Exact sciences

The unit of measurement of pressure in physics and chemistry is the letter “P” (translated into Latin as “pressūra”). If there is equilibrium inside and outside the cylinder walls, the indicator is designated “P”. The international system uses Pascals. Using the formula for fluid pressure and force, we can come to the conclusion that 1 Pa = 1 N/ 1 sq. m. Since the unit is small, it is difficult to use in calculations.

From the table of standard converters in physics, the following notations are more often used:

- Bars. 1 Bar=105 Pa.

- Torrs or mmHg (1 torr equals 133 Pa).

- mm water pillar

To determine pressure, force and area are used: P = mg / S. There is a dependence of the value on volume and mass. The indicator is characterized by the following property: the smaller the area, the greater the force exerted on the body. If the pressure does not change, but S increases, then the desired indicator decreases.

Causes of low blood pressure

The pressure in the gas pipeline is maintained using special compression stations . Since the blue fuel distribution network itself assumes a decrease in pressure as the end point is reached, the consumer does not encounter high performance in the network .

Low pressure in a gas pipeline , as a rule, is associated with some kind of ongoing work on the line, connecting a new consumer, reinstalling pipes, or replacing equipment. The gas pipeline is an extremely reliable system; it rarely needs to be repaired. However, during repair work, individual fragments are turned off and this can also cause a decrease in the indicator. The tenant of the apartment or the owner of the house cannot influence the situation.

If an autonomous gas supply is installed in a private home, the decrease in pressure may be due to several reasons. The most common one is emptying the gas tank . If less than 20% of gas remains in it, the latter is supplied under very low pressure. The same picture is observed when pipes are clogged, the condensate collector is overfilled, or the gearbox freezes . In the first case, you should look at what the level gauge indicates. If the scale shows 20–25% full, you need to call a gas truck and fill the gas tank.

In all other cases, you must contact specialists ; only they have the right to check and repair the system.

General information about pressure

The maintained gas pressure depends on the purpose of the pipeline

By definition, pressure is a physical quantity equal to the force that acts per unit area at 90° to the surface. Since blue fuel is transmitted through pipelines, the cross-sectional area of the pipe is the conventional surface, and the pressure determines the speed of movement of the substance.

The pressure in different sections of the gas pipeline from the field to the nozzle in the gas boiler is maintained at different levels.

Types of pressure

The pressure in the pipes is strictly standardized. If the value in the main pipe is too small, it will simply not be possible to move the gas to another station. If the pressure in the home network is too high, at the final point - the burner, the gas mixture will not be able to be mixed with oxygen in the required proportion to support combustion and not provoke an explosion.

Gas pipelines are classified according to the pressure. And since it is constantly maintained, the gas is “associated” with this value.

There are main and distribution gas pipelines.

Trunk

Distribution

Trunk - through such a pipeline the gas mixture is transmitted over long distances. Gas compressor stations are installed here at a certain frequency to maintain the required level. The final destination for the main line is the local distribution station. Based on the pressure level, there are 2 types:

- 1st class trunk networks – with operating pressure from 2.5 to 11.8 MPa inclusive;

- Class 2 – maintained according to the standard 1.2–2.5 MPa.

Distribution - gas is delivered through pipelines from stations to the end consumer - in-house networks. There are:

- Category 1 – household gas is transmitted under pressure from 0.6 to 1.2 MPa;

- category 1a – more than 1.2 MPa;

- Category 2 – 0.3–0.6 MPa.

Residential buildings are traditionally equipped with the lowest pressure networks. However, with the advent of gas boilers, the situation has changed somewhat. To satisfy the demand for gas, a gas pipeline with average performance is connected to residential multi-storey buildings.

Units

Pressure is measured in a variety of ways. But when it comes to a gas line, the following options are most often used:

- 1 mm. Hg st - this unit is very clear, especially when a liquid pressure gauge is used for measurement.

- 1 atm is a more traditional unit of measurement. The first quantity that could be compared with something was atmospheric pressure. The value calculated from absolute zero is called absolute. Hence, excess pressure is equal to the difference between the absolute and atmospheric values. When the vacuum changes, it is determined how much the level in a certain limited volume - a pipeline - is less than atmospheric. This value is called vacuum pressure. When repairing or inspecting intra-house networks, vacuum pressure is measured in the smoke removal system, and excess pressure is measured in the gas pipeline.

- 1 bar is a unit more common in Europe. 1 bar is equal to 100000 Pa.

- 1 Pa is the unit of measurement adopted in the SI system. It is inconvenient because it is too small - only 1 newton per 1 m². When inspecting gas pipelines, a large unit is used - 1 MPa, equal to 1,000,000 Pa (pascals).

Specifications

| Name of hackkristika | Meaning |

| Gas pressure measurement range, kPa | from 0 to 20 |

| Maximum supply pressure (overload), kPa | 40 |

| Limits of permissible reduced error, % of the upper measurement limit: | |

| Variation of the output signal (readings), % of the upper measurement limit, no more | 1 |

| Nominal price per unit of the smallest digit of a digital indicator, kPa | 0,01 |

| DC supply voltage, V | From 4.2 to 6.0 |

| Warm-up time, s, no more | 5 |

| Continuous operation time, h, not less | 80 |

| Power consumption, VA, no more | 3 |

| Dimensions, mm, no more | 185x60x35 |

| Weight, kg, no more | 0,430 |

| Degree of containment according to GOST 14254 | IP20 |

| Operating conditions: — ambient temperature, C | from -30 to +50 98 (at 25°C) from 84 to 106.7 |

| Mean time between failures, hours, not less | 15000 |

| Average recovery time, h, no more | 2 |

| Average service life, years, not less | 10 |

| Explosion protection marking according to GOST 30852.0-2002 (GOST R 51330.0-99), GOST 30852.10-2002 (GOST R 51330.10-99) | IExibIICT5 |

Pressure measurement methods

The widespread use of pressure, its differential and vacuum in technological processes necessitates the use of a variety of methods and means of measuring and monitoring pressure.

