Hazards and safety precautions

- oxygen is not toxic, in itself is not explosive or flammable, but is a strong oxidizing agent and actively supports the combustion of various materials, especially organic and other flammable substances; therefore, for work in contact with oxygen, only materials approved for this purpose should be used;

- when compressed oxygen under a pressure of more than 30 kgf/cm2 comes into contact with fats and oils, their instant oxidation occurs, accompanied by the release of heat, which can lead to their ignition, and under certain conditions, to an explosion; in this regard, when working with oxygen, it is necessary to ensure that cylinders, equipment and personnel clothing do not contain traces of fats and oils;

- substances such as wood, coal, paper, asphalt, etc., saturated with liquid oxygen, can detonate;

- to avoid fires, the oxygen content in the air of working premises should not exceed 23% by volume; rooms in which the volume fraction of oxygen may be exceeded must be equipped with exhaust ventilation and air control means; in such premises it is necessary to limit the presence of people and exclude the presence of flammable substances;

- after being in an environment with a high oxygen content, it is forbidden to approach the fire, smoke, it is necessary to ventilate clothes for 30 minutes;

- liquid oxygen affects the mucous membrane of the eyes, and if it comes into contact with the skin, it causes frostbite to the tissue; sampling of liquefied gas must be carried out wearing protective glasses and gloves;

- cylinders and pipelines intended for transporting oxygen cannot be used for storing and transporting other gases; It is necessary to take measures to prevent contamination of cylinders with oil, their collisions, falls, and they also need to be protected from heating by heat sources and precipitation.

Welding and cutting applications

Oxygen is the most important gas for welding and cutting. When a flammable gas is burned in air, a flame is formed with a temperature of no more than 2000°C, and in technically pure oxygen it can exceed 2500–3000°C. It is this flame temperature that is practically suitable for welding many metals.

Flame processing typically uses oxygen with a volume content of 99.2–99.5% or higher. For non-critical types of gas welding, soldering, surface hardening and other methods of heating with a gas flame, oxygen with a purity of 92–98% can be used.

For welding and cutting, oxygen is used in gaseous form, supplied from a cylinder, a gasification plant (SGU-1, SGU-4, SGU-7K, SGU-8K, GKh-0.75, GKhK-3, etc.) or an autonomous station ( KGSN-150, K-0.15, K-0.4, K-0.5, etc.). With significant volumes of consumption, oxygen is safer and more economically feasible to store and transport in liquid rather than gaseous form, despite the inevitable losses during evaporation of liquefied gas.

The conversion of liquid oxygen into gaseous oxygen is carried out in gasification plants - pumped or pumpless. An example of a pumping installation is the stationary installation SGU-1, designed for gasification of non-supercooled oxygen and filling recipients and cylinders under pressure up to 240 kgf/cm2 (24 MPa).

Along with gas-flame processing processes, oxygen is also used:

- as an auxiliary gas for laser cutting of a number of materials;

- for oxygen cutting with laser beam support;

- as a plasma-forming gas for plasma cutting;

- when cutting with a spear;

- for addition in small quantities to the shielding gas (argon, carbon dioxide) during arc welding of some steels and metals (in order to increase productivity, prevent porosity, etc.).

New reliable and convenient oxygen cylinder!

The new oxygen cylinder is designed for transportation and storage of gaseous substances.

It is worth noting that the new oxygen cylinder is a classic type of chemical element concentrator. Humanity has been using a special container for several decades. Even leading European countries continue to use this type of equipment.

Currently, the Russian market offers a wide range of oxygen equipment for domestic, industrial and clinical use. Scuba divers always use a new oxygen cylinder when diving under water, craftsmen during welding and work, dentists when treating teeth, etc.

The new oxygen cylinder performs a wide range of serious tasks in each of these areas. That is why a number of important requirements apply to its production. This type of cylinders is made from seamless pipes with compression of the neck and bottom.

The grade of alloy and carbon steels can be different. The stronger the material, the more the container can withstand maximum pressure. The design of the vessel includes a special high-pressure valve, which ensures efficient distribution of oxygen.

The owner of the equipment must be aware of the increased explosion and fire hazard of the new oxygen cylinder. In a standard container, the pressure of the chemical element reaches 200 atmospheres.

