Fastening products such as concrete anchors can ensure reliable fixation of various objects and structures on concrete surfaces. The problem of attaching various objects to concrete is quite relevant both in the field of capital construction and in the field of repairs carried out by the owners of real estate themselves.

Concrete anchors can provide reliable fastening of any structure

Such difficulties do not arise if the fastener needs to be fixed in a softer material - wood or plastic. If we are talking about concrete, a material characterized by high hardness and, accordingly, fragility, then it is necessary to use special fasteners, which, in particular, include anchor-type bolts.

Advantages and disadvantages

A stud anchor is a fastening element with a threaded rod and a spacer type coupling.

Modern industry produces such parts in a wide range of metric thread sizes - minimum M6, maximum M24. But the M10 stud anchor occupies a special place among professional builders and home craftsmen. This phenomenon is due to the following advantages of this fastener:

- reliability and simplicity of design;

- high load capacity;

- speed of installation. This does not require any specific skills;

- The M10 stud anchor is present in the assortment of almost any building materials trade enterprise. So choosing the right option is not difficult at all;

- affordable price.

Among the disadvantages it is worth highlighting:

- Not recommended for use in drywall, wood or other soft materials. The reason is design features;

- the need to drill holes with high precision;

- use is one-time only.

Mechanical Anchor Bolts for Concrete

The most common types of anchor bolts include fasteners that operate on a mechanical principle.

Drivers

One such product is a drive-in anchor, which has a thread inside the spacer sleeve. This anchor, designed for concrete and other dense and hard materials, is expanded in the hole using a special device, after which the fastener itself is screwed into it.

Types and installation procedure of a drive-in anchor

Spacers

Expansion anchors for concrete and other building materials are also widespread on the modern market. In the design of such anchor fasteners, which can withstand very significant loads, there is a special wedge, which is responsible for expanding the spacer sleeve. Using such anchors, it is possible to ensure reliable fixation of even heavy objects on a concrete surface - metal gates, large equipment, etc. Meanwhile, it should be borne in mind that the reliability of fastening that such an anchor provides for concrete work largely depends on the strength characteristics structure in which it is installed.

Expansion anchor HILTI HSL-3

One of the representatives of this family of fasteners is the frame anchor. Bolts of this type are used for installing windows and doors. The spacer sleeve of frame anchors has two wedging zones: at the bolt head and in the body of the load-bearing base.

Double spacer anchors for concrete, as their name suggests, have two spacer sleeves at the same time. Due to this, anchors of this type provide a more reliable grip, which allows them to be used for mounting objects of significant mass.

Metal frame anchors are designed for through-hole installation in brick, stone and concrete

Wedge

The wedge-type anchor for concrete, mentioned above, can have two design options. In the first case, a hammer and a special punch bit are used to wedge the inner sleeve of such an anchor. After wedging the sleeve, such an additional device is removed from the inside of the anchor and a fastening bolt or pin is screwed into it.

When twisting the wedge anchor, the pin is pulled out and wedges the spacer skirt with its cone-shaped shank

Installing other types of wedge anchors in concrete is somewhat simpler. Their main element is a threaded rod, one end of which is cone-shaped. When tightening the nut, which rests on the surface of the structure in which such a fastener is installed, its conical part expands the spacer sleeve, ensuring its reliable fixation in a pre-prepared hole. In some models of anchor fasteners of this type, there are teeth on the outer surface of the spacer sleeve, which provide better adhesion of this element to the inner walls of the hole.

Rod anchor for adjustable floor

The rod anchor, which is also a wedge type, differs from the usual one in its increased dimensions (bolt length). Using this anchor, multilayer systems with significant thickness are installed.

The choice of the type of anchor is made based not only on its dimensions, which are specified by GOST, but also on the type of fastening that must be performed with its help. It is also important to calculate the load that will fall on the concrete anchor. When performing this calculation, it should be borne in mind that the load on the fastening element should not exceed 25% of that indicated by GOST.

Specifications

Until 1995, the production of anchor studs was subject to the requirements of GOST 28457-90. And even though it lost its force then, the majority of enterprises producing these hardware continue to adhere to the norms of this standard. The reason is simple – there is still no replacement for it. And without unification of sizes, chaos will reign in the fastener market. Moreover, in this case, both parties will lose – both consumer firms and companies involved in their production.

