Selecting and purchasing a two-post lift is only part of the work that needs to be done before you start using it in your car service. An important issue remains the installation of the lift. 90% of our clients trust us with the installation, but some decide to handle this task themselves. Especially for those who decided to install a lift in their garage or garage, we have written a small cheat sheet.

Next, we will show the sequence of actions that must be followed to install the lift:

1. Determine the installation location of the two-post lift, its most convenient location for work. We check that electricity is supplied to the installation site.

2. Unpacking and checking components. The easiest way to ensure that all the details are available is to use your passport. Just look into it and check everything on the list.

There are two foundation options:

- According to the manufacturer's passport. A screed with a thickness of at least 200 mm is poured around the entire perimeter of the room.

- Filling the cabinets. Pouring pedestals for lift posts measuring 1m*1m*1m. This option is used if it is impossible to make a screed around the entire perimeter of the room.

If the floor screed is filled with concrete grades 150, 200 or 250, we recommend using chemical anchors. Chemical anchor – epoxy resin based adhesive.

After pouring the screed or cabinets, you should wait, according to GOST, 28 days. The drying time of chemical anchors depends on the following factors: temperature, humidity, concrete density, groundwater conditions.

4. Installation of two post lift:

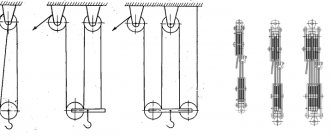

- We install the lift struts vertically opposite each other.

- We attach a moving bar (floor plate) between the posts.

- Next, use a level to level the racks horizontally and vertically.

- We fasten the stand to the concrete with a wedge anchor, which is included in the delivery kit. A hole is drilled in the concrete in accordance with the diameter of the anchors. We drive an anchor into this hole and clamp it with a torque wrench.

- We remove the moving frame (floor plate) and stretch the cables from the left column to the right one and vice versa, in accordance with the diagram in the lift’s operating instructions.

- We connect the hydraulic hoses to the cylinder in both racks. We put the moving bar back.

- We put the lifting legs on the carriages and secure them with a locking pin.

- We hang the engine on the rack and attach it with bolts. We connect the hydraulic system hose to the engine.

- We connect the lift to the network and fill the barrel with oil.

- We start the lift by pressing the lift button. For smooth operation of the lift, it is worth raising the legs 1-2 times to the maximum height, all the way.

Problems that may arise while working with the lift and their solutions are described in the table below.

Different carriage heights

Adjust cable tension and tighten nuts

The carriage fixation system does not work

Open the column protection and check the locking lock. Adjust or use machine oil.

The motor does not work

Turn off the power. Inspection and replacement must be carried out by qualified electricians.

Does not lift or moves very slowly when descending

Clean the release valve or replace if necessary.

Leak in hoses

Use self-adhesive tape and tighten the nuts.

If you cannot solve the problem yourself, contact customer service.

Extraneous noise when ascending and descending

Lubricate the moving and contacting elements inside the columns with lubricant. Lubricate the cables and pulleys with machine oil.

The convenience of using a garage depends on the size of its internal space. The room should have enough space for servicing the car, placing various tools, mechanisms and spare parts. Correctly calculated ceiling height in the garage is necessary for the safe operation of the car.

SNiP states that the ceiling height in the garage must be at least 2000 mm and does not limit the choice of a higher value. The lower limit may well satisfy any owner of a passenger car whose average height is 1540 mm. But you won’t be able to feel comfortable in such a room.

A garage is not only a place to park a car. It is repaired and serviced here. In garages built into residential buildings, cargo transported in the vehicle is constantly loaded and unloaded. In this case, the trunk must open completely and not touch either the ceiling or the elements of the automatic gate.

When choosing the ceiling height in the garage, it is necessary to take into account the factor of the future. Let's assume that today you are the owner of a car and a sectional garage door. After some time, your financial situation has improved and a decision will be made to replace the passenger car with an SUV, and for ease of entry and exit, it is necessary to replace the sectional gates with automatic ones. The height of the jeep and the space for mounting elements of the new type of door will require sufficient ceiling height in the garage. In order not to spend money on restructuring, it is better to foresee the likely development of events in advance.

Read also: Why does a furniture stapler bend staples?

Simple lift

For several decades now, the most common and durable method of lifting a car has been turning it on its side.

