There are many craftsmen in the country who construct with their own hands various technical devices, vehicles, and metal structures for various buildings on the site using curved pipe products. To obtain the necessary blanks, use a pipe bender for a round pipe, which is purchased in a retail chain or made by yourself.

It is worth noting that many factory pipe bending devices have wide functionality thanks to a number of interchangeable nozzles included in the package. But if in a household it is necessary to bend pipe elements of only one diameter, it makes sense to make a pipe bender yourself.

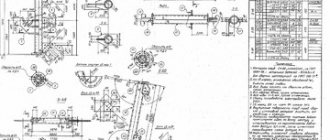

Rice. 1 Crossbow hand pipe benders with ratchet mechanism

Pipe Bender Introduction

Unlike plate bending, pipe bending machines are mainly used for bending steel pipes.

The pipe bending machine is mainly used in power construction, public railway construction, boilers, bridges, ships, furniture, decoration and other aspects of pipeline laying and construction. It is also one of the most important devices in the tubing category.

Advantages including multi-functionality, reasonable structure, simple operation, etc.

Operational areas and service features

Pipe bending machines are most widespread in two industries:

- construction;

- housing and communal services.

In addition, it is worth noting that bending machines are used less intensively in other areas:

- automotive industry;

- petrochemical industry.

And also such machines are indispensable when making pneumatic and hydraulic pipeline structures. The operational scope of this equipment is very wide, so it is very popular and in demand everywhere. Let's look at what else pipes bent on pipe bending equipment are used for:

- Sports Equipment;

- various design solutions inside residential premises;

- when installing fences, railings, stairs, etc.;

- in the production of chairs and other furniture elements.

The need to bend pipes may arise in the manufacture of structures of various types and purposes.

Important! Before you start bending pipes on a pipe bending machine, you need to read the instructions for its use, and also study all the necessary contraindications, safety rules, etc.

The operator of a pipe bending machine must be trained in all the nuances of bending and, in addition, carry out preventive cleaning of the device (once a month), inspection of the main working parts of the device and preventive maintenance. Prevention of a pipe bending machine includes:

- lubrication of working elements

- adjustment of working elements;

When performing maintenance on a hydraulic model, do not forget to change the oil in the pump. The pump oil must be of high quality. If any functional element of the bending equipment fails, it must be replaced. It is recommended to purchase new spare parts only from trusted suppliers.

Classification of pipe benders

Categories include: hydraulic electric bending machine, horizontal hydraulic pipe bender, multi-functional rolling pipe bender.

Electric pipe bender is pure electric, motor driven, speed switch, gear driven;

Hydraulic pipe bending machine www.prof-inst.by performs bending operation, which includes a driven clamp for retracting with hydraulic pressure, bending the pipe back, auxiliary forward and backward movement, feeding and retreating of the core.

Hydraulic pipe bender is a general automatic flat winding bending machine, bending is done automatically during pipe bending production, but its feeding, three-dimensional angular rotation can only depend on the manually fixed length and angle positioning mechanism.

The CNC pipe bender uses servo motor instead of hydraulic motor, which can control the feeding and retracting, tilt angle rotation, pipe bending and retracting, auxiliary forward and backward movement, head lifting, etc., but its clamping and releasing, rod feeding and retreating are carried out hydraulically or pneumatically. The difference between CNC pipe bender and hydraulic pipe bender is the continuous production, processing precision and three-dimensional molding of pipe fittings.

Types of pipe benders

Pipe benders are widely used not only in industrial production, but also in everyday life. When choosing, they are guided primarily by cost, dimensional parameters of bent products, production volumes, and the operating principle of devices.

Based on the drive, there are manual mechanical, hydraulic or electrically driven pipe bending mechanisms.

The distribution network presents the following main categories of pipe benders:

Manual with ratchet mechanism. These are crossbow-type devices with rollers on the edges and replaceable hemispherical pressure attachments for different pipe diameters. The movement of the rod with the stop in the pipe is carried out using the handle of a ratchet mechanism.

Since human muscular strength does not allow for significant physical effort, such devices bend mainly copper, stainless steel, aluminum and steel with thin walls with a diameter of no more than 1 inch (25 mm)).

Rice. 4 Pipe bending machines with winding the workpiece onto a template

Manual with hydraulic drive. These are crossbow-type devices in which, instead of a mechanical ratchet, a hydraulic drive is used to feed the pressure head. The tool is designed for domestic and professional use when installing pipeline communications for gas supply, heating and water supply. Typically, such devices are equipped with a number of heads for pipe diameters of 15, 20, 25, 32, 40, 50 and 60 mm, or 1/2, 3/4, 1, 1 1/4, 1 1/2, 2 inches.

