A thimble for a steel rope or cable is a frame made of high-strength carbon steel, which can have various shapes: round, triangular or teardrop-shaped. It is assumed that such a useful device as a thimble was originally used to equip ship ropes and cables. The name of this device, which is actively used in the construction industry today, has Dutch roots and means “stocking” (kous). It’s no wonder that the Dutch are also considered the authors of this device.

Throat DIN 6899B

Choosing a thimble according to its intended purpose

Today we produce round thimbles intended for use on ships, cable-stayed thimbles, acid-resistant thimbles and wedge sockets.

A round thimble with zinc coating is a product of a regular round shape, with which you can create an even circle inside the rope.

Thimbles, which are common in maritime affairs, are most often teardrop-shaped and made by hot forging. There are two types of such thimbles: C and P. The first type is used to work with steel ropes, and the second - with plant ropes. Throngs of types C and P can be made of both carbon and low-magnetic steel. The largest type C fastener is the thimble, which is produced for cables with a thickness of more than 6 cm in diameter. When choosing these products, you should pay attention to the markings, because the numbers show how much load a particular thimble can withstand. So, C400 can withstand a load of 40 tf, and P20 - 2 tf.

Cable-stayed products were also directly related to port work. But today, this type of thimble is increasingly used in construction to create a variety of braces, supports, and, if necessary, to connect structural elements and mechanisms. A distinctive feature of this species is its small diameter.

For the manufacture of elements resistant to various acids, acid- and corrosion-resistant steels M1-M12 are used. The use of such raw materials guarantees additional strength and reliability of thimbles in production. This species is easy to recognize - it has a shiny surface. Wedge versions of thimbles are a kind of clip for fixing steel ropes during rigging work. The design contains a wedge that fixes the rope between two more elements of the thimble: the clip and the bet.

Semi-thongs are designed to eliminate the possibility of bending of thick ropes with small bending radii, which often occurs during lifting and transporting loads. A special feature of the thimble for artificial ropes is that its groove is closed. This solution prevents the soft material cable from slipping out.

Mounting methods09/26/2019 10:16:46

This is interesting: Thick-walled steel pipes - application and main characteristics

Crimp sleeves

Crimping sleeves for steel cable assemblies are one of the frequently performed functions of equipment for lighter operating conditions.

The question often arises , which is better, crimp ends or wire rope clamps?

Steel Cable Clamps and Crimping Sleeves

Crimp sleeves, stronger and more efficient. Requires no future maintenance or re-tightening of nuts. It has a streamlined shape than metal rope clamps.

Crimping refers to the process of using a tool or machine to apply force to a bushing or ferrule. As a result of this process, the sleeve is sealed on and around the cable portion.

Sleeve crimp

Aluminum crimp fittings

Most often, an aluminum cable clamp is used with galvanized steel cable to form cable assemblies.

Aluminum sleeve placed on a galvanized cable

Aluminum is soft. When compressed, using a crimping tool, it will be pressed into the grooves of the rope , locking the aluminum sleeve in place.

Aluminum sleeve in cable

Installation

Passing the steel rope through the sleeve.

Pass the cable through the sleeve

Before crimping, make sure that the “cut end” of the steel rope sticks out to a length of at least 2 cable diameters. This ensures full contact with the cable as the sleeve expands during crimping.

Two cable diameters

Place the sleeve into the jaws of the tool.

Sleeve correctly in the tool

Sleeve incorrectly in tool

Pay attention to the correct orientation of the crimping tool cavity with the aluminum bushing.

The sleeve should always be aligned vertically, not horizontally.

Keeping the case in the correct position, make your first crimp by squeezing the crimping tool handles together until the jaws are completely closed.

Forging

Sleeve crimp

For each sleeve size there is a prescribed number of crimps that must be completed.

Leave a little space between each crimp. Your finished assembly should look like the image shown.

Crimping distance

For 1/16" and 3/32" sleeves, 2 crimps will be required.

For 1/8" and 5/32" sleeves, 3 crimps will be required.

For 3/16" and 1/4" sleeves, 4 crimps will be required.

For 5/16" and 3/8" sleeves, 5 crimps will be required.

Pressure gauge

To ensure that the crimps are done correctly, use a calibrator.

Pressure gauge

Using the appropriate measuring cavity, slide the sensor onto the sleeve.

If the pressure gauge rotates freely around the crimp zone, then everything is done correctly.

