If you have ever used a portable burner with piezo ignition, then you have probably encountered the problem of such a device breaking down. Agree, it would be somewhat inappropriate to throw away an almost new burner due to a malfunction that you can fix yourself.

In order not to spend “extra” money on repairs, for which the technician will demand the cost of the device, you should figure out how to repair a gas burner with piezo ignition with your own hands, and not spend a penny from the family budget.

A gas burner can stop working for completely different reasons, ranging from water or dirt getting inside the mechanism, and ending with a breakdown of the piezo ignition itself. Further in the article, you will become familiar with the main causes of burner malfunction, and learn how to disassemble the mechanism yourself and repair it without the help of an experienced technician.

Using a gas burner with piezo ignition

The classic burner with piezo ignition is especially popular among tourists who willingly use such a simple device as an alternative to a fire.

With its help, you can quickly boil water or cook food, and unlike a fire, the device allows you to regulate the strength of the flame, and at the same time, control gas consumption. In addition, modern portable burners are equipped with a windproof function, a holder for utensils and other “devices”.

This burner with piezo ignition is also actively used in dachas, where there is no need to supply gas to the house. The device will greatly simplify your task of cooking, for which even a small gas canister will be enough for you. In addition, gas burners are often used for soldering and heating metal parts.

The popularity of burners with piezo ignition is quite justified, since the user does not have to worry about the presence of matches, but only until the device breaks. It is the presence of piezo ignition - an additionally inserted element that produces a spark - that often causes the problem of frequent breakdowns of the gas burner.

Diagnostics of a gas burner with piezo ignition

Often the reason for the malfunction of such a device lies in the breakdown of the piezoelectric element, after replacing which the burner works again without any problems.

However, in some cases, the operation of the device can be restored by simply cleaning the nozzle or sprayer, which can become clogged from time to time, as a result of which the gas in the burner simply does not ignite.

The cost of repairing a gas burner with piezo ignition can be equal to the cost of a new device, so there is no more profitable option than fixing it yourself. To identify the cause of the breakdown, you will need to diagnose the gas burner, during which you can understand why it stopped working.

When disassembling the burner, special attention should be paid to whether a spark appears when you press the button. The presence of a spark indicates the serviceability of the piezoelectric element, which means that the cause of the device failure lies in the contamination of individual parts of the burner.

If, even though there is a spark, the burner still does not ignite, then most likely the problem is that dirt has gotten inside the atomizer - a small hole through which gas enters.

Often, a gas burner can leak gas into a can, which indicates wear of one of the rubber gaskets inside the device. Also, the device may not work due to contamination of the mesh on the back of the sprayer. In this case, it is recommended to wash this element with alcohol or gasoline.

If the piezoelectric element is in good condition, a spark will be supplied, but due to oxidation of the wire through which it is supplied, the gas may not be ignited. If the wire insulation has melted, then you will need to clean it with a file or sandpaper, and, in general, the problem will be solved.

It is important to understand that the absence of a spark means only one thing - the piezoelectric element has failed, which means it requires urgent replacement. You can do this yourself, relying on simple instructions, and you don’t even have to look for a long time for a new piece.

Instructions for replacing the piezoelectric element

Despite the external differences of many burners, everything inside is arranged according to the same principle, and all parts have standard sizes, which makes it easy to choose a replacement for a broken element. Since the piezoelectric element is the most vulnerable part of the device, it is not at all surprising that in most cases it is its breakdown that causes the entire burner to stop working.

The piezoelectric element can fail either as a result of a strong impact or as a result of water or any other liquid entering the burner. To replace the piezo element, you will need to prepare all the necessary bits for the screwdriver, a new lighter from which the new piezo element will be removed, as well as heat shrink to connect the two wires.

First of all, you should make sure that the piezo is malfunctioning, which you will be “notified” by the absence of a spark when you press the button. Next, we disassemble the burner body using a screwdriver and the corresponding bits, which are included in any set of attachments. At the same time, we check all burner parts for contamination and, if necessary, clean them.

Overview of market offers

Gas-air burners are the safest of their kind. Easy to use, lightweight and creates a flame of sufficiently high power. But the modern market also offers more standard options that work without oxygen. Choose the one you feel most comfortable working with:

GG-2U: comfortable and light

GG-2S: against strong winds

And this is already professional equipment. This burner runs on propane and differs from previous models in that it works great in strong winds. The whole secret is in its structure - two valves and two housings, with which it is easy to precisely regulate the operating mode.

