The burner of a gas boiler converts the chemical energy of the fuel into the thermal energy of water, which is supplied to the heating and hot water supply system of the house. Gas burners for heating stoves are installed in special devices called boilers. The correct choice of burner device will ensure not only a comfortable living environment in the house, but also its safety.

Modernization of heating equipment

You cannot objectively judge the quality of the purchased injector.

Do not disassemble the finished product in search of possible defects. So there is a chance to damage rather than check an expensive device. By assembling each element of the burner yourself, you will receive not only pleasant satisfaction from the work done, but also savings. At the same time, the operation and repair of gas bath equipment will become safe and conscious.

https://www.youtube.com/watch?v=QvYJGR89Uhw

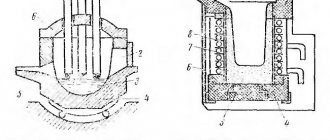

The heating gas unit is a sauna stove body with a gas supply device located in it. Here are the main elements of the control mechanism with which the fuel supply is regulated.

The burner heats the air in the firebox. The thermal energy of the nozzle is transferred through the body to the tray with stones

The advantages of heating water and sauna stones with a gas burner include:

- Simplicity of the workflow. To heat up, just turn the valve and ignite the gas in the burner. In an hour, the steam room of the bathhouse will be sufficiently heated.

- Environmentally friendly. During operation of a gas device, harmful emissions during gas combustion have the smallest volume compared to other types of fuel.

- Ease of maintenance of the burner and the stove itself. There is no need to deal with soot from walls and remove waste, as with coal or firewood.

You can equip the oven with special sensors that are triggered at a critically low exhaust speed. In this case, the gas supply is automatically turned off.

Inexpensive fuel from a gasified stove allows you to not limit the number of bath procedures. Even with daily heating of the bathhouse, maintaining cleanliness becomes very easy

Such a disadvantage of a homemade burner, such as additional registration of technical permits, pays off due to high productivity. Using a gas injector will save 30% costs compared to solid fuels. Heating a sauna with gas is two times cheaper than using an electric boiler.

Before you begin assembling the burner parts, it is better to have a drawn diagram on hand for convenience.

Self-production technology provides for the following sequence:

- the base of the device, the nozzle, is made using a grinder;

- the fuel dispenser is assembled from a valve and a steel cap screwed onto it;

- a cap is welded to the nozzle, then a piezoelectric element is installed.

Any home craftsman can install a homemade atmospheric gas burner for a sauna stove. So, without any special costs, a solid fuel boiler can be converted into a gas one.

Equipping an existing solid fuel stove in a sauna with a factory-made gas burner unit will require some adjustment. You will be faced with the need to modify the dimensions of both the burner and the combustion chamber of the wood-burning stove.

Converting a solid fuel sauna stove into a combined gas and wood stove is within your power, but it will require precision and some effort. Do not allow the flame to come into contact with the walls of the firebox

To heat the combustion chamber evenly, the burner should be positioned closer to the bottom of the stove and strictly in the center. It is unacceptable to place the source high and offset in any direction. In this case, the camera will not warm up completely. And the flame from the burner can touch metal parts or the heater of the sauna stove.

DIY options

Often, a homemade gas heating unit is made from an old empty cylinder, which is first filled with water to remove any remaining fuel. To assemble a metal heat generator with your own hands, use ready-made drawings.

Materials and tools:

- empty gas cylinder. You can buy a new cylinder or find a used one at a scrap metal collection point,

- used wheels from trucks and cars, they are selected depending on the expected power of gas-fuel heating equipment,

- metal pipes. For gas and air supply, a model with a cross section of 2 cm is used; for the construction of a chimney, a pipe with a diameter of 4 cm is suitable,

- atmospheric burner,

- Bulgarian,

- drill with appropriate attachments,

- welding machine.

Sequence of work:

- Using a grinder, cut a hole in the upper part of the cylinder to fit the dimensions of the wheel rim.

- The disk is inserted into the hole and welded using a welding machine.

- The air supply structure is made from a pipe d2 cm by drilling 9-11 holes with a diameter of 5 mm on the surface.

- A hole d50 mm is drilled in the lower part of the cylinder, a pipe is inserted so that on one side it protrudes 15-20 cm. The seams are sealed by welding.

- The gas pipe is welded in a similar way, the free end is equipped with an adapter for connection.

- A chimney is installed in the upper part of the structure.

At the end, the firebox door is made from a steel plate, a hole is cut out from the side of the homemade structure for it and installed on the hinges.

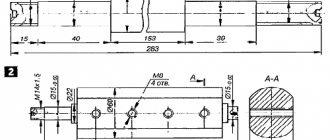

Hand-drawn diagram of a homemade gas burner for a sauna stove

Atmospheric and forced-air burner

The atmospheric burner is distinguished by its simplicity of design. The air needed to form the mixture is taken from the room where the stove is located through natural means. For the system to function, a complex automatic component is not required. The burner is non-volatile. The diagram is in the photo below.

The disadvantages of atmospheric burners include only compliance with air circulation requirements, namely, the presence of a sufficient amount of oxygen in it. New models are already equipped with special sensors that stop the supply of the gas component if the oxygen level is too low.