The pressure gauge rotates freely around the crimp area

If the sensor does not slip in the crimp area, use a re-crimp tool to ensure that the coupling has been fully compressed.

Steel rope with polymer coating

It is recommended to trim the vinyl far enough to ensure that the sleeve makes direct contact with the cable.

Vinyl coated cable

Using the same crimping method, elbow joints can be made to connect two pieces of cable.

Knee connection

Remember to leave a small area between the sleeves.

Small area between sleeves

Extend the end of the metal cable beyond the outer edge of the coupling at least 2 cable diameters.

Cable end

Zinc Copper Sleeves

Zinc, copper and glass sleeves are recommended for stainless steel wire ropes.

Zinc and copper hoses

Aluminum sleeves are not recommended for use with stainless steel cables due to the possibility of corrosion of aluminum upon contact with stainless steel. Over time, this can lead to weakening of the contact between the coupling and the cable.

What is a thimble and its types

A thimble is a special mandrel for a loop (fire) of a cable (steel or soft materials), protecting it from damage, breakage and rapid wear (abrasion). What is the protective function of this product and how is it actually carried out? The outer side of the thimble is made in the form of a groove (has a groove), into which the cable, that is, its loop, is placed, quite tightly. And this mandrel itself has a shape as close as possible to the contour of the fire.

Koush

Thanks to this design of the thimble, the cable, being in its groove, does not come into direct contact with the part (element) to which it is attached with its loop. The shape and dimensions of the mandrel ensure that the rope fits evenly and without kinks. The sides of the thimble groove do not allow the loop to come off, and also protect the cable from damage from the side, although there it is least susceptible to wear and other mechanical stress.

Since thimbles are used in so many areas of production and human activity, several types are produced, which are listed and briefly described in the corresponding publication on the site. This is the article “Kushi - what it is, main characteristics and varieties.” For the purposes of this publication, we only note that in shape (appearance) this mandrel can be round, triangular or teardrop-shaped. Thimbles in the latter version are the most common and are used in almost all cases where such cable protection is necessary.

Thimbles are made mainly from carbon steel, but there are also plastic ones. Steel ones are made by casting, stamping or forging, followed by galvanizing or painting to ensure their protection against corrosion. Structurally, the thimble can be made one-piece or composite, consisting of several parts. One of the types of such mandrels is shown in the photographs below. Moreover, this is a teardrop-shaped thimble.

Of course, each rope (a certain range of diameters) has its own thimble, that is, with the corresponding external, internal and groove dimensions.

Moreover, for the same cable, the dimensions, dimensions and weight of thimbles produced in accordance with different GOSTs differ. As an example, we can compare the two most common and most popular types of mandrels. These are drop-shaped thimbles of standard 2224-93 and the same shape, but produced in accordance with GOST 19030-73. The drawings according to which they are made are presented respectively in Fig. 1 and 2. Taken from these GOSTs.

Rice. 1. Throngs standard 2224

Rice. 2. Throngs standard 19030

Let's compare the characteristics of these two products, designed for a cable with a diameter of 3 mm. Both standards produce thimbles used to protect the fire of ropes with diameters in the range of over 2.5 and up to 3.5 mm inclusive. But the characteristics of these mandrels differ, as can be seen from the table presented.

Table 1. Dimensions and weight of thimbles for cables with a diameter over 2.5 and inclusive up to 3.5 mm (including 3 mm) standards 2224 and 19030

| GOST products | Size designation on the corresponding drawing and its value, mm | Weight, g | ||||||

| 2224-93 | D | L | L1 | B | S | R | S1 | 8 |

| 12 | 20 | 32 | 7 | 1,5 | 2,0 | 2,5 | ||

| 19030-73 | d | l* | b | s | r | h*–s = r (h* = 2.2) | 1,1 | |

| 10 | 17 | 4,5 | 0,5 | 1,7 | 1,7 | |||

The weight of thimbles of these standards for a rope with a diameter of 3 millimeters, as can be seen from the table, is only 8 and 1.1 grams. But the weight of mandrels for powerful cables is already measured in kilograms and even tens of kilograms.

What is shakl?

So much for the size of the problem. There is a tractor and there is a cable that cannot be secured to a stuck car. All you need to do is have a device with you, which is a metal bracket with a locking device in the form of a screw. There are jacks with nuts and cotter pins, but for off-road use a screw will be more convenient. The nut and cotter pin always tend to get lost, and finding them in a dirty puddle is almost impossible. So is it worth talking further about the need to equip your SUV with such a simple, inexpensive and effective device?

