The information below on the classification of ropes is far from new, and we cannot add practically anything new. You can easily find similar materials on other resources, so why do we host it? Looking at the classification below, you will understand that there are a large number of types of rope and sometimes even a specialist can find it quite difficult to understand what Rope 12—GL—VK—L—O—N—1770 GOST 2688–80 is.

Working with the same ropes, it’s quite easy to decipher everything, but if the client wants to buy a non-standard rope? This is where “Where to watch?” comes in. Where to get? What does this letter in the name mean? We have previously published material about ropes, but did not describe the classification in detail, so we hope that this article will be useful to you.

Classification, technical requirements, test methods, rules for acceptance, transportation, and storage of steel ropes are set out in GOST 3241-91 “Steel ropes. Technical conditions".

Prices and characteristics of steel rope

Steel cargo rope

| ø, mm | GOST / Lubrication | Weight 1000m, kg | Price m, ₽ (per drum) | Price m, ₽ (unwinding) | |

| 4,1 | Steel rope 2688-80/A1 | 64 | 31.10 | 35,77 | Buy |

| 5,1 | Steel rope 2688-80/A1 | 96 | 35,36 | 38,19 | Buy |

| 6,2 | Steel rope 2688-80/A1 | 142 | 43,83 | 47,34 | Buy |

| 7,6 | Steel rope 2688-80/A1 | 211 | 54,80 | 59,18 | Buy |

| 8,3 | Steel rope 2688-80/A1 | 256 | 62,55 | 70,68 | Buy |

| 9,1 | Steel rope 2688-80/A1 | 305 | 70,30 | 75,92 | Buy |

| 9,6 | Steel rope 2688-80/A1 | 359 | 75,62 | 81,67 | Buy |

| 11 | Steel rope 2688-80/A1 | 462 | 92,63 | 100,04 | Buy |

| 12 | Steel rope 2688-80/A1 | 527 | 104,78 | 113,16 | Buy |

| 13 | Steel rope 2688-80/A1 | 597 | 113,70 | 122,80 | Buy |

| 14 | Steel rope 2688-80/A1 | 728 | 134,41 | 145,16 | Buy |

| 15 | Steel rope 2688-80/A1 | 844 | 150,08 | 162,09 | Buy |

| 15 | Steel rope 2688-80/A2 | 844 | 150,08 | 162,09 | Buy |

| 16,5 | Steel rope 2688-80/A2 | 1025 | 177,51 | 191,71 | Buy |

| 16,5 | Steel rope 7668-80/A1 | 1045 | 193,52 | 209,00 | Buy |

| 18 | Steel rope 7668-80/A1 | 1245 | 227,11 | 245,28 | Buy |

| 19,5 | Steel rope 2688-80/A1 | 1405 | 237,84 | 256,87 | Buy |

| 20 | Steel rope 7668-80/A1 | 1520 | 266,62 | 287,95 | Buy |

| 20 | Steel rope 7668-80/A2 | 1520 | 266,62 | 287,95 | Buy |

| 22 | Steel rope 7668-80/A1 | 1830 | 301,59 | 325,72 | Buy |

| 23,5 | Steel rope 7668-80/A1 | 2130 | 349,33 | 377,28 | Buy |

| 24 | Steel rope 2688-80/A2 | 2130 | 345,21 | 372,83 | Buy |

| 25 | Steel rope 3079-80/A1 | 2245 | 391,69 | 423,03 | Buy |

| 27 | Steel rope 3079-80/A1 | 2650 | 460,04 | 496,84 | Buy |

| 30,5 | Steel rope 3079-80/A1 | 3405 | 584,14 | 630,87 | Buy |

| 33 | Steel rope 3079-80/A1 | 3920 | 666,00 | 719,28 | Buy |

| 35 | Steel rope 3079-81/A1 | 4435 | 747,23 | 807,01 | Buy |

| 39 | Steel rope 3079-82/A1 | 5395 | 906,18 | 978,67 | Buy |

Galvanized steel rope

| Length | Price m, ₽ | ||||

| from 1 meter | To order | Buy | |||

- Types of steel ropes (cables)

- STEEL ROPES GOST 3063-80

- STEEL ROPES GOST 3077-80

- Aviation steel ropes GOST 2172-80

- STEEL ROPES GOST 3079-80

- Steel ropes GOST 14954-80

- Steel ropes GOST 3062-80

- Steel ropes GOST 3071-88

- Steel ropes DIN 3061

- Steel ropes DIN 3062

- Steel ropes DIN 3071

Ropes

- Double lay LK-R

- Double lay TLK-O

- Single lay TK

- Double lay LK-RO (Organic core)

- Double lay LK-RO (Metal core)

Steel rope is used in various industrial sectors where lifting equipment is used (cranes, rigging equipment, etc.). ropes vary in design, stretch coefficient, and flexibility. The most commonly used steel ropes are GOST 2668-80 and GOST 7668-80.