For normal operation of a gas burner installation, good draft is necessary. Its power is low, so this type of burner is more suitable for small water heating columns. The combustion process depends on the height of the fuel pressure in the gas main and the rate of its combustion. An atmospheric burner is suitable for a sauna stove if the room has good ventilation and a square area of 12 m2 or more. In addition, it should only run on gas.

A block (or pressurized) gas burner is a more complex design that requires automatic control. Air is forced into the combustion chamber. To create the necessary pressure and regulate the pressure of the flame, a fan is used. Similar systems are installed for household stoves or bathhouses.

Air is pumped from the street. The design does not require significant oxygen control. The control unit provides complete control of the combustion process. In an emergency, the gas supply is stopped (pressure drop in the gas main, fire extinguishing, power supply cutoff).

For a home bath you will need a high-temperature burner with a power of 35-100 kW. If the stove is installed in a house, gas must be supplied at a pressure of 2 kPa through a half-inch pipe. This will give 115-350 kW. Calculations are made based on the proportion of 1 kW per 10 m 2. Pressurized gas burners can be combined or gas.

Pulse burner design

It has a higher efficiency compared to natural ones, is more efficient and complex in design. The fuel burner consists mainly of seven elements:

- Fuel pump, it supplies the boiler with fuel from the tank (liquid fuel) and is equipped with a pressure regulator that returns the excess fuel required for combustion.

- The fan provides the combustion process with the air necessary to burn the fuel.

- A solenoid valve is a valve that operates automatically. It is used to supply a jet of fuel in sufficient quantity for combustion.

- The nozzles are the central part of the burner. The nozzle allows the fuel to be atomized very finely to promote thorough mixing with air to form a fuel-air mixture for combustion.

- A fuel heater, it allows the liquid fuel contained in the tank to be made less viscous to aid combustion. This initial viscosity is related to the storage temperature in the tank as well as the specific characteristics of the fuel.

- Electrodes, they allow you to ignite the gas-air mixture to create the desired flame.

- The combustion head, which consists of two elements. The tip that directs the flame and the reflector that holds the flame in the stove.

The burner operating mode can be divided sequentially into stages:

- Pre-ignition. Turning on the fan, which allows the engine to run.

- Ignition. Opening of the solenoid valve, which directs fuel to the nozzle.

- Ignition. A spark is created to maintain a stable combustion flame.

- Operating mode. Turn off the igniter after the flame has stabilized.

- Stop. Closing the solenoid valve, turning off the burner and after 15 - 20 minutes of ventilation of the firebox in order to free the combustion space from explosive mixtures, turning off the fan.

DIY gas burner

Manufacturing does not require expensive components or complex tools. A camping gas burner or a simple soldering iron for the garage can be made in less than an hour if you have the necessary materials. Let us describe the main nuances that will be encountered in this work:

- It is better to make the body and divider from steel.

- As a basis, you can take a piece of pipe with a diameter of 40 mm.

- We make a new fitting on the machine or adapt a part from an old fire extinguisher.

- We select a smaller pipe for the inner part, cut off the blank and weld the fitting.

- We weld the other side of the pipe and drill a hole for the propane outlet.

- We select the diameter of the outlet hole experimentally, starting from 0.9 mm.

- If there is not enough gas supply, the hole should be drilled.

- We connect the gas burner only through a reducer.

What types of gas ovens are there?

Gas stoves are used to heat households and country houses, but such devices have gained the greatest popularity in the construction of bathhouses. Most often, for this case, they buy factory-made units that have a metal body. In this case, you need to choose the right model in terms of power and purpose, taking into account the operating conditions. Brick ovens are also being built.

Based on the method of generating heat, furnaces can be divided into two types:

- Having a combustion chamber. The gas enters the heating chamber and, when burned, heats its walls.

- Furnace with heat exchanger. In the designs of these heating units, gas enters a curved, heat-resistant steel tube, which acts as a heat exchanger.

In the second case, the furnaces are additionally equipped with a system of forced air supply and exhaust of combustion products.

Gas furnaces are distinguished by heat capacity. This indicator depends on the ability of the unit to accumulate heat.

According to this parameter, furnaces are divided into the following categories:

- Constant burning stoves. They have thinner walls that cool quickly enough. However, there is a significant plus - they warm up the room just as quickly, releasing heat outside. In order to maintain a constant comfortable temperature in the room, the stove must be in the “on” mode. This is a typical country house option. You can come and immediately warm up.

- Intermittent furnace. This is a massive heat-intensive structure that is capable of giving off heat even after the gas is turned off. In order to retain heat, the channels and combustion chamber are lined with clay bricks. It is very convenient to install such stoves in baths. They will warm up the stones in a short time and begin to give off heat for a long time. For heating households, this option is also more acceptable.

Stove gas burners, which are installed in the stove of a household or a country house, are similar to each other. Like a gas burner for a boiler, it has a combustion chamber (heat exchanger), a housing, a smoke exhaust system, channels for heated air and an automatic unit.

However, there is one obligatory part that has its own characteristics in each case - a gas burner for the stove. It is she who is responsible for the efficiency of the heating unit, power characteristics, economical fuel consumption, safe operation and other important parameters.