Fixation options

It is important that the fire be reliable, otherwise the thimble will be useless. Various methods are used to form loops. For light loads, it is possible to prepare the loop using a clamp or tube.

It is important to choose and install the thimble correctly. Be sure to pay attention to the load and maximum breaking force. Products with metal cores are more durable. The reliability is also affected by the type of lay, which can be single, double or triple. Before choosing, define your goals to quickly find the right option.

Methods for fixing the cable to the thimble

Rope or cable thimbles will be useless if the fire itself is not reliable enough. Loops can be formed at the ends of cables in various ways. If the loads on the cable are insignificant, then a loop can be formed using a regular clamp or a metal tube, which is flattened after it is used to form a loop at the end of the cable. You can see the details of such a simple technological operation in the photos, which are not difficult to find on the Internet.

In order to make a more secure loop at the end of the cable, you will need to unravel it into two parts, approximately equal to each other in thickness and number of fibers. It is necessary to unravel the end of the cable to a length of approximately 30 cm. This procedure should be performed with gloves so as not to injure your hands with steel fibers. The two unraveled halves of the cable are placed crosswise in the thimble groove and connected to the unraveled part of the cable. The most important thing is to ensure such a connection is highly reliable. To do this, each half of the loose part is passed between the turns of the unloose part, for which a screwdriver is used, with which the turns are moved apart, and the loose part is passed into the resulting gap. For greater reliability, the resulting braided connection can be further strengthened with clamps, a flattened tube or wire twists.

One of the ways to fix a cable with a thimble

Choosing a cable and thimble - what comes first and what rules must be followed

Of course, you first need to choose a suitable cable. In this case, first of all, one should be guided by the value of the maximum breaking force of the rope. That is, such a tensile force that cannot be exceeded, and it is able to withstand it without any damage. No less important are the conditions, method and purpose (for what work it is intended) of using the cable. Only by taking into account all these parameters will it be possible to correctly select the necessary steel ropes corresponding to GOST standards or soft ones made from natural or synthetic materials.

Selection of the necessary ropes for the thimble

Only after choosing the type of cable, and then its diameter, can you begin to select a suitable thimble. First of all, his appearance. In this case, first of all, one should proceed from what type of rope is used (steel or soft) and, again, be guided by the conditions, method and purpose of its use. The thimble standards reflect this information, including restrictions on use. And only after deciding on the type of mandrel, you can begin to select a specific product, that is, to match the diameter of the existing cable. The standards for thimbles contain tables of their standard sizes, which indicate what dimensions the mandrel should be taken for each rope thickness. So, when using GOSTs or reference books, the process of choosing a thimble at all stages (from selection by type to mandrel dimensions) will not cause any difficulties.

If the search for the required thimble is carried out without using regulatory documentation for it and only by size, then you should be guided by the following standardized requirements, which will ensure maximum rope service life and work safety:

- The inner diameter of the mandrel (in the above figures and tables these are D and d) should be approximately 4 times greater than the thickness of the cable. For a rope with a thickness of 3 millimeters indicated as an example, the thimble has D = 12 and d = 10 mm (according to GOST 2224 and 19030, respectively).

- The dimensions of the groove on the outer side of the thimble must be such that the rope fits into it (“sank” in it) from 2/3 of its diameter to a position almost flush with the edges.

Compliance with the last requirement can be determined by applying the cable to the mandrel, or by calculation - by measuring the thickness of the cable, the diameter of the groove and its depth. For the 3 mm thick rope indicated as an example, the thimble of standards 2224 and 19030 have a groove diameter of 4 and 3.4 mm, respectively. Divide by 2 to find the radius. We get 2 and 1.7 mm, respectively. Or we measure the depth of the groove: 2.5 and 1.7 mm, respectively. Judging by the diameter of the cable (3 mm), it will not fit completely into the gutter, and 2/3 of its thickness is 2 mm. That is, these thimbles are suitable for rope with this thickness.

Not just a thimble - we select the cable for its intended purpose

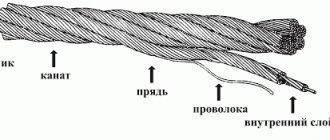

Along with the thimble, you also need to select a modern cable for its intended purpose. This product in most cases consists of wire wound around a core. The more fibers there are for the same thickness of cable, the more flexibility it will have. Both organic and metal materials can be used as a core. Organic cores are often soaked in a special impregnation, which is gradually released during the operation of the rope and reduces friction between individual strands and fibers in the rope itself, thereby extending its service life.

