Wheels play two roles in a car's design: aesthetic and practical. Car owners have different attitudes towards these functions. Some people prioritize beauty, while others prioritize functionality. But all drivers worry after a wheel falls into a hole. After a strong blow, aesthetics and practicality may disappear. The thought immediately creeps in about how empty your personal budget will be. Sometimes, it is possible to repair steel wheels yourself. We will tell you in this article which damages can be corrected, and after which ones it is easier to throw away the disc.

What is disk editing?

Disc straightening is the process of recreating the original geometry of a stamped or cast product after it has been damaged or fatigued as a result of too much use and physical wear. To ensure that the wheel is corrected, the car owner needs to come with his car to a service station, where the technician will perform the following procedures on the damaged wheel:

Disc straightening press

- To begin, the wheel is removed from the hub using a balloon or hydraulic wrench.

- The product is cleaned of dirt with a brush and then washed under running water.

- The technician will carefully examine the disc for damage and cracks due to deformation.

- After this, the wheel is placed on a special straightening press, securely fixed on it, and the specialist begins his work.

- The first thing that happens is the correction of the curvature along the inside of the product, during which it acquires the correct rounded shape. This happens due to the operation of a hydraulic press, which exerts a force of 5 to 10 tons, depending on the manufacturer and power of the device.

- Quite often it happens that the structure of the disk itself is not touched, but due to a strong impact, one of the edge edges on the side is jammed. For this purpose, a rolling mill is used; the product, rotating, passes through a system of rotors, where the wheel is restored.

- Stamped steel disks are much easier to edit, since their metal bends easily and to achieve the result you only need to restore the geometry. If the disc turns out to be light alloy, then microcracks may form in it, which can cause it to burst. In such cases, the master resorts to argon welding, eliminating the defect.

Editing alloy wheels

- After welding, he grinds the disc and paints it, first removing the old paint layer. Editing steel wheels is much easier; they can be painted using a regular spray can, especially if after that decorative caps are installed on them.

- Upon completion of the operation, the wheel is tested on a special balancing machine, and if everything is in order, a tire is put on it, and the finished product assembly is fixed back to the hub. If the disc needs painting, then the whole procedure will take about a day, if not, then the driver will leave the service station in 1-1.5 hours.

That is why official dealers, at the slightest bend in the wheel, immediately insist on replacing the disc. However, if we are talking about steel stampings, then straightening them is a common thing, since simple bending does not in any way affect the properties of the ductile and easy-to-work metal. The only thing that will definitely need to be done when the stamped discs have already been straightened is to paint the restored products to avoid the formation of corrosion.

Rolling of stamped discs

Types of repairable damage

Alloy wheels are designed not only to give the vehicle an attractive appearance. Damage to these parts can cause deterioration in vehicle handling while driving. However, driving on damaged rims is unsafe.

Main types of damage to wheel rims:

- Cracks and chips – the formation of small defects on the surface of products, damage to the paint layer. The reasons for such damage: the car getting into potholes and large holes on the road.

- Radical displacement - dents on the product. Reasons: wheel falling into a hole, hitting a curb.

- Axial displacement - as a result of a side impact of a car wheel on a curb or other vehicle, a “figure eight” has formed on the part.

Disks with such faults can be repaired.

Editing a disk yourself

To do this, a car enthusiast just needs to have an absolutely rigid steel base on hand, for example, a vice or just a block, a sledgehammer and a hair dryer or a gas torch, which can easily be replaced with a blowtorch. Next, all steps are done in the following order:

- Similar to the previous method, you need to remove the wheel, wash it and inspect it for other defects other than the jammed edge.

- The next important procedure is heating the damaged area, which is best done with a hair dryer, since the flame from the burner will hopelessly stain the surface of the product. As the temperature rises, the steel will become more pliable, but at the same time, in everyday conditions, the temperature is still not enough for the material to lose its structure or for any changes to occur in it.

- Next, you need to carefully place it on the metal base with the straight deformed part, fix it or hold it securely with your hand. For these purposes, it is best to use the help of another person.

- After the product is securely fastened to the steel backing, you need to take a sledgehammer and apply several precise blows to the bent area to straighten it.

- The procedure for straightening alloy wheels is completed using a 1-kilogram hammer, which strikes and the remaining deformations are straightened until the wheel reaches the required shape.

- Of course, in the process of straightening car rims, the paintwork can be damaged, especially when the product is heated over an open flame. If this is a stamped product, then the car enthusiast can restore it on his own, but in the case of casting, it is still worth contacting a service station where there is a paint booth, and specialists will do the work in compliance with the necessary technology.

Installing the disk before editing

Making a stand for wheel correction

To make a disk straightening machine, follow this procedure:

- install the shaft on the frame, where fasten the universal hub;

- Place the product that needs to be fixed on the hub;

- secure the bed to the stand. The stand itself is attached to a hydraulic station, which will power the mobile hydraulic cylinder. A tool for straightening discs is mounted on its rod;

- control the cylinder using a hydraulic distributor with a pressure reduction valve;

- To be able to install the cylinder at any angle relative to the product being repaired, use a pair of movable brackets.