Single-stage atmospheric gas burners for a home stove are not difficult to use, they are easy to install in a heating unit. They don't need electrical power. This burner is placed on the front side, where the combustion door is located.

If a gas burner is considered from the point of view of the method of controlling thermal power, then all models can be divided into the following categories:

- Single stage. In this case, gas supply (switching off) occurs automatically, based on a rheostat signal.

- Two-stage. The burner has the design ability to switch to an economical mode. This process is regulated automatically.

- Burners with floating adjustment. The burner power can be changed smoothly, from 10 to 100 percent.

Burners are divided according to the method of air supply:

- Atmospheric. In this option, no electricity is needed; air flows to the burner under the natural action of draft. The efficiency is not very high, no more than 90 percent. This is a simple design: a pipe with holes into which fuel is supplied. It works in open combustion chambers. They can be quickly converted, if necessary, to use liquid fuel; the service life of such burners is very long. However, such burners impose increased safety requirements.

- Supercharged. They are also called blower or fan burners. This is a rather complex design. Air is supplied to the burner by a fan; in this case, the combustion chamber is closed. Efficiency exceeds 95 percent. Stoves with such burners do not require bulky chimneys. At the same time, the furnace operates stably even at low gas pressure. However, they produce a lot of noise and are volatile.

- Diffuse-kinetic. The air is partially pumped into the combustion chamber, the rest is supplied directly to the flame.

Types and characteristics of elements for gas combustion

The gas burner for the boiler is selected according to the following characteristics:

- Life time. The period cannot be less than the operating life of the heater.

- Low noise level. If the injectors make a lot of noise, this indicates a malfunction - all parts are checked at the factory and must comply with sanitary and hygienic standards.

- Type of fuel. Manufacturers offer universal nozzles that operate on main gas, bottled gas, diesel fuel, etc. When changing the energy carrier, a simple reconfiguration of the equipment is required - such burners are especially convenient for owners of country houses.

- Easy to install and dismantle.

The main purpose of the device is to mix gas and air to form a flammable medium. The efficiency of the burners is high; the type of mixing differs between atmospheric and fan. It is worth considering their features in more detail.

Atmospheric burners

To form a combustible substance, the burners take air from the room where the heater is installed. Atmospheric gas burners for heating boilers operate on the ejector principle - nozzles for supplying gas are located inside the channel structure. Air is delivered to the nozzles, then a combustible mixture is formed, exiting through the perforation of the nozzle.

As the mixture exits, a low air vacuum is created, which allows oxygen to be drawn in and a new portion of the mixture to be formed. The gas combustion chamber is equipped with several parallel channels with nozzles, so the process of forming the gas-air mixture is carried out in a continuous cycle.

After combustion, the heated gas moves to the upper part of the heat exchange structure, giving off heat to the heat exchanger, and then the combustion products are drawn into the chimney. The warm gas reacts with the cold outside air, resulting in the formation of draft, which provides the supply of fresh air to form a gas-air mixture.

Advantages of atmospheric gas devices:

Simplicity and relative cheapness; there will be no problems with replacing equipment. Energy independence. No electricity is required to start the boiler

It is important to maintain an optimal level of fuel supply pressure and build a high-quality chimney. Low noise level, compact device.

The disadvantages include the necessity of constructing a chimney so that combustion products are completely removed.

As for the efficiency of the equipment, it is quite high, since manufacturers are increasing the number of inlet holes with a small diameter. This “perforation” ensures uniform distribution of the gas-air mixture throughout the combustion chamber, increasing the performance and energy efficiency of the system.

Fan burners

These are more complex gas burners for heating stoves, allowing control of the fuel combustion process. The fan is installed to force air into the combustion chamber and ensures the formation of a gas-air mixture in a sealed compartment for fuel combustion.

Fan-type nozzles are used in combined heaters equipped with a sealed combustion chamber.

Device Features:

- high efficiency;

- forced air injection;

- the optimal combination of portions of gas and oxygen to form a combustible mixture.

In addition to pumping air into the chamber, the fan is responsible for removing combustion products to the outside and allows you to change the pressure in the network by changing the speed of rotation of the blades.

The main difference between fan nozzles and atmospheric ones is the formation of a combustible mixture. In atmospheric boilers, a gas-air portion is formed at the entrance to the burner, in fan boilers - at the entrance to the combustion chamber.

A fan gas nozzle for heating a private home has a wide list of advantages:

- Monitoring the operation of the network, the ability to influence the process of forming the gas-air mixture, and change the boiler power.

- Saving fuel consumption.

- High efficiency.

- Can be installed in apartments and small buildings. This is achieved by eliminating the need to connect to a standard chimney. The coaxial pipe is run through the nearest exterior wall.

Domestic gas fan heaters are expensive energy-dependent devices, which is a disadvantage of the units. If the device breaks down, only a specialist can replace it, and the burner turns off if there is a failure in the supply of fuel or electricity.

