It is possible to obtain a finished element with a complex design from the simplest metal workpiece using one unit - a metal turning and milling machine. Such machines represent a full-fledged production complex on which several types of metalworking can be performed at once. A metal turning and milling machine is a necessary tool in production of various specifications. To choose the optimal modification unit, you need to carefully study the offers that are available on the machine tool market.

Types of machines

Metal turning and milling machines have several classification principles. Experts in the metallurgical industry typically divide such machines according to the following principles and into the following categories:

Massiveness of the machine:

- Tabletop turning and milling devices. The weight of such machines does not exceed 400 kg. To operate them, a special industrial table is required.

- Small machines whose weight does not exceed 1 ton.

- Medium sized units. Their weight is more than 1 ton, but does not exceed 10 tons.

- Large industrial machines. These units weigh more than 10 tons.

Control type:

- Manually operated devices.

- Semi-automatic systems.

- Machine tools with numerical control (CNC machines).

Specification:

- Single-variant machines.

- Multifunctional, customizable systems.

Milling support type:

- With classic caliper.

- With counter spindle.

- Drive devices.

- With support for spindle with C-axis.

Metal workpiece material:

- Mono metal.

- High strength metal alloy.

- High carbon steel.

- Alloy steel.

The machine tool market has developed a clear relationship between the functional complexity of a machine and its price. The richer the set of functions of the unit, the higher the price of a metal turning and milling machine.

Equipment design

A metal turning and milling machine combines the basic functions of turning and milling devices. These functions are due to the integration of certain units (lathe and milling) onto a single base.

The main turning units of the combined machine:

- bed;

- rear beam;

- spindle;

- caliper;

- screw for creating threads.

The main milling units of the combined machine:

- cutter motor (located on the turning support);

- cone for attaching taps, cutters, or drills;

- type cutters or cutters with inserts made of hard alloys;

- additional support, which allows you to integrate additional taps, drills, face or end mills, reamers, and disk cutters into the unit.

The unique design principle of such multifunctional units turned separate lathe and milling machines into a full-fledged production machine.

Specifications

The name “metal turning and milling machine” speaks about its specification: this equipment is designed to simultaneously perform both turning and milling operations on the same part made of mono-metal or a metal alloy. The turning part of the equipment is usually used for turning and grinding cylindrical parts. Milling mechanisms allow you to make grooves (straight or shaped) and drill other holes.

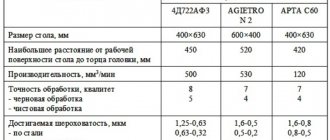

Generalized analytics on turning and milling machines for metal indicate the commonality of the following technical characteristics of units of this type:

- The height of the centers of the workpieces. This indicator determines the diameter of the part that is possible when processed on this machine. Most often it is from 100 to 380 millimeters.

- Width of the processing area. The maximum length of a metal workpiece suitable for turning on a particular device is directly dependent on this indicator. The most common maximum distance between the centers of elements: from 250 to 750 millimeters.

- Depth of part turning. This indicator indicates how thick a layer can be cut in one revolution of the shaft structure. As a rule, this figure does not exceed 0.3 millimeters.

- Number of processing speeds. Depending on the material from which the metal workpiece is made, you can select the required number of rotations per unit of time—the processing speed. Modern machines, as a rule, have up to 10 speed options.

- Dimensional characteristics of the cutter shank (diameter). The dimensions of the cuts and holes in the final product are determined by the diameter of the cutter shank. This figure most often does not exceed 30 millimeters. If you need to make several identical parts (identical grooves, slots), it makes sense to use a metal turning and milling machine with a copier option.

Specific technical characteristics depend on the specific model of metal lathe with milling function.

Varieties

Both types of machines have several varieties depending on the location of the part, the complexity of processing, power and capabilities. Modern machines allow you to create parts of different configurations from blanks and process the largest possible parts.

Milling machines

Using a milling unit, it is possible to produce parts with complex configurations, for example, a gear. There are a total of 7 types of milling machines:

- Universal with rotating faceplate. In this type of machine, the spindle is fixed horizontally, the part is processed along 3 axes using a rotary table. This machine is good for making corners, cutting spirals, and grooves.

- Horizontal milling. In this machine the spindle is located horizontally. The mechanism allows you to process small blanks using various types of cutters. When installing spare structures, it becomes possible to carry out vertical processing.

