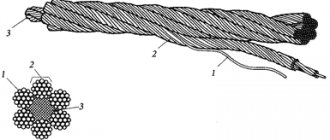

Steel cables are widely used in a wide variety of branches of human activity. These devices are most widely used in lifting mechanisms, where they are one of the most important and critical elements. Steel cables are made from high-quality wire, but they come in a huge number of different designs and can have different cross-sections. Ropes also differ in their performance characteristics, which largely depend on the physical and mechanical properties of the materials used for their manufacture.

Rope classification

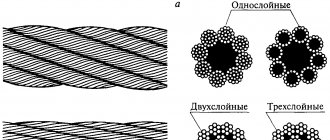

Modern steel ropes are divided according to the type of lay into the following types: · Single simple; · Double type; · Triple; · Stitched. According to the cross-section of rope strands, they are distinguished: · With flat strands; · Triangular; · With strands of oval section. In addition, ropes can be straight or reverse - this characteristic depends on the direction of laying of the strands.

How to choose the right rope?

The choice of rope primarily depends on the conditions in which it will be used. Therefore, the buyer first needs to decide what type of rope he wants to buy. In this case, the choice must be made taking into account the technical and mechanical characteristics of the cable.

Next, you will need to decide on the thickness and length of the cable, especially since today many companies can offer such products in the required sizes.

In addition, the choice of rope for loading or other mechanisms is determined by technical documentation, which precisely indicates the length, thickness, type of lay and other qualities of the product used in this unit. The client just needs to indicate the rope code (according to GOST) in the application, and the manager will send the required product to the specified address.

You can place an order for any type of cable in ours. If you need to buy hemp, jute or sisal rope, you can place an order on our portal.

For additional information about the characteristics and properties of cables, please contact our consultants, who will be happy to answer all your questions.

Steel rope core

All steel ropes have a common feature - they are made by spirally laying wire from various types of steel around a core. The core serves to ensure that there is no void inside the rope and helps the product maintain its correct shape. There are both steel cores and those made of synthetics or lubricated manila hemp or jute. Foam and jute cores are impregnated not only to protect them from rotting, but also to provide anti-corrosion protection for the internal layers of the cable - when the product bends, the lubricant seeps into the voids existing between the wires, ensuring their uniform lubrication.

In ropes, the core works as an excellent shock absorber, holding the strands in the designed position and, speaking in engineering terms, the core resists radial loads that inevitably arise during operation, preventing deformation of the product. As we have already said, there are cores of organic origin, hemp and jute, and cores made of inorganic materials - steel and synthetic. The material most often used for synthetic cable elements is polypropylene - a durable, resistant to external influences and inexpensive material. Hemp and jute cores are subject to mandatory impregnation with lubricant, the share of which ranges from 35 to 50% of the mass of the organic material itself. The highest quality materials are used to lubricate ropes, since the durability of the rope largely depends on the choice of lubricant.

Protective lubricant for steel ropes

The main purpose of rope lubricant is to protect the metal from corrosion. Additionally, the lubricant protects the organic core of the steel rope and reduces abrasive wear of both the external and internal wires of the rope.

Various lubricants are used in production - SK-50, KS-U, Torsiol, Elascon, Nyrosten, etc.

Rope lubrication codes of Severstal Ropes JSC

| Lubrication code | Organic core** | Metal core | Strands of rope | Rope | ||

| S P | PP | strands | generally | |||

| S(A) | — | without lubrication | without lubrication | without lubrication | without lubrication | without lubrication |

| A0 | soaked | — | blurred | without lubrication | without lubrication | without lubrication |

| A1 | soaked | without lubrication | blurred | without lubrication | blurred | without lubrication |

| A2 | soaked | without lubrication | blurred | blurred | blurred | greased |

| A2* | soaked | without lubrication | lubricated*** | without lubrication | lubricated*** | without lubrication |

| A3 | soaked | greased | blurred | without lubrication | without lubrication | greased |

| A4 | without lubrication | without lubrication | without lubrication | greased | blurred | without lubrication |

| A5 | without lubrication | without lubrication | without lubrication | greased | blurred | greased |

| A6 | without lubrication | without lubrication | without lubrication | greased | without lubrication | greased |