The most efficient devices of 2018

The most efficient certified boilers and gas burners this year:

- Bosch Greenstar series. The boiler is small, very quiet, environmentally friendly and uses economical condensing technology providing an AFUE rating of 95%. Greenstar is available in two models - combi for spatial and point-less water heating or space heating, which can be used with domestic hot water tanks. It is equipped with a heat exchanger with a 5-year warranty.

- Bradford White Brute Elite Series. The boiler with 95% efficiency has a condensing multi-pass stainless steel heat exchanger with an advanced modulation system. Innovative design features make Brute Elite easy to install in both new and existing heating systems.

- Bradford White Brute Elite 125 Series. Customizable combi based heating only models are 95% efficient with a combi unit providing heating and hot water from one unit. Requires only one gas connection, one ventilation system and built-in expansion tank and boiler pump, and is easily accessible for repairs.

- Buderus GB142 series. Condensing gas boiler. Using state-of-the-art condensing technology with 95% AFUE, the Boer Buderus GB142 wall-mounted condenser maximizes the heating value of every m3 of natural gas or liquefied propane.

- Boiler Alpine Series. This is a natural or liquefied gas condensing hot water boiler with a stainless steel heat exchanger. Equipped with Sage2 boiler control system. 1 TM, which supports multiple firing speeds, is also equipped with an external reset and a touch interface.

- Carrier BMW Performance Series. 95% AFUE. Stainless steel. The modulating condensing boiler is equipped with a unique vertically oriented stainless steel heat exchanger, 5 to 1 ratio, compact design with light weight, compact wall mounting, primary and secondary piping, with a 15-year warranty.

Having familiarized yourself with the design and operating principle of gas burners and popular models, you can easily choose exactly what suits your needs.

Metal sauna stove

To achieve good steam in a sauna, you need a good brick stove. It will keep you warm for as long as possible. However, such a furnace requires a serious foundation. This requires additional money and time.

In order not to spend money on pouring the foundation, you can make a metal stove yourself. Creating such a furnace does not require an in-depth study of the circuits, and its effectiveness has been proven in practice.

Although a metal stove heats up quickly, it cools down just as quickly. This is its main drawback.

In order to assemble such a structure, you will need a metal container, sheets of metal or pipes of various diameters, a gas burner, an angle grinder, and a welding machine. Those who do not know how to use a welding machine can make a body from an ordinary pipe. This will not make the stove any worse.

Gas cylinders and pipes can be selected in other sizes. The size of the required parts depends on the size of the heated steam room. If its area is large, then it is worth making the stove larger. She will cope with her task as efficiently as possible

The result will be a stove about 80 centimeters wide and about one and a half meters high. A heater and platforms for installing a container with water are mounted on top. Thus, to create a steaming atmosphere in the steam room, you will need to pour water on the stones.

When drawing up a conditional drawing, you need to take into account the exact dimensions of all parts. Initially, you need to find a pipe or gas cylinder with a height of 180 centimeters and a diameter of 80 centimeters. In this case, the walls of the pipes must be quite thick - from 0.4 cm or more.

You will also need a metal sheet one centimeter thick, a steel rod with a diameter of one centimeter, cast iron or steel doors, a chimney pipe, a gas burner and a tap. All material can be purchased at a hardware store. You will also need tools: a grinder and a welding machine. You can rent them or borrow them from friends.

First of all, the base is prepared at the place where the metal stove will be installed. It needs to be made even and level. It is necessary to cover the foundation with fireproof material.

Two rows of refractory bricks are laid on top. Do not forget that the ceiling and all walls at a meter distance from the stove must be covered with fire-retardant material.

The manufacture of the furnace is carried out in several stages. First you need to cut the pipe into two parts with a grinder, one of which will be the furnace body, and the second will be used to heat the water barrel.

In the lower part of the first section of the pipe, a rectangular hole measuring 20x5 centimeters is made with a grinder. This method provides access to the gas burner.

The vast majority of gas furnaces have approximately the same structure and sequence of assembly and installation. The water tank is installed on top or welded to the side. If you want to install an advanced model, you can additionally install a number of elements and devices that will automate the control of the furnace

In the middle of the first section of pipe, another rectangular hole of the same dimensions is cut. The brackets on which the mesh will be held are welded. The mesh cells should be smaller than the size of the stones that will be laid on it.

A tap is welded at the bottom of the second pipe. Then the second piece of pipe is attached to the heater. In this case, it is necessary to check the seam for leaks. Next, you need to weld one door and hang the second on its hinges.

The pipe is insulated using refractory bricks or other material. After welding all the elements, the burner is installed and the stove is ready for use. It is worth remembering that a metal oven heats up to high temperatures, so it is imperative to cover all nearby surfaces with refractory material.

Assembling a gas stove for a sauna with your own hands is not difficult. To implement such an idea, you need to observe safety precautions and follow recommendations. Thanks to self-assembly, you can save a lot of money, and the efficiency of this design is not much inferior to store-bought models. Before you start assembling the stove, you need to carefully prepare the room.

How to choose?

What you need to pay attention to when choosing a burner device for a boiler:

- productive power - noise level during operation (applies to supercharged models) - type of heating equipment for which the burner is purchased - type of fuel - pros and cons of this device - provide for possible malfunctions in the operation of the local gas supply line.