Hydraulic pipe benders are produced by the world's leading manufacturers of various hand and electric tools with the brands Rems, Rothenberger, Virax.

For industrial use, hydraulic pipe benders are equipped with an electric drive. In this case, they can work with tubular products of large diameters, reaching up to 100 mm.

Manual (lever) devices for running in. These are some of the commonly used hand looms in which a stationary tube is wound around a template.

Typically, the pipe end is brought to a roller or segment element, inserted into the gap between it and the adjacent supporting part. Then the pipe is crimped with a lever in which a roller rotates or there is a flat, profile plate.

To avoid ovality of the pipe at the bend, many manufacturers produce systems of several crimping stages designed for pipe diameters of 15, 20 and 25 mm. In this case, the appearance of ovality will be prevented by the walls of the template, into which the pipe shell will begin to abut during bending.

Many factory devices are equipped with a degree bending scale on a semicircular segment template.

Since during work it is necessary to exert significant muscular force, such pipe benders are designed to work with any types of metal pipes no more than 40 mm in circumference.

Rice. 5 Manual pipe benders with hydraulic drive

Manual type for radial bending. Usually these are large-sized stationary machines that bend pipes using rolling technology. They contain two outer rollers along which the pipe moves, and a central pressure roller that sets the bending radius. The upper roller is smoothly lowered on a threaded rod (spindle), which is secured in the thread of the machine bed.

Features of the pipe bender

- The pipe bender uses touch screen to add numerical control module, dialogue type operation, easy program setting;

- The structure is stable and does not deform;

- For each file, 16 bending angles can be set, 16 sets of files can be stored in memory;

- Slow positioning function, stable bending angle, repetition accuracy reaches ±0.1°;

- An error message is displayed on the screen, help the operator to resolve immediately;

- Provide your own research and development of pipe processing cost conversion coordinates, software can be purchased and installed on your desktop computer to edit the calculation.

Pipe bending technology

A pipe bender is similar to a sheet bender. In the case of pure bending, if the outer diameter is D, the wall thickness is T, when the pipe is bent under the external torque M, the outer side wall of the neutral layer pipe is under tensile stress σ1, and the pipe wall becomes equal thinner. The inner wall of the neutral layer experiences a tensile stress σ1, and the wall becomes thick.

And the cross-sectional shape turns into an approximate ellipse due to the resultant force F1 and F2, when the deformation is too large, the outer side of the wall will crack, the inner wall of the pipe will appear wrinkled.

The degree of pipe deformation depends on the relative bending radius R/D and the relative thickness value T/D, the smaller the value of R/D and T/D, the greater the degree of deformation.

To ensure the molding quality of pipeline fittings, the degree of deformation must be controlled within an acceptable range, and the bending limit of the pipe depends not only on the mechanical properties and bending methods of the material, but also on the requirements of the pipe. fittings

Pipe bender forming limit

The forming limit of pipeline fittings must contain the following:

- At the maximum relative elongation of deformation in the zone of lateral tensile deformation of the neutral layer, rupture does not occur, since it exceeds the plastic permissible value of the material;

- in the inner compressive deformation zone of the neutral layer, the thin-walled structure, which is subjected to tangential compressive stress, does not wrinkle because it exceeds the instability;

- If the fitting has an ellipse degree request, controls its cross section to create distortion;

- If pipeline fittings have strength requirements to withstand internal pressure, control the deformation limit of wall thickness thinning.

Pipe bender parts

- Rocker arm, its role is to ensure that the bending radius of the pipe meets the requirements, the clamping socket should limit the rebound of the steel pipe during the bending process.

- The pumping station is divided into two parts: high and low pressure to provide power for the opening and closing of the guide rollers, rocker clamp oil cylinder, opening and closing of the pusher trolley plate, opening and closing of the right roller.

- The guide roller device has two sets of guide rollers, a frame and a clamp transmission system, the opening and closing of the guide roller is driven by hydraulics, its function is to bend the steel pipe along with the rocker arm horizontally.

- T4, the driving device is the power source of the pushing device.

- The straightening roller is designed to prevent vertical deformation during the bending process, and the use of a floating anti-elliptical device ensures that the ellipse of the steel pipe meets the requirements after bending.