GGS1-1.7: universal option

This model is considered universal in the construction world due to its light weight, size and high level of performance. It is convenient for drying roofs and fusing soft materials. If necessary, it is easy to create an intense flame of up to 400°C, which is especially valuable in repair work. But such a burner can only be used on horizontal sections of the roof.

GGK-1: for precision repairs

This model features a heavier and more durable glass for burning old paint and waterproofing the roof. Perhaps this is the most convenient model for roof repair, especially since gas is supplied to it using a lever.

GGS 1-1.0 burners are well suited for minor work, especially repairing junctions, but can also be used for laying waterproofing. But the GGS-1-0.5 series pleases with economical fuel consumption.

GGS-4-1.0: four bells

And for professional installation of roofing materials, the GGS-4-1.0 model is used, which is equipped with four sockets at once and can heat the entire roll at once - all that remains is to quickly roll it out. Significant savings of time and effort! Moreover, it is easy for even one person to cope with such work, but for the repair of just one or two roofs of private houses there is no point in purchasing such equipment.

GV-3: for repairing metal roofing

This propane torch is specially designed for heating metals and manually soldering them, its glass is only 50 mm in diameter.

GV-111R: for stripping

Another popular gas burner is GV-111R. It is especially convenient for repairing roofs with old paint that needs to be removed, and for melting rolled bitumen materials.

GV-550: for junctions

This model is more suitable than any other for repairing roof junction points. The maximum heating of bitumen using this tool is 300°C.

GV-900: heavy fire

The most convenient sample, which gives a maximum flame length of up to 900 mm. You can work while standing, at full height, which is comfortable for daily tasks.

GV-850: fine adjustment

This propane torch is equipped with a special valve, which makes it possible to precisely regulate the amount of gas and the length of the flame using a lever. But such a burner does not operate on gas alone—technical oxygen is necessarily used here.

GGS2-1.5: parallel sockets

This burner is equipped with two parallel high-output sockets.

And finally, let's talk separately about homemade burners, which today are also often used in roof repairs.

SIEVERT: modern version

Other gas burner malfunctions

Breakage of the piezoelectric element is a fairly common problem, but far from the main one. As a result of frequent use of the device, other interruptions in its operation may occur, but the piezo ignition function will be fully operational.

To understand the cause of the malfunction of the gas burner, you will need to completely disassemble it and inspect each part of the structure.

Often the burner does not ignite due to contamination of the nozzle, which occurs as a result of filling the cylinder with low-quality gas. That is, the gas simply does not enter the burner, which is why it does not ignite. In this case, you can clean the nozzle in several ways, which you will learn about later in the article.

Another reason for the gas burner to stop working is the ring falling out inside the nozzle, as a result of which the spark will not fly to the ring, but in different directions, which means that ignition will not occur. If the ring is lost during operation, then the only correct solution would be to make a replacement, for example, from simple copper wire.

Nozzle contamination - how to eliminate it?

The gas burner nozzle may become clogged due to the presence of dirt impurities in the regular gas that we use to refill the can.

To clean the nozzle - a small hole on the burner, it is quite difficult to find a suitable wire or needle, which means that it will not be possible to mechanically clean the nozzle.

If you can find a wire thin enough to clean such a small hole, you can quickly remove the contamination.

Professional craftsmen recommend cleaning the burner nozzle in the following ways:

- Blow the debris back out . Remove the nozzle and firmly press it with the side with the hole against the valve of the gas cylinder. If the contamination is not serious, then it is likely that under gas pressure the dirt can be blown back out.

- Clear the blockage by heating the nozzle . We attach a strong wire to the removed nozzle, and using a second gas burner, heat it red-hot, and then lower the element into the water. The method is quite radical, since heating the part can lead to its destruction.

In this case, it would be more advisable to resort to mechanical cleaning of the nozzle. The ideal option is to choose a wire of a suitable diameter, preferably with a pointed end. This is the easiest and safest way to eliminate contamination without damaging the structure.

How to replace the nozzle ring?

As a result of prolonged use of the burner, the ring heats up at high temperatures, and after some time it simply falls out.