GOST 28457-90 standards establish one version of the M10 stud anchor.

The values of the M0 anchor-stud parameters shown in the drawing are presented below in tabular form. The unit of measurement here and below is millimeters.

| Standard size | 2M10×110 | M10×110 |

| L | 110 | |

| N | 70 | |

| D | 14 | |

| d | 10 | |

| OKP code | 52 2529 0006 | 52 2529 0005 |

The following designations are used in the drawing and table:

- L – total length of the part;

- H – height of the anchor part;

- D – diameter of the anchor part;

- d – thread diameter. In our case, this is M10.

In addition, GOST 28457-90 establishes the technical characteristics of the components of this hardware. So, the execution of the stud itself according to its standards looks like this:

The parameter values for the M10 stud anchor shown in the drawing are as follows:

- L – 110;

- l – not less than 60;

- l1 – 22;

- d – 10;

- c – 4;

- s1 – 1.6.

The design of the anchor-stud cone according to GOST 28457-90 is established as follows:

The numerical values of the parameters shown in the drawing look like this:

- L – 15.5;

- D – 14.0;

- X – 3.5;

- D1 – 11.0;

- S – 1.60;

- d – 10.

Below is a drawing of the bushing according to GOST 28457-90 standards.

The technical specifications shown in this drawing have the following numerical values for the M10 anchor rod sleeve:

- L – 25.5;

- D – 15.0;

- C – 2.0;

- d – 11.1;

- δ – 3.5.

Wedge anchors

This type is also called an anchor bolt or a stud anchor. It is most widespread due to its ease of installation and high load-bearing capacity. Installed in stretched and compressed areas of concrete, natural stone.

Withstands high loads subject to a number of conditions:

- sufficient tightening force of the nut to create frictional clamping of the sleeve with the walls of the hole;

- exact correspondence of the hole diameter to the anchor diameter;

- sufficient strength of concrete and absence of sinks;

- meeting the requirements for distances from the edge and between attachment points.

Wedge anchor elements

Company Sormat

(Finland) has developed highly effective wedge anchors for concrete with adjustable tightening torque for through installation of heavy and medium-heavy structures. They are made of high quality cold-formed steel. The consumer is offered a wide selection of sizes and levels of corrosion protection:

- S-KA – electrogalvanized;

- S-KAK – hot-dip galvanized;

- S-KAH – made of stainless acid-resistant steel A4;

- S-KAD – with “Delta” coating.

Table 1. Dimensions, installation parameters and loads of anchors S-KA and S-KAK

| Marking | Anchor and drill diameter, mm | Anchor length, mm | Thickness of the mounted part, mm | Hole depth, mm | Min. anchorage depth, mm | Tightening torque, Nm | Loads (compressed zone of concrete C20/25) | |

