How to make a bucket with your own hands from tin

How to make a bucket with your own hands from tin, galvanized iron or stainless steel with straight walls.

We cut out the product from the material

h

– height (set the given value)

d

– diameter (set the given value)

l

– circumference (we find by calculation)

l = πd = 3.14 * 329 = 1033

(mm)

h = 310

(mm)

In the middle of the reamer we mark holes for attaching the ear

1.

On a rectangular sheet of thin-sheet galvanized steel GOST 14918-80, on a homemade manual sheet bender, or manually using a mallet and a beam, fold the edges of the sheet “heightwise” in opposite directions.

Bend the sheet into a cylinder. 2.

Fasten the folded edges.

Press the resulting seam evenly with a mallet or mallet along the entire length of the cylinder. 3.

In order for the seam to remain inside the cylinder, it is necessary to carry out the following operation: turn the finished seam so that it is located near the edge of the beam; By hitting the seam with a mallet, we obtain the outer surface of the cylinder without a protruding seam.

The width of the fold depends on its purpose: obtaining a lock; rolling of wire.

4.

Set the cylinder relative to the block to its original position.

Tap with a hammer and bend the fold. 5.

Tap with the pointed side of the hammer.

We monitor the width of the fold - it should be the same. 6.

Align the fold by tapping with the blunt side of a hammer.

7.

We finally bend the bent fold at a right angle.

We insert a circle around the perimeter of the flange,

made of wire, the diameter of which must coincide with the outer diameter of the cylinder.

We round the circular edge and complete the seaming.

CONNECTION OF CYLINDER TO BOTTOM

8.

Fold the edges of the circle and insert it into the cylinder.

9.

With light blows of the pointed part of the hammer, we bend the fold inside the circle.

10.

Using strong blows from the blunt part of the hammer, we tap the seam on the beam, while turning the cylinder.

11.

Place the fold on the outer plane of the cylinder.

12.

If the work results in a convex bottom, it is necessary to level it.

13.

At the very edge of the bottom, hit with the blunt part of the hammer, along the entire perimeter of the circle. At the same time, the bottom will be leveled, the edges of the connection will receive a clearly defined contour.

ATTACHING THE INTERMEDIATE HOOP

The bottom of the bucket can be attached to the intermediate hoop, and the intermediate hoop can be attached to the cylinder.

14.

We attach the bottom of the bucket with a hoop.

15.

Connect the hoop to the cylinder (bucket body).

16.

Bend the fold at the hoop.

17.

Place the fold on the outer plane of the cylinder and thoroughly tap along the perimeter of the entire circumference.

We will cut out the ears from a similar material. Let's punch or drill through holes: two for rivets; one with a metal handle.

We bend the handle from metal wire with a diameter of 5...6 (mm) GOST 18143-72.

How to make a bucket with your own hands from tin – as you can see, it’s not complicated. Having mastered a simple model. You can move on to a more complex model with sloping walls.

Source

Tips for use - how to keep the bucket in service!

It’s simply impossible to do without buckets either at country houses, or even more so at construction work. With intensive use, they quickly lose their original shiny appearance and begin to rust and leak. Experienced summer residents recommend soldering a zinc plate to the bottom of the bucket immediately after purchase - this doubles the service life of the container. For convenience, attach a piece of rubber hose to the handle.

After work, the zinc bucket must be emptied of any remaining materials that have been in it during the day. It is important not only to rinse, but also to wipe the inside of the container with a dry cloth. You cannot leave such containers directly on the ground overnight; in extreme cases, place at least a few bricks under the bottom or a piece of wood. It is best to store buckets after work in dry areas.

About galvanized buckets: enameled, stainless steel, iron and aluminum

Metal buckets replaced wooden ones in the everyday life of the Russian people at the turn of the 19th and 20th centuries. Before this period, they were not available to ordinary people because they were expensive. With the development of the metallurgical industry, they supplanted their wooden predecessor and reliably took their position in every person’s home. Despite the fact that plastic buckets have now appeared, the metal bucket has not disappeared from circulation. Moreover, many people prefer a simple galvanized bucket to any shaped or folding plastic bucket.

