The use of shear presses for cutting metal

Separation operations with steels and alloys, performed using technological processes of plastic deformation, are considered the most modern, since they are highly productive and are characterized by minimal loss of metal into waste. That is why universal press shears have become widespread. Any press shop or site, construction metal depot or enterprise of the Vtorchermet system has press shears of the required standard sizes as part of its production fleet.

Combined shear press HB5222

Classification and designation

Combined press shears are an extensive class of forging and pressing equipment designed for cutting bulk metal products. The equipment in question is distinguished according to the following characteristics:

- According to the type of energy carrier in the drive. Mechanical and hydraulic shear presses are available.

- According to technological capabilities. Press shears are produced that work only with rod or wire, as well as combined press shears. capable of producing piece products also from strip and rolled products. Scrap shears for scrap metal should be placed in a separate category.

- According to the degree of automation. Shears can be manually operated or operated as part of specialized procurement lines. In the latter case, they are equipped with automated roller conveyors and dumpers of finished workpieces.

- According to the nature of the energy carrier. When cutting profiles with a small cross-section, moreover, in small-scale and single-piece production, manual press shears are popular.

- According to the installation features, a distinction is made between shears that are permanently mounted on the foundation, and mobile press shears, used in the structures of the Ministry of Emergency Situations, as well as for the primary cutting of scrap steel.

The parameters and technical characteristics of domestically produced shear presses are regulated by the relevant state standards. For combined shears, GOST 7355 applies, for grade shears - GOST 8248, and press shears for alligator-type scrap metal are produced in accordance with the requirements of GOST 15032.

The accepted designation for press shears for metal in our country is the alphanumeric type H _ _ _ _ (it is possible to add letters after the main “H” and after the digital index, which indicates a modification of the main, basic model). The classifier was developed on the basis of the industry standard KN-01-1. The first number indicates the type of scissors drive (0 - hydraulic, 1 - mechanical), the second - technical design features (2 - alligator, 3 - closed grade, 5 - for precision cutting, 7 - with a hydraulic clamping mechanism, 8 - with a mechanical differentiated clamp) . The last two digits indicate the value of the nominal force in tf. Since the basic line of equipment is built on a preferred series of numbers, the main technical characteristics of the scissors can be easily established using the data in the following table:

| The last two digits in the scissors model designation | 22 | 24 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 34 | 36 | 38 | 40 | 46 |

| Nominal force, tf | 25 | 31,5 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | 250 | 400 | 630 | 1000 | 4000 |

Types of cutting performed

Hand shears for metal

Hand scissors are used in small industries, metalwork shops, and scrap metal collection points. They are designed for a relatively small amount of processed metal and not too impressive workpiece sizes.

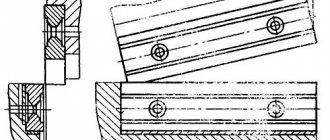

Design of manual shears

Manual press shears

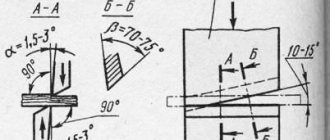

The working part of the machine is two blades (knives) about 10 cm long. One of them is fixedly attached to the bed, the second can move in a vertical plane under the action of a lever mechanism. The lever is driven by the operator's muscular force and, through a mechanical transmission system, acts on the knife.

Using manual lever machines, you can cut sheet metal (steel) up to 8 mm thick and non-ferrous alloys up to 10 mm, reinforcement and rods with a diameter of up to 1.8 cm. Lever-type manual scissors are made from tool steel and alloys of grades P18, U8, U9 or their analogues.

Composition of components and principle of operation

Crank press shears for cutting metal have a fairly uniform structure, which includes the following components:

- AC drive motor;

- the drive shaft on which the switching system is located;

- intermediate gear;

- flywheel;

- crank or eccentric shaft;

- a connecting rod with a slider to which movable knives are attached;

- clamping mechanism for the original workpiece;

- support unit for the cut part of the bar (strip, rolled products);

- adjustable roller conveyor for supplying source material;

- back stop;

- bed.

The process of a single cycle of metal cutting on combined press shears occurs in the following sequence. The operator, including the roller table, introduces the profile to be cut into the working area of the shear press, after which the required length of the workpiece is set using the back stop. After this, the material is fixed in the required position by a clamping device and supported by a compensator, which ensures the constancy of the horizontal axis of the rod/strip during the cutting process. After this, the electric motor of the combined shear press is switched on for the working stroke. The engagement clutch is activated (for large sizes it is pneumoelectric multi-disk; for shears with a force of less than 800 kN, the unit may contain one pressure disk), and the band brake releases the shaft, which transmits the required torque to the crank shaft through a gear transmission. The crank mechanism located there converts rotation into translational movement of the slider with the working knife. The cut product falls along the slide onto the receiving tray, and from there into the box for cut pieces. At this time, the crank mechanism returns to its original - upper - position. The activation system is activated, and the shaft is secured by the synchronous activation of a band-type brake.