Taking these factors into account, you can choose the most suitable burner device for your boiler so that it operates as efficiently as possible without the burden of frequent preventative maintenance.

Criterias of choice

When choosing a gas injector, take into account the following points:

- Model specifics - power, efficiency level, efficiency, economy, safety,

- Features of operation. When arranging a small bathhouse, preference is most often given to atmospheric models. Powerful automatic burners for blow-type sauna stoves are recommended for use in large rooms.

- Type of heating equipment.

- Features of fuel supply - from the main line, gas tank or cylinder.

- Purpose of the product.

Models of nozzles of certain categories provide for installation in certain types of heat generators. For example, some proposals from domestic manufacturers are designed for use exclusively in boilers with a long channel for the fuel mixture.

General rules for installing a chimney for a stove

Another condition for the normal operation of a gas stove is the installation of a chimney. For gas-fired stoves, smoke channels must be vertical, without ledges. The design of the chimney of a wood-burning stove is often not suitable for the removal of gas combustion products.

The slope of the chimney is allowed, but not more than 30°, and provided that the cross-section of pipes on inclined sections is not less than the cross-section of pipes installed vertically

You can refurbish an old chimney by lining it. Upgrade options:

- Installation of a stainless steel pipe in the chimney duct. In this case, the diameter and height of the pipe should be selected according to the characteristics of the chimney duct. The gap between the walls of the chimney and the pipe is filled with non-flammable heat-insulating material such as expanded clay or foam glass.

- Application of FuranFlex technology. The method involves placing an elastic polymer tube inside the channel, which, under pressure, takes its shape and hardens. The protective layer serves to insulate, seal and internally protect the chimney.

If none of the chimney modification options work, you will have to install a new one. Depending on the location of the stove, two options for installing a chimney are possible: an external attached one or an internal one.

The influence of the characteristics of the chimney on the safety of heating is such that it will necessarily be checked by the Fire Inspection authorities with the subsequent issuance of a written certificate, without which the equipment will not be connected to gas networks.

Combustion process in a boiler

The chemical reaction inside the boiler is a combustion reaction between oxygen (O2) in the air and hydrocarbons (CHyOx) in the fuel, which release energy as heat. During the combustion process, water vapor (H2O) and carbon dioxide (CO2) are formed, the latter being especially dangerous in terms of air pollution and global warming.

Other combustion products of injector gas may also appear depending on the type of fuel and combustion conditions: oxides of nitrogen (NOx) or sulfur (SOx), which are responsible for acid rain. Carbon monoxide (CO), a dangerous toxic substance, can cause death if inhaled.

Correct adjustment of the device reduces the amount of harmful combustion products. CO2 emissions are reduced when the gas is completely burned. In order to reduce NOx emissions, it is recommended to use the correct combustion technology, which is ensured by the design of the burner device.

Equipment setup

Floor-standing gas boilers with an atmospheric burner can be configured independently. Pressurized systems are regulated by an automatic control unit and do not require additional configuration.

Scheme of actions for setting up single-stage equipment:

- Install the device on the boiler.

- Connect to the gas pipe.

- Check for absolute tightness.

- Remove the burner housing.

- Using a pressure gauge, measure the gas pressure at the inlet.

- Connect to electricity. Make sure that the jumpers and phases are connected correctly.

- Place a gas analyzer in the chimney pipe.

- Start the device.

- Using a pressure gauge, take pressure readings at the outlet of the burner block. Pressure readings must correspond to the parameters indicated in the data sheet.

- Adjust the air flow using the air damper.

- The gas analyzer readings must also comply with all gas equipment installation standards.

Setting up gas equipment should be carried out by specialists. The simplest open-type boilers can be configured independently if you have certain skills and knowledge of the design of the burner unit. The efficiency of the boiler, its level of efficiency, and fuel consumption depend on the quality of the burner. It is possible to superficially determine that the equipment is malfunctioning by the changed burner flame.

A heating system where the main element is a gas stove is a common type of heating for private households and cottages. There are many things in favor of natural gas as a heat source: high efficiency, environmental friendliness, and the ability to make the heating process fully automated. The fuel itself is also the most inexpensive at present, unless, of course, you take into account wind energy and solar radiation. But these methods have not yet found wide demand due to the unaffordable price of the equipment.

The quality of gas heating depends on how efficiently the gas burner for the stove works.

Required Permissions and Installation Requirements

To install a burner in a sauna stove, permission from the gas supply authorities is required. In the case of atmospheric devices, operating conditions must meet the following requirements:

- the presence of a high-quality room ventilation system,

- adjustable traction,

- the volume of the premises being used is at least 12 m³,

- ensuring fire safety measures: reliable insulation of the chimney when laying the chimney through the floor slabs and roofing system, equipping the top with a spark arrester.

When purchasing a device, a set of documents is included in the form of certificates of conformity and permission from Rostechnadzor. If the installation rules are followed and the above documentation is available, there is a chance to obtain permission for operation from the gas supply organization.

When installing supercharged models, it is sufficient to comply with fire safety rules and the availability of accompanying documentation, since due to the features of the functionality, there are no requirements for the place of operation.