In order to prevent an emergency, everyone must fulfill a number of requirements.

First of all, the master must take safety courses on the use of specialized equipment of this type. fill a new oxygen cylinder only in official companies that have a profile and all the necessary licenses.

During operation, it is necessary to properly care for the vessels: constantly monitor the level of oil content, and also degrease the surfaces with alcohol.

Domestic and foreign manufacturers of specialized containers provide a high quality guarantee. However, before purchasing such important equipment, the owner should ask to open the new oxygen cylinder to ensure its reliability. The buyer, together with specialists, inspect the inner surface of the cylinder.

In a wide range of products, everyone will find a new oxygen cylinder!

Cylinder parameters

When oxygen oxidizes, it releases a lot of heat into the atmosphere. Excess energy can cause fire or detonation (explosion). Cylinders are a safe vessel that facilitates movement when using a substance. When choosing a container, pay attention to 3 parameters.

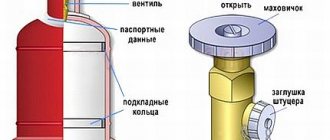

Structure

Structures for oxygen transportation are made using a seamless method from high-alloy or carbon steel grades. The thickness of the walls of the tanks is 6-8 mm. The cylinders are made in the shape of a cylinder with a rounding on one side. The container has a convex bottom. At the bottom there is a shoe made of metal tape, which helps keep the product in an upright position.

In the neck area there is a ring for mounting a safety cap. The device is installed on top of the valve. The element is used to protect against the ingress of explosive components and also protects the gearbox from mechanical damage.

An important additional part of the oxygen cylinder is the valve. The device is made of brass. The alloy of copper and zinc is much superior to other metals in terms of chemical properties. The substance has high resistance to oxidation and corrosion processes, which is necessary when working with gas.

A stamped brass valve is a shut-off part, thanks to which the element is connected to an oxygen cylinder. At the bottom of the body there is a threaded shank for the neck, and on the side there is a fitting for the tube. A valve and a coupling with a seat are screwed between the container and the element, and a copper seal is installed between the components.

When the valve rotates clockwise, the mechanism closes the gas hole. During the reverse movement, the valve rises, opens the well and oxygen begins to escape. The reliability of the equipment is ensured by the mechanical structure of the structure.

According to GOST, cylinders must be painted blue. The name of the gas is written across the tank in black paint. The manufacturer's mark and information about the container are stamped on the upper oval part of the surface:

To ensure that the data is clearly visible, the top is left unpainted. The weight of a standard cylinder varies from 67 to 105 kg. Weight of additional parts – up to 10 kg. The height of forty-liter models is 1.37-1.46 m, fifty-liter models are 1.68-1.76 m.

Pressure

The pressure characteristic is important when refilling oxygen cylinders. Professionals use a special formula that allows them to accurately determine the parameter. The calculations take into account the capacity of a particular model in cubic decimeters.

Types of oxygen

The choice of variety depends on the tasks that the substance must perform. Inexpensive technical raw materials are used for welding and cutting metal. The composition of oxygen must comply with the standards of GOST 5583-48.

The volatile component is produced by low-temperature rectification from air. The gas in the compressor is first compressed, then sharply cooled to room temperature. The result is concentrated liquid oxygen. The substance can be isolated by electrolysis of water.

Additionally, gas is divided into 2 grades, which differ in the proportion of different impurities. The composition of the technical form may contain minor inclusions of compounds and a subtle odor. The characteristics do not affect the operation, so the substance is not purified.

Medical grade is a concentrated version that contains no impurities or extraneous odors. Gas is supplied only in new cylinders, and the composition must fully comply with the standards of GOST 5583-48. Raw materials have a very complex, expensive and labor-intensive production process, which is reflected in the cost.

Medical liquefied oxygen is classified as a medicinal product, so the manufacturer must have a license. Raw materials go through several stages of testing, allowing defects to be detected at any stage. You can distinguish the type from the technical one by the inscription on the cylinder and by the accompanying documentation.

New oxygen cylinder

Oxygen is most abundant on Earth. In the earth's crust (about 47% by mass) it exists in a bound form, in the atmosphere (about 23% by mass) - in a free form.

