Representatives of the older generation probably remember how they woke up and fell asleep to the sound of a bugle in the pioneer camps, where most of the city children spent their summer holidays. The bugle is also known to the guys as a mandatory attribute of all training camps, rallies, and military-patriotic games. But few people know that this simple, well-known musical instrument is one of the oldest, which laid the foundation for the emergence of other brass instruments. The forges themselves originate from signaling instruments that were made in ancient times from the bone horns of animals. The material for the forge is copper, brass. Translated from German, horn means horn.

In Dahl's dictionary

m. and mining avg. (see goryat, burn, rake), a type of furnace with a wide brow (tent), with a bellows, a blower or draft, for heating and partly smelting work; own that part of the working furnace where the fire is, for heating, melting, etc. A forge forge, in which iron is heated or boiled for forging; it can be, depending on the work: welded, laid, wedge, oblique, etc. The forge is loud, large, for making iron from cast iron. G. blast furnace, and in a smaller form, cupola, iron-smelting. G. extractive (mining), where silver is smelted; G. separation (purification), where silver is purified. | Ur.-Kaz. forge, rod chuvala, butt, on which food is cooked, milk for kaymak; blmr. galley, carbass stove. Forge, pertaining to a forge. Forge casing, frame, arch above the forge, with a pipe. Forge window, an opening in the wall of the forge for setting up a tuyere. Forge stone, fire-resistant, used. when calcining forges. Crucible Wed. forge, a place for heating, melting, cleaning by fire. Crucible, belonging to or relating to the crucible. Gornovishche Wed. remains or ruins of an abandoned forge. Miner m. worker at the forge, to support the fire, etc. Miner m. church. pot; Little Russian Belarusian garnok, garnushka. There will be a merchant for a holey miner. In wedding The song remembers mountaineers, at feasts, mugs, glasses; Isn’t that why the proud guests are wrong? proud? Gornatik m. Kaz. clay or fashionable vessel. Gornushka eastern a corner with a hole, to the left of the hearth of a Russian stove, where the heat is raked; grandma, baburka, stove, zagnetka, zharotok, porsk, ash pan. BURN m. music. German a special type of clarinet, in military music, a type of trumpet, horn. Bugler m. musician who plays the bugle. Gornistov, which belongs to him.

Grate bars

This part of the furnace is used in the construction of a solid fuel furnace.

Most often, it is a massive cast-iron stove with holes or slots that allow air to penetrate to the burning fuel and holds the coal. The area of the grate may vary. It all depends on the size of the fire and the type of fuel.

The grate can also be made of refractory bricks or a steel plate.

Grate

In professional devices, the shape of the holes plays a role. By changing their configuration, the blacksmith gets the flame he needs, which is used to heat the part.

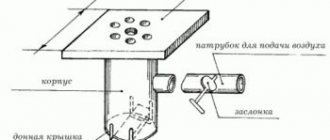

The placement of the grate can vary depending on the side of the air supply: from below (classic version), from the side or from above.

The main task of the grate is to provide the forging forge with a sufficient volume of forced air, hold fuel (coal) and withstand high temperatures.

Grate bars are used in all types of solid fuel stoves.

In Vasmer Max's dictionary

I I. “melting furnace”, folk. Goron (Shakhmatov, IORYAS 7, 1, 299), Ukrainian. mining, other Russian gurn, tslav. gran "lebes", bul. garne, Serbohorv. Grne, b. p. -eta, Slovenian. gŕnǝc, Czech, Slavic hrnec, Polish garnek "pot", v.-pud. hornc, nj.-luzh. gjarńc. Related to Lat. fornus “oven”, Old Indian ghr̥ṇás “heat, heat”, Old Prussian. goro “Feuerstand”, further, to burn; see Bernecker 1, 371; Trautman, BSW 102; Bezzenberger VV 12, 79; Osten – Saken, IF 22, 318; Walde - Gofm. 1, 533 et seq. Wed. also garnets. II •• (II. “musical instrument, trumpet” from German Norn “horn.” - T.)

