How much gas can you fill in a 50 liter cylinder?

A 50-liter propane cylinder holds no more than 42.5 liters of liquefied gas. The fact is that according to safety standards, no more than 85 percent of the total internal volume can be pumped into the container (50x85% = 42.5).

Interesting materials:

Is it possible to sprinkle ash on fruit trees? Is it possible to hang two birdhouses on one tree? Is it possible to nail a birdhouse to a tree? Is it possible to graft trees in August? Is it possible to cut down trees on your property? Is it possible to cut down trees on agricultural land? Is it possible to cut down trees in the forest? Can I cut down a tree in my yard myself? Is it possible to plant fruit trees in May? Is it possible to plant fruit trees in November?

Volume and weight of gases

Compressed and dissolved

Technical oxygen and acetylene are produced in cylinders: 40, 10 and 5 liters. Propane-butane is stored in containers: 50, 27, 12, 5 liters. Under standard conditions in a volume of 40 liters, technical gases have the following mass:

- Nitrogen 7.5 kg (5.7 m3)

- Argon 7.5 kg (6.3 m3)

- Helium 1 kg (5.7 m3)

- Oxygen 8.3 kg (6.3 m3)

- Carbon dioxide from 20 to 24 kg (6.0 m3)

- Dissolved acetylene 6.0 kg (5.5 m3)

Propane has a mass of 21.5 kg (9.5 m3) in a volume of 50 liters.

Liquefied

Based on capacity, cylinders are divided into groups:

| № | Capacity (liter) | Weight of liquefied gas (kilogram) |

| 1 | 5-12 | 2 |

| 2 | 12-27 | 3,3 |

| 3 | 27-30 | 11,4 |

| 4 | Over 30 | 21,1 |

Transparent walls

The gaseous substance in a vessel made of transparent material is easy to control. Availability is determined by weighing, pressure readings on the pressure gauge and visually. Transparency does not change depending on the service life and type of gas. The vessels are made of composite polymers (fiberglass).

Inspection of cylinders: sequence of operations

The status is checked in the following sequence:

1) Preparation.

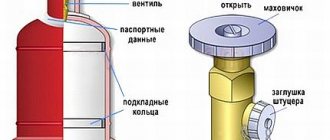

At the preparation stage, the remaining gas is removed from the container, the valve is dismantled, after which air is purged and the surface is thoroughly cleaned using water and, if necessary, a solvent. The dismantled valve is subjected to a separate check, and in the event of a malfunction, it is sent for repair or rejected with subsequent replacement.

Preparing the cylinder before testing

2) Visual inspection. The purpose of the visual inspection is to identify any structural defects: cracks, dents, caps, cavities, deep scratches (more than 10% of the wall thickness), thread wear, etc. For internal inspection, it is allowed to use a lighting device with a supply voltage of up to 12 V. If a loose ring on the neck or an incorrect shoe attachment is detected, the test is suspended until these faults are eliminated.

Inspection for defects

3) Checking weight and capacity. To determine how much corrosion and other physical and chemical transformations of the metal have reduced the wall thickness, measure the mass and internal volume of the product, as well as compare the obtained indicators with the original data from the passport. Weighing is performed on scales with an accuracy of 200 g. To determine the capacity, first weigh the empty vessel, and then the one filled with water, after which the mass of water is found from the difference in indicators, with further calculation of its volume.

Checking weight and capacity by weighing

4) Hydraulic test. To determine the strength of a container, it is filled with water under high pressure. The test pressure value is set by the manufacturer; it must be at least 1.5 times higher than the operating value. The duration of the check is at least 1 minute. The hydrotest is considered successful if during its execution the pressure gauge showed a stable value, and no cracks, leaks, tears or visible deformations were found on the body.

Hydraulic test

Exposure to test pressure during hydrotesting

5) Installation of the valve. Before connecting the valve and the reservoir, both components are degreased, then dried and blown with air. Installation is carried out using a seal, and the tightening force for the W27.8 thread is 300-400 N. m.