* - for lubricants Nyrosten T55, Nyrosten A19/200

** — sisal — S, hemp — P, polypropylene — PP

*** - lubricated without wiping

OJSC MMK-METIZ rope lubrication codes

| Lubrication code | Organic core | Metal core | Strands of rope | Rope | |

| strands | generally | ||||

| A0 | not soaked | without lubrication | without lubrication | without lubrication | without lubrication |

| A1 | — | blurred | greased | greased | without lubrication |

| A2 | soaked | — | — | blurred | without lubrication |

| A3 | soaked | blurred | greased | blurred | greased |

| A4 | soaked | without lubrication | without lubrication | without lubrication | without lubrication |

Rope lubrication codes of SE "KHSPKZ "SILUR"

| Lubrication code | Organic core | Metal core | Strands of rope | Rope | |

| strands | generally | ||||

| Dry | without lubrication | without lubrication | without lubrication | without lubrication | without lubrication |

| A1 | greased | blurred | without lubrication | blurred | without lubrication |

| A2 | greased | blurred | blurred | blurred | blurred |

| A3 | greased | lubricated* | lubricated* | lubricated* | lubricated* |

* Lubricated with rubbing.

OJSC "BMK" rope lubrication codes

| Lubrication code | Organic core | Metal core | Strands of rope | Rope | |

| strands | generally | ||||

| A0 | not soaked | without lubrication | without lubrication | without lubrication | without lubrication |

| A1 | soaked | blurred | without lubrication | without lubrication | without lubrication |

| A2 | soaked | blurred | without lubrication | blurred | without lubrication |

| A3 | soaked | blurred | greased | blurred | greased |

| A4 | soaked | blurred | greased | blurred | lubricated* |

* Lubricated without wiping.

Physical properties of ropes

Steel ropes can have different flexibility, which depends both on the properties of the wire used in the manufacture and on its quantity in the lay. The least flexible ropes consist of 42 wires, and the more flexible ones consist of 72 wires, located 12 in each strand. Highly flexible ropes are also produced, which consist of 144 wires, which are located around the core, 24 pieces in each strand. For use at elevated temperatures or in aggressive environments, cables with a steel core are used. Also, this type of rope is ideal if the product is wound onto a drum in numerous layers - the steel core prevents the rope from deforming under the influence of the load exerted by the overlying turns. The steel core makes the rope more resistant to deformation, but has virtually no effect on the load capacity. Ropes with synthetic and hemp cores have greater flexibility and provide uniform lubrication, since in them the lubricant enters the strands not only from the outside, during routine maintenance, but also from the inside, from the impregnated core material.

Strength characteristics of ropes, breaking force, marking group of ropes

| Catalog / strength characteristics, breaking force, marking group |

Steel rope is the main load-bearing element of most lifting, transport, road-building, earth-moving machines and mechanisms, which are one of the most common types of hardware and are widely used in a wide variety of industries: coal, mining, oil and gas production and processing, transport and agricultural engineering, construction industry, marine, river transport, etc.

Each type and design of steel rope has its own characteristics that must be taken into account when choosing for specific operating conditions. in this case, it is necessary to maintain the recommended ratios between the diameters of the winding elements and the diameters of the ropes, as well as the necessary safety margin to ensure trouble-free operation.

The product range includes crane ropes, for elevators, for hoists, lifting ropes for mine installations, for excavators, traction ropes for overhead roads and cable cranes, for skip hoists of blast furnaces, for car dumpers, for the production of prestressed reinforced concrete products, for ship lifting devices, for standing rigging of ships, reinforcement, spiral, mooring and towing, etc. We cut steel rope of any length, complete orders with non-standard lengths.