Let's get started

In order to create a pipe from tin, you do not need any special skills (see video). It is necessary to prepare a sheet of metal about 0.6 millimeters thick, pliers, and scissors for cutting metal. In addition, a hammer and rivets made of steel or aluminum should be ready. The metal sheet should be as smooth and polished as possible, and also have 90-degree angles, as in the photo. To make a pipe on a sheet, you need to present an unfolded sample of the structure with your own hands. This can be done either with any sharp object or with chalk. The width of such a sample should match the size of the pipe cross-section, to which another 1.5 centimeters is added. After the above steps, the workpiece is cut out with metal scissors.

Next, the structure is placed on the work table for manual processing of metal products and a so-called bend line is drawn on one side of it, the width of which should be 0.5 centimeters (see video). The drawn line is aligned with your own hands with the opposite corner of the metal sheet, and its edge is bent with pliers and pressed well. Thus, a pipe made of tin is obtained. The edges of such a pipe can be properly secured using rivets made of steel or aluminum. To do this, you need to make holes in both edges of the tin pipe in increments of about 3 centimeters, as, for example, in the video.

If this page loads slowly, its main images can be opened and viewed in the “Drawings, diagrams, site images” catalogue.

A cap is a cap made of galvanized sheet metal for a brick pillar.

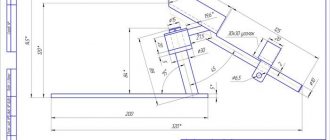

Choose any height “h”, or taking into account the dimensions of the finished pillar. It is sometimes useful to increase the planting dimensions “a” and “b” by 5 - 10 mm, depending on the quality of the masonry. The size “d” can be “estimated” with a tape measure directly on the pole, or calculated using the formula below.

* Place the pattern face up. Drill a hole Ф3.5 mm. Bend the stiffeners (15mm) down almost 90°. Bend all dotted lines at an angle of 90°. The bending of the lines should be done in a sheet bending machine, at least in a homemade one of two corners (it doesn’t take long to do). Then the bend lines will be straight, clear, without dents, and the product will ultimately have an aesthetic appearance. If there is no sheet bender, then bend lines “a” and “b” as usual; bend lines “A” and “B” on a piece of angle No. 50 - 63 fixed on the edge of the workbench with the shelf facing up. To bend plane A or B all at once, or almost all of it, use a 25x45 mm block (picket) 30-40 cm long.

Bend the edges along the lines “d” to the correct rectangular shape of the cap or umbrella. To do this, have a narrow mandrel: a 50mm corner with a cut flange, or a metal strip 1.5-2 mm thick attached to it, or even better, a saw blade.

Check the tight fit of the upper (closing) stiffener rib to the rear (rear) plane of the cap. Check again that the product is not distorted; Use a thin marker to mark the response hole (diameter 3.5 mm); punch, drill, and secure the assembly with a 3.2 mm rivet.

Bend the planes along lines “A” and “B” inside the umbrella (into its place), holding it with your hands between a strip of metal (2 mm thick, 40-45 mm wide, ~30 cm long); and a block (picket) 25×45 mm of suitable length. If necessary, compact this bend with a mallet. If necessary, slightly settle the top of the closing stiffener rib at the top of the cap.

The lower belt of the cap can not be included in the pattern, but can be made separately. From a strip of appropriate length and width, bend a rectangle with dimensions “a” and “b”; bend the sides in its upper part for rigidity and fastening, and place it inside the cap before the final bending of the planes along lines “A” and “B”. If necessary, secure with a 3.2 mm rivet.

When making large caps, divide the pattern into two halves, but not along the angular lines “d”, but along the middles of opposite planes-edges. Connect the halves with two slatted “seams”, installing the slats inside the umbrella, with the front side facing the joint. A folded seam, especially on painted material, can (and will) look sloppy. The lower belt for large caps should be made separately.

Appearance of a cap with a small height

— see the picture of a square umbrella on the “Gas hood” page.

Simplified pole cap

with a brick belt:

For support posts and metal pillars made of profile pipes, they are used in the form of small caps. The plugs are made of thicker metal, usually in the shape of a low pyramid.

For the production of single and double connecting seams, see the “Steel Roofing” page.

The passage unit for the exhaust pipe box in the roof roof.

The box is installed (put on) on a rectangular glass, all sides of which are 3 - 4 mm smaller than the sides of the box. The glass at the angle of the roof slope is riveted with a sheet of the same color as the color of the roof. It is convenient to draw the pattern of the box and installation cup of the cutting on one sheet of tin. With a small height of the structure, the ventilation (or protective, heat-insulating) box can be connected directly to the roofing sheet, i.e. without an intermediate glass.