In fact, it is not only the engine that needs repair from time to time, but also other components that can only be reached using a test pit. But not everyone has such a pit, and folk craftsmen have constructed an elementary, if not primitive, system. At least 3 people are required for this lift. This method can hardly be considered ideal, because not a single person wants to tempt fate by scratching a car on a concrete flooring.

However, if there is no other way out, then such a lift can help you out. His system is as simple as possible, and the production method is clear even from photographs.

An alternative to a lift can be an inspection hole (of course, if the garage system makes it possible to dig it). If you make a hole as tall as you are, you can easily examine the bottom of the car. If it is not possible to properly equip the inspection hole, then you can limit yourself to an overpass (but it will require the presence of quite significant ceilings in the room).

Instructions:

- 1. For the base, embed metal corners into the side walls of the room so that the car hood is located just under them. Next, install a centimeter plate on the corner racks and secure it with eight “M8” bolts. It will not merge with the corners, so in the future you will be able to change its placement above the car engine.

- Fix the worm adjuster on the plate. Next, take the key, put it on the electric drive shaft, and secure it. Then make a 2 cm opening in the tile for the chain, then pass the chain through the finished hole and close it into a ring.

- Place another sprocket on the outgoing shaft, smaller this time, and combine them.

- Make 2 more holes of 3 cm in the slab, pass the chain over the key. The 2nd chain must end with a metal hook capable of supporting the weight of the motor.

Two-post - the best option for small businesses

Affordable, reliable, repairable, and low maintenance. Therefore, they are popular and permanently installed in repair areas of many service stations. Electromechanical models that expired their declared service life more than 10 years ago are still working properly. But the majority prefer hydraulic equipment: even in second-rate versions, it is faster than mechanical systems, consumes less electricity, allows you to quickly lower the car if the electricity is lost and, in addition, is constantly upgraded by the manufacturer.

PGN 2 4.0 – from 75,500 rubles

A classic version of a four-ton lift with a three-phase, 2.2-kilowatt motor.

Confirmed advantages include the thickness of the metal on the racks and base elements, and full-size hydraulic cylinders. But this is only for models produced before 2015-2016. More than that, nothing unambiguous can be said about the models that Stankoimport sells. Because complaints about leaking hydraulics and extraneous knocks when the carriages are raised and fixed appear unsystematically. As a rule, replacing the internal seals of a hydraulic cylinder relieves the user of problems with the tightness of the hydraulic system for several years.

Please note: advertising promises from 3 years ago contain references to how much the metal thickness of PGN 2 4.0 differs from competing samples. Today, the official resource does not provide such information. And the difference of 50 kg between the old and new weight clearly explains why this happens.

Video review of the installation and launch processes of PGN 2 4.0:

PULI PL4.0-2B T4 – from 89,856 rubles

Electro-hydraulic lift with bottom synchronization and asymmetrical arms.

Here are the cables that align the position of both beams and the hydraulic circuit hose - between the racks, at the bottom. Covered with a metal casing-threshold.

The paws are different:

- shape – front with an angle, rear straight;

- maximum length – front 1045mm, rear 1228mm;

- minimum turning radii - front 705mm, rear 828mm.

The advantage of this variation is the five-millimeter walls of the stand and 16-millimeter platforms at the base, which is indirectly confirmed by the 680 kilograms of weight. There is automatic locking of the paws - the locking elements snap into place as soon as the car begins to rise.

The issues are the same as for all two-post hydraulic lifts assembled under contract manufacturing in the Middle Kingdom - oil seals are leaking, there are no seals where the rod passes through the lifting beam, “original” limit switches break haphazardly.

Problems with rubber bands are immediately visible and can be solved with the help of a repair kit. With some experience in carrying out the work, it takes no more than 3 hours. But the knocks of the beam are quite quiet and attract attention only when the suspension is diagnosed by ear. It is often more profitable to simply know about such a source of extraneous knocking than to try to get rid of it now, once and for all.

Video review of the PULI PL4.0-2B T4 lift:

AE&T 4t 220V T4 – from 91,983 rubles

Four-ton lift with two hydraulic cylinders, a cable system for synchronizing the position of carriages and a single-phase motor.

The advantages of single-phase equipment are obvious where it is not possible to connect a three-phase network, and the main traffic flow is made up of small cars. Under these conditions, the 2.2-kilowatt motor does not overload the network, and the design retains its original geometry longer.