According to the type of construction, steel ropes have many differences that are not noticeable to the eye. For example, there are only three types of lay: single, double and triple. In the case of a single lay around a central wire or core, the steel wires are twisted in a spiral in several layers, and if the first layer is curled in one direction, then the subsequent layer is curled in the other. When double laying is done, the wires are first twisted into strands, and these strands are curled into a cable; with triple laying, the process is even more complicated. Single fibers have the highest rigidity, but they wear out faster as a result of increased friction between the fibers.

When choosing, it is very important to take into account the maximum breaking force that a particular rope can withstand. For example, galvanized products with a diameter of 2.2 mm have a tensile strength of up to 300 kg, while a three-millimeter rope almost doubles this figure. Products with a diameter of 5 mm can withstand tensile forces of up to 1800 kg!

This is interesting: GOST 3262-75 requirements for steel water and gas pipes

A few words about soft shells

The appearance of these products is caused by the need to ensure safety when towing. Often during a jerk, the towing eyes come off the vehicle, which, together with the shuckle, fly away along an unpredictable trajectory at great speed. It’s good if there is no one or anything in the path of such a projectile. But unfortunately, history remembers very sad cases when people died as a result of a broken eyelet.

Soft shuckle removes the risk a little. But you need to understand that the towing eyes are still metal, and a 100% guarantee of safety cannot be achieved. Otherwise, soft shucks have advantages. They are light and durable, easily attached to the eyes and slings. True, the cost of these products is much higher than that of metal analogues. This is especially evident in branded models from ARB or Samson.

For towing passenger cars, we recommend using 2-ton shackles. Their strength is quite sufficient even for jerky towing, and the thickness of the locking screw will suit almost any eyelet.

For crossovers and light SUVs (Suzuki Jimny, Niva), 3.25-ton models are quite suitable, and for heavy, prepared all-terrain vehicles, 4.75-ton models can be used.

Moreover, for owners of prepared SUVs, we recommend having all the main models of shucks in stock. After all, it is precisely these vehicles that most often come to the aid of less prepared vehicles stuck in snow or mud. And as practice shows, a stuck car almost never includes a tow rope, much less a tow rope.

Throttle for steel ropes and cables - a reliable fire

Externally, a rope thimble is a triangular, teardrop-shaped or round frame, which is made by forging or casting from high-strength carbon steel. The products are inserted inside the loop - the fire, and do not slip out thanks to the groove running along the outside. The dimensions of such a product as a thimble can be impressive - some forged marine examples weigh almost 37 kg on their own and are capable of withstanding enormous loads. Of course, smaller specimens are used in construction and everyday life - it all depends on the diameter of the rope or cable that needs to be secured at the bend of the loop.

So, with a rope diameter within 2.5 mm, you will need a thimble with a diameter of 10 mm and a groove radius of 1.5 mm. The diameter of the thimble in this case refers to the distance between the two outermost points of the circle inside the product. If the thickness of the rope is 10-12 mm, you will already need an option with a diameter of 40 mm and a groove radius of about 7 mm. That is, whatever cable or rope you choose, according to the requirements, the diameter of the inner circle of the thimble must be 4 times larger, and the groove must be of such a size that the product “sinks” almost 2/3 into it. Thanks to this, you will ensure maximum safety during work and extend the life of the cable.

There are marine, round, cable-stayed, steel and acid-resistant thimbles, as well as wedge sockets.

- Marine cable thimbles are usually made by hot forging and have a teardrop shape. There are two types of marine products - type C is used for fastening steel ropes, while type P is intended for plant ropes. Both types can be made from either carbon or low-magnetic steels. The largest representative of type C is designed for a cable with a thickness of 66.5 mm in diameter. The numbers in the marking after the letter indicate what load the fastener can withstand, for example, C400 can withstand a load of 40 tf, and P20 can withstand a load of 2 tf.

- Cable-stayed options also came to us from the marine theme, but now they are more often used in the construction industry in various kinds of braces, supports, telescoping and for connecting parts of mechanisms and metal structures. A distinctive feature of cable-stayed products is their smaller internal diameter.

- Acid-resistant elements are made of corrosion- and acid-resistant steel M1-M12. This provides additional reliability of fastenings in production. Such products are easily recognized by their shiny surface.