Pressure measurement methods are based on comparing the forces of the measured pressure with the forces:

- pressure of a column of liquid (mercury, water) of the corresponding height;

- developed during deformation of elastic elements (springs, membranes, pressure boxes, bellows and pressure tubes);

- elastic forces that arise during deformation of some materials and cause electrical effects.

Classification of pressure measuring instruments

Classification by principle of action

In accordance with these methods, pressure measuring devices can be divided, according to the principle of operation, into:

Deformation measuring instruments are most widely used in industry. The rest, for the most part, have found application in laboratory conditions as exemplary or research ones.

Classification depending on the measured value

Depending on the measured value, pressure measuring instruments are divided into:

- pressure gauges – for measuring excess pressure (pressure above atmospheric);

- micromanometers (pressure meters) – for measuring small excess pressures (up to 40 kPa);

- barometers - for measuring atmospheric pressure;

- microvacuum gauges (draft meters) – for measuring small vacuums (up to -40 kPa);

- vacuum gauges – for measuring vacuum pressure;

- pressure and vacuum gauges – for measuring excess and vacuum pressure;

- pressure gauges – for measuring excess (up to 40 kPa) and vacuum pressure (up to -40 kPa);

- absolute pressure gauges – for measuring pressure measured from absolute zero;

Study of the purpose, design, principle of operation and calibration of pressure measuring devices (absolute, manometric, vacuum).

Pressure measuring instruments

Devices for measuring pressure are classified according to various criteria. Based on the nature of the measured pressure, devices are divided into the following classes:

- barometers – instruments for measuring atmospheric pressure:

- pressure gauges – devices for measuring excess pressure;

- vacuum gauges – instruments for measuring vacuum;

- pressure and vacuum gauges – devices for measuring both excess pressure and vacuum;

- absolute pressure gauges – devices for measuring absolute (total) pressure;

- differential pressure gauges – devices for measuring pressure differences.

According to the principle of operation, the devices are distinguished:

The simplest device for measuring excess pressure is a piezometer (Fig. 1, a). It is a vertically installed transparent glass or PVC tube with an open top end

Measurements using a piezometer are carried out in units of length, so sometimes pressures are expressed in units of the height of a column of a certain liquid. Piezometer height 1.5. 2m allows you to measure pressure up to 0.15. 0.20 atm.

The main advantage of a piezometer is its simplicity of design and measurement accuracy. The main disadvantage of a piezometer is the small range of measured pressures. At high pressures the piezometer becomes too bulky. The disadvantages of a piezometer also include fragility.

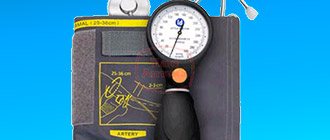

Excess pressure in liquids or gases is measured by pressure gauges. This is a very extensive set of measuring instruments of various designs and designs.

Figure 1,b shows the operation diagram of a piston pressure gauge. When the pressure in the vessel increases, the liquid or gas, according to Pascal's law, transfers this pressure to the lower surface of the piston, thereby causing it to rise or fall. The piston is connected through a system of levers with an indicator arrow.

Fig.1 Instruments for measuring excess pressure

a) piezometer, b) piston pressure gauge, c) liquid pressure gauge, d) membrane pressure gauge, e) bellows pressure gauge

Another type of pressure gauge is an open (liquid) pressure gauge (Fig. 1, c). It consists of a U-shaped tube filled with mercury or other liquid. The work is based on the law of communicating vessels and on balancing the measured gas pressure with the pressure of a liquid column (mercury, water, etc.). Pressure is applied to one end of the tube. The liquid in the other tube rises until the measured pressure is exactly equal to the pressure caused by the difference in liquid levels in the two legs of the tube. Knowing this height difference, the pressure can be calculated.

The disadvantage of such a pressure gauge is that the pressure value depends on the acceleration of gravity at a given location. Such a pressure gauge is not always calibrated in pascals; it is often convenient to measure pressure in units of the height of a column of a given liquid - in millimeters of mercury, water column (1 mm water column - 9.8 Pa; 1 mm Hg = 133.3 Pa)

One of the simple instruments for measuring increased and high pressures is a tubular pressure gauge or Bourdon pressure gauge. Its main component is a brass pipe 1 of oval cross-section bent in an arc (Fig. 2).

Liquid or gas is supplied to fitting 3, connected to tube 1. The tube, straightening, sets in motion a system of gears and levers 2, which turn arrow 4; the greater the pressure, the greater the angle the needle will rotate. The angle of rotation of the arrow is proportional to the measured pressure. The scale printed on the dial is graduated in pressure units. Typically the pressure gauge is calibrated in MPa. Such pressure gauges are used to measure the pressure of air, steam, gases and liquids. Pressure gauges for measuring car tire pressure are often of the Bourdon type.

So it is a strain gauge.

Deformation gauges also include membrane and bellows pressure gauges (Fig. 1, d, e)

The main part of the diaphragm pressure gauge is a flexible round flat plate capable of deflection under pressure.