| Breakout, kN | Shear, kN | |||||||

| 6x40 | 6 | 40 | 2 | 35 | 25 | 4 | 1,0 | 2,0 |

| 6/15x65 | 6 | 65 | 15 | 45 | 35 | 7 | 1,7 | 2,5 |

| 6/50x100 | 6 | 100 | 50 | 45 | 35 | 7 | 1,7 | 2,5 |

| 8x50 | 8 | 52 | 2 | 45 | 30 | 15 | 3,3 | 3,4 |

| 8/10x72 | 8 | 72 | 10 | 60 | 45 | 15 | 3,6 | 5,7 |

| 8/30x92 | 8 | 92 | 30 | 60 | 45 | 15 | 3,6 | 5,7 |

| 8/50x112 | 8 | 112 | 50 | 60 | 45 | 15 | 3,6 | 5,7 |

| 8/85x147 | 8 | 147 | 85 | 60 | 45 | 15 | 3,6 | 5,7 |

| 10x60 | 10 | 62 | 3 | 50 | 30 | 30 | 3,5 | 3,8 |

| 10/10x92 | 10 | 92 | 10 | 75 | 60 | 35 | 6,3 | 10,3 |

| 10/20x102 | 10 | 102 | 20 | 75 | 60 | 35 | 6,3 | 10,3 |

| 10/30x112 | 10 | 112 | 30 | 75 | 60 | 35 | 6,3 | 10,3 |

| 10/50x132 | 10 | 132 | 50 | 75 | 60 | 35 | 6,3 | 10,3 |

| 10/80x162 | 10 | 162 | 80 | 75 | 60 | 35 | 6,3 | 10,3 |

| 12x85 | 12 | 85 | 3 | 75 | 55 | 50 | 6,5 | 9,6 |

| 12/5x103 | 12 | 103 | 5 | 90 | 70 | 50 | 7,9 | 13,1 |

| 12/20x118 | 12 | 118 | 20 | 90 | 70 | 50 | 7,9 | 13,1 |

| 12/30x128 | 12 | 128 | 30 | 90 | 70 | 50 | 7,9 | 13,1 |

| 12/50x148 | 12 | 148 | 50 | 90 | 70 | 50 | 7,9 | 13,1 |

| 12/65x163 | 12 | 163 | 65 | 90 | 70 | 50 | 7,9 | 13,1 |

| 12/80x178 | 12 | 178 | 80 | 90 | 70 | 50 | 7,9 | 13,1 |

| 12/155x253 | 12 | 253 | 155 | 90 | 70 | 50 | 6,4 | 6,4 |

| 16x90 | 16 | 90 | 3 | 80 | 60 | 100 | 9,9 | 21,8 |

| 16/5x123 | 16 | 123 | 5 | 110 | 85 | 120 | 16,7 | 25,1 |

| 16/20x138 | 16 | 138 | 20 | 110 | 85 | 120 | 16,7 | 25,1 |

| 16/50/168 | 16 | 168 | 50 | 110 | 85 | 120 | 16,7 | 25,1 |

| 16/60x178 | 16 | 178 | 60 | 110 | 85 | 120 | 16,7 | 25,1 |

| 16/95x213 | 16 | 213 | 95 | 110 | 85 | 120 | 10,0 | 10,0 |

| 20/20x170 | 20 | 170 | 20 | 135 | 110 | 240 | 19,8 | 27,7 |

| 20/70x220 | 20 | 220 | 70 | 135 | 110 | 240 | 19,8 | 27,7 |

| 20/130x280 | 20 | 280 | 130 | 135 | 110 | 240 | 19,8 | 27,7 |

Mungo Company

(Switzerland) proposed its own version of wedge anchors, approved for use in crack-free concrete with a strength of at least 25 N/mm2 (C 20/25). The anchoring depth is marked on the stud for correct installation. The fastener is available in four versions:

Wedge anchor Mungo m2

- – with GreenTec coating and flat washer DIN 125A;

- m2f – hot-dip galvanized, coating thickness 40 microns;

- m2-C – with 5 micron zinc coating and wide washer DIN 9021;

- m2r – made of stainless steel A4 / 316.

| code | Thread | Loads in concrete C20/25 | Bending moment, Nm | Distance between fasteners, mm | Distance from edge, mm | Min. thickness of base material, mm | Tightening torque, Nm | |