- Vertical console-milling. This is a type of model in which the spindle is located vertically, but has the ability to rotate in a horizontal plane. Such equipment resembles a large drilling unit.

- Widely versatile machines are equipped with a standard spindle for horizontal processing, but there is also an additional spindle head located on a movable trunk. With the help of such equipment, it is possible to carry out milling at various angles and in a pair of planes. The master has the ability to use two spindles simultaneously or sequentially.

- Vertical and horizontal milling, non-cantilever. On machines that do not have a console, large parts can be easily processed. They are installed on a concrete slab or directly on the floor.

- Longitudinal milling. This equipment is used for processing long and large workpieces. The milling heads with a horizontal spindle are directly mounted on 1–2 racks. The machine is also equipped with a vertical version of the spindle, which is located on a perpendicular stand, on a traverse.

- Continuous milling machines. With such equipment it is possible to install and move a part without stopping the machine itself. This variety also comes in two types: rotary-milling, which are equipped with a round rotary table, and drum-milling, where the workpiece is mounted in a rotating drum.

Lathes

Lathes are used not only in large industries, but also in private workshops, as well as at home. Milling machines can often be found exclusively in production. Lathes also have 7 varieties:

- Screw-cutting. This is the most versatile type of turning equipment, which is suitable for all types of turning work, including polishing, grinding, boring.

- Carousel. This type of machine is designed for processing workpieces weighing several tons. The main element of such equipment is a rotating faceplate. This is the work table on which the workpiece is mounted. Two supports are designed for operation, which provide horizontal and vertical movement.

- Lobotovarnye. The unit is designed for the production and processing of cylindrical and conical parts of large diameter. Some blanks may exceed the diameter of a train wheel. The faceplate in such a machine is located vertically, and the support with the cutter are generally separated from the main structure.

- Revolving. The workpiece can be fixed vertically or horizontally. The support is equipped with a turret drum containing all the necessary tools. This allows you to apply several types of processing to a workpiece in one workflow. Machines with a horizontal axis of rotation of the turret drum are considered to be the most convenient, since with such a design it is possible to attach more tools to it.

- Automatic longitudinal turning machines. Such units are used for the manufacture of small parts from rod or wire. Depending on the model, the machine may have a movable or fixed spindle. To work with small-sized products, special collets are used.

- Multi-spindle machines. Large and complex equipment, which is used for large-scale production with serial production of precision and large parts. The unit operates several spindles simultaneously, which allows machines with such functions to perform several operations simultaneously.

- Turning and milling center. This unit is necessary for working with complex mechanisms and simultaneously performs the functions of a lathe and a milling cutter. It is possible to place a turning cutter in the milling head, and all actions occur automatically according to a numerical program entered into the computer.

When choosing equipment for certain technological processes, you should evaluate not only what type of processing needs to be done, but also the weight, size of the workpiece and the angle at which the processing should be carried out. The largest turning unit in history could process workpieces weighing up to 300 tons.

How to choose a metal turning and milling machine?

Before purchasing a metal turning and milling machine, you need to determine exactly what work you plan to perform on it. You need to understand what product, in what form, will need to be received at the output. Conclusion: the choice of a multifunctional machine directly depends on the specification and scale of production.

To perform a number of jobs at a small car repair station, for example, a table-top unit is sufficient. With its help, you can bring brake discs into working condition, grind a car crankshaft, or produce some part of a non-standard size or shape. Buying a complex, large CNC machine for a small auto repair shop is simply not profitable. After all, such a machine will not continuously produce identical parts in batches. And it may turn out that in a small workshop it is simply not possible to connect a large professional machine without special adapters - powerful units operate on 380 Volts, and not on 20 Volts.

If a metal turning and milling machine is needed for a medium or large industrial enterprise, then a system with numerical control will be the optimal (or even necessary) choice. After all, production involves the production of similar parts in whole batches.

You also need to focus on what metals and alloys will be processed and what human forces will be involved in the production process. High-tech machines must be operated by professional operators of a certain category.

Metal lathes

Lathes are the most common equipment used in machine shops of machine-building plants, enterprises of other industries, as well as in repair areas and workshops of various profiles.

Metal lathes are presented on our website in a wide range, which will allow you to choose and buy the equipment that is most optimal in price and functionally suitable for solving new problems posed in your production, or for replacing equipment, the operation of which in your enterprise becomes impractical due to moral or physical wear and tear.