Only manual unlocking of security locks is provided. That is, in order to lower the car, the mechanic must go around it. Even with a little workload, this moment is very annoying. In addition, owners of new lifts are often faced with shortages - when there are no spacers for the foot stops and traditional leaks.

Please note: once repaired, a hydraulic cylinder takes longer to maintain than with “original” rubber bands. Therefore, during a performance test, a clean rod determines the good condition of the used equipment. And visible violations of the geometry of the posts, beams, and feet indicate that such a lift will not work correctly.

Video review of AE&T 4t 220V T4 in operation:

Nordberg n4120a 4t – from 102,839 rubles

A typical 4-ton lift with an electro-hydraulic drive based on a 3-phase motor. The paws are asymmetrical, the unlocking of the locks on each rack is different.

Robust design, reliable hydraulic cylinders and insignificant problems with the electrical part allow sellers to offer not only service, but also warranty obligations - everyone only has a one-year warranty, and problems with hydraulics begin, on average, after 3-4 years. The equipment is common, so there are no difficulties with repairs or repair kits.

Keep in mind that it is best to choose a used version of the n4120a from the existing models. When disassembled, it is extremely difficult to identify signs of fatigue in moving parts and elements of a metal structure. With regard to repainted equipment, it is even more difficult - if it was painted, then there was deep damage to the “original” coating. That is, it will be necessary to periodically fight corrosion.

Video with installation details and operation of the Nordberg n4120a 4t lift:

Safety and reliability

In addition to price, there are also factors that cast doubt on the independent production of a car lift - safety and reliability. Even a small car can weigh more than a ton. If the lift fails, the car will fall onto the person below. There are many such cases.

The lift may fail for the following reasons:

- The structural supports are poorly secured.

- The locking device broke because it was not designed correctly.

- The weight of the car turned out to be more than permissible, as a result the drive mechanism could not stand it.

To make a lift yourself, they usually take a ready-made design, hoping that its developer has correctly calculated the strength of the parts, or they make these calculations themselves. Such a project can only be completed by a qualified engineer, and an ordinary driver is not able to do it. Also, you need to calculate what load can be applied to the drive and brake mechanism.

If these calculations are not performed correctly, then such a lift becomes a lethal device

It is also important to correctly calculate the base of this structure. Here you need not only to pour the required layer of concrete, but also to make fastenings in specified places

Do-it-yourself car lift drawings | Auto Bryansk

A considerable number of motorists try to repair their vehicles themselves. When repairing cars, a car lift is often used. Such a device can be purchased at a specialized store. However, to save money, some people make their own car lift.

Types of lifts

Before installing a car gearbox lift on a pit in the garage, we study its main varieties in more detail. This will help you figure out what a pit lift can be like.

By drive type

Jacks for lifting cars differ in the type of drive that is installed in them. There are two main models in this classification:

- hydraulic jack;

- devices with manual mechanical drives.

Experts advise using hydraulic models, as they are more efficient. However, it is not easy to make such a device yourself, and that is why many people make manual car lifts.

By type of lifts

Another distinctive feature of car jacks is the type of lift used in them:

- Screw. To install such equipment, use two durable racks in which special screws are installed. They are responsible for raising and lowering the vehicle. The operation of the installed screws is controlled by an electric motor.

- Mini. In the manufacture of such models, hydraulic or mechanical drives are used. A special feature of the equipment is its small size. Therefore, mini-lifts are not used to lift freight vehicles.

Electromechanical Engineering

Some models use different electromechanical technology. Based on this, car lifts are produced:

- Single post. Experienced motorists advise using such models in small garages, as they are compact. They consist of an electric motor, a movable carriage, and a vertical support.

- Scissor. Scissor car lifts can be mobile or stationary. They are equipped with a strong frame for attaching hinges and a compressor device.

By number of plungers

Based on the number of plungers, multi-plunger, double-plunger and single-plunger models are distinguished. In models with several plungers, a special traverse is installed, which is responsible for the efficiency of the equipment.

For passenger cars

Often single-column models are chosen for working with passenger cars. The advantages of such car lifts include:

- ease of operation;

- compactness, thanks to which the equipment does not take up much space in the garage;

- a modern lubrication system that does not require constant maintenance;

- reliable protection aimed at preventing the car from tipping over during repairs.

Scissor-type equipment is also used to repair passenger cars. With its help, a car mechanic can quickly raise or lower the vehicle to the desired height.

For truck

The main feature of any truck is its size and weight. Due to the non-standard dimensions and large weight, not all lifts can lift such cars.