It is worth considering that all this is valid when using main gas. In the case of autonomous gasification, for storing liquefied gas cylinders, according to the regulations, a separate metal cabinet is used or a gas tank is equipped. The underground tank provides for volumes of 3 m³ and a location at least 5 m from the building. A pipeline of steel pipes is laid from the storage facility to the heat generator, ensuring reliable tightness of the channel.

Purpose and advantages of nozzles

Gas burners (or nozzles) are designed to operate the stove on gas. Like other similar devices, the nozzle mixes fuel - natural or liquefied gas with air. As a result, the temperature in the oven increases.

Most often, such gas products are installed in baths, where high temperatures are required for a long time. However, nothing prevents you from installing a nozzle in your home in order to save yourself from the usual methods of kindling. In addition, such products have a number of significant advantages:

- Safety. Since such products work with explosive material, they are subject to strict requirements regarding reliability. You can verify this by reading the quality certificate.

- Availability of automation. Most gas products are equipped with automatic temperature control, which provides not only economical fuel consumption, but also protection from overheating or explosion of the furnace.

- Economical. As you know, gas is much cheaper than the cost of firewood, coal or electricity.

- Variety of fuels used. Many devices can operate on natural or liquefied gas.

- Ease of operation. The operation of gas devices for furnaces does not require any specific skills. In addition, some models can be operated from a special remote control.

- Ergonomics. Storing coal, firewood or other flammable materials requires a lot of space. The supply of fuel to the injector comes from the gas column.

Safety rules when using burners

Failure to comply with precautions when installing and using gas burners for heating premises can lead to emergency situations and accidents: fire in the house, carbon monoxide poisoning.

When operating gas equipment, you should adhere to the following rules:

- Observe the service life. The burner's service life, depending on the model, can range from 8 to 15 years. Then it must be replaced.

- Use models with a function that automatically turns off the device in the absence of draft or flame.

- A stove equipped with gas burner units must meet safety requirements.

The design, installation or repair of a gas burner must be carried out by certified gas service workers, with whom an agreement has been concluded for the supply of fuel and maintenance of the units.

If possible, it is still necessary to use gas boilers or special furnaces that are designed to work with natural or liquefied gas

To obtain permission to install and connect to the main gas network, a number of conditions must be met:

- compliance with the rules for connecting a gas burner;

- appropriate design of the smoke channel, its high-quality insulation;

- installing a spark arrester at the top of the chimney.

This is the minimum requirement for installing forced-air gas burners.

For atmospheric there are additional requirements:

- presence of adjustable traction;

- ensuring good ventilation;

- the volume of the room in which the gas burner is installed is from 12 m3.

If equipment is converted to use liquefied gas, it is necessary to ensure safe storage of the gas cylinder. This can be a separate room or a metal cabinet. If you plan to store gas reserves in a gas tank, then the tank is installed underground at a distance of no closer than 5 m from the building.

Choosing a gas burner: what should you pay attention to?

From the above review, it becomes clear that there is a wide variety of gas burners, both in design and in their area of use. The choice is very large and the question arises: how to choose a burner and not make a mistake?

If you decide to purchase a gas burner for a sauna stove, you should focus on several criteria and the main thing, of course, is power. The stove must be able to perform its direct function - to heat and maintain the set temperature in the steam room.

It is generally accepted that one kilowatt of power is needed per cubic meter of steam room. At first glance, it seems that there is nothing complicated about this. However, the approach only works in rooms with thermal insulation correctly performed according to all technical standards.

In fact, it turns out that there are areas in the bathhouse that allow heat to pass through. They also need to be taken into account. The window is one of the main sources of heat loss. For a square meter of a single-pane window, 3 kW of power is required and 1.5 kW for a double-glazed window.

Brick or tiled sections of the bathhouse will require an additional 1.2 kW to be added to the furnace power.

Log walls have a high heat capacity. A log bathhouse without internal thermal insulation will require an increase in power by one and a half times.

The result can be quite a lot of power. When choosing a burner, you need to focus on its technical characteristics. The resulting power value must be within the range of values specified in the passport.

Difficulties may also arise when choosing a heating system for your home. The market offers electric boilers, solid fuel and gas boilers, as well as GII infrared burners.

Each of the listed options has its own advantages and disadvantages. It is necessary to focus on the tasks that this equipment must perform.

For example, to warm up large rooms with poor thermal insulation, infrared heaters supplied with gas from a household cylinder are best suited, since they heat the surface, not the air.

Electric boilers are small, compact, silent, can operate autonomously and last a long time. Gas boilers with gas burner automation are the most efficient and economical. In addition, this fuel is the cheapest.

The most important thing when choosing is to focus on proven boiler models, as well as reliable stores. After all, no one is safe from buying a fake.

Types of portable burners

Gas burners are devices that differ in design and purpose, but they are united by a common feature - they operate using gas.

Portable devices designed to operate from a small tube filled with propane-butane or other gas should not be confused with ovens or powerful welding units that operate from natural gas or a large cylinder.

We offer a brief overview of the main design elements of an inexpensive gas cartridge burner, which serves as an excellent example of a home device. It may be useful for repairs in the country or for a barbecue.