Capabilities of turning equipment

Using lathes, surfaces are turned, ends are trimmed, threads and knurls are made, and holes are drilled. Lathes equipped with additional devices are also used for milling, drilling, grinding and cutting teeth. Metal lathes can process parts made of materials of varying hardness - steel, alloyed and ordinary, cast iron, non-ferrous metals and their alloys, plastics and wood.

Types and purpose of lathes

One of the important components of a lathe is the spindle - a supporting device that installs the workpiece of the part that needs to be processed. The spindle provides the main movement of the machine - the rotation of the workpiece, and the cutter acts as a cutting tool, the movement of which, longitudinal or transverse, is determined by another important mechanism - the caliper.

Depending on how the spindle is positioned, horizontal and vertical lathes are distinguished. Horizontal machines include screw-cutting lathes, turret lathes, pipe-cutting lathes, tabletop lathes and similar ones. The vertical type includes rotary lathes. They are used primarily for working with large workpieces (with large diameter and weight). Lathes vary in purpose, assembly, and mechanization. There are screw-cutting lathes, table-top lathes and CNC lathes.

Screw-cutting lathes

Screw-cutting lathes are the most popular equipment, belonging to the universal type and allowing to perform a wide range of technological operations associated with the mechanical processing of workpieces - turning of cylindrical and conical surfaces, external and internal, boring, axial drilling, reaming, countersinking, as well as cutting various threads with cutters and taps. They are used primarily for processing a small number of parts in a batch.

CNC lathes

CNC lathes are used in large-scale production. These machines have a high degree of automation; the operation of the machine is monitored visually by the operator. The machines of this group produce high-quality products. The person responsible for production takes part in the preparatory stage and at the final stage: he only needs to install and remove the part, set up the equipment. CNC lathes offer production flexibility, which is another advantage of these machines. This means that to process parts that differ in size and materials from which they are made, you simply need to change the program. Such machines can perform precise processing of parts, producing identical products.

Turning and milling machines

Turning and milling machines, usually called machining centers, carry out milling and drilling of parts. The processing center makes parts consisting of several parts, i.e. those that require turning and milling, such as a crankshaft.

Favorable prices for lathes

Lathes have great technological capabilities. This is a necessary tool for processing various metal and wooden parts. At the Stanochny Mir company you can buy new metal lathes from domestic and foreign manufacturers at competitive prices. Our sales team will be able to select the most suitable option for you.

Advantages of turning and milling machines

Multifunctional turning and milling machines have become integral parts of many large production lines or have become staple tools in small repair shops. Craftsmen who deal with such machines every day as part of their job responsibilities, business owners and third-party independent experts in the machine tool industry name the following advantages of turning and milling machines:

- Each model is distinguished by a design thought out to the smallest detail. This allows you to minimize the overall dimensions and weight of the unit, which, in turn, allows you to optimally use the production space of a workshop or, for example, a workshop.

- High accuracy of the finished product relative to the technical specifications. The less movement between processing devices, the higher the level of automation of the production process, the better the quality of the final product.

- Modern machines are characterized by a high level of rigidity. This minimizes vibrations that may occur during production. Consequently, the risk of damage to parts is reduced.

- High-quality machines are famous for their long service life. This is largely possible thanks to the thoughtful design, durable gears and repairability.

- The guides are usually subjected to a scraping procedure. This increases the level of precision in processing the metal workpiece.

- Options such as an emergency shutdown button or a protective shield increase the level of safety when working with a metal lathe.

- Many models are equipped with a telescopic chip guard (metal) for the lead screw.

- Milling heads are usually secured with a special integrated lock. This again has a positive effect on the safety of work and on the quality of the final product.

- Many machines have the ability to process both long and short cone-shaped elements.

Depending on the specific model of the device, other advantages of introducing turning and milling machines into production may be noted.

Classification of turning and milling machines

Lathe machining centers are classified according to several parameters: size and weight, type of milling support, complexity and versatility of the equipment.

Dimensions

Based on power and size, turning centers are conventionally divided by weight:

- mini – weighing less than 1000 kg;

- average from 1 t to 10 t;

- large ones weigh more than 10 tons.

Mini ones include tabletop turning and milling machines for metal and wood. They weigh 300 – 400 kg and allow processing parts up to 700 mm in length. The extended bed makes it possible to work with workpieces up to 1200 mm long. The diameter of the cylindrical surface does not exceed 90 mm. A special feature of tabletop turning and milling machines is their compactness and the ability to be located in a home workshop.

