At industrial enterprises, when standardizing working hours, calculating optimal volumes of supplies of consumables, and the cost of work, the amount of material deposited during welding work is calculated. The value of this indicator depends on the class of welding, the type of material, its thickness, the type and thickness of the wire (electrode), and the requirements for the parameters of the welded joint. The mass of deposited metal during welding is closely related to the consumption rates of electrodes and wire.

Calculation of deposited metal during welding

Weld metal is a filler material that is deposited onto the base material or introduced into the pool. This term is used when using thermal types of welding equipment in industry. For automatic and semi-automatic devices, wire of various types is purchased, differing in the design of the rod and composition, the presence/absence of alloying components.

There are 3 groups of steel wire:

- with a large volume of alloying components;

- with a minimum amount of alloying components;

- with carbon, titanium, chromium, nickel, silicon, manganese.

Each group, based on its composition, is divided into many subgroups.

By design, steel wire can be:

- solid;

- powder (in the form of a tube);

- activated (5-7% powder in the form of wicks in a continuous structure).

Aluminum and copper wires and powder additives are available. Each welding method has its own type of additive and its consumption rates, which are developed based on many years of experience.

Calculation of the mass of deposited metal is most often used when determining the time required to carry out a certain amount of work: manufacturing a product, creating a meter of welded joint. Although it is most convenient to express the time in minutes required to create a meter of weld, minutes are sometimes used to deposit a kilogram of additive.

Electrode consumption, norms, tables, how to calculate

An important part of any production or construction process is accurate and competent planning of material consumption, which is carried out to draw up estimates and calculate financial costs.

When erecting metal structures by welding, it is important to know not only the metal consumption, but also the required number of electrodes. A correctly performed calculation will allow you to find out the exact cost of the work, and the welding process will be carried out according to plan. It should be noted that calculating the consumption of welding electrodes is relevant and in demand only during the construction of large facilities . The large scale of work requires an accurate determination of the volume of materials, which will be included in the construction estimate. For this purpose, the concept of “electrode consumption per 1 ton of metal structures” was introduced.

Formula for calculating the weight of the molten additive

Formula for calculating the weight of deposited metal per meter of welded joint:

M=L*q*T, where

L(m2) – cross-sectional area;

q(g/m3) – specific gravity of the additive (7700-7900 – steel, 2640-2700 – aluminum, 8200-9100 copper and alloys);

T=1, if calculates flow per meter.

This formula is correct if welding is performed with the base material in a horizontal position. In other provisions, the formula is supplemented with a coefficient:

- 1.05 – the connection is inclined, formula:

M=L*q*T*1.05;

- 1.1 – the connection is located vertically, formula:

M=L*q*T*1,1;

- 1.2 – connection on the ceiling, formula:

M=L*q*T*1,2.

The seams can be double-sided, corner, T, V-shaped, X-shaped (GOST 5264 - 80), so problems may arise when calculating the cross-sectional area. If the seam connects two flat parts without bevel of the edges, then you need to multiply the width by the depth (thickness of the material being welded). If there is a bevel of more than 30 degrees, the result obtained is multiplied by 0.75. For corner and T joints, the result is divided by 2.

Parameters affecting flow

Before calculating the number of electrodes for welding, you should find out which indicators are of utmost importance:

- Weight of material deposited on the connection. The volume of this parameter should not exceed 1.5% of the total mass of the entire structure.

- Duration and depth of the weld.

- Total mass of surfacing per 1 m.p. connections. Electrode consumption rates per 1 meter of seam are reference indicators presented in VSN 452-84.

- Welding type.

Theoretical and practical calculations

The consumption of electrodes can be calculated from a theoretical point of view using a large number of special formulas. Let's look at the most common ones.

The first method - by coefficient - is used to calculate the consumption of various welding materials, and not just electrodes:

H = M * K, where M is the mass of the structure being welded; K is a special flow coefficient from the directory, which varies in the range from 1.5 to 1.9.

The second method is based on calculations depending on the physical properties of the electrode and the metal structure . Allows you to determine the mass of deposited metal. Here the performer will need to know the reference data, and it is also necessary to measure the connecting seam:

G = F * L * M, where F is the cross-sectional area; L – weld length; M – mass of wire (1 cm3).

Practical calculation involves carrying out test work. After their completion, the welder should perform the following actions:

- measure the cinder;

- take into account voltage and current;

- determine the length of the welded joint.

These data make it possible to determine the consumption of welding electrodes when welding structures with a seam of a certain length.

The contractor will be able to obtain accurate indicators only if the external data and the position angle during the main work are identical to those that were during testing. To avoid inaccuracy of parameters, it is recommended to carry out the experiment 3-4 times. This will allow you to obtain more accurate calculations than using theoretical formulas.

Using these methods, you can easily calculate the consumption of electrodes per ton of metal structures. However, you should remember that there is an error.

Content:

To determine the cost of welded products, it is very important to correctly calculate the consumption of materials during welding work. In addition, the quantity of required electrodes, welding wire, fluxes, shielding gases and other consumables must be known in order to ensure continuity of the work process by creating a sufficient supply of them in the warehouse.

The calculation of the required amount of materials for welding is carried out on the basis of existing standards for their consumption when using a particular welding method.

The consumption rate of welding materials is the amount required for the complete production of a welded product, taking into account all losses and waste. This standard includes the consumption of materials at all stages of the technological process associated with welding, namely during preparatory work (making tacks), conducting the welding work itself, as well as possible subsequent correction of the structure.

For each type of weld and each welding method, there are specific material consumption standards. In addition, when determining the amount of required materials, the inevitable losses during welding are taken into account, and there is also a certain rate of such losses, which depends on the welding method used and its mode, the length of the seam and the complexity of the entire welded structure.