Explanation and characteristics of symbols

The characteristics of ropes classified according to the above GOST standards may have the following designations:

- GL – cargo-human, G – cargo;

- VK – highest quality, B – standard, 1 – budget;

- OS – organic core, MS – metal;

- C - galvanized product is intended for use in average climatic conditions, Zh - in harsh conditions, OZh - especially harsh, P - the cable is coated with polymer materials;

- N – non-unwinding;

- R – straightened;

- T – increased manufacturing accuracy;

- K – combined lay, O – one-sided, L – left, P – right;

- R – straightened.

A cable that complies with GOST 2668-80 standards is designated LK-R according to the type of lay. This indicates that wire of different diameters (P) was used in the outer layer of the strand, with a linear tangency (LT) between the layers. The GOST 7668-80 rope is designated as LK-RO (that is, wire with different (P) and identical (O) diameters is used), laying technology is linear tangency (LT).

The rope design formula also needs to be deciphered and is the sum of the numbers of wires in the layers. For example, the GOST 2668-80 cable designation looks like this: 6x19 + 1 o.s. In this case, 19 is the number of wires in one layer, 6 is the number of layers, 1 o.s. – organic core.

scope of application of steel ropes

Cables of the LK-R or LK-RO type are used on construction and mining hoists, scrapers, various cranes, excavators, and overhead roads. They are used on earthmoving and mining machines as ropes for winches, on trawlers for equipping ladders, on drilling rigs, in elevators - for vertical lifting, for friction pulleys, and also for drum winches.

LK-R cables can withstand fairly high mechanical loads when used in aggressive environments, outdoors, and under stressful working conditions. LK-RO ropes are characterized by a large number of wires in the strands, which provides them with increased flexibility. Products of this type are resistant to abrasive wear and can be used in difficult conditions (with increased dust in mines, during excavation work, in sand quarries, etc.).

Properties and tasks of the core

The core is the internal support for the rope and also a shock absorber for the wire strands. Its main function is to withstand the radial pressure of the strands under the tested loads of the rope, without allowing its deformation. The core, made of organic materials, is impregnated with lubricant during production, which protects the inside of the rope from abrasion and corrosion.

The organic core can be made of the following materials:

- polypropylene, polyethylene;

- viscose, nylon, lavsan;

- hemp;

- cotton yarn or cord.

The production of cores is carried out under strict quality control, taking into account the technical standards provided for by GOST.

Method of laying ropes, degree of twist

Steel cables can be non-unwinding or unwinding. Types marked with the letter “H” (non-unwinding) have the following advantages:

- practically do not form loops or knots during operation;

- the free ends of the cable are not subject to unwinding and do not unravel;

- the rope does not rotate in a circular motion when cutting or when removing bandages from the end of the rope.

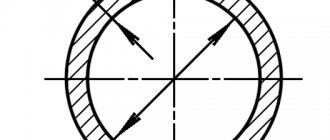

The method of laying ropes can be left (designation - Latin “S” or Slavic “L”) or right (Z). This depends on the screw direction in which the outer layers are located. The lay directions can be combined, one-sided (Zz or Ss) or opposite, cross (Zs, Sz).

The use of ropes of different lays helps to reduce the torsion of the suspended load. If it is made with the same lay direction of all wire strands, then it will have a high degree of twist. Opposite directions of lay give the effect of low twist (designation “MK” - low twist).

Types of lubrication for steel ropes

In order for the cables to serve as long as possible, they must be properly cared for. Regular lubrication will protect the cable from corrosion and mechanical damage, as well as from deformation and rotting of the organic core. The main types of lubricants used as protective compounds are Torsiol-55 (35), BOZ-1. The products can be used in a fairly wide range of operating temperatures ±50C. The lubricant should be applied in a continuous layer about 0.2 mm thick; it is used in the production of ropes, as well as during their operation.

Types of steel ropes (cables)

Although steel wire is used as the basis for the production of ropes, its characteristics vary. Various laying options can also be used. All this leads to a variety of cable designs.

Depending on the laying method, they are:

- single;

- double;

- triple;

- stitched.

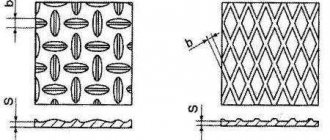

Based on the characteristics of the strand profile, ropes with flat, triangular and straight oval strands are distinguished. In the direction of weaving, products can be straight or reverse. Another classification is based on the material of the core. It can be steel, synthetic, natural hemp or jute.