Blowing

A certain volume of air must be supplied to a forge, especially one operating on solid fuel, otherwise the required temperature of 1100-1300 degrees will not be achieved.

Previously, blowing through the tuyere was provided using blacksmith bellows, pumping oxygen into the hearth. Today they have been replaced by fans and compressors.

Blowing can be arranged from below, from the side or from above. With bottom supply, air is initially pumped into the chamber in front of the grate - a lance, on top of which a grate with fuel is located.

Bottom air injection device

In small portable furnaces, air injection can be achieved using a small fan, but large stationary furnaces will require a larger volume of oxygen.

In the simplest homemade devices, airflow is provided by installing computer fans or even hair dryers.

In the Encyclopedia Dictionary

(from German Horn - horn), a wind-copper mouthpiece musical instrument without valves, with a conical barrel. Used for signaling.—(Cabo de Hornos, Hoorn), cape on the island. Horn, in the Tierra del Fuego archipelago, the southernmost point of the South. America (55°59′ S, 67°16′ W).—1) a small furnace with an open shallow shaft, used for melting metals in crucibles and heating blanks before forging. 2) The lower part of the shaft melting furnace. 3) The simplest metallurgical furnace (hearth) at the early stage of development of metallurgy.—A. B., see Hoorn A. B.—(Horn, Hoorn) Philippe de Montmorency (Montmorency) (c. 1524-68), count, one of the leaders of the anti-Spanish noble opposition on the eve and at the beginning of the Dutch Revolution. Executed.

Varieties of forge

The forge reached its heyday, perhaps, in the 19th century; it was then that many of its variations appeared using valves and taps. Thus, at the beginning of the century, a keyboard horn or a horn with valves was invented in England, which almost immediately became a fairly popular instrument. A large bugle with valves, called an ophicleide, was used in symphony and brass bands. Its popularity lasted until the middle of the century. Later it was replaced by another instrument - the tuba, which pushed the forge with keys far into the shadows. The valve horn or flugelhorn is used in brass bands and jazz ensembles.

In the dictionary Dictionary of foreign words

a, m.

A brass wind signal instrument in the form of a straight tube with a bell. Bugler - a musician who gives a signal on a bugle.||Cf. FORNISH" title='French horn, French horn is, what is French horn, French horn interpretation'>French horn, HELIKON" title='HELIKON, HELIKON is, what is HELIKON, HELIKON interpretation'>HELIKON II, CLARNET" title='CLARNET, CLARNET is , what is CLARNET, CLARNET interpretation'>CLARNET, SAXOPHONE" title='SAXOPHONE, SAXOPHONE is, what is SAXOPHONE, SAXOPHONE interpretation'>SAXOPHONE, TROMBONE" title='TROMBONE, TROMBONE is, what is TROMBONE, TROMBONE interpretation'>TROMBONE , TUBA" title='TUBA, TUBA is, what is TUBA, TUBA interpretation'>TUBA, BASSON, FANFARA, FLAGEOLET, FLUTE.

Share the meaning of the word:

How to play the bugle

The sound production technique is similar for all wind instruments. It is important for a musician to have a developed labial apparatus - an embouchure, and strong facial muscles. Several training sessions will allow you to master the basics and get used to the correct position of your lips - with a tube and your tongue - with a boat. In this case, the tongue is pressed against the lower teeth. All that remains is to blow more air into the copper tube through the mouthpiece. The pitch of the sound is varied by changing the position of the lips and tongue.

The low performing abilities of the bugle, while the ease of mastering this instrument, is rather an advantage than a disadvantage. Taking the “progenitor” of all wind instruments into your hands, you can learn to play music on it in a few lessons.

