockets - 2 for 220 V, 1 for 12 V;

- electrode diameter - 1.6-4 mm;

- weight - 112 kg.

Advantages:

- effective overload protection;

- sockets are equipped with additional protection;

- multifunctionality;

- uninterrupted power supply;

- quiet operation;

- welding power adjustment;

- economical fuel consumption.

Flaws:

- No.

Pramac W 220

Three-phase gasoline welding generator with manual start, air-cooled Honda GX390 engine system.

Capable of providing a large number of single-phase and three-phase users with electricity. If you connect the electrodes, you can weld any metals with a neat seam.

The front panel is equipped with a voltmeter and a display with operating parameters . Overload protection extends the service life of the entire device when used in extreme conditions.

Characteristics:

- engine capacity - 389 cubic meters. cm;

- fuel consumption - 2.8 l/h;

- tank volume - 6.1 l;

- active power - 4.5 kW, max. — 4.9 kW;

- sockets - 2 for 220 V, 1 for 380 V;

- dimensions - 87.5x60x62 cm;

- weight - 80 kg.

Advantages:

- multifunctionality;

- effective overload protection;

- high arc welding performance;

- durable reinforced frame;

- economical fuel consumption;

- quick manual start.

Flaws:

- No.

CALIBER BSEG-5500A

Single-phase gasoline power plant with electric starter and manual system start, with built-in welding . Developed on the basis of the HT190FDE air-cooled engine system.

For welding work, it is enough to select electrodes with a diameter of 2.5-4.2 mm.

Users note a high-quality, smooth and even weld at the junction of metal products . For convenient transportation, the manufacturer has equipped the generator with large wheels.

Characteristics:

- engine power - 14 liters. With.;

- fuel consumption - 1.1 l/h;

- tank volume - 25 l;

- active power - 5 kW, max. — 5.5 kW;

- there is a voltmeter;

- welding current strength - 50-190 A.

Advantages:

- high welding quality indicators;

- reliable overload protection;

- economical gasoline consumption;

- quite spacious tank;

- trouble-free electric starter;

- welding function;

- uninterrupted power supply.

Flaws:

- No.

Power calculation

To calculate power, you will need to take into account the following parameters:

- welding current I

- arc voltage U

- Efficiency taken as 0.85

- safety factor, recommended value is 1.2.

If a welding current of 200A is required at a discharge voltage of 25V,

then 200A*25V/0.85 = 5882 W

When adding headroom, the result is 5882*1.2=7058W

This calculation is relevant for constant work during a shift . If you plan only minor repairs to a fence or wheelbarrow on your property, the power can be halved.

Selecting a generator with welding function

To ensure that the welding gas generator lasts a long time, make sure that cast iron sleeves are used in its design. Such devices can easily withstand operation for 1500 hours. But their aluminum counterparts are less reliable and can fail three times faster.

In stores today you can purchase inverters with the function of adjusting the power percentage. This is an excellent option for use in conjunction with generators, as they support operation at reduced voltage. If you are interested in just such a model, we advise you to carefully study the markings before purchasing - it must contain the PFC prefix.

Remember that gasoline welding generators are not designed for continuous use. It is necessary to take breaks while working. If you are going to use this device for 5-8 hours a day, then it is best for you to choose a diesel model. A model with a power rating from 0.7 to 5 kW is ideal for relaxation and gardening. They are lightweight, so you won't have any problems with carrying and transporting them.

A generator with a power rating of 10 kW can easily cope with intensive work for 8 hours every day. Features that also need to be taken into account include the size of the fuel tank, as well as the presence of a soundproofing casing. Many experts consider the function that allows you to start a gas generator from an electric starter to be important.

An interesting solution are models with overhead valves. If you have experience working with diesel analogues, then be sure to pay attention to the quality of the energy released. These units have such advantages as compactness, long service life, high performance and low noise level.

You should consider such a generator model only if you are going to use it to perform work on a construction site, where you will need to supply a powerful flow of energy from time to time. If you are looking for a unit for a cottage or enterprise, we advise you to choose from generators with a capacity ranging from 10 to 20 kW. Many devices of this type have the ability to start automatically, and, in addition, they can be used as a permanent installation.

Can I do it myself?

Many home craftsmen make their own welding generators.

To create the unit, several horsepower engines at hand and a generator (or starter) from a powerful truck or tractor are adapted. How to make a welding machine from a car starter or generator? The frame is made from a corner; a belt or gear drive is usually used for the gearbox. The engine and generator are positioned so that their axes are parallel. An ordinary powerful transformer is used as a current source. Due to the fact that a home master cannot carry out a full-fledged engineering calculation, the efficiency of such devices rarely exceeds 40-50%. However, at low initial costs, such units make it possible to weld structures with acceptable quality.

Combining a generator and a welding machine in one unit is justified in the case of a large volume of work far from a constant power supply. Such devices are necessary for services for which constant high availability of the welding complex is important . The universal welding generator can also be used to power construction tools and household needs.