To repair such vehicles, they use cargo devices with a high carrying capacity. They can be movable, stationary and platform. They are used only in service stations that specialize in repairing tractors or trucks.

How to make a reliable car lift with your own hands

It is not easy to make a car lift from a jack yourself, and therefore you need to read the instructions in advance.

Calculation of dimensions and creation of a drawing

First you need to decide on the size of the equipment for working with cars.

The choice of car lift dimensions depends on the size of the garage in which it will be used. The average height of the device is three and a half meters, and the width is three meters. Equipment with such dimensions is capable of lifting a vehicle whose weight reaches 3-4 tons.

Important Lineup of the best 15 Japanese ECHO chainsaws from household to professional devices

Required Components and Tools

Having decided on the dimensions of the car lift, you can begin to prepare the necessary tools and materials. To work you will need:

- welding machine for joining iron components;

- drill;

- drill;

- tape measure for measuring the dimensions of device parts.

The materials from which the device is made include:

- bedding corners eight centimeters wide;

- iron plates, the thickness of which should be 1-2 centimeters;

- worm gearbox.

Characteristics of car lifts

Thus, among the important characteristics one can highlight load capacity, speed, as well as lifting height, ground clearance, and type of structure.

Lifting capacity ratings are determined by the weight of the vehicle that a particular piece of equipment can lift safely. For repair and maintenance of cars and small trucks, the permissible weight ranges from one and a half to five tons.

As for the lifting speed, this parameter differs only slightly for most units. The average speed is one to two minutes. Electromechanical equipment has a higher machine lifting speed.

The height on many types of lifts is often no higher than two meters. As for the total height, this parameter does not exceed four meters. Practice shows that to perform any repair work there is no need to lift the car very high. Sometimes, when servicing vehicles with a high roof, there is a need for a height of 4000 to 4200 mm. Also, based on lifting height, we can distinguish units for tire shops that are capable of lifting a car to a small height.

The clearance of machine lifts is the minimum height when the arms are down. This parameter for many types of equipment will be in the range from 95 to 110 millimeters. However, there are also low-profile mechanisms. Here the ground clearance ranges from 75 to 90 millimeters. Such systems are relevant for cars with low ground clearance or body kit.

Reliability and safety

In addition to cost, there are two more factors that cast doubt on the feasibility of making a lifting mechanism for a car with your own hands - reliability and safety. The weight of even a small car often exceeds one ton.

A car may fall off a lift for the following reasons:

- the weight of the machine turned out to be more than the drive or actuator can support;

- the locking device turned out to be of incorrect design;

- the locking device could not withstand the load;

- The lift supports are insufficient or incorrectly secured.

To make a lift with your own hands, you have to either take a ready-made diagram, hoping that its author has carefully calculated the strength of all the parts, or carry out these calculations yourself. Only a highly qualified engineer can do this kind of work; an ordinary car enthusiast cannot do it. In addition, it is necessary to calculate how much load the drive and brake mechanism can withstand. If any of these calculations are made incorrectly, the car lift turns into a deadly trap. No less important is the calculation of the basis of this mechanism. It is not enough to simply pour a thick layer of concrete, because it is necessary to provide fastenings located in strictly defined places.

Read also: Voltage stabilizer 220V photo

Search for parts

If you nevertheless decide to build a car lift with your own hands, and you are not afraid of the dangers of this homemade product, then start selecting parts by searching for the drive mechanism and stopper. These parts can be found in the following places:

- stores selling components for special equipment;

- enterprises that have old construction equipment on their balance sheet;

- enterprises that are updating their fleet of woodworking or metalworking machines;

- collection points for ferrous and non-ferrous metals.

For a scissor lift, you will need two hydraulic cylinders of suitable power and length, a compressor for them, and hydraulic hoses. The scissor circuit is the easiest to manufacture, but it is impossible to make a reliable brake in it. Therefore, if a hose bursts or one of the cylinders leaks, trouble cannot be avoided. Shafts and electric motors with gearboxes suitable for platform or fork lifts are easiest to find where old machines are replaced with new ones. This will cost much less than ordering worms from a turner. And the stopper of such mechanisms is not complicated - a helical bar with a lock, made of steel 1-2 cm thick.

Conclusion

If you still decide to take a risk and make a car lift with your own hands, then before choosing any scheme and starting assembly, find those who have already made such a device. See how it works, make sure it is safe. After all, you are not risking your car, but your life. If, when the car falls, one of your family members is under it with you, then you will put his life at risk.