In order not to look for a suitable ring, and especially not to spend money on buying a new burner, you can make a homemade replacement for such a ring.

Let's take a wire with a cross-section of 2.5 mm and bend a ring of the required diameter, having previously separated the required piece of material. As for the material, in this case it is recommended to use copper wire, although the original material of the ring is brass.

Making a brass ring will cost you more than buying a new burner, so the best option is a homemade copper ring.

There is only one way to distinguish this breakdown from a clogged nozzle - try to light the burner with matches. If the burner ignites, it means that the problem is not in the nozzle being dirty, in which gas does not enter the burner at all, and accordingly, it is impossible to light it.

Work safety

The main traumatic factor when using and setting up a burner is temperature.

Gas, even household gas, is also dangerous, as evidenced by accidents involving explosions or poisoning.

The power of a propane torch depends on the diameter of the injector and nozzle . We must remember: it is not the gas itself that burns, but its mixture with air (oxygen).

The larger the volume that reacts, the stronger the torch. At the same time, the danger of getting a dangerous proportion of propane with air in the injection chamber increases, and as a result, a small explosion - cotton.

Therefore, a homemade burner does not need to be too large. As a rule, the injector diameter does not exceed 3-5 cm, and the nozzle opening is 0.5 mm.

Important! Work in a ventilated area or outdoors. Use gloves to protect your hands.

How to avoid burner failure?

Since the most common reason for a gas burner with piezo ignition to stop working is the breakdown of its most important element - the piezo, it is important to take care of its safety.

Do not damage the device or allow water to get inside the burner, especially if you are going camping. At best, you will have to light the gas burner with matches, unless you remember to take them with you.

Even if the piezoelectric element is damaged in some way, you should not be upset, because today there are many autonomous piezoelectric ignition devices on sale. That is, it is the same piece, only portable.

So, you don’t have to unscrew the gas burner every time to put on a new piezo ignition, and such a portable piezo ignition will definitely come in handy not only outdoors, but also at home.

Do not forget that the cause of the malfunction may be simple contamination of the nozzle or a slipped ring, therefore, to identify the cause of the breakdown, it is important to conduct a thorough diagnosis of the device. If the piezo is working properly, you just need to try to ignite the burner to understand which part caused the burner to malfunction.

Which is better quality: professional or budget?

So, professional contractors purchase usually expensive professional gas burners that are reliable and safe to use. But for a home craftsman, a small, convenient tool without any additional pretensions will be suitable for equipping and repairing the roof of your own home. Will the quality of work be worse? Not at all! It’s just that such a gas burner is not suitable for industrial work, where it is used almost every day and where uninterrupted processes and absolute safety come first.

It is also not acceptable to have a situation where a team goes to a new facility (and, of course, deadlines are definitely running out), and the burner is defective. There is neither time nor reserve to stop everything and go out to purchase new equipment. Whereas, with careful handling in the hands of a home craftsman, even the most Chinese unit will serve faithfully for decades. Especially if you use it no more than once a season.

And in the end, when working with a massive professional burner or with a regular one, you will get the same result. But no matter how expensive and professional the gas burner is, before each use, be sure to check its connecting hose, the tightness of the connections and the clogging of the mouthpiece. Such problems do not occur often, but if you miss a defect, there is a risk of serious consequences.

Although, if you have an idea to buy the cheapest “lighter” (how much does it cost to cover a garage roof?), then we will hasten to dissuade you. The fact is that if a gas burner has a weak gearbox, then the fire will be no more useful than the same blowtorch. The work will proceed extremely slowly - while you heat one part of the sheet, the second will already have time to cool down. As a result, you will simply have to remove the gearbox and work without it at your own peril and risk.

Conclusions and useful video on the topic

The reasons for the breakdown of a gas burner with piezo ignition are described in more detail in this video:

A visual process of replacing the piezoelectric element of a gas burner is presented in the following video:

The breakdown of a gas burner with piezo ignition becomes a real problem if you go camping, and this device is the only source of fire for heating water and cooking. In this case, you should play it safe and take matches with you, since malfunction of the piezoelectric element in such burners is not uncommon.

If you have previously had to repair a gas burner yourself, please tell us what caused the device to break down and what difficulties you encountered during the repair process. Immediately after the article, you can leave a comment in which you can share your experience of independently repairing a burner with piezo ignition.