- Pushing device (contains vehicle, bed frame, transmission shaft, traction chain, etc.) to push the steel pipe forward under the action of the rocker arm and guide roller to bend the steel pipe.

Varieties of popular types of pipe benders

Spring pipe bender

This is the simplest tool for bending pipes. It is an ordinary spring made of an elastic alloy that holds its shape well. There are no complex structural elements; it is driven by muscular force. There are two types:

- External spring (fits onto tube)

- Inner spring (inserted into tube)

Has the following advantages:

- Ideal for working with small-diameter copper pipes and metal-plastic plumbing pipes.

- Allows you to make a bend at a sharp angle without the risk that the metal-plastic will burst or bend.

- Incredibly compact and easy to use.

- The ability to bend pipes “in weight”; you can easily bend a pipe already connected to the system.

However, this design also has disadvantages:

- There is no stop (roller) under the workpiece. The bend is of any shape

- A specific spring is suitable only for a pipe of a certain diameter

- This pipe bender is suitable for thin-walled pipes and is used only in plumbing

Manual lever pipe bender

Mechanical

This tool is a more convenient, but also more expensive alternative to a spring. But, unlike a spring, it is suitable not only for copper or metal-plastic, but also for pipes made of thin steel. The principle of operation is quite simple: the pipe bender has a roller suspension, two lever handles and a half-roller. The workpiece is secured with a clamp and bent under the influence of muscular force. In this way, you can bend the tube at an angle of 180 degrees.

The tool has the following advantages:

- You can bend pipes overhang, without support.

- The presence of a roll allows you to bend many pipes with the same bend angle.

- It can be made not only of metal, but also of plastic or fiberglass.

- The presence of a lever allows you to significantly relieve pressure on your hands and bend the pipe with less force.

There is only one drawback, but a significant one: this pipe bender has a limited scope of working applications. This is a highly professional tool. It is suitable for a plumber, but in other cases it is useless.

Automatic manual pipe bender

This device is an automated descendant of the manual lever pipe bender.

From its “big brother”, the automatic pipe bender inherited the angle principle of operation, bending along a movable roller and the ability to work “in weight”. A manual mechanical pipe bender with automation belongs to the category of portable tools; its dimensions usually do not exceed the dimensions of a standard hammer drill or drill. Used to work with the following materials:

- Copper tube (thin-walled) up to 1 inch in diameter

- Steel tube (thin-walled) with a diameter of up to 25 mm.

The bending force is transmitted through a gear reducer to the working shaft, which rotates the workpiece. As with the lever pipe bender, a bending angle of 180 degrees can be achieved.

The basis of the design is a gear reducer. Since the load on the device is quite high, it is necessary to evaluate the device, first of all, by the material of the gears. Cheap models use powder alloys, which quickly break down. In more expensive ones, the main gear material is steel. The better the gearbox, the longer the tool will last.

Crossbow type pipe bender

This tool is universal due to replaceable attachments for a specific diameter of pipe or metal profile. It is a T-shaped design. A pipe holder with rollers is installed at one end. Perpendicular to it is a lever for transmitting force. According to the drive design, the crossbow pipe bending machine most often uses muscular traction, but there are modifications with a different method of transmitting force to the bending shoe:

- Worm-gear.

- Mechanical hydraulics on the cylinder.

- Gearbox and electric motor.

- Hydraulics on an automatic pump.

This pipe bending machine provides bending at an angle of up to 90 degrees. For each type of pipe, the crossbow pipe bender has its own set of attachments. This design is called a “shoe” and is designed for quick replacement during operation.

The crossbow pipe bender works with both soft and hard metals. It can be used to bend products based on the following materials:

- Metal-plastic.

- Copper.

- Brass.

- Thin wall steel pipe.

The peculiarity of a crossbow-type pipe bender is that the bending angle can be changed during the processing of the workpiece. To do this, it is enough to change the distance between the support rollers on the guide.

The crossbow pipe bender has a significant drawback: each type of pipe or metal profile requires its own “shoes”. If the nozzle is incorrectly selected, this may result in rupture of the workpiece or a change in its internal diameter.

Important: This tool allows you to bend the pipe at a wide angle. But in some cases, if the pipe wall is thin, before using a pipe bender, you will have to fill the workpiece with sand so that the pressure is distributed correctly.