To service a car in a service station, a bunch of special equipment is used, from cheap to very expensive, completely inaccessible to a private technician or simply a vehicle owner who is used to servicing the car with his own hands. There are very highly specialized devices that can be useful to a private owner once or twice a year. And there are those without whom any repair or prevention is simply impossible. Car lifts are just that case.

Lift-tilter

To avoid costs and a lot of complications, you can give preference to a simple garage lift-tipper. The device will allow you to tilt the car to one side, and the tilt angle can vary from 45° to 60°. This is quite enough for most repair work.

To build such a unit, you will have to create and connect a number of parts: the front pillar, beams (top, bottom, rear), shoe. Various connecting elements will also be required. You will need to work a lot with metal, so you must have a special tool - welding, a grinder and a drill with a set of metal drills. The main material for work is 4 mm steel sheets, angles and bushings.

Creating a Top Beam

Next, proceed directly to creating the top beam. For this, take two 1.5 m corners and weld them into a U-shaped profile. It is also necessary to weld a metal insert in the middle, which will ensure the fixation of the jack. The beam will be ready when you weld a plate of the appropriate length and height to the profile. The result is a rectangular beam. One end of it must be welded tightly - the bushing will be attached to it, and the guides for the jack are welded to the other end.

The platform for the beam is created from a steel sheet. You can bend its sides to get something like a box, or weld the walls of this very structure. Inside the site there will be a piece of wood of the required size, which is fixed with fasteners, and rubber is mounted on top of the wood. The platform is attached to the beam using a pre-welded eye.

Final stage

To ensure that the machine is securely supported on the opposite side of the lift, a rear beam is required. It is welded from 4 corners 32, 1500 mm long, so that in the end you get a square the length of a car. The beams are connected to each other through a special unit on the rear beam. The lower beam is also created from the corners and is connected to the rack and the rear beam. All that's left to do is to make the stud pins and install the jack. As a result, you will have an effective tipper.

A car lift is equipment that is used to carry out maintenance and repair work on vehicles.

Strengthening the structure

Pipes of smaller diameter, which are located across the jack, are reinforced on all sides with metal plates. A thick plate is installed on top of a large pipe welded to the jack, and metal corners are installed below.

The structure is welded and ground with a grinder. To learn welding skills on your own, it is recommended that you familiarize yourself with the information in the useful DIY workshop

. Next, the stands are made.

Required materials for stands:

- Thick metal washers;

- Nuts for 20;

- Bolts 20.

Important: Choosing wheels for a walk-behind tractor and replacing them yourself: how to install Zhiguli wheels, video

For the construction of lift stands for the inspection pit

the nuts are welded vertically to smaller pipes that run across the jack. Then the washers and bolts are fastened together.

Next, the resulting structure is screwed onto the nuts. Rubber cups are placed on top of the washers. This is a DIY pit lift

ready for use. Thanks to the jack used, the traverses are raised quite high.

It is necessary to treat the metal with a special anti-corrosion compound, due to which the structure will last longer. To give the lift for the inspection pit

aesthetic appearance, the structure can be painted. The ready-made traverse is easy to use, does not require significant effort in operation and provides good lifting of the car.

Why can you increase it?

In addition to the dimensions of the transport, the size of the room for it is influenced by the presence of various equipment and additional premises. If you want to install a lift or crane in the garage to remove the engine, then the optimal height of the garage for a passenger car should be 3.5 m, and for a jeep - 4 m.

The length of the garage can be increased by 3-4 meters by adding a platform for repairs or other work related to metal or wood, or by adding a utility room. If you consider yourself a lover of comfort, then it makes sense to add a relaxation room.

Its size depends only on your budget and preferences - you can make either a small closet or a large place where you can sit with your friends after a successful renovation. It would not be a bad idea to equip the garage with a basement and an inspection hole, but in terms of dimensions they will only increase the depth, by about 1.8-2 meters.

All the above dimensions are not mandatory; they are based on accumulated experience in the construction and operation of garages. The main criterion that you must follow when planning is your comfort and the comfort of your family.

Single rack equipment

This is the most versatile and, in addition, mobile lifting equipment. They are used mainly in small service stations or garage-type services. There are stationary and mobile models. As for stationary equipment, the carrying capacity of such equipment is 2000 kg. The carrying capacity of mobile models is no more than 250 kg. No more than four mobile lifts for passenger cars can be used at the same time.