The main ways to obtain oxygen:

Technical gaseous oxygen , according to GOST 5583-78, is produced in two grades: first and second. The oxygen cylinder is painted blue, with the inscription “Oxygen” in black (PB 10-115-96, GOST 949-73). The nominal pressure of gaseous oxygen in the cylinder and auto-recipient at 20°C (GOST 5583-78) is 150 kgf/cm2 (14.7 MPa) or 200 kgf/cm2 (19.6 MPa).

Characteristics of grades of gaseous technical oxygen (GOST 5583-78)

| Parameter | Technical gaseous oxygen | |

| first class | second class | |

| Volume fraction of oxygen O2, %, not less | 99,7 | 99.5 (in some cases – 99.2) |

| Volume fraction of water vapor, %, no more | 0,007 | 0,009 |

| Volume fraction of hydrogen H2, %, no more (only for oxygen obtained by electrolysis of water) | 0,3 | 0,5 |

| Content of carbon dioxide CO2, carbon monoxide CO, gaseous acids and bases, ozone O3 and other oxidizing gases | Not standardized | |

| Alkali content (only for oxygen produced by electrolysis of water) | A piece of filter paper (moistened with a solution of phenolphthalein diluted with water in a ratio of 1:10) in a glass tube with oxygen passed through (0.1–0.2 dm 3 /min for 8–10 minutes) should not turn red or pink. | |

| Smell | Not standardized | |

Permissible oxygen pressure in cylinders depending on temperature (at a nominal pressure of 150 kgf/cm 2 / 20°C)

| Temperature, °C | -50 | -40 | -30 | -20 | -10 | 0 | +10 | +20 | +30 | +40 | +50 |

| Pressure in the cylinder, kgf/cm 2 | 99 | 107 | 124 | 129,5 | 134,5 | 139,5 | 145 | 150 | 155 | 160 | 172 |

To calculate the volume of oxygen gas in a cylinder in m3 under normal conditions, use the formula (GOST 5583-78):

where K1 is the coefficient, Vb is the capacity of the cylinder in dm 3 (l).

Some values of the coefficient K1 for calculating the volume of oxygen gas under normal conditions

| t of gas in the cylinder, °C | K1 value at excess pressure, kgf/cm 2 (MPa) | |||||||||||

| 140 (13,7) | 145 (14,2) | 150 (14,7) | 155 (15,2) | 160 (15,7) | 165 (16,2) | 170 (16,7) | 175 (17,2) | 180 (17,7) | 185 (18,1) | 190 (18,6) | 195 (19,1) | |

| -50 | 0,232 | 0,242 | 0,251 | 0,260 | 0,269 | 0,278 | 0,286 | 0,296 | 0,303 | 0,311 | 0,319 | 0,327 |

| -40 | 0,212 | 0,221 | 0,229 | 0,236 | 0,245 | 0,253 | 0,260 | 0,269 | 0,275 | 0,284 | 0,290 | 0,298 |

| -30 | 0,195 | 0,202 | 0,211 | 0,217 | 0,225 | 0,232 | 0,239 | 0,248 | 0,253 | 0,261 | 0,267 | 0,274 |

| -20 | 0,182 | 0,188 | 0,195 | 0,202 | 0,209 | 0,215 | 0,222 | 0,229 | 0,235 | 0,242 | 0,248 | 0,255 |

| -10 | 0,171 | 0,177 | 0,183 | 0,189 | 0,195 | 0,202 | 0,208 | 0,214 | 0,220 | 0,226 | 0,232 | 0,238 |

| 0 | 0,161 | 0,167 | 0,172 | 0,179 | 0,184 | 0,190 | 0,196 | 0,201 | 0,207 | 0,213 | 0,219 | 0,224 |

| +10 | 0,153 | 0,158 | 0,163 | 0,169 | 0,174 | 0,180 | 0,185 | 0,191 | 0,196 | 0,201 | 0,206 | 0,211 |

| +20 | 0,145 | 0,150 | 0,156 | 0,160 | 0,166 | 0,171 | 0,176 | 0,181 | 0,186 | 0,191 | 0,196 | 0,201 |

| +30 | 0,139 | 0,143 | 0,148 | 0,153 | 0,158 | 0,163 | 0,168 | 0,173 | 0,177 | 0,182 | 0,187 | 0,192 |

| +40 | 0,133 | 0,137 | 0,142 | 0,147 | 0,151 | 0,156 | 0,160 | 0,165 | 0,170 | 0,174 | 0,178 | 0,183 |

| +50 | 0,127 | 0,132 | 0,136 | 0,141 | 0,145 | 0,149 | 0,154 | 0,158 | 0,163 | 0,167 | 0,171 | 0,175 |

Thus, a new cylinder (150 kgf/cm2 at 20°C) with a volume of 40 liters contains 6.24 m3 of oxygen under normal conditions.