In models where movement occurs due to manual effort, a ratchet mechanism is used. The principle of operation of the ratchet mechanism is simple: a toothed roller and a tooth are installed on the device. This mechanism prevents the stressed pipe from returning to its original position when you grab the lever.

Roller pipe benders

A three-roll pipe bending machine is used where the strength of a crossbow tool is no longer sufficient. In particular, such devices are popular in the construction of greenhouses, gazebos and other types of construction. The principle of operation is rolling a bent piece of pipe or profile through rollers. Such a device is useful where you need to bend a pipe several meters long. By rolling the workpiece along rollers, it is possible to obtain a bend more than 5 meters long.

The three-roll pipe bender has a fairly simple type of design and can vary slightly depending on the model. The tool consists of two parallel rollers, which serve as guides and an upper roller, through which the bending force is transmitted.

Unlike lever pipe benders, a roller pipe bender bends the workpiece in stages. A force is applied, then the workpiece moves at idle speed along the rolls, and the action is repeated again.

Important: The roller pipe bending machine is ideal for square pipes. When bent at an angle, such pipes are deformed and it is almost impossible to bend them without crushing. A roller pipe bender distributes pressure more evenly, making it possible to bend even a complex-shaped part.

Advantages of roller pipe benders:

- Ability to bend products of large diameter and length

- Reduced risk of workpiece damage due to smooth pressure distribution

- Possibility of creating complex bends by changing the distance between the guide rolls

- Work with both round workpieces and metal profiles and corners

Flaws:

- Low mobility, difficult to transport

- High price compared to compact models

Mandrel pipe benders

These devices belong to the professional segment machines. They are equipped with automation and a computer control system. The pipe bending machine is designed for a working bending length of <1 meter and can automatically create finished products of complex shapes (coils, heated towel rails, etc.).

As a rule, such machines are rarely considered by specialists as an everyday working tool. They are not mobile, weigh up to 1000 kg and are used in industry.

Pipe bender use and precautions

(1) Link to the electric pump operating manual.

(2) The working cylinder is first screwed into the inner thread of the square block, so that the rear end of the cylinder is mounted on the support wheel.

(3) According to the diameter of the pipe to select the stamping head installed in the plunger, two rollers corresponding to the groove towards the stamping head, then insert the corresponding hole size into the flower board, and then close the top of the flower board, insert the pipe into the groove , and then pull the active part of the quick coupling at the end of the high pressure tube back and install on the slave cylinder connector, tighten the oil release screws on the electric oil pump to bend the tube. When the pipe bending is completed, loosen the oil release screw and the plunger will automatically return to its original position.

Notes:

(1) link to the electric pump instruction manual.

(2) Do not remove the quick connector when loading.

(3) The machine uses oil as the medium, it must do the cleaning and maintenance work of oil benders and pipe benders well to prevent oil clogging or leakage, which may affect the use.

Types of pipe benders according to the mechanics of work

Pipe benders can be divided according to the type of drive used. In this case, the following devices are distinguished:

- Manual pipe bender. The simplest type of machine, the effectiveness of which depends on the strength of the operator’s muscles. Such pipe benders are often assembled by hand, but there are also commercial options.

- Pipe bender based on a hydraulic jack. Here the main structural element is the hydraulic cylinder.

- Electric pipe bender with gearbox. Such devices have a motor with a mechanical gearbox. Depending on the type of machine, either chain or gear reduction can be used.

- Electric pipe bender with hydraulics. As a rule, such devices are used in heavy industry, where process automation and work with large volumes of products are needed.

The presence of electromechanics in pipe bending equipment does not have the best effect on the mobility of the structure. The use of a powerful gearbox not only increases the cost of the tool, but also affects its weight. Therefore, in plumbing, the construction of greenhouses, gazebos, in auto repair shops and medium-sized businesses, either manual pipe benders or devices with primitive hydraulics are most often used.

According to the bending method, pipe bending equipment is divided into 2 groups:

- Roller

- Corner

The operating principle of a roller pipe bender is to bend the workpiece using several pressure points simultaneously.

In this case, a radial bend with a smooth angle is obtained by changing the bend radius. Such devices are more suitable for hard metals, where bending at a strong angle increases the risk of cracking or deformation, as well as for pipes with a square cross-section.

The angle pipe bending machine allows you to create products of any shape, but is more suitable for soft metals. This is the most popular type of device because its design is very simple. The principle of its operation is to bend that section of the workpiece that is placed between special supports. The angle tool has limited potential use. It cannot be used for bending channels, angles and pipes with complex cross-sectional geometry.