- Semi thimbles - used to prevent wear and tear of large diameter ropes at small bending radii, which is typical when lifting or towing loads.

- A round galvanized thimble is a solid round product, thanks to which an even circle is formed inside a loop of a cable or rope.

- Wedge options are clips for securing steel ropes in lifting mechanisms. The device consists of a clip, an insert and a wedge, which jams the rope between the walls of the clip, the insert and the wedge itself.

- The thimble for synthetic rope is characterized by the fact that its groove on the sides is closed, which prevents the soft synthetic material from slipping out.

Using a thimble to improve the reliability of cables

The looped ends of the cables and ropes (ogons) are put on the thimble and securely held on it due to the shape of its section, which has the configuration of a gutter. Depending on the scope of application, the size of the fire and the loads experienced, the thimble for ropes or cables can have different sizes. Some models of thimbles for ship ropes, for example, can weigh up to 40 kg, and devices used in the construction industry and everyday life are small in size and weight. The main technology used in the production of thimbles is forging.

The choice of thimble size is mainly influenced by the diameter of the cable for which it will be used. The dimensions of such a device include its diameter, equal to the maximum diameter of the circle that can be inscribed in its inner part, as well as the radius of the groove of its groove, measured in the cross section of the thimble.

There are generally accepted recommendations, according to which the diameter of the thimble should be 4 times the diameter of the cable itself, and the radius of the groove of the groove should be chosen so that the cable in such a groove is buried by 2/3 of its diameter.

Types of thimbles

According to their design and scope of application, thimbles are divided into round, cable-stayed, marine, acid-resistant, and wedge sockets. Let's take a closer look at their features.

- A round cable thimble is a galvanized product shaped like a solid ring. When using such products, the cable loop has the shape of an even circle.

Round cable holder

- The ship's thimble, which has a teardrop shape, is produced by hot forging. Such products are divided into two main types: for use in conjunction with steel ropes (type C) and thimbles used with ropes made from plant materials (type P). In the marking of such thimbles, in addition to designating their type, the value of the maximum load that such fasteners can withstand is also given. A ship's thimble, the marking of which contains, for example, the number 400, is capable of withstanding a load of 40 tf.

- The cable thimble, characterized by a small internal diameter, is today used not only for ship ropes, but also in the construction industry for fixing and securing various mechanisms and metal structures.

- Acid-resistant thimble, which has a shiny surface, is used in production enterprises where there is a high risk of contact with an aggressive environment. Such products are made from steels that are highly resistant to corrosion and acids (M1-M12).

- Semi thimbles are products designed for large diameter cables used for lifting and towing loads.

- Wedge sockets or clips are devices with which cables are fixed in lifting mechanisms. Such a thimble consists of several structural elements: a clip, an insert and a wedge, due to which the rope is jammed between the insert and the cage body.

- There are also thimbles that are used only for cables made of synthetic materials. The design feature of such products is that the side part of its gutter is completely closed, which prevents the lightweight synthetic cable from slipping out of it.

Synthetic rope thimble

Flemish eye

Eye Splice - Used to splice the free end of a cable to form a loop. The threads of the end of the cable are unwound over a certain distance. The wire is then bent around so that the end of the unfolded length forms a peephole. Next, the unfolded strands are braided back into the wire rope, forming a loop or eye - called a Flemish eye.

Flemish eye connection

The threads of the end of the cable unwind to a certain distance

Consists of a combination of splicing and pressing. Steel rope slings are often used in steel mills where the ropes are exposed to high temperatures and serve as a replacement for thimble splices.

Splicing and pressing

Flemish eye end connections can be used at temperatures from 60 C to + 400 C. At temperatures from + 250 C to + 400 C, the load capacity of the ropes should be reduced to 75%.

Standardization

The types of Flemish eyes are designated as follows:

- Flemish eyes without a thimble.

- Flemish eyes with a thimble.

Various designs of the Flemish eye

Manufacturing and installation

The rope sling, which has not yet been processed, is pulled through the selected steel clamp (Fig. A).

Making a loop of steel rope

The outer threads of the lifting rope are divided into the required lengths (Fig. B).

The core of the rope sling is bent back and formed into a loop. The loose cable halves are then closed around the cable core. For example, the core of an eight-strand rope is closed on the right and left with only four threads until the threads on both sides are joined at the head of the loop (Fig. C).