METHODOLOGY FOR DETERMINING AND ESTABLISHING OPTIMAL VALUES OF LAYING STEPS

The optimal values of the laying pitches of the rope and strands are selected within the limits established by clause 2.1.8 of this standard (the laying pitch of the rope is no more than seven values of its diameter and the outer layer of wires in a strand is no more than 11), and from the condition that the characteristic number l

, determined by the formula

(1)

where N -

step of laying strands into a rope;

h -

laying step of wires into a strand;

z —

adjustment coefficient of the mechanism for unscrewing the frames of the charging reels of rope machines;

+ - for cross lay of rope;

— — for one-sided rope laying.

Lay angle of strands in rope b

, degree, calculated by the formula

(2)

where dк

and

dpr -

diameters of the rope and strand, mm.

Deviations l

should not exceed ±0.15.

As an example, the calculation of the optimal lay parameters of a six-strand cross-lay rope with a diameter of 32 mm (strand diameter is 10 mm) is given.

The maximum calculated pitch of laying strands into a rope should be no more than 7 ´ 32 = 224 mm.

The technical characteristics of the rope winding machine allow you to set the technological step H

t = 203.5 mm, angle

b

will be equal to 18° 10¢ according to formula (2).

Taking the value of the characteristic number l

= 6 ± 0.15, set the range of steps for laying wires into a strand using formula (1)

h

= 103 - 109 mm.

Based on the parameters of the spinning machine in the specified range, select the technological step h

t = 106 mm.

The value of the technological step h

t should not exceed the optimal values of laying steps, namely

h

t £ 110 mm.

If laying steps do not comply with the requirements set out above, they are recalculated.

Steel rope

Steel rope or cable has a wide range of applications. Products are an important element:

- many lifting systems and equipment;

- tower, gantry and truck cranes;

- winches, hoists;

- pipe-laying, shaft and elevator installations;

- hoists, mounting and traction mechanisms.

Our association also sells steel cables with various characteristics of breaking force and flexibility. To give the products the required properties, high-quality carbon steel is used; upon agreement with the client, the cargo rope is coated with a layer of zinc in accordance with the requirements of class “C” and “F”.

Load rope - prices and characteristics

A steel cargo rope is based on a core, around which a rope strand consisting of wire of different sections is wound. Elements made of hemp, metal or inorganic compounds can be used as a core. This information is placed in the product passport and is reflected in the markings, which are applied directly to the cable tag. To protect the cargo rope from moisture and other unfavorable factors, even during production, the products are coated with a thin layer of zinc and a special lubricant.

At the final stage, the product is wound onto a drum or folded into a coil. You can buy steel cable from us with a winding length of 500 or 1000 m. At the client’s request, it is possible to cut products to the required length with an accuracy of one meter.

Products are shipped from a warehouse where the availability of the most popular product options (diameter from 4.1 to 39 mm) is constantly maintained. Prices for cargo ropes are based on the diameter of the products. The cross-sectional circumference can range from 4.1 to 39 mm. We recommend checking current prices for cargo ropes with managers; they will also advise on all issues of ordering and delivery, and calculate the cost and timing of transportation.

ACCEPTANCE

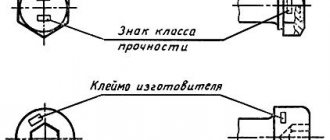

3.1. Ropes are accepted in batches. The batch must consist of a rope of the same standard size in one packaging unit, issued by one quality document, which indicates:

trademark or name and trademark of the manufacturer;

name of the organization in whose system the manufacturer is included; rope number in the manufacturer’s numbering system; symbol of the rope; the length of the rope or each segment; gross weight of the rope; mechanical test results;

the total breaking force of all wires in the rope or the breaking force of the rope as a whole; organic core material; date of manufacture of the rope; rope lubrication type; drum number; technical control stamp;

image of the mark of conformity for mandatory certification.

(Changed edition, Amendment No. 1).

3.2. The appearance, size, mechanical properties of the rope wires, total breaking force, and quality of the zinc coating are checked on each rope.

3.3. The breaking force of the rope as a whole is checked at the request of the consumer.

3.4. The results of tests for tensile, torsion, bending and wire diameter control are considered satisfactory if the total cross-sectional area of the wires that do not meet the requirements of this standard is no more than 5% of the nominal cross-sectional area of all wires in the rope at 100% testing, no more than 2 % of the nominal cross-sectional area of the rope for 25 and 10% tests of wires in the rope, and for single lay ropes the number of wires that do not meet the requirements of the standard should not exceed 5% of the tested wires from the rope. In this case, the actual value of the diameters of these wires should not exceed the nearest adjacent diameter in accordance with GOST 7372 in relation to the diameters specified in the standards for the range or specified in accordance with clause 2.1.6. It is allowed in cargo ropes to have wires that differ in diameter from those specified in the assortment standards by 0.2 mm for wires with a diameter of St. 1.20 mm in the quantity stated above.

If the test results do not comply with the requirements of this standard, the rope is retested. The results of repeated tests are applied to the entire batch.