| pullout, kN | shear, kN | |||||||

| m2, m2f | M6 | 3,6 | 2,1 | 5,8 | 120 | 60 | 100 | 5 |

| M8 | 5,7 | 3,9 | 14,3 | 150 | 75 | 100 | 15 | |

| M10 | 7,6 | 6,2 | 28,5 | 174 | 87 | 120 | 30 | |

| M12 | 8,3 | 8,4 | 46,8 | 204 | 102 | 140 | 50 | |

| M16 | 9,9 | 15,7 | 118,6 | 240 | 120 | 160 | 100 | |

| M20 | 16,5 | 24,5 | 231,5 | 300 | 150 | 200 | 200 | |

| m2-C | M8 | 5,7 | 3,9 | 14,3 | 150 | 75 | 100 | 15 |

| M10 | 7,6 | 6,2 | 28,5 | 174 | 87 | 120 | 30 | |

| M12 | 8,3 | 8,4 | 46,8 | 204 | 102 | 140 | 50 | |

| M16 | 9,9 | 15,7 | 118,6 | 240 | 120 | 160 | 100 | |

| m2r | M6 | 3,6 | 3,9 | 6,4 | 120 | 60 | 100 | 6,5 |

| M8 | 5,7 | 7,1 | 16,1 | 150 | 75 | 100 | 25 | |

| M10 | 7,6 | 11,2 | 32,2 | 174 | 87 | 120 | 35 | |

| M12 | 11,9 | 16,3 | 56,4 | 204 | 102 | 140 | 125 | |

| M16 | 14,3 | 30,3 | 142,8 | 240 | 120 | 160 | 140 | |

Table 2. Dimensions, installation parameters and loads of anchors m2, m2f, m2-C, m2r.

Note:

The table shows the recommended loads taking into account the safety factor of resistances, as well as the safety factor of the actual load yF = 1.4. Let us recall that 1 kN = 101.9 kg.

Technical data valid for single fastening installed in concrete C20/25

(minimum compressive strength 25 N/mm2), without taking into account the influence of edge (

C

) and interaxial (

S

) distances.

When reducing parameters S, C or the thickness of the concrete base, it is necessary to take into account reduction factors to clarify the pull-out and shear load.

Material of manufacture

To produce anchor studs, metallurgical enterprises use different grades of steel. This can be acid-resistant stainless steel A4 or its domestic analogue - steel 10X17H13M2. Another widely available option is carbon steel, coated with a protective anti-corrosion layer using hot-dip or galvanizing methods.

In general, the manufacturing material is selected taking into account the required strength class of the final product. So, for example, if it is necessary to produce a stud anchor with strength class 10.9, manufacturing plants use the following grades of steel:

- chromium-manganese-silicon alloy structural steel St. 35KhGSA and St. 30KhGSA;

- alloy structural steel St.40X and St.40X Select;

- low-alloy structural steel St.40G2 and St.45G;

- high-quality alloy structural steel St. 38XA;

- structural chrome alloy steel St. 35X.

Installation of M10 stud anchor

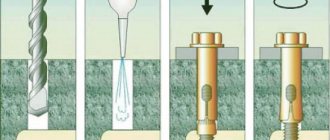

The M10 stud anchor is installed in the following order:

- first, a hole is drilled with a diameter strictly the same as that of this fastener, that is, 10 mm;

- fragments of the base building material are removed from the recess. Thorough cleaning is not necessary;

- then a pin anchor is inserted into the hole and driven in using a hammer or mallet. To prevent damage to the product, this must be done through a soft pad;

- the final stage is the connection of the stud anchor with the object to be attached. This procedure is carried out using the special nut included in the delivery of this fastener. When it is twisted, the petals located in the fixing cylinder are unclenched. In this way, the stud anchor is firmly held in the base material.

As a result of these actions, the required object is attached to the supporting structure very securely.

Features of installation of anchors for concrete

The reliability of fastening obtained using an anchor bolt is influenced by a number of factors:

- the quality of the material in which the anchor is installed;

- the type and dimensions of the fastening element, which must be selected in accordance with the loads perceived by such a product;

- correct preparation of the site for placing fasteners and compliance with the technology for its installation;

- strength characteristics of the anchor itself.

Sequence of installation operations (click to enlarge)

Installation of anchor-type bolts can be carried out in various structures, the material of which must be of sufficiently high strength. These include, in particular:

- concrete foundations;

- walls and partitions made of concrete and brick;

- floor slabs, which are usually made of concrete.

Mechanical anchor installation diagrams

Objects and structural elements that are fastened with such bolts are usually:

- beams made of rolled metal of various types;

- elements of suspended ceiling structures;

- lamps and chandeliers;

- wooden beams used for installation of floor and ceiling coverings;

- elements of staircase structures;

- load-bearing structures with large weight and dimensions.

Load calculation depending on anchor parameters

As mentioned above, fixing an anchor-type bolt inside a pre-prepared hole can be achieved in two main ways:

- by wedging the spacer sleeve inside the hole;

- due to a special adhesive composition that binds the bolt and the inner walls of the hole (chemical anchor).

There are requirements for holes in the fastened part, which should not exceed the values specified in the table. Large gaps can be filled with mortar