Using this equipment, the car is lifted by the wheels or by the sills. The car is lifted from one or both sides at once. This depends on the number of such equipment available.

Often, single-post lifting units can be found at car washes and service stations, where they provide anti-corrosion treatment of the bottom. Often models are found in tire shops.

Installation of lifts in a car service center

The PRO-PODEMNIK company provides services for the installation of car lifts in car services, workshops, service stations, workshops of transport companies, etc. Correct installation of a car lift is the key to its functionality, efficiency and quick payback. We carry out installation work in professional quality with a guarantee at an affordable price from 8,000 rubles.

We install different types of car lifts:

- scissor;

cargo;

pneumatic; two-post; four-post.

We carry out installation strictly according to technology in compliance with safety regulations. This approach ensures error-free assembly and stable operation of the lifting structure throughout its entire service life.

is a process that requires careful planning and preparation. The first step is to select equipment taking into account the workload of the service center and the type of vehicles being serviced. The foundation is prepared in advance. It is usually made of concrete with reinforcement. You can use concrete with topping, technical porcelain stoneware. The main thing is that the coating is smooth and durable. Installation begins after the floor has hardened.

Which to choose

There are several types of garage lifts on the market. It is necessary to select equipment taking into account the size of the room; you need to take into account the height of the garage, its width and length.

The car scissor lift is equipped with a hydraulic drive. It is suitable for tire fitting work, as well as for wheel alignment adjustment. Such equipment helps to gain access to the vehicle from all sides. The maximum load capacity of such a mechanism is about 3000-5000 kg. It is recommended to be used for body repair work.

Small plunger-type lifts have a simple design that includes arms mounted on hydraulic cylinders (plungers). Such cylindrical elements are mounted on the garage floor. The device can consist of either one or two legs. Using this device you can carry out maintenance of any vehicle (car or truck). The design is characterized by a high level of reliability and long service life.

A mini garage lift is used to lift vehicles whose weight does not exceed 4,000 kg. The raising time of such equipment can be from 45 to 60 seconds, and the lowering time - from 50 to 60 seconds. The height of the loading platform does not exceed 1700 mm. Both self-propelled and stationary units are available on the market. Such lifting devices are powered by rechargeable batteries, the power of which does not exceed 2.2 kW.

An electrohydraulic two-post lift is equipment presented in the form of a platform that is raised and lowered using special handles. The unit itself does not take up much space and is equipped with a silent hydraulic system, in which a powerful fuel drive is responsible for the reliability of the design and long service life. For proper operation of the equipment, oil fluid is required, which activates the fuel pumps.

Read also: Laser cutting plywood crafts

A pneumatic vehicle lifting device is used for technical inspection. All structural mechanisms are attached to a support frame made of steel. The lift consists of two loading platforms, retractable consoles, an electric power unit, a pumping element, a station, and a hydraulic system.

How to install

Before carrying out installation work, measurements of the room are taken to ensure the compatibility of the dimensions of the two-post lift for the service station. When determining the area, the craftsmen take into account the average size of the cars that will be repaired, and the remaining amount of free space for comfortable access to components and assemblies under the bottom.

Regulatory requirements require maintaining the distance between the lift and the wall panels at one meter. To service passenger vehicles, it is necessary to allocate 7 meters of space in the room, for freight and passenger transport - 8-12 meters.

Before installing the columns, the floor surface is cleaned of dust and construction debris using a pneumatic gun. After applying the markings, marks are made in the concrete base and holes 12 centimeters deep are drilled into them. Next, anchor bolts are installed through the steel base and driven in with a hammer. The nuts are tightened using a torque wrench. The tightening force is specified in the operating instructions.

Then the vertical installation of the supports is carried out, checking the symmetry of the placement of the racks. When connecting parts, you need to ensure that the fasteners are tightly tightened. After completing this procedure, the device is connected to the power supply, a test lift is carried out without load, and then under load, hanging the car on its feet and lifting it three times - to the minimum, medium and highest height. At the same time, the pressure level in the hydraulic fluid supply system is checked.

After installation, you must remember that extraneous sounds - crunching, creaking, crackling - are unacceptable. After checking, you can start using the lift on an ongoing basis.