Marking of steel ropes:

The strength characteristics of the rope are reflected in its markings. Marking of a rope with a diameter of 15 mm for cargo-carrying purposes, brand VK, galvanized according to group Zh, low-twisting, left-hand cross lay, non-unwinding, increased manufacturing precision, marking group 1900 N/mm2 has the following symbol:

Rope 15 GL-VK-Zh-MK-L-N-R-T-1900 GOST (TU)

.

Marking of rope GOST 3079 with a diameter of 25.0 mm, cargo purpose, grade 1, galvanized according to group Zh, left one-sided lay, non-unwinding, non-straightened, increased accuracy, marking group 1370 N/mm2 (140 kgf/mm2) has the following symbol:

Rope 25 G-1-Zh-L-O-N-T-1370 GOST 3079-80

Rope GOST 16853 with a metal core, diameter 32 mm, grade B, right-hand cross lay, increased manufacturing accuracy T, marking group for temporary tensile strength 1570 N/mm2 (16 kgf/mm2) is marked as follows:

Rope MS-32-V-T-1570 GOST 16853-88

The cargo rope GOST 2688-80 with a diameter of 16.5 mm, grade VK, galvanized according to group C, right-hand cross lay, increased manufacturing accuracy T, marking group for temporary tensile strength 1570 N/mm2 (16 kgf/mm2) is marked as follows:

Rope 16.5 G-VK-S-T-1570 GOST 2688-80

Strength characteristics of ropes:

| Design, GOST | Diameter, mm | Marking group, N/mm2 (kgf/mm2) | ||

| 1570(160) | 1670(170) | 1770(180) | ||

| Breaking force in general, N, not less | ||||

| GOST 2688-80 6x19(1+6+6/6)+1о.с | 3,6-51,0 | 15800-1295000 | 16800-1340000 | 7465-1395000 |

| GOST 3062-80 1х7(1+6) | 0,65-10,5 | 715-93200 | 764-97750 | 431-102000 |

| GOST 3063-80 1x19(1+6+12) | 1,1-17,0 | 1900-244500 | 2015-255500 | 1145-267500 |

| GOST 3064-80 1х37(1+6+12+18) | 1,6-24,0 | 3485-448500 | 3700-463500 | 21,5-48200 |

| GOST 7668-80 6x36(1+7+7/7+14)+7x7(1+6) | 10,5-57,0 | 66150-1905000 | 70450-1950000 | 71800-2000000 |

| GOST 14954-80 6x19(1+6+6/7x7(1+6)) | 9,7-49,5 | 56350-1480000 | 59850-1535000 | 61700-1595000 |

| GOST 16853-88 6x31(1+6+6.6+12)+1 o.s. | 25,0-38,0 | 349900-781000 | 371000-830000 | 393000-878500 |

| GOST 16853-88 6x31(1+6+6.6+12)+7x7(1+6) | 25,0-38,0 | 400500-896500 | 426000-952500 | 451000-1009000 |

| GOST 3066-80 6x7(1+6)+1x7(1+6) | 3,8-27,5 | 8495-470000 | 9035-499500 | 9954-514500 |

| GOST 3067-88 6x19(1+6+12)+1x19(1+6+12) | 6,2-18,5 | 21200-190000 | 22550-202000 | 23850-214000 |

| GOST 3068-88 6x37(1+6+12+18)+1x37(1+6+12+18) | 8,0-13,0 | 35500-88550 | 37750-94300 | 40000-99700 |

| GOST 3069-88 6x7(1+6)+1о.с. | 3,3-29,0 | 5405-421500 | 5730-448000 | 6085-465500 |

| GOST 3070-88 6x19(1+6+12)+1о.с. | 6,5-13,0 | 19550-77750 | 20800-82600 | 22000-87250 |

| GOST 3071-88 6x37(1+6+12+18)+1о.с. | 8,5-15,5 | 32400-110000 | 344550-117000 | 36450-124000 |

| GOST 3077-80 6x19(1+9+9)+1о.с. | 7,8-41,0 | 29900-843000 | 31300-872000 | 32750-906500 |

| GOST 3079-80 6x37(1+6+15+15)+1о.с. | 11,5-58,0 | 62600-1610000 | 66500-1715000 | 68750-1765000 |