A bellows pressure gauge (bellows) is a thin-walled cylindrical shell with transverse corrugations, capable of significant movement under pressure. To increase rigidity, a spring is often placed inside the bellows. Bellows are made of bronze, carbon steel, aluminum alloys. Seamless and welded bellows with a diameter from 8-10 to 80-100 mm are mass-produced. Bellows are more sensitive than diaphragm pressure gauges and have a larger measuring range.

The main advantages of the devices are a wide range of measured pressures, simplicity of design and use, portability and versatility.

The main disadvantage of the devices is the variability of their readings, due to gradual changes in the elastic properties of the spring element, the occurrence of residual deformation, and wear of the transmission mechanism. Therefore, such devices must be checked periodically.

Pressure gauges allow you to determine pressure only with a certain accuracy; the accuracy class of pressure gauges is determined by the value k, which expresses the maximum permissible error of the value corresponding to the maximum reading of the instrument scale

Nominal range of classes, accuracy of pressure gauges: 0.005; 0.02; 0.05; 0.1; 0.2; 0.35; 1; 2; 2.5; 4.0; 6.0.

Pressure gauges and vacuum gauges, standard spring gauges, are used to control general-purpose pressure gauges and to carry out particularly precise measurements. To control standard pressure gauges, deadweight piston pressure gauges are used.

Pressure gauges of class 0.05 are intended for testing standard spring and other precision pressure gauges, pressure gauges of class 0.2 are for testing technical general-purpose pressure gauges.

Types of measuring instruments

Instruments for measuring pressure are divided into the following types:

- Thrust and pressure gauges are pressure and vacuum gauges that have extreme measurement limits of no higher than 40 kPa.

- Traction gauges are a vacuum gauge that has a measurement limit of (-40) kPa.

- A pressure gauge is a pressure gauge of low excess pressure (+40) kPa.

- Pressure and vacuum gauges are devices that are capable of measuring both vacuum and excess pressure in the range of 60–240,000 kPa.

- A vacuum gauge is a device that measures vacuum (pressure that is below atmospheric pressure).

- A pressure gauge is a device that is capable of measuring excess pressure, that is, the difference between absolute pressure and barometric pressure. Its limits range from 0.06 to 1000 MPa.

Most imported and domestic pressure gauges are manufactured according to all generally accepted standards. It is for this reason that it is possible to replace one brand with another.

When choosing a device, you must rely on the following indicators:

- The location of the fitting is axial or radial.

- The diameter of the fitting thread.

- Instrument accuracy class.

- Case diameter.

- Limit of measured values.

Types of devices

Based on their structure and principle of operation, there are 5 main types of sensors:

- liquid;

- spring;

- electrical contact;

- membrane;

- differential.

Spring and liquid devices are the most popular. They are quite accurate and reliable at their low price. These two types are well suited for private homes and small businesses. In most boiler rooms, spring pressure gauges are used.

Gas pressure measuring range

This is the most important parameter when choosing measuring equipment for a boiler room.

The main thing is that the operating pressure in the boiler pipe falls within the range of 1/3-2/3 of the instrument’s measurement scale. If the pressure is less, then the measurement error is too high, and if it is more, the device will be overloaded and fail before the warranty period.

Accuracy class

The lower this indicator, the more accurate the device. The accuracy class is the percentage of measurement error from the measurement scale.

The error is easy to calculate, for example, if the device is 10 atm. has an accuracy class of 1.5 units, then its permissible error is 1.5%. If the device indicator is higher, then it must be replaced.

The malfunction can only be determined using a reference pressure gauge; this is done by a special organization that verifies the equipment. A high-precision device is connected to the system, and then the readings are compared.

Size

The diameter of the device is selected depending on the purpose.

- 50, 63 mm - for installation on portable equipment or for monitoring the pressure of oxygen cylinders and welding machines.

- 100 mm is the most common size, most convenient in most cases.

- 160 mm, 250 mm - for monitoring devices that are located visually far away, for example, under the ceiling of a boiler room.

Functional load

Depending on the type of functional load, devices are:

- Indicating devices are technical devices. Pressure is measured.

- Signaling - control an external electrical circuit.

- For accurate measurements they have an accuracy class of 0.6-1.0 units.

- Reference ones are used to check the accuracy of other instruments.

- Recorders record blood pressure as a chart on paper.

Photo 2. Model pressure gauge for a gas boiler. The device is highly accurate and is used to calibrate other devices.

Operating conditions

The device is selected taking into account the environment in which it will be used. The environment can be different, including aggressive

There are devices with different housings; it is important to consider whether it will work in conditions of humidity, dust, or vibration, in order to prevent the development of corrosion or damage to the housing

Classification by type of pressure measured

Instruments used to obtain data on gas pressure parameters in gas tanks, transport lines, gas cylinders and other reservoirs are classified according to several criteria. They differ in their structure and principle of operation.

Devices used to measure pressure are divided into classes according to:

- type of pressure being measured;

- purpose;

- operating principle;

- accuracy class.

Based on the type of pressure being measured, instruments designed to determine accurate indicators are divided into pressure gauges, vacuum gauges, draft gauges, pressure gauges, barometers and others.

Depending on the degree of protection from the influence of the external environment, the following devices are produced:

- standard;

- protected from dust;

- waterproof;

- protected from aggressive environments;

- explosion-proof.

One product can combine several types of protection.