Mark a rectangular hole on the back (not front) side of the roofing sheet. The dimensions of the sheet should be taken such that, with a sufficient margin (minimum 20 cm), they cover the areas of the roof adjacent to the pipes, and cover the part of the sheet from the ridge side with the roofing sheet from above.

Check the tightness of the glass on the sheet. Mark matching holes Ф3.5 mm for fastening the rear side. Remove the glass and drill holes. Before final installation of the glass on the sheet, apply sealant or any water-freeze-resistant glue under the mounting sides. Secure the rear side with 3.2 mm rivets; then side and front.

The glass and the box (already with an umbrella) are alternately installed (put on) on the exhaust pipes to insulate them heat and moisture and improve their appearance. On the side of the roof ridge in the lower part of the structure, additionally install a corner-breaker in front of it to drain the flowing water, especially if the flow pressure increases on a steep or long slope of the roof.

Square umbrella

and its pattern, a pattern for

a round umbrella

for a pipe with a diameter of 160 mm, is on the “Gas Hood” page.

Umbrella, smokebox, weather vane.

Choose any height of the umbrella. If you cut off small sections in the end parts in their upper corner (along the “K” line), then the “smoke chamber” will have two additional windows for exhaust hood. Close these windows from above with a protruding ridge, the ends of which can be cut off figuratively. Along the level of the same line (“K”) you can make one rectangular window at the top of the entire umbrella, which will have to be protected from above by a second umbrella, but of a smaller size. A weather vane is an umbrella with a weather vane; often a weather vane is a combination of two umbrellas of different sizes and shapes; one of its simpler options is on this one. The pattern of the main (large) part can be divided into two identical parts - along the line of its ridge.

Drill four holes Ø 3.5 mm in two end parts.

Bend all the stiffeners along the lines “d” almost 90°.

Bend the stiffeners 15 mm along lines “A” and “B” by 90°.

Bend the umbrella along the line of the ridge to the corner of the planes.

Bend all lines *60 taking into account the slope of the umbrella planes.

It is advisable to do bending in a sheet bending machine - even a homemade one made from two corners will significantly improve the quality of line bending and the appearance of the product.

Temporarily fix the main part on a flat surface, maintaining dimension “B”.

Place the end piece tightly against the main piece. Mark the counter holes Ø 3.5 mm; drill. Secure the assembly with 3.2 mm rivets.

Make the racks from strips of the same material, folding the strip (width 105-110mm, length about 40cm) twice - that is, in three layers of 35 mm each, WITHOUT SETTING along the fold lines to maintain rigidity.

Marking the holes for attaching the poles to the umbrella:

In calculating the size » y

» Take 3 cm for an umbrella for boxes or belts made of tin, 6 cm for an umbrella for a brick pipe.

Tee for exhaust hood.

Mark and cut a hole in the pattern of the main pipe “D”. The lower drawing shows (as an example) the exact marking of the hole for the entrance d 140 mm to D 150 mm. On the “Gas Exhaust” page there is a drawing of the marking of the inlet hole for a tee connecting a diameter of 120 mm with a pipe of 140 mm; and an outlet with a diameter of 120 mm, as most often used when installing individual gas heating in a private house or apartment.

Marking an inlet hole with a diameter of 140 mm into a pipe with a diameter of 150 mm:

Prepare the folds, “roll” the pipe “D” into the shape of a pipe, but do not connect the folded seam.

Temporarily install the inlet pipe “d” into the folded (but not sealed at the seam) pipe “D”. Align the relative position of the pipes. Draw out the branch pipe “d” (inlet) and cut it along the line of the inlet hole. Along the cut line on the pipe “d”, bend the side 8 - 10 mm wide as shown in the figure. Install the inlet pipe into the tee from the inside of the “unfastened” flow pipe “D”, fasten the folds, check the tightness of the parts. Seal the folded seam, drill matching holes Ø 3.5 mm - secure the assembly with rivets Ø 3.2 mm. If necessary, add any sealing material to the connection line from inside the tee: putty, paint, sealant.

When installing an exhaust from gas equipment, from a heating boiler or from a water heating column, special attention should be paid to the tightness of the connections.

Corners, ventilation and flue outlets.

A simplified method for marking the mating line of branch links is presented, which gives, although approximate, a pattern that is quite applicable in practice. Reducing the number of bend links (angle) increases distortion and the need for adjustment (trimming) during assembly. Precise patterns of bends are constructed using descriptive geometry techniques.