| GOST 3081-80 6x19(1+9+9)+7x7(1+6) | 8,6-40,5 | 45800-974500 | 48650-1005000 | 50150-1045000 |

| GOST 3083-80 6x30(0+15+15)+7о.с. | 6,5-57,0 | 28650-1300000 | 30450-1380000 | 17800-1430000 |

| GOST 7665-80 6x25(1+6;6+12)+1o.s. | 16,0-45,0 | 126500-999500 | 134500-1055000 | 139500-1095000 |

| GOST 7667-80 6+25(1+6;6+12)+7x7(1+6) | 15,5-44,0 | 146000-1145000 | 155000-1220000 | 160000-1260000 |

Maximum deviations for the diameter of single and double lay ropes

Limit deviations of ropes with a metal core and with an organic core.

| Diameter, mm | Limit deviations, %, no more, for ropes | |||

| Increased accuracy | Normal accuracy | |||

| with metal core | with organic core | with metal core | with organic core | |

| Up to 3.0mm incl. | +7 -1 | +6 | +10 -2 | +10 |

| St. 3.0 to 6.0 incl. | +6 -1 | +6 | +10 -2 | +10 |

| St. 6.0 to 80 incl. | +5 -1 | +6 | +10 -2 | +10 |

| St. 8.0mm | +4 -1 | +5 | +6 -2 | +7 |

Maximum deviations for the diameter of single lay ropes

| Diameter, mm | Maximum deviations of single lay rope diameter, %, no more | |

| Normal accuracy | Increased accuracy | |

| Up to 1.5 mm incl. | +10 -2 | +5 |

| St. 1.5 to 8.0 mm incl. | +10 -2 | +4 |

| St. 8.0 to 16.0 mm incl. | +6 -2 | +4 |

| St. 16.0 mm | +6 -2 | +3 |

Wire made from steel grades 80, 85 is used for the manufacture of reinforcing ropes.

Rejection of ropes based on the number of wire breaks per length of one lay step

| Initial safety factor | Design | |||||||

| 6x19=114 organic core | 6x37=222 organic core | 6x61=366 organic core | 18x19=342 organic core | |||||

| The number of wire breaks over the length of one pitch of rope laying, at which it must be rejected. | ||||||||

| Cross. lays | Single sided lays | Cross. lays | Single sided lays | Cross. lays | Single sided lays | Cross. lays | Single sided lays | |

| Until 6 | 12 | 6 | 22 | 11 | 36 | 18 | 36 | 18 |

| From 6 to 7 | 14 | 7 | 26 | 13 | 38 | 19 | 38 | 19 |

| Over 7 | 16 | 8 | 30 | 15 | 40 | 20 | 40 | 20 |

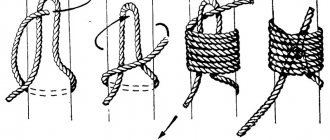

Steel ropes are widely used in all branches of industry and construction. They are used in installation, crane operations, rigging work, for braces, hangers, rods, load hangers, etc.

For cargo and lifting slings, flexible ropes with an organic core are used.

For braces, shrouds, rods, and hangers (in maritime affairs, this is “standing rigging”), more rigid ropes are required.

The selection of steel ropes of the required strength is carried out by determining the maximum design forces and multiplying them by the safety factor.

The obtained result is compared with the breaking force of the rope. Safety factor of steel rope

| Purpose | Safety factor K3 |

| Manually operated load ropes | 4 |

| Machine driven load ropes for light duty applications | 5 |

| Machine driven load ropes for medium duty applications | 5,5 |

| Heavy duty machine driven load ropes | 6,0 |

| Ropes for pulleys with variable length under load with a lifting capacity from 5 to 50 tons with a D/d ratio: | |

| Load capacity from 13 to 16 | 5,0 |

| Load capacity from 16 or more | 4,0 |

| Ropes for pulleys with variable length under load with a lifting capacity from 50 to 100 tons with a D/d ratio: | |

