What the article is about:

Who is flux-cored wire suitable for, and who should not use it?

Semi-automatic welding has a number of significant advantages. Firstly, the speed of welding work increases significantly. Secondly, there is no slag during welding. You can weld long seams without interruption. Thirdly, this is more delicate work with workpieces that are very thin.

The only thing needed for semi-automatic welding is shielding gas. But what if there is no protective gas? How to cook semi-automatically without gas? In fact, there is a way out, and its name is “cored wire”.

Flux-cored self-shielding wire independently takes on the task of protecting the weld pool. That is, if in the usual case, when welding with a semi-automatic machine, gas is needed for this, then, without using it, you can weld with only flux-cored wire.

How does cored wire work and how does it work?

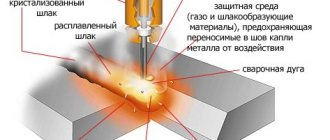

Everything is simple here. To protect the weld pool, a gas of substances contained in the flux-cored wire is used. The wire itself is made of metal, in the form of a tube, inside of which there is a special filling. When the metal of the tube melts, substances that form a gas cloud to protect the weld pool are also burned.

A conventional electrode in the form of a metal rod works in exactly the same way. On its surface there is also a coating of special substances that, when burned, form a cloud of protective gas. When welding semi-automatically with carbon dioxide, there is none of this, and only carbon dioxide acts as a shielding gas. I hope I expressed myself in accessible words and everything fell into place.

So, you can cook semi-automatically without gas if you have cored wire. Who is this method of semi-automatic welding suitable for, and in what cases?

Semi-automatic welding with and without gas. Wire. Recommendations.

Semi-automatic welding has advantages over a non-consumable electrode.

- Everyone knows how important it is to carry out the welding process without breaking the arc, maintaining a constant distance between the electrode and the workpiece (arc clearance). If the parameters are set correctly, the semi-automatic device will independently adjust this clearance if there are slight deviations from the optimal position of the burner. In other words, the device takes on half of the tasks that were previously solved primarily by the skill of the welder.

- No need to hold filler material. The right hand is freed, which allows you to freely manipulate the part manually.

- Speed and efficiency increases.

Standard consumable electrode welding consists of:

- inverter power supply (IPS);

- copper-plated wire feed unit;

- special burner

- mass crocodile

- shielding gas cylinder with flow meter.

There are inverters in which the SMPS and the feed mechanism are assembled under one housing. Such devices, operating on the “all-in-one” principle, are most often purchased to satisfy personal needs:

- welding of sheet material (especially thin sheet),

- welding a canopy or gate at the dacha,

- installation of pipelines, etc.

And also for solving special issues, such as, for example, body repair of passenger cars at service stations.

In factory conditions, more powerful equipment is usually used, so the SMPS and wire feeding are separated in them.

The principle of operation of the semi-automatic device is simple: it rectifies the alternating current entering the input into direct current at the output. At constant current, the current vector is determined by its polarity and how the cable is connected to the terminals.

The wire used is designed for a specific polarity. For common wire type 09G2S, “+” DC current is used on the torch.

During the welding process, when the distance from the consumable electrode to the metal changes, the working current and voltage are automatically adjusted so that the arc does not break. The SMPS “tries” to keep the voltage constant while the current increases or decreases.

The feed mechanism block consists of a spindle on which the reel is fixed, and the wire enters the hole of the feed roller through a guide. The feed wheel is designed for a specific wire diameter and can be replaced.

We have examined frequently repeated questions asked by novice welders who are learning to work on a semi-automatic inverter-type machine.

What protective gas is used when working with a semi-automatic machine?

Semi-automatic welding is carried out in a carbon dioxide environment, which is 100% carbon dioxide. You can work exclusively in argon, or in a mixture of argon and carbon dioxide. The welding wire, which is also an additive, is coated with a copper layer to improve electrical contact and smoothness of its feeding.

What should the shielding gas pressure be?

Choose 0.6 ... 0.8 MPa. This is if everything is fine and a new burner is used. If it wears out, you can add a little gas. The main thing is that there are no pores in the weld. If porosity does occur, then the pressure is insufficient (or very high, which can cause air to enter the welding zone, especially when working with an outer corner). Pores can also arise due to “dirty” gas, if there is be wind or drafts. The purity of the gas is especially noticeable when welding aluminum - the seam will simply become covered with a layer of soot and burning. When working with aluminum, choose only high-purity argon.

| Read the article on the website: Welding aluminum - instructions, apparatus, wire, gas |

What wire do you use? What polarity should be observed?