Rules for safe operation

Working with flammable materials and open flames is always associated with risk, so when using even a simple hand-held device, you must follow safety rules.

Overheating of the cylinder, which can be caused by the proximity of a heat source, for example, a fire or stove, is unacceptable. The canister may explode and cause injury due to the sharp edges of the torn casing. It is also not recommended to leave it in the sun.

Professional devices that are usually used for a long time require special care. Suppose, in order to preserve the functions of the burner and the power of the torch, after prolonged operation the device is packaged in a catalytic heating pad.

An overview of the best gas-air burners, as well as additional recommendations for choosing a suitable device, are presented in this article.

Mini soldering torches

1st place – mini gas burner with soldering attachment

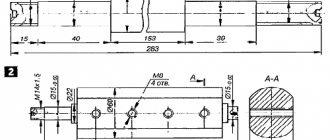

Designed for both heating medium-sized parts and for contact soldering due to the heating of the tip from the flame. A kind of soldering iron without wires. The gas tank capacity is 8ml. The flame temperature when filling with butane reaches 1300 degrees Celsius, and the tip temperature – 450 degrees. The flame length is adjustable from 4 to 6 cm. The burner length is 13 cm and the diameter is 1.5 cm.

small and inexpensive, the refill is enough to solder several medium-sized parts, there is a nozzle for contact soldering, it is easy to refill.

2nd place – gas micro burner

There is nothing in it except a tank with a filling valve and a nozzle with a gas supply regulator. The ZC57100 does not have piezo ignition and it is supplied unfilled, so you will also have to buy a gas cartridge - it will be suitable for lighters. In general, to solder two wires or heat heat shrink without a soldering iron, such a torch is enough. The burner is also about 20 cm long and weighs 43 g.

This is the cheapest burner that can be found and the price of such a micro burner is 200 rubles.

the cheapest, easy to refill.

small flame, the filling runs out quickly, there is no piezo ignition.

3rd place – mini gas soldering iron KVT XZ-1

This remarkable soldering iron from the gas powered brand features piezo ignition and comes in a case with a set of 4 soldering tips, a spool of solder, and a tip cleaning sponge. Thus, the declared power of the soldering iron for contact soldering is 137 W - this is a lot for a soldering iron with a length of 21 cm and a weight of 120 g. Electric soldering irons have never dreamed of such weight and size characteristics. This soldering iron is not positioned as a torch, but it can be used as a torch - the flame is pencil-type.

This soldering iron is good for everyone, except for the price of 2300 rubles, which is why it landed in 3rd place.

burner from a famous brand, easy to solder, set of components, good case, high heat output.

4th place – gas burner IRIS BARCELONA

This torch is not only designed for soldering, welding, repairing electronic devices and jewelry. The flame of this burner is of course adjustable. Can be charged with a standard lighter gas cylinder. The flame length reaches 3 cm. The operating time is about 20 minutes. The flame temperature reaches 1300 degrees Celsius. The length of the burner itself is exactly 20 cm.

small size, piezo ignition, brand.

The length of the flame does not allow heating medium and large parts.

5th place – butane burner KVT X-220

It is positioned as a burner for construction and repair work. She looks very stylish. The knurled handle fits nicely in the hand. Has a piezoelectric flame ignition system. The capacity of the cylinder for highly purified butane is 22 ml. This amount of gas is enough for 110 minutes of continuous operation. The flame length is adjustable from 30 to 80 mm from a sharp wedge-shaped flame to a soft flame with yellow tongues. The weight was only 226 grams with a length of 14 cm.

a good option for desktop work, there is a stand, piezo ignition, and a comfortable handle.

It's bulky, you can't put it in your pocket, you can't fit it into a narrow place.

Choosing a torch for roofing work

The main operational characteristics of gas burners for roofing work are:

- Propane consumption, kg/h.

- Thermal power of the burner, kW.

- Limits of torch length adjustment, mm.

- The largest heating width of roofing felt or other material used for laying soft roofing.

- Nominal surface heating temperature, ºС.

- Specific fuel consumption per unit of covered surface, kg/m2.

- Burner weight, kg.

The parameters are selected for ease of use. For example, a burner that weighs more than 1.5...2 kg is simply inconvenient to work for a long time. The length of the torch is determined in the same way. Usually this parameter is taken within the range of 300...900 mm, and in the latter case the burner can be operated while standing.