Liquid technical oxygen , according to GOST 6331-78, is also produced in first and second grades. It is stored and transported in Dewar flasks, as well as in other cryogenic reservoirs (tanks).

Characteristics of brands of liquid technical oxygen (GOST 6331-78)

When 1 liter of liquid oxygen evaporates, about 860 liters of gaseous oxygen are formed (at normal atmospheric pressure and temperature 20°C). When transporting liquid oxygen, the container weight per 1 kg of oxygen is 10 or more times less than when transporting gaseous oxygen. During storage, transportation and gasification of liquefied gas, losses due to its evaporation are inevitable.

Terms of use

Oxygen is a dangerous gas that can explode upon contact with fire or oil. The sealed container protects the raw material from contact with unfavorable conditions, but trouble can arise if it falls or is heated by the sun's rays. There are recommendations to keep people safe when using volatile substances.

Welding

Oxygen is prohibited from combining with asphalt and coal, wood and paper. Materials saturated with concentrated compressed liquid can detonate. After working with the substance, you need to ventilate your clothes for half an hour.

Combustible and flammable components are located at least 5-10 m from the gas container. For safety reasons, the tank is placed in a vertical position. Before connecting, degrease the cylinders with a rag. The structure is connected firmly and steadily, otherwise the structure will collapse.

If the valve is frozen, it is forbidden to warm it up with fire. It is better to keep the tank in a warm room or use hot water. The cap is easier to remove with a key, but some models can be unscrewed by hand. When moving, try not to make sudden jerks, otherwise fire may occur.

When inspecting the surface of the locking part, pay attention to dents and scratches. It is prohibited to operate equipment with damaged containers or with expired expiration dates. If accidentally ingested, the ingredients can burn the mucous membranes of the eyes and freeze the skin. Work with the substance is carried out wearing protective gloves and a mask.

Refueling

Reliability and safety of operation of the tank depends on correct filling. The substance enters the station in liquid form and enters the cylinders in gas form. The procedure is carried out through a valve to which a pipe is hermetically connected. One end is connected to the base, the other to the container.

The connecting parts are screwed tightly, but not pinched. Be sure to ensure the tightness of the connection. The tap is carefully opened until a characteristic hissing sound occurs. The cessation of noise is a sign that the container is full.

Injection for large tanks is carried out using a pump; small vessels can be pumped without additional equipment. The pressure in a full oxygen cylinder is reduced by a reducer, otherwise the structure may break. Upon completion of the procedure, the valve is screwed in and the pipe is unscrewed.

How to store and move

The storage of gas tanks is prescribed in GOST 26460. The room must have electricity, heating and exhaust ventilation. It is prohibited to place other gases, flammable ingredients and heating devices near the substance. The building is located away from industrial buildings. The tanks are kept in metal boxes with holes, away from the direct sun.

To move oxygen cylinders, special equipment (stretchers, carts) is used. Containers are prohibited from being carried on the arms (shoulders). When transporting over long distances, you need a car with a cargo compartment. The tanks are laid horizontally in cells; felt is used for compaction and protection against collisions. If events take place in the heat, the structure is hidden under a tarpaulin.

The empty container is marked with chalk with the word “Empty” and the cap and plug are closed. Oxygen from the cylinders cannot be completely consumed, so a little substance is left under a pressure of 0.5 kg/cm2. The residues are needed for laboratory analysis of gas composition at a gas station. If the information matches the data from the previous procedure, then there is no need to flush the equipment.

OIL HAZARDOUS.

Storage and transportation of oxygen.