Valve installation

6) Applying a brand. If, based on the test results, the tank is allowed for further operation, the organization that carried out the certification stamps an individual stamp on the body, as well as the date of the performed and the next test.

Applying a brand

7) Painting the body. In case of unsatisfactory quality of the external coating, the cylindrical body is coated with oil or enamel paint or nitro enamel. In this case, it is not allowed to paint the container under pressure.

Painting and drying

Which vessels are subject to discarding?

If one of the following conditions is present, the cylinder is not subject to inspection and is subject to rejection:

- the presence of visible defects in the body;

- reduction in actual mass by 7.5% or increase in volume by 1%;

- identification of insufficient strength during hydraulic testing.

- absence of at least one of the following passport stamps: manufacturer's sign, serial number, actual weight and capacity, date of manufacture and next test, operating and test pressure, quality control mark, type of heat treatment.

On tanks that have not passed inspection, the neck thread is deformed by notching or a hole is drilled in the body. This is done to ensure that further operation of the defective vessel is impossible.

Since some unscrupulous companies refurbish rejected vessels and then provide them to the customer as new products, it is important to purchase and refill only from trusted suppliers, where all products comply with strict government regulations. You can find out more about the types of gases and containers to be filled here.

Formulas will help

For oxygen

V = K coefficient × Vb

K=((0.968× D + 1) × 293×10-3)/((273+ T) × Z)

Vb in dm3 ─ capacity, D in kgf/cm2 ─ pressure gauge data, Z ─ oxygen combustion coefficient. The parameter 0.968 kgf/cm2 recalculates the technical indicators of atmospheres.

For propane and butane

Gas mass = Vcylinder m3 × (0.4× Flat prop. + 0.6 × Flat bottle)

Under normal conditions, the density of liquid propane is 510 kg/m3, and butane is 580 kg/m3. The numbers 0.4 and 0.6 indicate the percentage of chemical elements.

Dimensions of methane cylinders of the second type

Model: CNG-2 DIGITRONIC Light

| 27 | 229x855 | 180-200 |

| 38 | 273x850 | 220-240 |

| 55 | 316x910 | 270-300 |

| Volume (liters) | Size(mm) | Weight, kg) |

| 50 | 325 x 780 | 40 |

| 55 | 325 x 830 | 44 |

| 60 | 325 x 880 | 47 |

| 65 | 356 x 800 | 57 |

| 70 | 356 x 880 | 60 |

| 80 | 356 x 980 | 65 |

| 80 | 406 x 800 | 64 |

| 90 | 406 x 890 | 72 |

| 100 | 406 x 980 | 79 |

| 110 | 406 x 1140 | 91 |

| 120 | 406 x 1180 | 98 |

Read also: Toyota chr test drive video

Ultrasonic devices

In specialized stores you can purchase modern equipment that works stably in any environmental conditions and shows values that do not depend on external factors. The measurement method is based on the properties of ultrasonic waves. The device is brought closer to the tank and the color indicator is followed. By moving parallel to the wall of the tank, you can find out its level of fullness. Such equipment is not cheap, but it is very useful if used frequently. Quick gas measurement allows you not to tire yourself with lengthy calculations and moving the cylinder.

