The double column band saw machine is a metalworking equipment for cutting with an endless hole saw. With equipment of this type, it is possible to saw products made of ferrous and non-ferrous metal with a “circle”, “square” section or profiled products, both in single and in batch mode.

Double-column metal band sawing machines in our catalog are represented by semi-automatic and automatic equipment, which allows you to perform a full cycle of cutting a workpiece into parts of a given standard size without operator intervention. The use of different speed modes of movement of the belt and saw frame ensures high processing accuracy and uniform distribution of force over the entire cutting plane.

Production of band saw machines

The main manufacturers of high-quality equipment intended for a wide range of enterprises are world leaders in the field of machine tool manufacturing:

- Delta (Korea);

- Amada (Japan);

- Daito (Japan);

- Kasto (Germany);

- Behringer (Germany);

- Everising (Taiwan);

- Carif (Italy);

- Doall (USA);

- FMB(Italy);

- Danova (Spain);

- Jet (Switzerland);

- Proma (Czech Republic);

- Optimum (Germany);

- Bomar (Czech Republic).

Tabletop band saw Elmos Cantilever band saw Beka Mak Double column band saw Pilana

Producing bandsaw machines of various designs:

- cantilever/pendulum (used for cutting workpieces up to 350 mm);

- two-column;

- portal;

- vertical;

Products from leading manufacturers are supplied to Russia and are widely used at various enterprises for the manufacture of equipment and various groups of goods.

How to choose

When wondering how to choose a band saw, you must first decide on the range of tasks that it will perform. For a private workshop or small workshop, a Jet, Bomar or Enkor metal band saw of a console type with a rotary table or a vertical one with an inclined frame is sufficient. For a home workshop, you won’t find a better vertical saw. It will also be useful for roofers - such saws cut corrugated sheets and galvanized sheets perfectly.

Industrial production requires more powerful bandsaw equipment - single or double-column machines with hydraulic feed. For large-scale production, it is best to pay attention to CNC machines.

Features and types

The design features of machines produced by different manufacturers make it possible to cut and cut materials using a tape blade, which is made according to the principle of a closed ring and is equipped with teeth, due to which the workpiece is cut. Cutting can be carried out along a straight or shaped trajectory, according to the existing drawing.

When choosing a machine design for carrying out technological cutting operations, you need to know the operating features and the main characteristics of the equipment offered by manufacturers.

Produced professional machines are regulated in several categories, taking into account the main indicators:

- number of speed modes for material processing;

- equipment productivity (the amount of work performed per unit of time);

- rotation angle of the feed mechanism;

- the width of the tape used.

According to the degree of automation of work processes, equipment is divided into:

- manual;

- automatic;

- semi-automatic.

Manual band saws are used in small-scale production of metal products and other materials. The advantage of this type of machine is: low cost, the ability to cut material at an angle from 0 to 60°, high quality metal processing. Manual machines are widely used in small and medium-sized production, repair services and the construction of construction projects.

Video review of the Jet band saw family

The semi-automatic band saw machine is used for multi-operation cutting of tool steels, non-ferrous metals and alloys. On this type of machine, some operations are performed automatically: feeding the saw frame, clamping and opening the vice. A semi-automatic band saw machine has a number of advantages: a smooth change in the speed of cutting the material, automatic adjustment of the accuracy of lowering the frame and the use of a hydromechanical method for tensioning the cutting blade of the device.

Automatic machines are characterized by the highest level of design automation during operations and a fairly high cost of equipment.

Models of manufactured machines differ in the ability to program the process of cutting a workpiece and equip it with equipment for adjusting the shutdown of the working cycle after completion of the process.

Machines are also divided depending on the scope of application and design into:

- columned;

- using the pendulum principle;

- household stationary;

- household tabletop.

The use of the machine park depends on the technologies used, the operations performed and the volume of required equipment performance.

Principle of operation

A belt machine is based on the use of an endless (closed) metal belt, with teeth cut on one side, as a working tool. Most often, bimetallic saws are used, in which the main part is made of durable steel (spring or similar in elasticity and strength), and the teeth are made of tool steel or particularly strong alloys.

The band saw is driven by pulleys, one of which (the lower one) is connected to an electric motor. The peculiarity of the movement of the saw towards the workpiece eliminates the ejection of sawdust or parts of the tape in the event of a break towards the operator. This determines the safety of the machine when cutting both flat sheets and complex rolled profiles.