Copper-plated welding wire OK Autrod 12.51 ESAB

The most universal is 08G2S, all welders without exception are familiar with it. It is used for welding low-carbon and electrical steels. Naturally, this material is now sold under various trademarks. The world-famous company ESAB produces 08G2S under the name OK Autrod 12.51 - its composition is strictly controlled, which ensures stable mechanical properties of the seam. Also subject to control is the condition of the copper-plated surface, which is applied in a layer that is not too thick and not too thin, i.e. has an optimal size. Why is it important? Because low-quality wire quickly leads to failure of the feeding mechanism due to contamination with copper dust and chips.

The quality of the wire and copper coating directly determines the condition of the seam and the feed body.

Solid wire welding is carried out using reverse polarity current, that is, the torch is connected to the output with a plus sign. Also for corrosion-resistant steels, the additive ER-308 LSi is used - it contains 20% chromium and 10% nickel - exactly the ratio that gives the weld the greatest resistance to corrosion.

Is welding possible without shielding gas? If yes, what are its features? What are the pros and cons of this welding method?

Flux Cored Self Shielding Wire E71T-GS

It is possible to do without inert/active gases. In such cases, flux-cored wire is used, which is similar in its action to the piece electrode used in manual arc welding.

Flux-cored wire is a hollow tube filled with flux. During combustion, the latter provides the necessary gas protection from external influences for the correct formation of the weld.

Flux-cored wire is also often called flux-cored wire; it is less rigid than regular wire, therefore, in order to work correctly with it without stopping the feed mechanism, it is necessary to loosen the compression force of the roller. Or you shouldn't tighten it too much.

The wire is soft and will wrinkle. In order to avoid such problems, before feeding it for the first time, you should remove the tip on the burner and only then pull it through. Only install a tip of the appropriate size. There is no need to install a nozzle, since welding will be carried out without shielding gas. On the inverter, you should set the voltage, feed rate and inductance parameters using the smooth adjustment knobs.

Another peculiarity of working with such wire is the need to change the polarity on a semi-automatic inverter. The welder must be adapted for this. For example, on the OVERMAN 180 device, the polarity is changed inside the case next to the feed mechanism (the terminals are unscrewed and the wires are swapped). Do not forget also that the size of the feed roller groove must correspond to the diameter of the wire.

Welding a sheet 1-2 mm thick should be done with short seams at an angle back, in which case the seam is formed much better. For welding thin metal, 0.8 mm wire is commercially available. Maximum diameter 2.4 mm – for serious industrial applications.

Advantages:

- no need to carry heavy cylinders, mobility.

Flaws:

- high cost of wire,

- you need to be careful about its quality,

- A slag crust forms on the surface of the seam, which needs to be cleaned off.

| Read the article on the website: Semi-automatic welding for beginners |

When to weld with flux-cored wire without gas

In principle, you can always cook; in such cases there is no need for protective gas. The only drawback is the price; it is quite high for self-shielding wire for a semi-automatic machine, so not everyone can afford to weld with cored wire every day.

The second point is related to the fact that it is not always possible to deliver gas cylinders to the welding site. Well, let's say you need to cook at a height. How to deliver a carbon dioxide cylinder there? That's right, it will be better and faster to weld semi-automatically using flux-cored wire.

The next point is related to weather conditions. As you know, the main enemy of semi-automatic welding is the wind. If the weather is windy outside, the shielding gas will simply blow off, which will negatively affect the quality of semi-automatic welding.

Consequently, cored wire will also help get rid of this problem; it can be welded even in very windy weather.

Welding with flux-cored wire - questions for a beginner.

Palmman wrote: The store sold me Wester FW 08045b flux wire with the note “aluminum”

Was the “postscript” handwritten? Surely the storekeepers simply wrote it down for reasons of “classification” (as they understand it) - flux-cored wires do indeed usually have a “metallic” color. Or just a simple mistake.

Palmman wrote: Complies with AWS HTE71T-1 standard

By the way, AWS does not have such a standard, it has E71T-1. Everything else is a “hint” to the standard and certification, without any special responsibility for it... something like the Pauasonic brand. As, in fact, it is impossible to find a site like this on the Internet. Surely it’s just a “brand” born on paper, under the “name” of which the Chinese are selling a lot of things in the Russian Federation. All links to it on Google - exclusively in Russian, as well as links to “HTE71T-1” - refer ONLY to this WESTER. But we will assume that there should still be correspondence with E71T-1.