A number of characteristics depend on the heat capacity of the soft roofing material. In particular, for roofing felt to be ready, temperatures of 160…180ºС are required, and for surfaced materials – 300…350ºС.

For the productivity of the process, the relationship between the thermal power of the burner W (indicated in the product passport) and gas flow V (this parameter is important for propane cylinders) is important. To calculate, you can use the dependence

Q = 12.88 kWh/kg – calorific value of propane;

n is the number of nozzles/sockets through which the burning gas-air mixture is directed to the heated (or melted) roofing material;

η = 0.8…0.91 – efficiency of the heating process (with an increase in the number of nozzles, the efficiency decreases).

The most popular models of gas burners for roofing are:

GV-850. It has a control valve for gas supply; the length of the torch is easily controlled using a lever. The power of the burner allows it to be used effectively also for heating metal-plastic pipes and for preparing copper alloys for welding or soldering. Price – 1700...2200 rubles;

GGS-1-1.7. It is popular due to the high heating temperatures achieved, simplicity and reliability of the design. Price - 2000...2200 rub. A version of the same device, but with 4 bells and a roller, will cost 12,000...12,500 rubles;

Torches for soldering with gas from a can

6th place – metal burner for a spray can

A very simple and narrow burner that fits onto a gas canister. The regulator and narrow nozzle allows you to get to the right parts in narrow places. There is no piezo ignition, but everything looks high quality - there is metal all around and a large gas supply regulator. A butane cylinder allows you to get a temperature of about 1300 degrees Celsius from this burner.

a lot of metal, narrow nozzle.

7th place - a standard burner that fits onto a can

Positioned as a burner for tourists and cooking: barbecue, cakes, sushi, etc. Of course, it can be used for soldering, cutting and welding metals. Piezo ignition and flame regulator are present. The burner works classically with butane. The body is made of plastic, the nozzle casing is made of stainless steel.

well suited for cooking, has piezo ignition.

The body is made of plastic, so you need to be careful not to break it.

8th place – canister burner with a wide nozzle

The brass burner does not have piezo ignition, but it can fry barbecues and massive metal parts well. Orange Adjuster allows you to easily change the flame length. Butane from a cylinder heats the flame to 1300 degrees.

Well suited for cooking and massive parts.

High temperature lamps

- There are devices where MAPP gas is used instead of a propane-butane mixture. The flame temperature in these devices is 2200−2400°C. The main energy is concentrated in a cone, which is quite stable and has a pronounced boundary.

- Such products are used for heating, bending and forging massive parts and high-carbon steels. High temperature allows for better tempering and hardening of metal.

- As for welding and soldering, MAPP gas devices do an excellent job with stainless steel, and even thin parts do not overheat. Another advantage of MAPP is its low boiling point, which allows it to be used at temperatures of -20°C even in products without a heating circuit.

Large torches for brazing and dual gas welding

9th place – popular mini burner for jewelry work

Can be used with two gases - acetylene + oxygen or hydrogen + oxygen. It has convenient flexible hoses and gas supply regulators directly on the burner. There are replaceable nozzles for different flame intensities. You may have to purchase additional adapters for cylinders or pressure regulators.

Convenient to hold in your hand, convenient twists, availability of replaceable attachments.

You need to take care of the thin hoses so that they do not poison the gas.

10th place - oxygen-acetylene burner with two gas mixture supply knobs

It has a long curved tube with a nozzle at the end. These torches are designed for cutting and welding metal. The increased combustion temperature makes it possible to weld ferrous metals with a weld thickness from 0.5 to 0.2 mm. Burners are available from 30 cm to 45 cm in length.

- Racks for winter fishing rods

- Stands for jigs

- Nod stands

- Ice auger stands

- Float stands

- Reel stands

- Stands for landing nets

- Tube stands

- Rod stands

- Motor racks

- Download catalog

- About company

- Wholesalers

- Franchise

- Contacts

February 26, 2016

A gas burner with piezo ignition for a cylinder is a practical tool to use, the presence of which can significantly make your life easier. This tool can be used both in small household chores and in the kit of a prudent tourist.