Pattern and marking of the mating line of the links of a three-link bend at 90 degrees.

For the exact (in numbers) marking of the pattern line for an outlet with a diameter of 120 mm, see the “Gas hood” page. The pattern and marking of the connecting line of the links for a five-link 90 degree bend is on the page “Tee, bends, transitions”. Mirror the patterns on the left side of the patterns to the right side.

Connect the marking points into a smooth line, mirror the resulting pattern on the right.

Pattern and approximate marking of the line of conjugation of two links of a right angle:

The drawing shows a ninety-degree right angle pattern for a pipe with a diameter of 100 mm.

Feeder for rabbits.

Pattern for making a bunker-type feeder from galvanized sheet. The drawing shows the dimensions of the parts of a feeder with a capacity of 3.5 liters of dry bulk food.

Assembly with rivets can be replaced by resistance welding or spot soldering.

Drill all the holes in the parts of the first (test) copy. Make cuts along the edges of the fold lines of the back and inner walls. Bend the sides of the fastening 15 mm by 90 degrees. Bend the 25 mm line of the rear wall inward by approximately 135 degrees, giving the shape of a feeder tray. Bend the inner and rear walls to their working positions, using the side walls as a jig. Make sure the holes match. If necessary, correct their location on the parts of the following copies. Connect the inner wall with both side walls using 3.2mm rivets. Place into the back wall and install rivets.

The feeder can be supplemented with a top cover and elements for attaching to the cage.

Drainage funnel, drainage gutter.

Dimensions, shaped edge of the top and artistic elements of the water inlet funnel are at the discretion of the artist. It is useful to increase the width of the strip for cutting each section of the gutter following the water flow by 1 - 2 mm.

Due to the large amount of material, some drawings and drawings have been moved to other pages, in accordance with their topics.

Patterns for a confuser, a diffuser, a transition from a round cross-section to a round of a different diameter (bucket), from a rectangular cross-section to a round, to a rectangular one are located on the page “Drawings, diagrams, site drawings.”

Every residential or even country house or bathhouse that is not connected to a central heating system is equipped with a heat-generating device. To remove the products of fuel combustion in the firebox from the interior, a smoke exhaust duct is connected to them. The most affordable option is a galvanized chimney; in construction stores the price of 1 m of pipe made of this material is about 110 rubles. If you add to this the costs of the rotating elements, deflector and brackets, installation will cost a pretty penny. However, in this article we will tell you how to reduce costs by 60% and how to make a chimney from a steel pipe with your own hands.

The advantage of store-bought models of galvanized steel chimneys is that manufacturers produce a wide range of sizes. In addition, among the factory products you can find double-circuit, thermally insulated, corrugated, with increased flexibility and single-circuit. When making a homemade chimney, you have to limit yourself to only single-circuit pipes. In order for the smoke removal system to work effectively, the following parameters should be taken into account:

Important! A sheet of galvanized steel measuring 2500x125 mm in construction stores costs about 600 rubles, with proper cutting, one sheet produces 8.75 m of pipe with a diameter of 100 mm, the cost of 1 m is approximately 68 rubles, which gives 60% savings!

Tin pipe - making it yourself in 3 steps

Despite the many different tin blanks that are sold in construction supermarkets, sometimes when installing drains, ventilation or other similar engineering systems, it becomes necessary to install parts of a non-standard configuration or size. That’s why many home craftsmen are interested in how to make a pipe from tin with their own hands.

If necessary, you can make a tin pipe yourself

Features of the material used

Before starting work, it is advisable to carefully familiarize yourself with the features of the material from which the pipe is supposed to be constructed. Tin is an ordinary sheet of steel with a thickness of 0.1 to 0.7 mm. It is formed by sequentially rolling the workpiece through the rollers of a rolling mill.

However, the processing does not end there. In order to protect the resulting sheet from corrosion, it must be coated with a layer of another substance that does not oxidize in air.

As a result, the finished product warehouse receives steel sheets, the width of which, according to GOST, can be 51.2-100 cm, coated with an ultra-thin layer of zinc, chromium or tin.

Please note! The material is very plastic, which allows you to process it at home.

On the other hand, when arranging stiffeners, you can get a structure that is not inferior in strength to thicker steel.

Considering that the price of tin is also low, it is often used to manufacture many different parts of complex shapes.