The diagram shows the division of measuring devices according to operating principle, type of pressure, application and display. Liquid and deadweight instruments are rarely used to obtain data on gas pressure

A pressure gauge is a small device that is used to measure pressure or pressure difference. The operating principle of this instrument depends on its internal structure. Within one class, they are further divided into groups depending on the accuracy class.

To measure absolute pressure, measured from absolute zero (vacuum), absolute pressure gauges are used. Excess pressure is determined using an excess pressure gauge. In general, all varieties of such devices are called in one word: “pressure gauge”.

Most types of pressure gauges are designed to measure excess pressure values. Their peculiarity is that they show pressure, representing the difference between absolute and atmospheric.

Vacuum gauges are devices that indicate the pressure value of a rarefied gas. Using pressure and vacuum gauges, excess pressure and rarefied gas pressure are measured. Information is displayed on a single scale.

Using pressure meters, excess pressure parameters are determined with values up to 40 kPa. Traction meters, on the contrary, make it possible to measure rarefaction down to – 40 kPa. Thrust pressure meters measure rarefaction and excess pressure in the range from – 20 to + 20 kPa.

Pressure gauges are used in a wide variety of industries. Working with gas involves a high risk, so it is important to monitor all system indicators. Pressure information gives users information about the current state of the object being measured

Differential pressure gauges can be used to determine the pressure difference at two arbitrary points to be studied. A micromanometer is a differential pressure gauge that allows you to measure pressure differences within 40 kPa.

Division by functional purpose

According to their intended purpose, the following types of pressure gauges used to measure gas pressure are distinguished:

- general technical;

- reference;

- special.

Let's look at the features of each type.

Pressure gauges for general technical purposes

This type of pressure gauges is produced for the purpose of measuring vacuum and excess pressure values for general technical purposes. Various modifications of the devices allow them to be used in a wide variety of environments. They are used to measure pressure in production directly during technological processes.

The pressure in such devices acts on the tube from the inside and causes the loose end to move. A mechanism interacts with it that moves the arrow

Such pressure gauges can measure the pressure of gaseous media that are non-aggressive towards copper alloys at operating temperatures up to 150 °C. Typically, the body of the product is made of steel, and the mechanism parts are made of brass alloy.

General technical pressure gauges for low or high pressure gas are manufactured to be resistant to vibrations with a frequency in the range from 10 to 55 Hz, as well as a displacement amplitude of a maximum of 0.15 millimeters. They have several accuracy classes from 1 to 2.5.

Digital pressure gauges are small in size, characterized by high measurement accuracy and long service life. Moreover, such devices can be calibrated

Gas pressure gauges for general technical purposes with an electronic board on which the measurement data are displayed are gaining popularity. They are often equipped with converters, which automates technological processes. Pressure values are displayed on an electronic dial.

Group of special pressure gauges

Such devices are manufactured for a specific type of gas and the environment it creates. For systems with increased pressure, pressure gauges are made for high-pressure gas. Some gases are aggressive towards certain alloys, so it is necessary to use resistant materials when working with them.

Special pressure gauges are painted in different colors depending on the type of gas.

Propane pressure gauges are painted red, have a steel body and have the characteristics of general technical pressure gauges. The operating pressure of such devices is from 0 to 0.6 MPa. This is standard propane pressure. Operation is possible in the temperature range from – 50 to + 60 °C. Working environment temperature up to + 150 °C. Often included with balloon reducers.

Ammonia pressure meters in cylinders and other containers are colored yellow. Units with multi-stage compression are equipped with a temperature scale. The pressure gauge components are made of materials resistant to ammonia vapors.

In the presence of serious dynamic loads, pressure gauges are filled with glycerin or silicone

The acetylene pressure gauge is painted white. Manufactured as a pressure gauge for security systems from fat-free materials. Used to measure excess pressure in various acetylene distribution and generating systems. The body is made of steel, the internal components are made of brass alloy. The permissible temperature range is from – 40 to + 70 °C.

The hydrogen pressure gauge turns dark green. The pressure gauge for other flammable gases is painted red. The measuring device for non-flammable mixtures is painted black. The oxygen pressure gauge is painted blue.

Reference devices for pressure measurement

This type of pressure gauge is designed to test, calibrate and adjust other instruments to ensure the highest possible measurement accuracy. Such devices are distinguished by a higher accuracy class in comparison with general technical ones. Working standards are divided into three categories.

Control pressure gauges, used to monitor the reliability of the readings of measuring instruments at the installation site, are also called high-precision pressure gauges. The operating measurement range is from 0-0.6 to 0-1600 bar for gaseous media.

Pressure gauges for conventional and composite gas cylinders must undergo a verification procedure at least once a year, unless other periods are specified in the documents for the device. Verification is carried out by accredited metrological organizations that have the status of legal entities. After verification, a certificate is issued and a stamp is placed.

The device must be removed from the cylinder and taken to the metrological service. There, verifiers and calibrators, using a set of standards and auxiliary instruments, will carry out verification for about 10 days

The transmission mechanisms in the reference pressure gauges are machined at a higher gearing frequency. They are characterized by minimal friction in the pointer mechanism, as well as high sensitivity of the internal elements.

Standard pressure gauges with an accuracy class of 0.4 have a scale of 250 units, with an accuracy class of 0.15 or 0.25 they have a scale of 400 units with a division value of 1 unit. Operation of the device is possible at different temperatures depending on the housing filler. The ideal operating temperature is 20 °C.

The following article will introduce you to the specifics of refilling gas cylinders. All owners of country property not connected to a centralized gas supply should read it.