Read also: Igbt module how to check

In order for a machine for rolling cast discs to fasten products with different diameters, its hub must be equipped with centering washers of the required diameters (a total of 18 fasteners will be required).

How to straighten light alloy and aluminum wheels

Unlike steel stamped products, aluminum-based alloys, although they have increased strength, corrosion resistance, and also have low density, are difficult to deform. In addition, when restoring the geometry of a wheel, experts do not recommend using high temperatures, because it will lose its physical and mechanical properties and fall apart at the first strong impact.

This operation for straightening discs without heating has the following important features:

- First of all, the driver should remember that aluminum wheels are subject to straightening only in case of minor deformations, and some more serious damage is almost always accompanied by cracking, requiring welding work with a complete restoration of the wheel, and in some cases, its replacement with a new product. It should be remembered that after long-term use, professionals do not recommend changing wheels one at a time. This means that you should ideally buy new discs to replace them for all 4 hubs at once, or, if this is too expensive for you, then at least 2 pieces for the whole axle.

- The heating limit of aluminum disks is a temperature of up to 300 degrees Celsius, since it is known that sintering of powder coating occurs precisely under this thermal influence, and the structure of the aluminum is not disturbed in any way.

- Also, slight heating is necessary to relieve all stress in the metal after an accident, since non-design deformations are always accompanied by strong internal forces in the metal structure.

Heating an alloy wheel before straightening

- You should resort to straightening wheel rims using a press only if the rim with spokes is bent in the shape of an egg and needs a comprehensive restoration of its geometry. In all other cases, including local deformations, it is better to turn to a rolling mill, since it puts less load on the entire structure of the product, which largely makes further operation safe.

Thus, straightening cast or stamped disks, despite the assurances of professionals interested in conducting this activity, is a rather dubious procedure. If a car enthusiast is only focused on saving money, and is not forced to contact a technical center, then he should remember that the difference saved can result in more than just a broken tire.

Hello, dear car enthusiasts! What do rims mean to you? Personally, what role do you assign to them, first of all? Aesthetic or practical?

Don't let these questions seem strange to you. After all, let’s be honest, it’s a very rare motorist who thinks about the role and significance of a wheel rim in everyday life.

Only fans, and perhaps that’s all. And we, the majority of car owners, remember about rims only when we find ourselves in a hole, and we absolutely need car rims repaired.

It is important to always remember! A faulty wheel drive means extra costs for repairs or replacement of parts:

- failure of steering mechanism elements;

- failure. In particular - ;

- violation, with the resulting “eating” of rubber;

When to roll

The car itself helps to understand that the rims need to undergo restoration in order to return to the correct geometry. The car changes the nature of its behavior on the road, making the driver feel something is wrong and feel the changes.

Experts and simply experienced motorists identify 3 key signs by which one can certainly understand that the geometry of the violation, displacements have occurred, and some action needs to be taken.

It is a mistake to rely solely on visual inspection. Externally, the wheel may look quite normal and not cause any suspicion. But even with small defects and geometry violations, you can encounter unpleasant consequences. Better listen to your own vehicle. If you notice at least one of the signs listed below, you should at least visit a car service center and undergo a diagnostic procedure. In the case where the check confirms axial, radial or combined displacement, the rolling itself is carried out directly.

- The rubber on the wheels begins to wear out too quickly. Moreover, in parallel, an uneven decrease in tread thickness is observed. This does not always indicate problems with disk geometry. But it acts as one of the potential reasons.

- There is a deterioration in the level of adhesion between the wheels and the road surface. Steering efficiency also decreases, braking takes longer, and braking distance increases. To do this, you need to understand and know how the car behaves under normal conditions. Inexperienced drivers may not always notice such signs.

- An extraneous vibration is felt when moving. These vibrations are transmitted to the steering wheel in a situation where the front wheel rims located on the front axle are damaged. And when the geometry is disrupted on the rear axle, then vibrations will be transmitted to the body.

It is extremely reckless and wrong to ignore such symptoms. If you continue to operate the car with such a problem, this will gradually lead to the destruction of the structural elements of the suspension and steering components. One can only imagine how much it would cost to repair or replace them. Compared to disc rolling, this is a huge financial cost.

Rolling process

Existing dyeing methods

Gone are the days when car enthusiasts who wanted to do the painting themselves could only use nitro enamel, and, as a last resort, used oil and pentaphthalic paints. Now new chemical compositions have appeared, thanks to which it is possible to paint rims in several ways:

- using acrylic paints sold in aerosol cans;

- application of polymer coatings;

- the old method is painting with automotive nitro enamel;

- laying a layer of so-called liquid rubber;

- chrome plating

This is what a newly painted wheel on a car looks like

Not all of the options listed are suitable for implementation at home. Take a polymer (powder) coating that is very resistant to environmental influences and mechanical damage. It is applied using a certain technology, consisting of the following stages:

- Surface preparation, including degreasing.

- Priming with a special composition.

- Application of powder enamel.

- Curing the paintwork in an oven.