Dimensions of methane cylinders of the fourth type

Model: TK-FUJIKIN (TKF), Korea

| Volume (l) | Outer diameter (mm) | Length (mm) | Weight, kg) |

| 42 | 310 | 810 | 16 |

| 61 | 336 | 1000 | 22 |

| 68 | 392 | 850 | 27,1 |

| 73 | 392 | 900 | 28,5 |

| 101 | 452 | 950 | 37,5 |

| 103 | 452 | 950 | 37,5 |

| 107 | 448 | 940 | 40 |

| 123 | 452 | 1110 | 43 |

| 131 | 460 | 1090 | 40 |

| 138 | 358 | 1830 | 47,8 |

| 145 | 485 | 1090 | 46 |

| 164 | 392 | 1820 | 61 |

| 230 | 458 | 1830 | 63 |

| 35 | 280 | 864 | 16 |

| 91 | 452 | 850 | 39,5 |

| 99 | 462 | 864 | 35 |

| 103 | 452 | 950 | 43 |

| 105 | 408 | 1143 | 38 |

| 132 | 408 | 1397 | 48 |

| 138 | 462 | 1143 | 45 |

| 175 | 408 | 1829 | 65 |

| 187 | 537 | 1143 | 64 |

| 192 | 408 | 2032 | 66 |

| 194 | 462 | 1524 | 59 |

| 198 | 408 | 2108 | 66 |

| 264 | 537 | 1524 | 82 |

When is gas tank certification performed?

The frequency of technical certification for vessels operating under excess pressure is 5 years. That is, from the date of manufacture, every 5 years the cylinder must be subjected to tests, during which the integrity of the body and valve, the weight of the structure, the internal capacity and the ability to withstand increased pressure are determined.

However, in some situations, the survey is performed earlier than the deadline, when:

- valve is broken;

- a leak was detected at the cylinder-valve connection;

- the ring on the neck is faulty or missing;

- shoe damaged;

- The painting of the outer surface is of poor quality.

The decision to repair or discard such vessels is made only based on the results of a visual inspection and technical studies.

Converting gas volume to standard (normal) conditions

Converting gas volume to standard (normal) conditions

The state of a gas is uniquely determined by three macroscopic parameters: pressure, volume and temperature. This ideal gas law calculator will help you determine the volume of your gas under standard conditions.

Standard conditions are a standard set of conditions (temperature, pressure) for measurements, allowing comparisons between data sets. The pressure and temperature values accepted in different industries under standard conditions are different, therefore, when recalculating, it is necessary to clarify the conditions under which the process takes place.

| Name | IUPAC | GOST 2939–63 | Aviation | SATP |

| Pressure | 100000Pa (1000 mbar) | 101325 Pa (1013 mbar) | 101325 Pa (1013 mbar) | 100000 Pa (1000 mbar) |

| Pressure | 273.15 K (0C) | 293.15 K (20С) | 288.15 K (15C) | 298.15 K (25C) |

| Notes | IUPAC standard conditions are also called simply "chemical" normal conditions | Standard conditions according to GOST 2939–63 in the gas industry | The standard is used in the calculation of aircraft and aircraft engines | Used mainly in the West, in industry |

The calculator uses the Mendeleev–Clapeyron equation to find the value of the ideal gas equation variable. An ideal gas is a set of randomly moving particles that interact with each other through an elastic collision and obey a certain law, an elementary equation and are amenable to research. In general, a gas can act as an ideal gas if the temperature is high and the pressure is low because under such conditions the potential energy becomes less significant compared to the kinetic energy.

As mentioned above, the ideal gas equation of state establishes the relationship between gas volume (V), pressure (P) and temperature (T). The ideal gas law was formulated by the French physicist Emile Clapeyron back in 1834 by combining the equations characterizing the Boyle-Mariotte and Gay-Lussac gas laws. This equation looks like this: .

Mendeleev's surname appeared in the name of this equation due to his contribution to the transformation of the original expression to the modern form. In 1874, a Russian chemist, using Avogadro's law, provided Clapeyron's equation in a more convenient form. Mendeleev also introduced such a concept as the universal gas constant.

Mendeleev-Clapeyron equation: .

where: P—gas pressure, Pa; V—gas volume, m³; T—gas temperature, K; v is the amount of substance, mol; m—gas mass, kg; M—molar mass of gas, kg/mol; R is the universal constant of an ideal gas R=8.31431 J/(mol K).

Water for volume determination

If you need to quickly determine the volume of gas at home or while traveling, use a simple calculation method using ordinary water. To do this you need to prepare:

- 1 partially used tank;

- 1 empty tank of appropriate volume;

- 1 full cylinder with the same volume;

- Marker for marks;

- A large saucepan in which to place the tank;

- Ordinary water.