Legislative framework of the Russian Federation

Free legal aid hotline

Free consultation

Navigation

Federal legislation

Actions

- home

- “TECHNICAL OPERATION OF GAS DISTRIBUTION SYSTEMS. BASIC PROVISIONS. GAS DISTRIBUTION NETWORKS AND GAS EQUIPMENT OF BUILDINGS. TANK AND CYLINDER UNITS. OST 153-39.3-051-2003" (approved by Order of the Ministry of Energy of the Russian Federation dated June 27, 2003 N 259)

| Name of document | “TECHNICAL OPERATION OF GAS DISTRIBUTION SYSTEMS. BASIC PROVISIONS. GAS DISTRIBUTION NETWORKS AND GAS EQUIPMENT OF BUILDINGS. TANK AND CYLINDER UNITS. OST 153-39.3-051-2003" (approved by Order of the Ministry of Energy of the Russian Federation dated June 27, 2003 N 259) |

| Document type | order, list, standard |

| Receiving authority | Ministry of Energy of the Russian Federation |

| Document Number | OST 153-39.3-051-2003 |

| Acceptance date | 01.01.1970 |

| Revision date | 27.06.2003 |

| Date of registration with the Ministry of Justice | 01.01.1970 |

| Status | valid |

| Publication |

|

| Navigator | Notes |

6.3. Measuring gas pressure in gas distribution networks

6.3.1. Gas pressure in gas pipelines is monitored by measuring it during the period of highest flow (in winter) and during hours of maximum gas consumption.

It is recommended to carry out unscheduled pressure measurements to clarify the operating ranges of existing hydraulic fracturing units, identify the possibility of connecting new consumers, as well as when commissioning new consumers with a gas flow rate of more than 10% of the flow rate in the gas pipeline section to which the consumer is connected.

6.3.2. Pressure measurements are made at predetermined points in the gas network, at the outlet of the gas distribution center and at consumers according to a scheme approved by the technical management of the operating organization in the prescribed manner.

Points (points) for measuring pressure on gas pipelines are determined by the operating organization, based on operating experience, taking into account consumer requests to reduce gas pressure.

The measurement scheme should include measurement points on sections of gas pipelines at the consumers most distant from the hydraulic fracturing unit (along the gas flow) and other points in the gas network that are unfavorable in terms of gas supply conditions.

When identifying and clarifying places where gas pipelines are blocked by hydrate and condensate plugs, additional measurements are taken.

6.3.3. Pressure measurements should be made simultaneously at all points provided for in the measurement scheme. The duration of work should not exceed 1 hour.

The detection of sudden pressure drops in individual linear sections of the gas pipeline indicates the presence of blockages.

6.3.4. The pressure at the outlet and inlet of the gas distribution unit (GRU) of consumers is measured by pressure gauges.

To measure pressure on gas pipelines, the following types of pressure gauges should be used:

— at pressures up to 0.01 MPa — U-type, filled with water;

- at pressures above 0.01 MPa - standard or spring control with the appropriate scale.

6.3.5. The tightness of connections of plugs and fittings installed after gas pressure measurements are completed must be checked with instruments or other methods.

6.3.6. The results of pressure measurements are recorded in a special journal. If it is necessary to assess the actual pressure regime in the gas distribution system based on the measurement results, a pressure regime map should be drawn up to compare it with the design calculation diagram and identify the causes of insufficient gas pressure.

6.3.7. To restore the optimal operating mode of gas distribution systems, it is recommended to provide for cleaning of gas pipelines, replacement of individual sections or laying additional gas pipelines, increasing gas pressure after hydraulic fracturing, installation of new hydraulic fracturing, ringing of distribution gas pipelines.

About pressure gauges

Externally, the devices resemble a small cylinder consisting of a metal body and a glass lid. As a rule, the diameter of pressure gauges is 50 mm. The scale, visible through the transparent glass, displays the pressure value in Pa or Bar. These devices are used in various systems, such as gas and water pipelines, heating boilers, autoclaves, compressors, cylinders, etc. Pressure gauges are connected to the systems through a tube that comes out of their housing. The tube has an external thread, due to which it is screwed into the desired place. The pressure gauge allows you to measure vacuum or atmospheric pressure, excess pressure or pressure difference.

Device structure

Among the many devices, the device and principle of operation should be considered on the most common model. The device of a pressure gauge for measuring pressure is as follows:

- Device body.

- Bourdon tube.

- Indicator arrow.

- Connection fitting.

- Transmitting lever-spring mechanism.

- Scale.

- Protective glass.

The pressure gauge body is made of steel, and its image resembles a cylinder, which is plugged on one side. A lever-spring mechanism with a Bourdon tube is fixed in it. A scale is installed to display the readings. And the indicator arrow, which is rigidly attached to the mechanism, shows the applied force. Glass protects from external influences.

Installation on a water supply system is carried out through a hollow fitting. The liquid, passing through the fitting, enters the tube, which it tries to bend.

ECM device

The ECM is a cylinder-shaped device very similar to a conventional pressure gauge. But unlike it, the ECM includes two arrows that set the setpoint values: Pmax and Pmin (their movement is carried out manually along the dial scale). A moving arrow showing the real value of the measured pressure switches contact groups that close or open when it reaches the set value. All arrows are located on the same axis, but the places in which they are fixed are isolated and do not touch each other.

The axis of the indicator needle is isolated from the parts of the device, its body and scale. She rotates independently of others.

The bearings with which the arrows are attached are connected to special current-carrying plates (lamellas) connected to the corresponding arrow, and on the other side these plates are brought out into the contact group.