Mini turning and milling machine

The tabletop CNC metal machining center is capable of producing complex products with an accuracy of 0.01mm and angle control down to 0.001°.

A wood lathe also belongs to the mini class. The relatively low hardness of the material allows the production of models with motors powered from a 220 V network with a consumer frequency of 50 Hz. A three-phase connection to a household outlet with grounding is sufficient.

Milling head type and drive

Based on the design of the milling spindle, turning centers are distinguished;

- simple;

- with drive center;

- spindle with C-axis;

- with counter spindle.

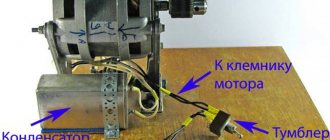

The device diagram represents the connection of working units from different equipment on the bed of a lathe. Longitudinal turning is carried out by rotating the workpiece and a permanently fixed tool - a cutter. The milling tool rotates from a separate drive, cuts the surface and drills a stationary blank. The simple design of the equipment requires manual control. To produce large batches of identical parts, CNC is used.

Spindle

Complex CNC routers have a C-axis spindle. The location of the milling tool and its independent movement parallel to the main axis allows you to make complex parts with processing of the side surfaces and ends.

By purpose and complexity

According to their purpose and processing complexity, turning centers are divided into:

- woodworking;

- tabletop for metal;

- multifunctional;

- universal.

Manual control of woodworking machines is allowed for single production of parts and small batches. It is easier to make a series of repeating spare parts by connecting a CNC. The operator types the program, places the workpiece and presses the start button. His further presence near the machine is not necessary. Used in carpentry workshops to make furniture legs and stands.

Woodworking lathe with milling head

Tabletop and benchtop machines for metal are used in workshops producing products in small batches and in large enterprises that produce a large number of different equipment. At low loads and single production, they are controlled manually. Most of them are CNC controlled and can be connected to a computer. They process parts of complex configurations with high precision. They cannot independently control the sizes. When the cutting edge wears off and the tool breaks, they continue to work according to the given program. The operator must periodically check the cutters and cutters for the integrity of the inserts and monitor the main dimensions.

A counter spindle installed in place of the tailstock increases the number of simultaneous operations.

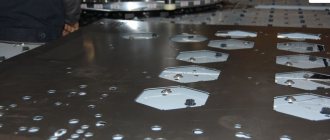

With independent supports and numerical control, flat workpieces are placed in groups of 2 and processed simultaneously. It is possible to alternately process one workpiece in different spindles. The multifunctional CNC turning center has high productivity and allows you to process parts from all sides, including the ends. Turning, drilling and milling are carried out in any plane and at an angle.

Universal machines

Universal lathes with a milling head have a support located parallel to the axis of the part - a C-spindle. The milling tool is mounted in it and rotates from an independent motor. The cutter head can move in any direction, processing at different angles. The changer changes the milling tool according to a given program, increasing the number of operations. The machine performs:

- cylindrical, conical, end turning;

- making worms;

- milling;

- drill;

- boring;

- trim;

- alignment;

- internal thread cutting;

- cutting external threads with a cutter and a die;

- groove milling;

- tooth milling;

- grinding;

- Slotting.

The result is parts of any configuration, with grooves, grooves and holes, both at the ends and on the sides. At the same time, high accuracy and alignment of all working surfaces are maintained, since processing is carried out from one installation.

When manufacturing rolls and other parts with complex configurations, a copier is used.

The universal center moves, repeating the shape of the template installed on the machine. A special flat copier is made and inserted into a special compartment of the program unit. When moving, the cutter follows its shape. When connecting a CNC machine to a computer, a copier is not needed; the movement of the tool is controlled by a special program. As a result, the machine processes workpieces along a given curved line. The results are parts with a complex surface in the form of parabolas, sinusoids, curves with different radii and smooth transitions.

CNC turning and milling machines for metal have action adjustments built into the program. For example, when they heat up, they reduce the number of revolutions, reducing the load. If the temperature reaches a critical value, the machine stops automatically. You can continue working after cooling.

In older models, the program is not adjusted, and the machine starts working from the first operation. The tool cuts the air for some time. Normal processing then continues. Modern CNC machines can turn on and continue working on their own after an emergency stop and cooling. No operator intervention is required.