Required Tools

Cutting and bending sheets of tin does not require much effort. However, it would be useful to arm yourself with special tools and devices, the list of which is given in the table.

| Tool | Purpose |

| Metal scissors | Used to cut sheet metal into pieces of the required size. The maximum thickness of the material, as you know, is 0.7 mm, so it is enough to apply only a slight muscular effort. |

| Kiyanka | You can replace it with a rubber hammer, as well as a steel tool with rubber pads that do not leave dents on the tin during use. |

| Pliers | Used to make bends. Can be replaced with pliers. |

| Crafting table | For marking and cutting, it is necessary to place the sheet of tin on a flat surface. It is best to use a carpentry workbench, but cutting can also be done on a floor cleared of large debris. |

| Calibrating elements | Their role is played by a thick-walled steel pipe with a diameter of about 100 mm (or round wood) and a steel corner 75 mm wide. It is secured to the edge of the workbench or clamped in a carpenter's vice. The pipe will be needed to make a longitudinal pipe seam. |

| Marker | Used for marking sheet metal. It is a thin steel rod with a sharp end. |

| Measuring tool | This includes rulers, tape measures, squares and other similar devices. |

Video: making pipes

With the development of the construction market, the need for tin pipes is gradually decreasing. Today they are used more as integral interior decorations (see photo). Tin is a very thin sheet of steel that is susceptible to rust. That is why today, instead of it, galvanized iron is used to make drainpipes, interesting canopies over them, as well as small roofs over chimneys. But there are still areas where this material is still in demand, for example, for the manufacture of pipes for a samovar, cans, containers for paint coatings and chemical products, household products, information signs and more (see photo).

There are several types of tin. So, today it comes in canned or food grade, thin-sheet black, single- and double-rolled, as well as varnished. They first started making it many years ago, and they did it with their own hands. Sheets of material measuring 1 x 1 meter and about 2 millimeters thick were made using large hammers, after which they were left for some time in containers with lactic acid. Since that time, the technology of its manufacture has changed significantly and today special mechanisms are used for this. Making a pipe from such high-quality sheets is not difficult.

Manufacturing

To make a pipe from a sheet of galvanized steel, you will need a rubber or wooden mallet that is heavy enough to bend the metal. In the process of work, scissors are used for cutting metal, a long ruler, a scriber for marking, a corner and a “gun” for bending. The bending process occurs as follows:

Note! The installation of a chimney requires rotating parts, which are made by cutting straight pipes at an angle. If you cut the pipes at an angle of 75 degrees, then when joining, you get a 150-degree turn; if you cut them at an angle of 45 degrees, you get a 90-degree turn. To improve the efficiency of a homemade chimney, it is wrapped in non-flammable thermal insulation material.

Assembly Rules

To properly assemble a chimney made of galvanized steel, you must first mark out the layout and laying of the pipe. Using this drawing, you should determine how many pipes are required and cut them into sections of the required length. Assembly is performed as follows:

Note! The smoke exhaust duct is installed on the roof at a distance of 30-50 cm from the ridge. To ensure the level of traction, the skate should be 50 cm higher. Incorrect placement on the roof can cause backdraft or wind backlash.

Advantages

With the advent of a large number of factory products for assembling galvanized steel chimneys, the need to make pipes with your own hands has decreased. However, homemade pipes allow you to reduce costs and choose the ideal diameter.

In addition, they are used to equip drains, so the ability to make pipes with your own hands will be useful in everyday life. Metal chimneys have the following advantages over others:

- A light weight. Smoke exhaust ducts made from homemade galvanized pipes weigh much less than brick or ceramic ones. Therefore, there is no need to equip a foundation, the cost of pouring which exceeds the cost of material and installation work.

- Fire safety. According to building codes, steel chimneys are completely fire safe. High quality metal can withstand heating up to 900 degrees, so it is suitable even for solid fuel stoves and fireplaces.

- Low cost. Chimney pipes made of steel are the most democratic way to organize smoke removal; the cost of installation is several times lower than the installation of brick and ceramic analogues.

- Easy to assemble. You can easily assemble a chimney made of galvanized steel with your own hands according to the instructions, thereby saving money spent on hiring professional workers.

Important! The effectiveness of smoke removal depends on the correct assembly of the chimney. Experienced craftsmen advise choosing a predominantly vertical configuration with the least number of turns. Each rotating element acts as an obstacle to the smoke, reducing the draft force.