Features of choosing a compact device

Before buying a gas burner, you need to decide on its purpose - for repairs, soldering parts, tourism, cooking. The choice of model depends on the tasks that the device will have to cope with

And here it is important to understand the differences between burner types

Varieties of popular devices

There are 4 main designs: “lighters” screwed onto a cylinder, with a fuel hose, blowtorches. There are also integrated cooking systems, but they are difficult to classify as mini. These devices are large in size and weight, expensive, and can only be used with original cookware.

Type #1 – portable torch lighter

The smallest “lighters” are convenient for household purposes and minor repairs. Some models produce more power and can be used for soldering.

Type #2 – balloon type mini-burner

Compact cylinder burners are convenient and light in weight - most devices fit in your hand and fall in the weight range of 70-90 g. They are easy to use, inexpensive, and relatively reliable.

The cylinder itself cannot be forcibly heated, so such burners are not entirely suitable for use in difficult weather conditions.

Another nuance is that the lightness of the design does not allow you to place large-capacity dishes (from 3 liters) on it. But for some models branded adapters are sold: hoses, additional legs.

The rating of the best gas burners for a can is presented in this review.

Type #3 – device with remote hose

But devices with a hose perform well in bad weather conditions. You can place bulky or heavy dishes on them. Fuel consumption in such burners is minimal.

A continuous wind shield can be installed around the burner with a hose, which will increase work efficiency. The design itself is distinguished by the wide setting of the legs and squatness. The permissible volume of dishes is up to 8 liters.

Often in such devices the nozzle itself is larger than that of the bulbs. Due to this, the dishes are heated evenly, and the flame power is conveniently regulated. The burner allows you not only to heat water, but also to fry and stew food.

Devices with a hose also have their disadvantages. They are heavier and larger in size. The hose requires careful operation; the part may break and lead to a gas leak.

Type #4 – blowtorch

Portable blowtorches are designed for the application of machining connections made of ferrous and non-ferrous metals. They are found in piping systems, electrical appliances, cables, and car parts. These also include torches for soldering copper pipes.

The characteristics indicate the flame temperature and power. A device whose flame heats up to 1200-1500°C can cope with parts up to 3 mm thick. A power of 2-3 kW is enough to heat and bend reinforcement up to 14 mm.

The scope of application of such devices is not limited to soldering. They do an excellent job of lighting a fire, working in a summer cottage (removing leaves, getting rid of insect colonies), wood burning, and culinary experiments.

Method of connection to the cylinder used

Most models on the market are adapted for threaded cylinders. But purchasing them in remote settlements is problematic.

If the hike will take place in such areas, you need to very accurately calculate the required amount of gas or additionally buy an adapter for a collet one.

Collet cylinders are also called “dichlorphos”. They are sold at almost any hardware store. But the seam design is less reliable, and the gas mixture is sensitive to low temperatures.

There is also a third type of cylinders on the Russian market - without threads with a bayonet mount. But they are represented only by the Campingaz brand and are not as widespread as abroad.

There are models adapted for use in conjunction with a threaded and bayonet standard.

Additional device options

The presence of piezo ignition is a useful addition, but it is still worth having a backup fire source with you. For some models, this element quickly becomes unusable.

If your camping burner is missing a grate, a protective cover on your computer fan can easily replace it. It is lightweight and does the job perfectly.

When choosing a device for delicate work, welding, soldering, you should pay attention to the ergonomics and balancing of the model. The shape of the body and the arrangement of the elements matter, because the burner will have to be turned on and off frequently. It’s convenient if you can do it with one hand

It is convenient if this can be done with one hand.

Soldering tool

A gas heater with piezo ignition is a compact and mobile alternative to a hair dryer. To operate, it does not require a connection to wires; the fuel source is a gas cylinder; in this case, a burner with piezo ignition significantly bypasses a construction hair dryer, which is less convenient to use due to the need to connect wires, which are not always convenient to pull.

Application of gas burner:

The gas temperature during combustion reaches 1300–1800°C. The tool is easy to use with one hand.

DIY repair

Like any other tool, a gas burner can fail over time. This problem can be caused by the following reasons:

- nozzle clogged with debris;

- divider clogged with dirt;

- melting of parts;

- hose damage;

- damage to gaskets;

- mechanical deformation.