In addition to the above components, the ECM, like any pressure gauge, also has a sensitive element. In almost all models, this element is a Bourdon tube, which moves along with a pointer rigidly fixed to it; also, a multi-turn spring is used as this element for sensors that measure medium pressure more than 6 MPa.

Classification by mode of operation

According to the method of operation, devices can be water, electric or digital; in addition to these categories, there are other varieties.

Water devices operate on the principle of balancing a gaseous substance with pressure, forming a column of liquid. Thanks to them, it is possible to clarify the level of sparsity, difference, redundancy and atmospheric data. This group includes U-type regulators, the design of which resembles communicating vessels, and the pressure in them is determined taking into account the water level. Also included in the water category are compensation, cup, float, bell and ring gas meters; the working fluid inside them is similar to the sensitive element.

Resistive electric pressure gauge

This device for measuring household gas pressure converts it into electrical data. This category includes resistive and capacitive pressure gauges. The first ones change the readings of conductive resistance after deformation and measure values up to 60-10 Pa with minor errors. They are used in systems with fast processes. Capacitive gas meters affect a movable electrode in the form of a membrane, the deflection of which can be determined by an electrical circuit; they are suitable for systems with accelerated pressure drops.

Digital or electronic instruments are high precision devices and are most often used for installation in air or hydraulic environments. Among the advantages of such regulators are their convenience and compact size, the longest service life and the ability to calibrate at any time. They are mainly used to monitor the condition of vehicle components. In addition, digital gas meters are included in fuel lines.

In addition to regulators with standard characteristics and settings, other types of devices are used to obtain accurate data. This list includes deadweight gas meters, which are original samples for testing similar devices. Their main working part is the measuring column, the condition and accuracy of the readings of which changes the magnitude of the error. During operation, the cylinder is held inside the piston at the desired level, while on the one hand it is influenced by calibration weights, on the other only by pressure.

What instruments measure gas pressure?

The characteristic of pressure is the force that uniformly acts on a unit surface area of the body. This force influences various technological processes. Pressure is measured in pascals. One pascal is equal to a force of one newton applied to a surface area of 1 m2. Instruments are used to measure pressure.

Pressure gauges: selection of a device that measures the pressure of gas and other media, types and installation

A reliable pressure gauge is a guarantee of trouble-free operation of the system, regardless of whether it is a water supply system, a gas pipeline, a heating system or a closed cycle of any production. There are different types of such devices and in this article we will discuss them in detail.

Pressure gauges

There are three main types of pressure:

- Atmospheric . This is when the atmosphere affects the surface of the earth, as well as everything on it. A healthy person does not feel it, since it is usually compensated by the internal pressure of the body.

- The water in the water supply may be overpressured . Hence the rule - it occurs in a confined space in various environments.

- Absolute arises from the interaction of the first and second types of pressure, that is, it is the sum of atmospheric and excess indicators.

A pressure gauge is a device that measures the second type of pressure (excess) in various systems.

Device selection

Today's industry uses different types of pressure gauges. To make the right purchase of a measuring device that will be suitable in all respects for solving production processes, you need to know:

- Pressure gauge type.

- Operating pressure measurement range.

- Its accuracy class.

- Its installation environment.

- Case dimensions.

- Functional load of the device.

- Where it will be installed, as well as the thread size of the fitting.

- Operating conditions.

If you follow the above list, then you can choose the optimal device, since all manufacturers of pressure gauges adhere to established standards . Therefore, devices from different companies are essentially interchangeable.

Types of pressure measurement systems

There are many different pressure gauges for measuring low and high pressure. But their technical characteristics are different. The main distinguishing parameter is the accuracy class. The pressure gauge will show more accurately if the value is lower. The most accurate are digital devices.

According to their purpose, pressure gauges are of the following types:

- Self-recording. They contain a mechanism that allows you to draw a graph of the device’s operation on paper.

- Railway. Used in railway transport.

- Ship's. Used on sea and river vessels.

- Reference. They have a high accuracy class. That is why they are used for testing, adjusting and checking other pressure measuring instruments.

- Special. Used to measure the value of various gases. Depending on what gas they are intended for, they have different body colors and marking letters: for measuring flammable gases - red, for non-flammable gases - black, yellow ammonia (A), white acetylene (Ac), blue oxygen (K).

- Electric contact. They have an electrical alarm that allows you to regulate the measured environment. These devices are divided into two types: based on an electrical contact attachment and with microswitches.

- General technical. Designed to measure pressure in various environments. They can measure excess and vacuum pressures.

Based on the principle of operation, the following types are distinguished:

- Piezoelectric. Based on the piezoelectric effect. A charge appears in a quartz crystal under mechanical action.

- Deformation. They are based on the deformation of the sensitive element (membrane, bellows, spring, etc.), which, when deformed, acts on the pointer.

- Liquid. Their basis is a tube filled with liquid. They can be of two types: with one or two tubes. Devices with two tubes are used to compare pressure in different environments.

- Piston. They consist of a cylinder with a piston inserted inside.

Conclusions and useful video on the topic

Operating principle of a spring pressure gauge:

Characteristics and scope of application of the pressure gauge:

Pressure gauges are produced to solve various problems. The most popular are the general technical types used in small industries and by various companies when working with gas equipment and systems. Electrical contact pressure gauges are devices that signal when a critical value has been reached.

For checking and adjusting pressure gauges, standard pressure gauges are used. Special pressure gauges are produced to measure the pressure of a specific gaseous medium. Among them, propane pressure gauges are very popular, which are often installed complete with a reducer on gas cylinders.