As the outer strands of the rope have been completely enclosed around the rope core (Figure D), a steel clamp slides over the ends of the strands and is pressed.

APPENDIX (reference). LIST OF CODES OF OKP TITS

APPENDIX 1 (for reference)

| Thimble designation () | OKP thimble code for operation at temperatures | |

| up to minus 40 °C | up to minus 60 °C | |

| 10 | 31 7829 3101 | 31 7829 3125 |

| 12 | 31 7829 3102 | 31 7829 3126 |

| 15 | 31 7829 3103 | 31 7829 3127 |

| 20 | 31 7829 3104 | 31 7829 3128 |

| 25 | 31 7829 3105 | 31 7829 3129 |

| 30 | 31 7829 3106 | 31 7829 3131 |

| 34 | 31 7829 3107 | 31 7829 3132 |

| 40 | 31 7829 3108 | 31 7829 3133 |

| 45 | 31 7829 3109 | 31 7829 3134 |

| 56 | 31 7829 3111 | 31 7829 3135 |

| 63 | 31 7829 3112 | 31 7829 3136 |

| 75 | 31 7829 3113 | 31 7829 3137 |

| 85 | 31 7829 3114 | 31 7829 3138 |

| 95 | 31 7829 3115 | 31 7829 3139 |

| 105 | 31 7829 3116 | 31 7829 3141 |

| 120 | 31 7829 3117 | 31 7829 3142 |

| 130 | 31 7829 3118 | 31 7829 3143 |

| 140 | 31 7829 3119 | 31 7829 3144 |

| 160 | 31 7829 3121 | 31 7829 3145 |

| 180 | 31 7829 3122 | 31 7829 3146 |

| 200 | 31 7829 3123 | 31 7829 3147 |

| 220 | 31 7829 3124 | 31 7829 3148 |

APPENDIX (reference). DIMENSIONS OF STEEL ROPE THINGS ACCORDING TO ISO 2262

APPENDIX 2 (for reference)

mm

| Rope diameter | |||||||

| 4 | 4,5 | 4,3 | 7 | 10 | 18 | 2,2 | 2,8 |

| 6 | 6,9 | 6,5 | 10,5 | 15 | 27 | 3,3 | 4,2 |

| 8 | 9,2 | 8,6 | 14 | 20 | 36 | 4,4 | 6,6 |

| 10 | 11,5 | 10,8 | 17,5 | 25 | 45 | 5,5 | 7 |

| 12 | 13,8 | 12,9 | 21 | 30 | 54 | 6,6 | 8,4 |

| 13 | 15 | 14 | 22,8 | 32,5 | 58,5 | 7,2 | 9,1 |

| 14 | 16,1 | 15,1 | 24,5 | 35 | 63 | 7,7 | 9,8 |

| 16 | 18,4 | 17,2 | 28 | 40 | 72 | 8,8 | 11,2 |

| 18 | 20,7 | 19,4 | 31,5 | 45 | 81 | 9,9 | 12,6 |

| 20 | 23 | 21,5 | 35 | 50 | 90 | 11 | 14 |

| 22 | 25,3 | 23,7 | 38,5 | 55 | 99 | 12,1 | 15,4 |

| 24 | 27,6 | 25,8 | 42 | 60 | 108 | 13,2 | 16,8 |

| 26 | 29,9 | 28 | 45,5 | 65 | 117 | 14,3 | 18,2 |

| 28 | 32,2 | 30,1 | 49 | 70 | 126 | 15,4 | 19,6 |

| 32 | 36,8 | 34,4 | 56 | 80 | 144 | 17,6 | 22,4 |

| 36 | 41,4 | 38,7 | 63 | 90 | 162 | 19,8 | 25,2 |

| 40 | 46 | 43 | 70 | 100 | 180 | 22 | 28 |

| 44 | 50,6 | 47,3 | 77 | 110 | 198 | 24,2 | 30,8 |

| 48 | 56,2 | 51,6 | 84 | 120 | 216 | 26,4 | 33,6 |

| 52 | 59,8 | 55,9 | 91 | 130 | 234 | 28,6 | 35,4 |

| 56 | 64,4 | 60,2 | 98 | 140 | 252 | 30,8 | 39,2 |

| 60 | 69 | 64,5 | 105 | 150 | 270 | 33 | 42 |

The electronic text of the document was prepared by Kodeks JSC and verified according to: official publication M.: Standartinform, 2007