Band saw machines are regulated by the speed of the belt, which is selected depending on the type of metal. The saws themselves are made with different tooth shapes, intertooth distances and sharpening angles. The design of most machines allows you to quickly change the saw blade if you need to switch to a different type of metal or rolled product.

Structure and characteristics of a band saw machine

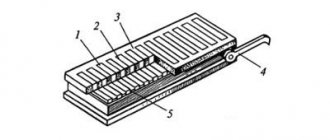

The machine used for cutting various materials consists of the following components:

- rigid frame;

- set of system pulleys;

- clamping vice using a hydraulic clamp;

- working drive;

- systems for supplying coolant to the workpiece processing area;

- adjustment mechanism, tension;

- workflow control panel;

- control and security systems;

- sources of additional lighting (lamps and spotlights for illuminating the workplace and workpiece).

Roller conveyors

Batch cutting of round pipes

Batch cutting of rectangular pipes

The design of the working cutting mechanism is a circular saw mounted on 2 or 3 pulleys that perform a rotational movement driven by an electric motor. The more powerful the installed electric motor, the higher the productivity of the machine and the available capabilities for processing and cutting metal. To increase productivity on the machines, bimetallic saws are used, made using two metals that provide strength and flexibility of the working element. The cutting blade is formed from hard spring steel, to which a strip of tool steel is welded and teeth are cut.

The machines are equipped with two types of working mechanisms: a rotating vice or a rotating frame that allows you to change the angle of processing the workpiece.

The metal processing process is carried out in a horizontal plane. A vice is installed on the base table in which the workpiece is fixed. When the frame moves, the material is cut, which can be used for straight and oblique cuts. To more conveniently change the position of the workpiece, the vise jaws can be rotated 45º.

In addition to metal, band saws can process: wood, graphite and plastic. The sawing process is adjusted using a blade speed control mechanism. When processing metals, with a decrease in strength characteristics, the processing speed increases. Before purchasing, you need to correctly define the task that the equipment will perform and select the appropriate model.

Manual band saws are mainly used for processing plastics, metals - cast iron, low-alloy and non-alloy steel, non-ferrous metals, titanium and nickel alloys.

Coolant nozzle

Coolant storage tank with pump

Coolant supply to the cutting zone

Metal processing can be carried out at a right angle or a given angle not exceeding 60º. Changing the cutting angle is done by changing the position of the cutting saw when turning the frame. The cutting process is controlled by sensors, and the working contact area between the metal being processed and the saw is cooled using the supplied coolant. Water or a special emulsion can be used as a coolant, which also washes away chips and metal dust. Some models of machines are equipped with cleaning brushes that remove metal shavings, thereby facilitating better sawing of metal and increasing the service life of the blade.

Types of equipment

Band saw metal cutting is common both in large industrial enterprises and in medium and small workshops for the production or repair of metal-intensive machines and mechanisms. Band cutting is also used on construction sites, for example, during roofing work, installation of ventilation, chimneys, and boiler equipment.

Pendulum (cantilever) machines

Cantilever band saws are the most common type of band sawing equipment. Their distinctive feature is the presence of a rotating saw frame. It is mounted on a hinge and can be raised and lowered within 900 above the desktop. They are very convenient for cutting:

- pipes;

- corner;

- channel;

- stripes;

- square.

Often, cantilever band saws are used for cutting wood, frozen meat, fish, pressed boards, and plywood. Their versatility and compact design determine their wide distribution.

Machine with rotary console

Pendulum machines are available in two main modifications - with a rotating console, which allows you to cut metal at any angle, and non-rotating, allowing only vertical cuts. According to the level of automation they are divided into:

- manual;

- semi-automatic;

- automatic.

The Jet metal band saw is a prime example of a typical console saw. The band saw can cut metal at an angle of ±45° and vertically. The workpieces are clamped with a special vice, the table can be installed in two positions, the console and material feed are hydraulic. Equipped with Jet bimetallic universal tape. The Enkor (Corvette) installations are not inferior to them.

Manual machines, such as the Bomar PULLDOWN, are portable and have decent power. They can cut metal at 90, 45 and 60 degree angles. The diameter of the blanks 2014 is up to 230 mm (circle) and the cross-section is 260 x 230 mm (rectangle).

Cantilever band saws are produced in a wide range of capacities and dimensions. When choosing a machine, it is easy to find a model that suits your needs.