Using a compact device, you can quickly light a barbecue, heat bolts or nuts in the cold, melt plastic parts, and process heat shrinks. The flame temperature (up to +1300°C) is enough for soldering metal pipes.

This is an example of a burner type that is popular among users, but the range of devices is much wider. Let's look at the most popular types.

Difference by area of use

An open flame may be required at home, on vacation, and during installation work. One of the areas of application is tourism. When camping, use a simple device to light a fire and heat up canned food.

Devices for heating food have a special design - instead of a muzzle-nozzle, there is a long thin gas supply hose to an external burner with a stand

Burners with a directional torch of a “pistol” type are often used in installation work when soldering copper pipes and for bending plastic elements.

The flame, heated to the required temperature, is directed to the mating area of the copper parts, resulting in a strong permanent connection between pipe and pipe or fitting.

High-temperature high-power lamps can also process steel parts, but this requires hard solder and a slightly modified soldering technique.

Gas portable burners are also used for the following work:

- processing of wooden parts;

- lighting a barbecue or a fire in the country without the use of chemicals;

- calcination and cutting of metal blanks;

- singeing animal carcasses during butchering;

- thawing frozen pipelines.

This useful device is always at hand for craftsmen who love to improve their homes and improve their garden plots on their own. The burner can be useful in a car repair shop, during the construction of a greenhouse or other structures.

Division according to the method of attaching the can

The fuel cartridge is a consumable item. As soon as the fuel runs out, it is disconnected from the burner, and a new cartridge is installed in its place.

There are several ways to attach a cartridge to a device:

- threaded - fixed with a thread, in other words - screwed on;

- collet - put on and slightly rotated to one side;

- valve - secured with a retainer;

- pierced - connected with light pressure.

Threaded models are more common than others. They form a strong connection between two elements that can be separated at any time. Punctureable ones, on the contrary, cannot be turned off until the gas in the can runs out.

Devices with collet fixation are quickly installed. To attach them to the cylinder, you just need to put them on and turn them 25-30 degrees to the side

The weakness of collet devices is the rapid loosening of the clamp, resulting in loss of gas.

Valve burners, which are usually designed for heating food, are considered more reliable.

Differences in gas burners by fuel type

Manufacturers use various fuels to fill consumable cartridges. The choice of liquefied gas is based on the purpose of the burners, the required flame temperature, and power. To improve the characteristics of the composition, several different types of fuel are sometimes mixed.

The following combinations of substances are used most often:

- a mixture of propane and butane (70:30) - mainly for summer use, but with a heating device it is also used in winter;

- a combination of propane, butane and isobutane in various proportions;

- a mixture of MAPP - methyl acetylene-propadiene-propane, most often used for welding at temperatures of 1600-2500 ° C.

But there are cans filled with one gas, for example, butane.

An example of inexpensive gas cartridges is “Pathfinder”. Price – 90 rubles. Filling – universal gas fuel, suitable for portable burners, cutters, stoves, heaters

The choice of fuel is important when work is to be done in harsh conditions - in the cold or at high altitudes. And in the summer, any universal gas is suitable for lighting a barbecue or fire.

Operating principle and differences of gas equipment

You cannot objectively judge the quality of the purchased injector. Do not disassemble the finished product in search of possible defects. So there is a chance to damage rather than check an expensive device.

By assembling each element of the burner yourself, you will receive not only pleasant satisfaction from the work done, but also savings. At the same time, the operation and repair of gas bath equipment will become safe and conscious.

The heating gas unit is a sauna stove body with a gas supply device located in it. Here are the main elements of the control mechanism with which the fuel supply is regulated.

The burner heats the air in the firebox. The thermal energy of the nozzle is transferred through the body to the tray with stones

A heating stove with a gas nozzle requires special attention to the chimney, which must be cleaned periodically.

The advantages of heating water and sauna stones with a gas burner include:

- Simplicity of the workflow. To heat up, just turn the valve and ignite the gas in the burner. In an hour, the steam room of the bathhouse will be sufficiently heated.

- Environmentally friendly. During operation of a gas device, harmful emissions during gas combustion have the smallest volume compared to other types of fuel.

- Ease of maintenance of the burner and the stove itself. There is no need to deal with soot from walls and remove waste, as with coal or firewood.

You can equip the oven with special sensors that are triggered at a critically low exhaust speed. In this case, the gas supply is automatically turned off.

Inexpensive fuel from a gasified stove allows you to not limit the number of bath procedures. Even with daily heating of the bathhouse, maintaining cleanliness becomes very easy

Such a disadvantage of a homemade burner, such as additional registration of technical permits, pays off due to high productivity. Using a gas injector will save 30% costs compared to solid fuels. Heating a sauna with gas is two times cheaper than using an electric boiler.

Operating principle of combination burners

Combination burners are the most advanced devices; they are used only in high-power units and energy boilers, when the technology requires burning several types of energy fuel.

They are installed in cases where there is an unstable supply of one type of fuel:

- there are interruptions in the supply of main gas or it is transported to consumers with low pressure, and it is urgently required to transfer the boiler to backup fuel;

- low consumer quality of gas, unable to provide the required temperature conditions;

- with a night gas supply schedule in a power plant, when there is a night mode for equalizing daily gas consumption in the area where the thermal energy source is located.