Calculation of electrodes per 1 meter of seam: online and independently

Some websites on related topics provide the opportunity to make calculations using an online calculator. This method is simple and convenient. The performer will only need to enter the numbers in the appropriate windows, click the “calculate” button and automatically receive the finished result.

Read also: How to identify a faulty transistor

Welders can also perform calculations on their own. For this, the following general formula is used:

N = Nsv + Npr + Npr, where Nsv is the consumption of electrodes for welding; Npr - consumption of rods for tacks; Npr - consumption for straightening using the blank roller method.

The consumption rates of welding electrodes for tack work are determined as a percentage of the consumption for main work:

- The thickness of the walls of the structure is up to 12 mm. - 15%;

- over 12 mm. - 12%.

There are also standard standards that vary depending on the type of electrode and the thickness of the walls of the structure.

Depending on the consumption coefficient, according to the passport data, electrodes used in arc and combined welding of pipelines made of alloy and high-alloy steels are combined into 6 groups (Table 1). Group 1 includes electrodes with a flow coefficient of 1.4.

Electrode consumption coefficient

OZL-E6; OZL-5; TsT-28; OZL-25B

TsL-17, OZL-2, OZL-8, ZIO-8, OZL-6, OZL-7, OZL-3, OZL-21

OZL-9A, GS-1, TsT-15, TsL-11, UONI-13/NZh, TsL-9

OZS-11, OZL-22, OZL-20, NZH-13

ANZHR-2, OZL-28, OZL-27

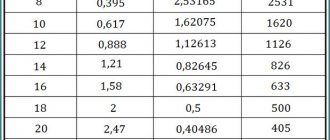

Let's look at these standards using the example of connecting vertical seams of type C18:

| Wall thickness, mm. | Weight of deposited metal, kg. | Electrodes of group II, kg. | Electrodes of group III, kg. | Group IV electrodes, kg. | Group V electrodes, kg. | Electrodes of group VI, kg. |

| 3,0 | 0,201 | 0,366 | 0,390 | 0,415 | 0,439 | 0,464 |

| 4,0 | 0,249 | 0,453 | 0,484 | 0,514 | 0,544 | 0,574 |

| 5,0 | 0,330 | 0,600 | 0,640 | 0,680 | 0,720 | 0,760 |

| 6,0 | 0,474 | 0,861 | 0,918 | 0,975 | 1,033 | 1,090 |

| 8,0 | 0,651 | 1,182 | 1,261 | 1,341 | 1,419 | 1,498 |

| 10,0 | 0,885 | 1,607 | 1,714 | 1,821 | 1,928 | 2,035 |

| 12,0 | 1,166 | 2,116 | 2,257 | 2,398 | 2,539 | 2,680 |

| 15,0 | 1,893 | 3,436 | 3,665 | 3,894 | 4,123 | 4,352 |

| 16,0 | 2,081 | 3,778 | 4,030 | 4,281 | 4,533 | 4,785 |

| 18,0 | 2,297 | 4,532 | 4,834 | 5,136 | 5,438 | 5,740 |

Let's look at these standards using the example of connecting horizontal seams of type C18

| Wall thickness, mm. | Weight of deposited metal, kg. | Electrodes of group II, kg. | Electrodes of group III, kg. | Group IV electrodes, kg. | Group V electrodes, kg. | Electrodes of group VI, kg. |

| 3,0 | 0,152 | 0,269 | 0,286 | 0,305 | 0,322 | 0,340 |

| 4,0 | 0,207 | 0,368 | 0,393 | 0,417 | 0,442 | 0,466 |

| 5,0 | 0,262 | 0,465 | 0,497 | 0,527 | 0,588 | 0,590 |

Number of electrodes in 1 kg

After receiving ready data on the required number of electrodes, the welder proceeds to purchasing materials. Here another question arises: how many packages of consumables should be purchased. To do this, you need to determine how many rods make up 1 kg (standard pack). This indicator is influenced by all parameters of welding materials:

- diameter;

- rod length;

- rod weight;

- thickness of sealed packaging.

The larger these parameters, the fewer rods in the pack.

However, you should know that electrodes of a certain diameter have their own average mass:

Basic formulas for calculating the consumption rate of welding materials.

There is a certain regulatory formula that helps calculate the consumption of materials during welding work. This formula allows you to understand how many welding materials are required per meter of seam:

N – rate of consumption of welding materials per meter of weld

G – mass of deposited metal of a weld, the length of which is 1 meter

K – coefficient of transition from the mass of deposited metal to the consumption of materials for welding

And in order to determine the mass of deposited metal per 1 meter of weld (G), you can use the following formula:

F – cross-sectional area of the weld (in mm 2)

y – specific gravity of metal (g/cm3)

L is the length of the weld (it is equal to 1 meter).

The above formulas allow you to calculate the material consumption rates for a weld in the simplest position - the lower position. If welding work is carried out in a vertical or overhead position, then the resulting standard must be multiplied by a correction factor, which takes into account the peculiarities of material consumption at different positions of the weld:

- for the lower position of the seam this coefficient is 1.00

- for a semi-vertical position of the seam, a coefficient of 1.05 is taken

- with a vertical (horizontal) position of the seam, the coefficient is 1.10

- when the seam is in a ceiling position, the previously obtained norm is multiplied by a factor of 1.20.

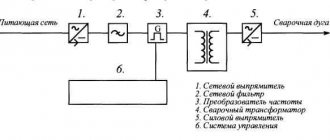

Let's consider what features you should pay attention to when determining the required amount of specific welding materials - welding wire and shielding gas.