Source drive2.ru

Then do the following:

- Pour water into the pan until it reaches about halfway;

- Place the tank in the water in a vertical direction;

- Note the level of contact with the liquid;

- Remove the cylinder and mark the waterline with a marker;

- Transfer labels to all tanks;

- Immerse the partially used cylinder in water;

- Note the location of the waterline and mark it with a marker;

- Compare the marks on all three cylinders.

How to properly clean a gas cylinder?

Clear

a used

cylinder

can be removed from accumulated residues with a solution of: acetic acid;

potassium permanganate; detergents and soaps. ... When preparing a container for cleaning, you must:

- unscrew rather than cut off the valve;

- don't hit;

- rinse away from fire and living quarters;

- Do not cut with a grinder, but only with a hacksaw.

Interesting materials:

How much does it cost to take Ielts in Kazakhstan? How much does it cost to make a deed of gift in Kazakhstan? How much does it cost to get a patent in Moscow? How much does it cost to get a passport in Ukraine 2022? How much does a donation transaction cost at a notary? How much does the Northern Commission cost? How much does SMS bank cost? How much does it cost to remove and install a suspended ceiling? How much does it cost to deregister a car in St. Petersburg? How much does it cost to deregister?

Price and sizes of methane cylinders of the first type

The most common are still the first type of methane cylinders. Their price depends on the size and capacity and, at the current time, is:

Volume (liters)

Size(mm)

Price ($)

- The second type can be purchased for approximately $7 per liter;

- Third type $8-8.50 per liter;

- The fourth, the most expensive at the moment, costs about $18 per 1 liter.

Dimensions of methane cylinders of the third type

Model: CNG-3 STAKO

| Volume, l | Outer diameter, mm | Length, mm | Weight, kg |

| 47 | 326 | 860 | 33,6 |

| 50 | 326 | 900 | 35,2 |

| 67 | 326 | 1140 | 44,6 |

| 80 | 326 | 1360 | 53,2 |

| 100 | 326 | 1660 | 65 |

| 123 | 326 | 2000 | 78,4 |

| 67 | 398 | 840 | 45,6 |

| 80 | 398 | 965 | 52,3 |

| 85 | 398 | 1015 | 55 |

| 96 | 398 | 1125 | 61,1 |

| 100 | 398 | 1165 | 63,5 |

| 132 | 398 | 1485 | 80,5 |

| 160 | 398 | 1765 | 99,5 |

| 185 | 398 | 2005 | 108,5 |

Weighing

The simplest method, accessible to every consumer and not requiring complex mathematical calculations. Before refilling a gas cylinder in Moscow or any other city, you need to study the container markings located on the bottom. The inscription must contain the manufacturer's data, the date of the last certification, the date of production, the nominal volume, dimensions, operating pressure and weight of the empty container. After this, all that remains is to weigh the cylinder with the remaining gas and determine the difference.

To roughly calculate the amount of content, you can multiply the resulting value by 2. This approximation is acceptable, since the weight of compressed household gas is approximately 0.5 kg/l. That is, if the difference in mass was 1 kg, then the amount of residue is about 2 liters. Knowing the remaining gas will help you calculate when to replace the cylinder.

Why is this necessary?

According to the rules for operating gas cylinders, the gas contained in them cannot be completely consumed. The residual gas pressure inside the cylinder must be at least 0.5 kgf/cm2 (0.05 MPa), otherwise the emptied container will not be accepted for refilling. This requirement to control the gas balance prevents the possibility of foreign substances from the external environment entering the cylinder. If the contents are completely used up, an additional washing operation must be carried out. After this, the cylinders are refilled or stored in a warehouse in an empty state with safety caps. What methods are used to determine the remaining amount of gas?

Pressure gauge

On large tanks, a pressure detection apparatus must be installed. You can determine the amount of fuel in the tank by multiplying the volume of the cylinder by the pressure gauge values. In this way, the value is determined only approximately, since the internal pressure is significantly influenced by the properties of the contents and the external air temperature.

Source ru.wikipedia.org