Saw Bomar PULLDOWN

Single Column Band Saws

A stationary automatic or semi-automatic column-type band saw machine is designed for sawing all types of rolled steel and non-ferrous metals at right angles.

Some models are equipped with a rotary table that allows for angled cutting. The saw unit with a horizontal saw moves vertically along the support column, moving onto the workpiece and sawing it at a given speed. Hydraulic feed allows you to adjust the cutting speed over a wide range.

Double-column (double-column) machines

Structurally, they resemble single-column ones, but cutting metal with a band saw is ensured by feeding the saw unit along two vertical guides. This eliminates blade deflection when sawing large workpieces and makes it possible to process parts made of very hard alloys.

Some of the best two-column machines are produced by the Czech company Bomar, for example, Bomar INDIVIDUAL, Bomar CONSTRUCTION. They are produced in automatic or semi-automatic versions, equipped with a hydraulic feed system, rotary tables, and an intelligent coolant supply system.

Double-column machines are characterized by increased structural rigidity, which provides high productivity and the ability to use CNC. Thanks to this, they have become widespread in the engineering industry. Often used as cutting machines.

Gantry band saws

The design of the saw unit is a rotating or non-rotating installation around a vertical axis. The desktop is fixed or rotating. A portal vertical metal band saw allows you to cut massive workpieces - castings, forgings, steel plates. The portal moves along horizontal guides and slides onto the workpiece. The hydraulic supply system allows you to regulate the saw pressure over a wide range.

Vertical machines

As a rule, a manual vertical band saw is equipped with a stationary saw unit, with a saw moving in a strictly vertical direction. Metal cutting on a band saw is done by feeding the workpiece manually; the pressure and feed speed are adjusted by the operator depending on the cutting conditions.

Vertical manual machines produced by Enkor have become widespread. They are known under the Corvette brand. The Corvette 33 universal band saw can serve as an illustration of the capabilities of this brand’s machines. In addition to steel, aluminum, stainless steel and copper, it can cut textolite, plywood, wood, and OSB boards.

The Corvette band saw is equipped with a 750 W asynchronous motor. It is connected to a 220V network, which allows you to use the saw not only in industrial workshops, but also in small workshops or at home. Two gears that determine the speed of the belt make it possible to quickly switch to cutting dissimilar materials, which is important when used in small-scale production or in repair shops.

Corvette 33 saw with tilt table

The Corvette band saw is equipped with an inclined work table with an inclination range of 0-450. The assembled machine weighs only 75 kg, which is very convenient for transportation, for example, when used in construction and restoration. The worktable dimensions and power allow processing parts up to 135 mm thick. To increase the degree of operational safety, the Corvette band saw is equipped with a magnetic starter, which prevents spontaneous starting if the button is accidentally touched.

A manual vertical band saw can also be equipped with a rotating tilting frame, but most often in a rotating version you can find a semi-automatic band saw. This design allows you to perform angular cutting of metal without changing the horizontal position of the table. This is relevant when processing large-area parts. It is convenient to use such machines to cut channels, pipes, and complex rolled products.

Vertical band saw equipment for industrial use is also produced with a movable frame that moves along a large work table. Belt machines of this type are used for the production of similar parts and are equipped with CNC.

Gravity hand machines

This is a type of cantilever-type machines in which the movement of the saw unit and the pressure of the belt on the workpiece occurs under the influence of its own gravity or the muscular effort of the operator.

One of the varieties of band saw is a table saw, which is characterized by high precision in sawing thin workpieces. Good universal hand-held machines of this type are produced by the company Enkor. The workpiece is clamped with a special vice and is in a stationary state; the saw unit moves. To prevent the feed from being too sharp, the console is equipped with a return spring. A manual band saw belongs to the cheapest type of metalworking machines, which in no way detracts from its advantages. Some disadvantages, such as low power or difficulty in adjusting the pressure on the workpiece, are compensated by the mobility of the installation, its versatility and the ability to work with all types of materials.

Benefits of use

This group of equipment has certain advantages:

- the ability to cut metal up to 400 mm thick;

- cutting of material can be carried out in a wide range of angles;

- during the working process, the material is cut to form a smooth edge;

- a metal band saw is an equipment that occupies a minimum of production space;

- low noise level during technological operations.

Band saws are high-performance equipment and are used to carry out technological operations that cannot be performed on other devices.