Video tutorial

Be that as it may, design and technological engineering calculations must be taken very seriously. Thus, it will be necessary to calculate the minimum cross-section of beams, calculate the axes of hydraulic cylinders, select hydraulic cylinders based on performance and rod length, select the correct hydraulic pump and control system

When designing, special attention is paid to safety and emergency mechanisms for raising/lowering the car

The task is quite difficult, but solvable. If you have the materials and knowledge, you can assemble a small scissor lift that will be useful not only to you, but also to your friends and neighbors. Happy designing!

No auto repair shop is complete without a car lift. The equipment is available on the market in a wide variety of models from local and foreign manufacturers. A car lift installed in a car service will pay for itself quickly, but purchasing a car lift for personal needs is a stupid expense. Moreover, it is possible to build a car lift with your own hands.

Four Post Car Lift

These systems have a large load capacity. They are widely used in truck service stations. Models in this group are differentiated by their load capacity and platform length. With dimensions up to 5000 mm, the unit is suitable for passenger service stations.

Among the advantages are the ability to repair long-wheelbase vehicles, low price, simplicity and reliability, and the ability to use a lift for trucks. Among the disadvantages are the size and the inconvenient jumper.

DIY garage lift

For use in the garage, it is possible to make a kit for lifting a car with your own hands. You will need the necessary components, tools and plumbing skills.

A homemade lift is made using the following parts:

Steel corners measuring 8x8x1 cm, for making a stable structure. Worm type gearbox. A new product can be expensive; it is usually selected during disassembly or removed from a non-working mechanism

Important Do you need a tachograph for KAMAZ: how the device works, connection method, possible fines

It is necessary to pay attention to the load capacity, the indicator starts from 350 kg, the transmission force indicator is 60 kg. A steel plate with a minimum thickness of 1 cm is removed from old equipment. Set of bolts, mounting hook, star-shaped keys. Several iron chains with a link diameter of 2 cm or more. Weak chains will not withstand the load, you should pay attention to the quality of the product, some materials can stretch during operation. Steel cable, 5 mm thick.

Assembly and installation of components occurs in the required sequence, following the proposed instructions. The steel corners are fastened to the walls in the opposite direction from the hood of the car. On top of the corners for the lift, a steel plate is installed with your own hands. The connection is made with prepared bolts. Next, you need to install the worm gear, securing it with a key on the drive shaft. A key of smaller diameter is installed on the output shaft of the gearbox.

DIY chain lift

Holes suitable for the diameter of the chain are made in the plate, after which the chain mechanism is installed

It is important to pay attention to safety; holes are made in the frame at a certain distance, and a locking mechanism is inserted into them

Features of operation of such a lift

The use of a worm-type unit during operation is suitable for lifting a car engine or load-bearing parts. The procedure for using a self-made car lift is simple; you must follow these steps:

- Remove engine mounts, bolts, nuts.

- Afterwards, the steel cable loops are supplied and the structure is coupled.

- The drive shaft rotates by turning the chain; with a little effort you can slowly lift the part to the desired position.

Worm type garage lift

After lifting, it is necessary to remove the car from the work area by placing a table under the engine. It is possible to make a stand or table with your own hands; the design must be durable and withstand heavy loads. Convenient to use is a table on wheels, which allows you to move the part in the required directions.

If the car is too big

Repairing large vehicles is not uncommon; wheel size and ground clearance may not allow you to raise the necessary parts to the required height. The process takes place with an assistant, who pulls the part onto a pre-prepared table. The gearbox rotates with the opposite side to the installed element.

Car lift for large cars

Such situations lead to thoughts about improving and modernizing a car lift for a garage with your own hands. It is possible to manufacture a movable structure that will make it possible to move the lifted part to the required distances. It is possible to make an aggregate installation with an electric motor on a reduction gear, in which case it can be a real crane for lifting large-sized mechanisms.

Locking method

To prevent the occurrence of distortion during operation of the lift, a set of special cables is used that synchronize the lift. The parameters of the cables are selected by the manufacturer so that they can withstand the rated load (the maximum weight for which the device is designed) and critical stress (from 30 to 70% above the maximum permissible weight). This is necessary to ensure the safety of personnel.

There are two blocking options. Some models have a set of electromagnetic stops that allow you to remove the lift by pressing one button. Mechanical analogues, in turn, also come in two types. The first involves pressing and holding the lever, which simultaneously removes the right and left carriages from the stopper. The second option is to separately pull out the stoppers from the carriages. It must be remembered that electromechanical lifts are completely devoid of stoppers.