Palmman wrote: I thought since the owner was working without a cylinder, then his polarity should be correct.

Eh, here it’s better to always rely on yourself, especially since it’s not at all difficult to check. Where and how is in the manual; it’s probably not difficult to find it on the Internet. But - the polarity required for different flux-cored wires is DIFFERENT, you need to look at the specifications for a specific type. In particular, the E71T-1 requires just a “+” on the wire (see link below).

Palmman wrote: I can’t get a normal bath - it shoots all the time, balls with a whitish coating fly off. I tried adjusting the current/feed and voltage. Instead of a seam, there are a bunch of balls of different sizes, which also easily jump off if you hit them with another piece of metal.

Well, now - the main thing. Flux-cored wires are divided into two classes - self-shielded (FCAW-S, i.e. “self-shielded”) and for gas-shielded welding (FCAW-G, i.e. “gas-shielded”). Those. There are wires, even though they are flux-cored, but still REQUIRE external gas protection. Unfortunately, the E71T-1 type wire sold to you is just the latter, see, for example, this one from Lincoln Electric. Why is there such a result without gas?

So you will have to put this wire aside until you get hold of gas yourself (or donate it to the owner of the device who has gas), and buy another one yourself. The best-selling self-protective one is E71T-GS (for example), but for “delicate” work it is a bit rough, because noticeably deposit - has a large transfer of metal and its rapid solidification, since it is intended for massive filling of seams (the letter “S” here means single-pass - single-pass). Really produces tall rolls with poor flow. Of the ones we sell in this sense, the best one, I think, should be the T-8 (from Moscow companies, for example, it seems to be in the price list and at a very good price, but you have to call), in terms of characteristics it seems to be the best for body iron - multi-pass, all spatial positions, low thermal impact.

You can also think about the E71T-11, for example - from BARS (apparently - the same China, but, I hope, there is at least some attention to quality), especially since in the same All Tools the T-GS wire is from the same little-known NWT has almost caught up with it in price (~800 rubles/kg). However, in the characteristics in the link above for this type, I am confused by the words about High-Speed and Spray Type Transfer - these modes are NOT at all for neat body work... I myself actually never had the chance to cook anything other than T-GS with flux - I got hold of gas and experimented with flux-cored wires stopped, based on these others I judge by the characteristics and indirect reviews on the Internet.

When is it better to refuse welding with self-shielding wire?

There are only two drawbacks here - the high cost and lower quality of the weld than when welding semi-automatically in a shielding gas environment. Flux-cored wire has also performed rather poorly when welding pipes under pressure. Therefore, this method is not at all suitable for performing these works.

In general, as you can see, there are pros and cons when using self-shielding wire. The advantages are associated with the ability to weld in hard-to-reach places and in any weather, and the disadvantages are with the high price and lower quality of the seam.

Which flux wire is best for cooking without gas?

The most popular brand of flux-cored wire for semi-automatic machines without gas is self-shielding wire E71T-GS. This wire ensures quick filling of the weld and greater metal transfer. However, such flux-cored wire is not very suitable for performing delicate work.

Self-shielding wire Spark E71T-8 can provide a much better quality semi-automatic weld. This is the most preferred wire option for semi-automatic machines without gas for welding body metal.

In addition to multi-passability, the wire provides low thermal impact; it can be welded in all spatial positions. Thus, it turns out that not all flux-cored wire is intended for welding without a protective gas atmosphere.

I hope the article will be useful not only to novice welders who have encountered difficulties when welding semi-automatically without gas.

Pros and cons of using a semi-automatic machine without a gas cylinder

For semi-automatic welding, a special electrode wire is used. Entering the welding site through the welding head, the wire melts the metal and reliably connects it. The use of shielding gases and special fluxes makes it possible to increase the depth of metal penetration, even using low welding current values.

But the most important advantage is the quality of the weld and increased productivity. It is equally important that semi-automatic welding is ideal for joining thin metals, where a conventional electrode is powerless.

Despite all this, semi-automatic welding without gas, using only flux-cored wire, requires experience. When working with such welding, it is very difficult to monitor the progress of seam formation. Also, given the fragility of the cored wire, careful handling of the hose is especially inconvenient. It is important to avoid sudden movements here.

When using flux-cored wire for semi-automatic welding without gas, it is necessary to observe the polarity of the welding machine connection. The positive terminal should be connected to the holder with ground and to the product, that is, in the direct version. This feature is due to the fact that when melting flux-cored wire, a high temperature is required, under the influence of which a cloud of protective gas would form.