Operations performed on press shears NG5224

During the automatic operation of combined press shears, during the reverse stroke of the slide, the next workpiece is pushed and fixed in the cutting zone.

Hydraulically driven shear presses (for example, from the Heck company of the Multicrop series) operate from a hydraulic power cylinder, which controls the reciprocating movement of the slide. Such equipment is characterized by lower productivity, but it provides the ability to hold the slider at the lowest point. In some cases this improves the quality of the cut. Geka shears are distinguished by the presence of an option for angular profile cutting, as well as the possibility of subsequent bending.

Alligator-type metal cutting shears, as well as reinforcing shears designed for mechanized separation of reinforcing steel bars, have slightly different kinematics. There are less torques there, so instead of a friction clutch, the design provides for a structurally simpler rigid coupling with rotary keys. In addition to being unpretentious in maintenance, it does not require a continuous supply of compressed air at a pressure of more than 5...6 at. The slider itself makes not reciprocating, but rocking movements. With a slightly worse cutting quality (this circumstance is not particularly important for scrap), the height of the working space between the movable and stationary knives increases, which makes cutting scrap metal easier.

Design

The tool is based on a welded frame, which consists of two sheets: back and front. Their thickness varies from 25 to 50 mm. The device resembles a guillotine with a press that enhances its effect. The design of the equipment includes blades for cutting metal and a tool for punching holes - they are mounted on one frame, and receive energy from a hydraulic drive.

The tool consists of three parts:

- mechanism for working with high-quality metals;

- mechanism for cutting rolled metal;

- mechanism for punching holes.

The advantages of modern models are the ability to perform many operations, saving work space, and the presence of a computer numerical control (CNC) system. The system is controlled using an automatic remote control. The machines have special fuses against overloads during operation.

Components

The crank press shears include the following components:

- AC drive motor;

- intermediate gear;

- drive shaft with activation system;

- flywheel;

- support unit for the cut part of a bar or rolled product;

- eccentric shaft;

- a connecting rod with a slider with attached movable knives;

- mechanism for clamping the workpiece;

- back stop;

- adjustable roller conveyor for supplying source material;

- bed.

Manual equipment

Manual shear presses are adapted for primary use in small and private businesses associated with the production of piece parts of small diameter or cross-section. They are equipped with a multifunctional working area (for example, model H9818 scissors have four working positions), which does not require adjustments during operation. The force is transmitted from a pair of handles. It is possible to cut strips, sectional profiles, as well as punch holes and cut narrow grooves. Such combined press shears are distinguished by their compact dimensions, do not require pouring a foundation, and can be easily reinstalled to a new place of application. The drive of hand scissors is lever type, with an eccentric clamping of the metal being cut.

Combined hydraulic press shears Geka HYDRACROP 110/180

Selection principles

When choosing combination shear presses, you need to pay attention to a number of parameters:

- drive power;

- press force;

- required current strength, ability to connect to the network;

- dimensions of cutting parts;

- machine dimensions;

- availability of additional functions;

- the ability to change the position of the blades for cutting at different angles.

For mass production, it is advisable to choose CNC models. For the home workshop, manual installations are used.

Advantages and disadvantages

Press shears for metal have a number of strengths and weaknesses that you need to familiarize yourself with before purchasing. Advantages:

- High power.

- Possibility of carrying out different technological operations due to the replacement of equipment.

- CNC models do not require any effort from the operator during operation.

- High cutting precision.

- Maximum thickness of cut sheets.

- Hydraulic models allow you to work with parts of large thickness.

The disadvantage of the devices is that it is necessary to change the equipment when processing parts of different thicknesses and shapes. Models with high power take up a lot of space in the room. Another drawback is that it is impossible to make curved cuts.

Manufacturers and cost

There are different types of narrow-profile and combined press scissors. Manufacturers:

- Stalex;

- Metalmaster;

- Proma;

- JET;

- Rems;

- Kingsland.

The cost depends on the power of the equipment, dimensions, additional functions, and technological operations performed. The average price for manual models is 30,000 rubles, for industrial equipment - 400,000 rubles.