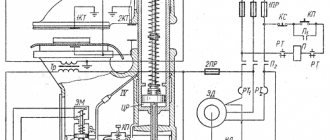

Device and principle of operation

To understand how to assemble a homemade structure for heating metal parts, you need to know the structure of the forge and the principle of operation. The equipment consists of the following elements:

- Metal base. Must be stable so that the equipment does not tip over during operation.

- Hearth and work table made of fireclay bricks. A grate is fixed to the hearth.

- Cover, walls. They are made of the same material as the hearth.

- Chimney for removing fuel combustion products.

- Fan, air supply system.

- An umbrella is a part to improve traction.

- A lance is a connecting element through which air is supplied from the fan to the grate.

- Hole for feeding workpieces with a closing door.

You can make a design with a natural air supply or install an electric blower on the forge. The second option is considered more effective. It allows you to reach high temperatures in a short period of time, regardless of environmental factors.

We must not forget about the features of the household forge. The principle of its operation is that the hearth is filled with flammable fuel, which must be set on fire. Then you should wait until the temperature rises to the desired level. Using blacksmith tongs, place the workpiece on the work area. It should warm up to the required state. Then the blacksmith pulls out the part and continues working on the anvil. When working with a forge, we must not forget about the use of high-quality charcoal. It's better to use coke.

Classification of types of forges

It can be carried out according to the following main indicators:

- According to the type of fuel used. There are gas furnaces, as well as devices operating on solid (coal) or liquid (fuel oil) fuel.

- According to the design features, open and closed forges are built.

- By hearth size (effective surface) – small, medium and large.

Mobile open type forge

Solid fuel furnaces, which require the use of coking coal, are an effective technical solution for video shooting, but an outdated one. This will require not only ensuring a continuous supply of high-quality charcoal, but also coming to terms with technological shortcomings, including:

- uneven heating;

- inability to control the process;

- increased sulfur content, which will increase fragility during the forging process;

- increased fuel consumption, it can be up to 120 - 150% of weight;

- low efficiency of the device, accompanied by significant waste.

Nevertheless, such designs can be used at home in conditions of single production of products, especially if they are mini-forges running on cheap fuel oil.

Stages of making a homemade forge

Making a forge for forging yourself is a step-by-step process. To manufacture the equipment, it is necessary to prepare consumables:

- thick sheets of heat-resistant steel;

- refractory clay for external coating of the structure;

- fireclay bricks;

- metal corners, channels;

- metal pipe for the chimney;

- a metal grate that acts as a grate;

- construction sand;

- metal door with hinges;

- old vacuum cleaner to create air flow.

If the heating device will operate on fuel oil, you need to consider a combustible mixture supply system. Stages of making a homemade heating device:

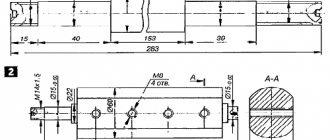

- Draw a drawing with exact dimensions marked with holes.

- Assemble a support structure from metal channels. To connect individual elements you need to use a welding machine. The seams are cleaned and covered with an anti-corrosion coating.

- Assemble a chamber with a door for filling solid fuel. Air must be supplied through it for the coals to produce heat. Install the grate.

- Build a chamber from fireclay bricks to heat the workpieces. Make a hole on the top and secure the chimney pipe.

- Connect an old vacuum cleaner that can blow out to the air supply system. Install the door on the window used for feeding workpieces.

- Coat the outside of the bricks with refractory clay so that the heat is retained in the heating chamber.

After assembling the structure, you need to check its functionality. To do this, you need to conduct a test run and light the fireplace.

DIY horn

Selection principles

When choosing purchased equipment for a blacksmith shop, you need to consider a number of factors:

- The size of the heated surface. The possible size of the processed workpieces will depend on this.

- Type of fuel used. It is necessary to take into account the characteristics of the consumable material.

- Air supply option. Equipment with an electric compressor allows you to work faster and more productively.

- Dimensions of the forge.

It is necessary to remember about the reliability of removing combustion products from the structure. To do this, you need to check the chimney and the holes that create draft.