Reference. On sale you can find polymer paints that harden without heat treatment. But their strength and durability are not so high and in terms of performance properties they are equal to acrylic coatings.

Since not every home has an oven for heat treatment of painted products, this method is not suitable for the average car owner. Unless you go to a specialized auto repair shop, where they will apply the polymer with high quality and charge a decent price.

For the same reasons, it is almost impossible to perform chrome plating at home. This is a complex technological process that includes the sequential application of various components with several intermediate rinses with distilled water. Moreover, the time for placing chemicals on the surface is strictly regulated. Therefore, to give the wheels the effect of a chrome surface, you will again have to turn to professionals.

Wheel rim with chrome finish

Note. Chrome plating can be imitated using special “chrome effect” aerosol paints applied to a layer of black primer. True, you will have to spend money on expensive enamel, since using a cheap one will give you a “metallic” color, and not a shiny surface. The coloring technology is similar to the use of acrylic compositions, which will be discussed below.

Pricing factors

- Place of service provision.

- Difficulty of work.

- Part size.

- Automobile model.

- Qualification and experience of the master.

- Urgency of work.

- Tools and equipment used.

- Reputation of the service company.

- The need to call a specialist.

- Availability of promotions and discounts.

- The need for additional work.

The larger the disc size, the more expensive its restoration will cost. The higher the qualifications and more experience of the master, the higher the price for his work will be. The more famous the service station, the more expensive its services are. The more complex the work, the more expensive it will cost. Additional work (cleaning, grinding, painting, polishing, filling cracks) is paid to the specialist separately.

Preparation of equipment and materials

The technology for applying any paint to car rims involves spraying from a can or with a spray gun; brushes are not applicable here. To operate a spray gun, you need a compressor or an oxygen cylinder, and a small number of country house owners have such equipment.

A set of tools and materials for restoring rims

Hence the conclusion: it is best to buy coloring compounds and primer in aerosol cans, fortunately, there is a wide selection of enamels on sale in such containers. In addition, to complete the work you will need the following tools and materials:

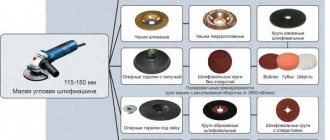

- an electric drill or an angle grinder with a steel wire attachment (the so-called brush);

- coarse and fine sandpaper, 400 and 200 grits are suitable;

- rust converter or its analogue - phosphoric acid;

- degreasing agent - white spirit, nefras (otherwise - Galosha gasoline), organic solvent;

- masking tape, contour tape;

- paint is calculated as 1 450 ml bottle for 2 discs, more liquid rubber may be needed;

- primer (1 bottle for 4 discs);

- rags, rubber gloves, respirator or gauze bandage.

Set of chemicals for painting

Note. Acetone and inorganic solvents for nitro paints are not suitable for degreasing, since they are not capable of decomposing fats.

Important point. The primer must be selected so that it matches the base on which the paint is made. For example, acrylic-based compositions require acrylic primer, and so on. The application technology itself differs little from the type of enamel; the operations are performed the same.

Rolling stages

The rolling procedure requires special equipment and the involvement of experienced specialists, so a car owner cannot do without a good tire workshop. As a result, it is carried out in several stages, which are discussed in more detail below. This procedure is carried out in several stages:

- Visual inspection.

- Rolling.

- Measurements and revision.

At the first stage, the part is inspected. An attentive specialist will assess whether it is worth processing this wheel rim or whether it is more advisable to purchase a new element. If even minor cracks are noticed on the metal surface, such a disc cannot be repaired. In other cases, most defects are leveled.

Rolling is carried out on a special stand. The equipment is adjusted to the diameter of the disk and the part is installed on it. The roller moves under the influence of hydraulics. Operating time depends on the degree of damage.

The third stage consists of refining and final balancing of the wheel. Even during the rolling process, a specialist periodically checks the geometry of the disk and takes measurements. If there is a deviation from the norm, he additionally adjusts the equipment and eliminates defects, achieving a perfectly flat surface.

Finally, the part is checked again and the wheels are balanced. What if you don’t roll? Most car owners will not drive on a bent rim simply because it is uncomfortable. Defects on the wheel will be constantly accompanied by shocks and vibrations. But in addition to loss of comfort, such damage can lead to more serious consequences. Even if the defect is minor and almost unnoticeable while driving, it cannot be ignored. Studies say that with a 15 gram deviation in balancing, 14-inch wheels accelerated to 100 km/h experience a load comparable to being hit by a medium-sized hammer 800 times per minute.

Now imagine what will happen to your car’s suspension after two to three thousand kilometers. In addition, such an imbalance in the wheels will completely destroy a new set of tires in just a couple of months

Therefore, do not underestimate the importance of little things. If you drove into a deep hole at speed and received a noticeable blow, hurry up and contact a trusted car service center for diagnostics.

Tire fitting work in a car service center The quality of rolling directly depends on the equipment on which the work will be performed. Therefore, wanting to repair a car and bring it into proper shape, owners are faced with another problem: where to find a reliable car service center that can carry out high-quality work at the appropriate level.