Before you start repairing your device, you should prepare some tools:

- equipment for dismantling burner parts;

- a thin needle or wire necessary to clean the nozzle;

- a towel or film for covering the surface.

To learn how to properly use a gas burner, watch the following video.

Manual gas burner with piezo ignition

This model of gas burner is a replacement stove for lovers of outdoor activities. This item is indispensable for camping fans. Of course, you can try to challenge this fact by citing the classic example of making a fire. But in order to prepare soup or porridge, it is necessary not only to collect firewood, but also to wait until it burns out a little. For long-distance hikes, this is a significant waste of time; for resting at a rest stop, you can limit yourself to a short break. Another significant bonus is that in bad weather and in the pouring rain you can’t dream of a fire, but nothing prevents you from hiding under the crown of a tree and warming up with hot tea or porridge cooked on a gas burner. Piezo ignition eliminates the need to look for matches or a lighter, gas is consumed economically and one cylinder lasts for a long time.

Advice! If you take a gas burner on a hike, make sure to store the cylinder; do not expose it to direct sunlight; overheating in the sun will cause the cylinder to explode. When putting it in your backpack, it is better to place the cylinder in the middle so that it is reliably protected from high temperatures. The gas is also sensitive to low temperatures; burners operate properly at temperatures down to -20. For more severe temperatures, it is necessary to purchase a cylinder of a gas mixture that is not sensitive to cold.

For gas burners, odorless liquefied gas is used, this adds a certain specificity to the use of the tool. Firstly, when using a burner, you should not turn it over or tilt it too much; the flame may get lost and lose its static properties and become uneven. Secondly, you need to be careful when using cylinders. If there is a malfunction, a gas leak may occur, which cannot be felt due to the lack of odor. You can check the cylinder for leaks using a soap solution; you can also immerse the cylinder in water for testing.

Which is safer: compact or large?

At first glance, it seems that hauling a gas cylinder onto the roof is the most dangerous undertaking. Moreover, today you can purchase more compact versions of gas burners:

But in fact, it is precisely these cans that can cause burns and even fire. We are talking about counterfeit Chinese products, which are abundant in the construction market. A large cylinder is still located far from the operating burner, while a small cylinder is constantly in the high temperature zone, which is not at all safe. Decide for yourself!

One more point about safety. When choosing a gas burner for your roof, try to avoid counterfeits and overly cheap products - this is simply unsafe. So, the most common problem with such burners is that the operating pressure may be indicated in the technical data sheet as 0.05-0.08 MPa, but in reality it turns out to be up to 1.6 MPa, as in any propane burner. But the supplied gearbox is not at all designed for such parameters, and a closed valve may not withstand the pressure directly on the roof. Such a burner requires a gearbox, but an inexperienced user may simply not know about it.

Read also: What are cutters used for?

Features of a gas burner with piezo ignition

The device is portable; the mechanism includes a gas valve handle. In most models, the adjustment of the flame flow and piezo ignition are carried out separately, which makes it easier to use, since by extinguishing or increasing the flame, you cannot accidentally turn it off completely. The burner body is made of plastic or metal. The minimum time of continuous operation of the temperature flow of the burner on the cylinder is 2 hours.

Different models of burners may differ in the power of the gas flow and the ability to regulate it; for some simplified mechanisms, the power of the gas flow is practically unchanged.

Since the gas is liquefied, when the cylinder is tilted, the flame may go astray. This happens as a result of gas in the liquid fraction entering the mechanism of the device. But in this regard, everything depends on warming up the device; when it warms up enough (the first few minutes have passed), you don’t have to worry about such failures.

Types and classification

Based on their intended purpose, devices are divided into professional and household.

The first include:

- Burners for work related to metal processing: soldering, forging, welding.

- Devices for general construction, road work, roofing, wood burning, and removal of old paint.

- Technological equipment for various purposes. For example, drying chambers, food industry tools.

For household purposes, this includes a gas stove, nozzles for home stoves, heating boilers, and gas convectors.

Household devices include home workshop devices . This is where you most often find do-it-yourself burners, not only manufactured, but initially designed to perform specific tasks.

They are arranged according to two main schemes:

- injection or injection;

- with complete preliminary mixing of the working mixture, or ejection.

In the first type, air (or oxygen) is captured by the supplied gas stream. In the latter, the gas-air mixture is obtained in a preliminary chamber.