There are several types of combined burners: gas-oil and gas-coal. The first ones are most widespread and, as a rule, are produced with forced air supply for both medium and high gas pressure. The installation of such combined devices provides the greatest effect than the parallel operation of gas and fuel oil nozzles or gas and pulverized coal devices separately.

Such modifications of universal burners are installed according to the requirements of reliable and uninterrupted operation of powerful industrial or power boiler houses, in which stopping the production of thermal energy is unacceptable.

Other differences

Let's consider the division of gas burners by type of ignition. The simplest option is with a burning igniter (wick). When the automation is triggered, the wick ignites the gas and the boiler begins to heat the coolant. There are two disadvantages here - increased gas consumption and low safety (the igniter may go out). Primary ignition is carried out with matches or using a piezoelectric element that produces a spark.

Natural gas from the mains provides even combustion without forming excessive soot on the walls of the chimney pipe.

Electronic ignition of the burner requires the presence of a high-voltage converter in the gas boiler. Energy is taken from batteries or the electrical network. The first option is used in non-volatile boilers that do not have electronic automation. The second option is relevant for complex units with electronics on board. Along with such ignition, modules for ionization control of the presence of flame are often installed.

There is also a division according to the type of fuel used. Natural gas supplied from the pipeline is cleaner, it is supplied at optimal pressure (we do not consider cases of pressure surges in both directions). The flame in the boiler is clean, without soot. The equipment is connected to the network without modifications. There are burners that can operate on propane - this requires setting up the system and installing a jet. The flame from propane combustion gives off a yellow color, and there is increased soot deposits on the chimney.

Jets allow you to normalize the propane pressure to an acceptable value - they are supplied as a set or purchased separately.

Trouble-shooting

Having a boiler at home brings many advantages, but it also has a number of disadvantages, and the user does not always know what to do correctly. Boiler faults are common to many types. It is important to promptly determine the cause of these faults before calling emergency services. List of the most common and most likely faults.

First of all, if the boiler does not start, you need to check the circuit components:

- network voltage;

- faulty boiler fan switch or motor;

- damaged boiler cables;

- false triggering contacts of automation or commissioning equipment;

- availability of water, whether the gas boiler is powered to the minimum required level specified by the equipment manufacturer.

If the boiler failure is not caused by any of these problems, the following procedure:

- Pay attention to the noises made by the boiler, because they are often the first witnesses of destruction. They can also be due to hot water trapped inside the firebox or due to the presence of air in the heating system due to clogged air ducts.

- Pipe rupture. It usually occurs due to problems with a jammed boiler feed valve, various scale-forming deposits in the boiler, or a malfunction of the condensate drainage systems.

- Failures due to exceeding the pressure and temperature readings, their corresponding sensors can trigger, for example, due to a broken thermometer or, conversely, which is especially dangerous as a result of real overheating of the boiler.

- The heating circuits are not working, possibly due to poor quality of feed water and scale formation in the boiler pipes.

- A problem occurs with the burner (flame breaks, gas accumulation causes detonation and explosion).

For some of these problems, mainly pressure or temperature, the boiler monitor displays an error message, then the system shuts down and automatically restarts. If the problem persists after restarting, it is best to call a professional to troubleshoot the problem. It should be noted, however, that most of these failures can be avoided.

The best prevention is to have your boiler inspected, maintained and cleaned annually, usually by a professional. This will prevent the pipes from clogging and bursting. Prevention is better than restoration, and a simple annual inspection will protect the equipment and the health of users from possible emergency situations.

Device classification

The industry produces a very large number of gas injectors of various types, purposes and designs, which are strictly classified by type of fuel and method of air supply. Air supply classification:

- Atmospheric burners are burners in which air is supplied naturally; it is captured in a Venturi tube by a gas stream using the principle of an injector.

- Forced air or pulse burners are equipped with a fan that provides air flow for combustion of the air-fuel mixture and removal of products resulting from fuel combustion.

The gas burner for the stove in the house is divided by type of fuel:

- Gas for burning gaseous fuel.

- Burner for burning liquid fuel.

Liquid fuel combustion device

These burners are used to burn liquid fuels such as low sulfur fuel oil, diesel fuel or biofuels. Unlike gas, this type of fuel must be atomized to a gas state. If this is not done, large drops of fuel oil will enter the combustion chamber.

They will not be able to burn completely and will cause the formation of soot, which will settle on the heat exchanger and reduce the useful heating surface of the boiler. These burners at one time offered a pressurized combustion process, as blower burners, due to which the necessary air was mechanically supplied to the combustion point. According to the color of the flame, a distinction is made between so-called yellow and blue burners.

While yellow burners atomize liquid fuel, blue burners use part of the combustion heat to completely evaporate the fuel oil. This way, less soot is produced and combustion occurs at higher temperatures - hence the blue color.

Since clean combustion always depends on sufficient throughput of liquid fuel and its sufficient quantity, the use of such burners in everyday life is limited compared to gas burners.