| Load capacity from 13 to 16 | 4,0 |

| Load capacity from 16 or more | 3,5 |

| Ropes for chain hoists with variable length under load with a lifting capacity of 100 tons or more with a D/d ratio: | |

| Load capacity from 13 to 16 | 3,5 |

| Load capacity from 16 or more | 3,0 |

| Slings with strapping or hooking with hooks or earrings | 6,0 |

| Twisted slings with a D2/dc ratio of 2 or more | 5,0 |

| Towel slings with a ratio D3/dc 3.5 to 6 | 5,5 |

| Towel slings with a D3/dc ratio of 6 or more | 5,0 |

| Braces, guys, traction with a D3/d ratio of 4 to 5 | 5,0 |

| Braces, guys, traction with a D3/d ratio from 5 to 7 | 4,0 |

| Braces, guys, traction with a D3/d ratio from 7 to 9 | 3,5 |

| Braces, guys, traction with a D3/d ratio of 10 or more | 3,0 |

Letter designations: D – roller diameter; d – rope diameter; D3 – diameter of the gripping device (element encircled by a sling, brace, rod, fastening rope); dc – diameter of the twisted sling. The light mode is characterized by the operation of the rope at low speeds without jerks with the number of bends on the rollers no more than four, and the heavy mode is characterized by the operation of the rope at high speeds, with jerks and the number of bends on the rollers more than four.

At the customer's request, it is possible to ship steel ropes of unmeasured length (with unwinding).

We sell ropes and cables with shipment by any type of transport from 100 meters or reels to all regions of Russia.

Delivery within the Russian Federation: Moscow, St. Petersburg, Arkhangelsk, Astrakhan, Barnaul, Belgorod, Bryansk, Vladimir, Volgograd, Vologda, Voronezh, Yekaterinburg, Ivanovo, Izhevsk, Yoshkar-Ola, Kazan, Kaluga, Kirov, Kostroma, Krasnodar, Kurgan, Kursk, Lipetsk, Omsk, Orenburg, Penza, Perm, Pskov, Rostov-on-Don, Ryazan, Samara, Saransk, Saratov, Sevastopol, Simferopol, Smolensk, Stavropol, Tambov, Tver, Tomsk, Tula, Tyumen, Ulyanovsk, Ufa, Chelyabinsk, Yaroslavl, etc.

The information presented on this website contains a catalog of reference information on more than 3,000 types of metal products, is for informational purposes only, and can be used in various areas of enterprise activity.

| Steel wire Welding electrodes Steel rope Fasteners | Metal mesh Hex bolts Nut GOST, DIN Steel rivets | Adjustable cotter pins GOST, DIN washers Threaded rods Calibrated rolled products | Slings, rigging Construction nails Steel cable Screws GOST, DIN |

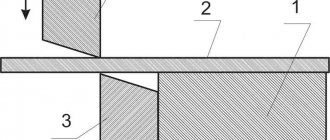

Packing of steel ropes

Steel ropes reach the consumer on wooden or returnable metal drums, and in some cases in coils. Winding on drums is carried out in accordance with GOST 11127-78, which stipulates packaging rules. The standards stipulate that the drum neck must have a diameter of no less than 15 full rope diameters, and the side of a fully equipped drum, with a rope diameter of 25 mm, must protrude by 2 diameters and by at least 50 mm if the diameter of the rope section exceeds 25 mm .

Rope diameter

The diameter of the rope section is one of the most important characteristics of this product. Usually all the characteristics of the product are indicated on the drum tag or in the certificate attached to the rope by the manufacturer, but sometimes it becomes necessary to check the diameter of the rope, for example, if there are any doubts or the marking is simply lost. The diameter of the steel rope is measured with a caliper and measured at two different points, with a distance of at least 1 meter between them. At each point, two thickness measurements are made, in planes necessarily perpendicular to each other. The diameter of the rope is determined by taking the arithmetic mean of these four quantities, taking into account the tolerances accepted for the nominal diameter of this product.

Articles about products Updated: 12/03/2020 12:35:58