Packaging and storage of oxygen is carried out in accordance with the requirements of GOST 26460. All types of transport, including pipelines, are used to transport technical and medical oxygen. Transportation and storage of gaseous oxygen is carried out in metal oxygen cylinders manufactured in accordance with GOST 949-73. Oxygen cylinders are blue in color and have the word “oxygen” written in white. At an ambient temperature of +20 C°, the gas pressure in the oxygen cylinder should not be higher than 14.7 MPa (150 kgf/cm²) - in accordance with the requirements of GOST 949-73, according to which oxygen cylinders are produced. In the case of oxygen transportation through a pipeline, the oxygen pressure in the pipeline is agreed upon between the supplier and the consumer.

Safety requirements.

Oxygen in cylinders is not a toxic, flammable or explosive gas. Oxygen in cylinders is a strong oxidizing agent that can cause ignition of some materials upon direct contact or increased concentration in the room, which should not exceed 23%. Before inspecting oxygen cylinders or pipelines, purging is performed with ordinary atmospheric air (to reduce the oxygen concentration). Repair of oxygen cylinders or pipelines is also carried out with preliminary purging. When in rooms with high oxygen concentrations (more than 23%), it is strictly forbidden to smoke, turn on heating electrical appliances, or have an open flame, because this contributes to a fire. Premises with high oxygen concentrations must be equipped with ventilation equipment and fire extinguishing equipment. It should be remembered that oxygen cylinders are not intended for storage or transportation of other gases! To maintain product quality, the oxygen cylinder or pipeline must be clean inside and free of foreign contaminants (dust, sand, etc.). When transporting and carrying out loading and unloading operations, the possibility of falling or impact of oxygen cylinders should be excluded. During storage of oxygen cylinders, they must be protected from exposure to direct sunlight, because an increase in temperature increases the gas pressure inside the cylinder. If the gas pressure in the oxygen cylinder is high, the cylinder should be cooled with water.

Rules for oxygen intake.

The sale and delivery of oxygen to the consumer is carried out in batches. The oxygen delivery batch can be any one, with an accompanying quality document.

Rules for returning oxygen cylinders to the supplier.

practices leasing of gas cylinders of various types. When returning a gas cylinder, the consumer must ensure that the residual pressure in the empty oxygen cylinder is not lower than 0.05 MPa (0.5 kgf/cm²).

Dependence of oxygen pressure on temperature during filling, transportation and storage of cylinders

| Temperature, ºС | Working pressure, MPa (kgf/cm²) | Gas pressure at filling temperature, MPa (kgf/cm²) |

| -50 | 9,7 (99) | 12,4 (127) |

| -40 | 10,5 (107) | 13,5 (137) |

| -30 | 11,2 (114) | 14,5 (148) |

| -20 | 11,9 (121) | 15,5 (158) |

| -10 | 12,6 (128) | 16,6 (169) |

| -50 | 9,7 (99) | 12,4 (127) |

| 0 | 13,3 (136) | 17,7 (179) |

| 10 | 14,0 (143) | 18,6 (190) |

| 20 | 14,7 (150) | 19,6 (200) |

| 30 | 15,4 (157) | 20,6 (210) |

Note:

When filling cylinders, as well as storing or transporting filled cylinders at temperatures exceeding those indicated in the table, the gas pressure in the cylinder should not exceed:

Sale and delivery of gas cylinders with oxygen.

supplies enterprises (of various profiles) with technical gases: nitrogen, argon, acetylene, gas mixtures, helium grade “A” and helium grade “B”, technical oxygen, propane, as well as carbon dioxide. In addition to the supply of technical gases, the company specializes in the sale of gas cylinders produced in accordance with GOST 949-73 and GOST 15860-84 (for propane). Among the additional

Source

Oxygen in cylinders

You can buy oxygen in cylinders of 40 liters and on request 5, 10 and 20 liters, fill the cylinders with oxygen, and also buy liquid oxygen.

Oxygen is the most popular technical gas that is required in many industries including metallurgy, food industry, medicine, cosmetology and many others. It is necessary for oxidative processes and without it the combustion process is impossible.

This gas, heavier than air, has neither color nor odor. It is also very important that it is non-toxic, which means it is safe for humans and the environment. However, high concentrations of oxygen cause some chemical materials to ignite.

Requires a high production culture.