Would you like to share useful information on the topic of the article, ask a question or post a photo? Please leave comments in the form below. Share useful information and recommendations that may be useful to site visitors.

Requirements for pressure gauges

The color of the housing indicates the type of gas being measured: yellow - ammonia, blue - oxygen, black - non-flammable, red - flammable

The exact indicators according to which the device takes measurements directly depend on the correctness of its selection and installation in combination with operating conditions. When selecting, it is necessary to take into account the physical and chemical properties of the measuring medium and the expected pressure data. For example, for conditions with a high content of aggressive gases, it is better to purchase special devices made of durable materials. The diameter of the pressure gauge glass must be at least 10 or 16 cm if it is placed at a distance of 2 to 3 meters.

Devices used in gas environments have different body colors, for example, blue indicates work with oxygen, yellow with ammonia, red and black are suitable for flammable and non-flammable gases, respectively. According to safety rules, it is not recommended to use pressure gauges with an expired verification period, as well as in the absence of a seal or mark on this procedure. If the needle of the device does not return to zero after switching off, it is also considered inoperative.

Any damage, such as deformed housing or broken glass, indicates that the regulator needs to be replaced, as they directly affect the accuracy of the meter.

Instrument selection criteria

The best option is a regulator with a scale from 0 to 10 atm

When selecting a device, you need to take into account all the requirements for pressure gauges used in the gas industry. The main criterion is the measuring range; during the selection process, it must be remembered that the standard pressure should fall within the range from 1/3 to 2/3 on the measurement scale. The ideal option would be a regulator with a scale of up to 0-10 atm. In second place in terms of importance is the accuracy class indicator, which shows the normal error of measurement results during operation of the device.

If desired, this indicator can be calculated individually, for example, if the device is designed for 10 atm, and its class is 1.5, the error rate of such a gas meter is 1.5% of the total scale. Depending on the type of mounting of the fitting, pressure gauges can be radial or end, in addition, the regulators are supplemented with metric or pipe type threads. When choosing a device, you need to take into account its calibration interval; it would be better if it is two years.

Household appliances may not undergo a verification procedure, but it is mandatory for devices used in factories, gas pipelines, heating or combustion units, as well as similar facilities.

What is important to pay attention to when buying a pressure gauge?

It is important to consider:

- the pressure gauge must be new. Many instrument sellers understand by the word new that the pressure gauge has not been used. But the pressure gauge may be 15 years old, and they will tell you that it is new. Check the year of manufacture of the device or you may be in for an unpleasant surprise in the form of purchasing an illiquid item.

- there must be a mark on the initial verification on the pressure gauge or in the passport. There are sellers of illiquid goods who erase the verifier's mark so that they cannot be accused of selling old devices.

- The pressure gauge must be verified for 2 years; if you buy a device with initial verification for 1 year, within a year the savings will disappear and unnecessary complications will begin.

- The pressure gauge must have a passport and a valid certificate for measuring instruments.

- If the device is new and verified for 2 years, choose the cheapest option.

- pay attention to the measurement range, scale diameter, type of fitting location, type of thread and design of the device - if you buy the wrong device, then replacing it may be difficult, because if the device has non-standard parameters and is made for you, then Most likely you will have to keep it as a souvenir.

- You can search for reviews about pressure gauges on the Internet, but most of them are custom-made and it is better to rely on the advice of people who have experience in actually operating the devices.

- You should buy pressure gauges from an organization that inspires your trust, because the sale of illiquid goods from the USSR still exists and then it will be quite difficult to return old instruments or exchange them for normal instruments.

In this article we tried to consider the most popular questions about the whole variety of pressure gauges. If you want other questions to be considered or you do not agree with any answers, write to us and we will try to expand the article based on your experience. In the letter, do not forget to indicate your details, location, conditions and region of installation.

Sources

- https://nauka.club/fizika/formula-davleniya.html

- https://titan-spec.ru/instrumenty-i-stanki/pribory-izmereniya-davleniya-gaza.html

- https://morflot.su/kakimi-priborami-izmerjaetsja-davlenie-gaza/

- https://sovet-ingenera.com/gaz/equip/manometry-dlya-izmereniya-davleniya-gaza.html

- https://instrland.ru/c/manometry/

- https://MetEkspert.ru/oborudovanie/kakimi-priborami-izmeryayut-davlenie-gaza.html

- https://kangen.ru/osnastka/kak-zamerit-davlenie-gaza.html

- https://msk.specarmatura.ru/articles/113950/

What devices measure gas pressure

First of all, it is worth noting the versatility of the pressure gauge, which lies in the ability to control pressure and maintain it at a certain level.

Secondly, the device allows you to obtain accurate indicators of the norm, as well as deviations from them. Thirdly, accessibility, almost anyone can afford to purchase this device.

Fourthly, the device is capable of operating stably and uninterruptedly for a long time, and does not require special conditions or skills.

The use of such devices in areas such as medicine, chemical industry, mechanical and automotive industry, maritime transport and others requiring precise pressure control greatly facilitates work.

Purpose

Monitoring fuel pressure is important for injection and diesel engines. If the required pressure is not provided, the fuel will not cope with the resistance of the injectors, the engine will operate intermittently, and fuel consumption will increase.

The condition of a modern car is monitored by an on-board computer, if installed. But monitoring fuel system pressure is not its function. This is done by a pressure gauge to check the fuel pressure.

It is used to control the elements of the fuel system.

It is important that the pressure gauge can be connected in parallel without disturbing the operation of the fuel system (the author of the video is his own mechanic)

Design and principle of operation

When operating a pressure gauge, the principle of equilibrium is used. The measured pressure is balanced by the force created by the elastic deformation of the sensing element, for example, a tubular spring or a membrane with two plates, etc. One end of the device is sealed in a holder, and the other is connected with a lever to a mechanism that translates linear changes into the movement of the arrow on the dial.

Let us consider a pressure gauge device for measuring pressure, the sensitive element of which is a tubular spring. These are the most common meters, as they have good technical characteristics, a simple design, are reliable in operation, and allow measurements to be made over a wide range.

Wide application was achieved due to the simplicity of the device design. It is based on an empty tube with a cross-section in the form of an oval or ellipsoid. The medium being measured acts on the tube, which deforms under pressure. On one side, the tube is connected to the system using a fitting, and on the other, it is connected to a mechanism that transmits deformation changes.

The transmission mechanism consists of the following elements:

- gears;;

- pointer (arrow);

- gear sector;

- leash.

A spring in the form of a spring is inserted between the sector teeth and the gear to eliminate backlash.

Since the tube has different surface areas inside and outside, under pressure it tries to straighten.

The soldered free end moves the meter needle relative to the scale using a lever. If the maximum pressure does not exceed 25 bar, the accuracy of the device is 2.5, above 25 bar - 1.5.

Types of pressure gauges differ according to their operating principle:

- liquid (pipe);

- membrane;

- spring;

- bellows;

- piston;

- piezoelectric pressure gauges;

- radioactive;

- strain gauges (wire).

Each type of the above devices differs in the sensitive element used and operating principle.

Meters differ in purpose:

- General technical, used for measurements in environments that are not aggressive to copper alloys.

- Electric contact. A distinctive feature of the devices is the ability to regulate the measured medium.

- Special. They are designed to measure pressure in different gases; they distinguish between oxygen, ammonia, acetylene, non-flammable and flammable gases. They differ in color.

- Reference. They are distinguished by a high accuracy class, therefore they are used as a sample for checking, testing and adjusting other measuring instruments.

- Ship's. They are used in sea and river transport.

- Railway. Used in railway transport.

- Self-writing. The devices are equipped with a mechanism that records the meter's operating schedule on chart paper.

Pressure gauges are used in industry, in everyday life, and in other fields of activity, depending on the purpose of use and technical characteristics.

Criterias of choice

Before buying a device, you need to understand exactly what it is needed for and where it will be installed.

Important selection criteria:

- Measuring range. Rule: the working pressure in the pipeline should be no more than 2/3 of the maximum of the measurement scale, but not less than 1/3. If the pressure in the pipe is 5 atm, then you need to buy a pressure gauge with a scale of 0...10 atm.

- The accuracy class varies from 0.15 to 3. The lower, the more accurate. For a cold or hot water supply system, an accuracy of 1.5% is sufficient.

- The location of the fitting can be radial or end when it is from below; and axial or frontal, when he is behind.

- Operating temperature range.

- Temperature operating conditions.

- Working medium (water, steam, oil and so on);

- Diameter. It should be such that the device fits in the chosen location and the dial is clearly visible.

It is also necessary to pay attention to the connecting thread of the fitting. It can be metric - its parameters are measured in mm, denoted by the letter M, for example M20/1.5, which means the outer diameter is 19.9 mm, the inner diameter is 18.7 mm, pitch 1.5

Domestic manufacturers use it by default.

Pipe thread is designated by the letter G. G1/2" means an outer diameter of 20.9 mm, an inner diameter of 18.6, a pitch of 1.8 mm or 14 threads per inch.

The technical passport of a new device must contain a factory verification mark. A verification period of less than a year confirms that the device gives correct readings.

Operating principle

In a deformation (spring) pressure gauge, water enters a curved tube made of copper alloy. The water pressure causes the tube connected to the mechanism to deform, which causes the needle to turn.

Pressure gauges with a single-turn spring are designed for pressures up to 100 atm. To measure higher pressures, springs with several turns twisted into a spiral or screw are used.

There are devices in which a thin two-plate membrane is installed instead of a tube. They are suitable for viscous or contaminated solutions, withstand strong vibrations, but are sensitive to temperature fluctuations.

Features of setting up the pressure gauge

The pressure gauge is adjusted using a reference spring gauge. The pressure in the system is changed and the needle on the measuring scale is adjusted accordingly, achieving accurate results.

The adjustment is made by rotating the screw press flywheel to change the pressure. Using the screw and moving the rod, the position of the arrow is adjusted.

The adjustment begins with the initial value, and then the adjustment is carried out across the entire scale.

To control the fuel system of a car, a manually adjustable fuel pressure regulator with a pressure gauge can be used. It can be installed instead of the standard regulator on a car with an injector. Thanks to the device, the performance of the injectors increases, which makes it possible to pump more fuel into the cylinders. Thus, the power of the power unit increases.

Classification of pressure gauges according to operating principle

Nowadays, devices operating under pressure are used in almost all spheres of human activity. Consequently, pressure gauges are also used with them, providing accurate information about pressure indicators. In this case, measuring instruments may differ from each other in design and principle of operation. The devices available on the market are divided into the following types:

Modern pressure gauges are also divided into mechanical and electronic devices. A mechanical pressure gauge for a pump or water supply system has a simple design, but cannot accurately measure pressure. The design of the electronic device includes a contact unit that more accurately measures the pressure of the working medium.