Pipe bender design

- Key

- Steel pipe

- Steel pipe clamp

- Pin axis

- Pen

- Spring

- Adjustment screws

- Roller seat

- Spindle

- Guide pulley

- Roller press wheel

- Player

- Pipe bending module

(1) FLEXIBLE PLATE

Installation:

- remove the nut securing the bending die counterclockwise.

- insert the bending die, and then fix the bending die nut.

(2) CLAMPING DIE

Installation:

- Pull the clamping ram to secure the centering shaft.

- insert the clamping die, then insert the stationary mandrel.

Correction:

A. Lock and loosen the clamping socket, then set the control panel to manual mode, press the clamping button to the end of the clamping path. (At this stage, there should be a gap between the wheel clamping die, which can be adjusted using the clamping seat for the adjusting screw).

B. Adjust the clamping socket to adjust the screw so that the clamping die and bending die are completely sealed.

C. Press the return button to return the clamping die, and then adjust the clamping screw clockwise 1/2-1/4 circles.

D. and then lock the fixed clamp seat nut.

(3) DIE pressure

Installation:

A, Remove the fixed screw on the press die and then insert the press die.

B, lock the guide mold screws.

Correction:

A, Fix and loosen the clamping socket, then set the control panel to manual mode, press the clamping button to the end of the clamping path. (At this stage, there should be a gap between the wheel clamping die, which can be adjusted using the clamping saddle to adjust the screw).

B, Adjust the clamping socket for the adjusting screw so that the clamping die and bending die are completely sealed.

C, press the return button to return the clamp die, and then turn the clamp screw clockwise about 1/2-1/4 circle.

D, and then lock the nut of the fixed clamping seat.

(4) mandrel

Installation:

A. Insert the mandrel into the core rod clockwise.

B. then secure the mandrel with screws.

(Please note that the mandrel must be in the direction of bending)

Information and documents on labor protection and industrial safety - Naine.ru

1. General safety requirements. 1.1. To work on pipe bending machines, I allow gay persons: - at least 18 years of age; — trained to work on pipe bending machines; - have undergone safety training; - have passed a medical examination. 1.2. Before starting a new job or if you have any doubts during the work process, contact the foreman for clarification or additional instructions on the correct and safe techniques for performing the assigned work. 1.3. Do only the work that is assigned to you and authorized by your immediate supervisor. 1.4. Keep your work area clean and tidy. Do not allow the workplace, aisles, or driveways to be cluttered with blanks, parts, finished products, etc. Parts and workpieces must be stacked stably on supports or in racks. 1.5. It is not allowed to splash oil on the FLOOR. Remove spilled oil from the floor immediately. 1.6. The main dangerous and harmful production factors are: - cluttering of passages and work areas: - malfunction or lack of protective devices: - working with a faulty tool or on faulty equipment; — falling of cargo during loading and unloading operations and its transportation. 2. Safety requirements before starting work. 2.1. Organize your work clothes. 2.2. Make sure that the machines are grounded and that protective casings, covers and operating springs are in good condition. 2.3. Check and ensure the serviceability of all mechanisms of the pipe bending machine and the correctness of their interaction and operation of the stopping and starting devices. Make sure the rollers are installed correctly and the gearbox mounting studs are tightened. 2.4. Check the presence of guards, covers, brackets and clamps, the tension of the V-belt drive belts, and the oil level. 2.5. Check operation at idle speed. 2.6. Install the required rollers and mandrels with the mechanism de-energized. 2.7. Make sure that the air line is connected correctly, that there are no air leaks or homemade twists on the air hoses, and that the air valve is clearly fixed. 3. Safety requirements during operation. 3.1. Be attentive, do not be distracted yourself and do not distract others from their work. 3.2. Start work only on a working machine. It is prohibited to work without a casing on the gear wheels of the working mechanism, as well as other casings, working springs and clamps. 3.3. Pipe bending should be done only with rollers and blocks (mandrels) that correspond to the pipe diameters. 3.4. Do not lean on the machine or place your hands near moving parts of the machine. 3.5. It is not allowed to clutter the area around the machine with foreign objects at a distance of 1.5 meters from the extreme points of the machine. 3.6. Remove machine covers only when the mechanism is de-energized and only for repair purposes. 3.7. Change rollers only when the main switch is turned off. 3.8. When working on a pipe bending machine, monitor the air pressure in the system and prevent leaks. The air hoses are connected to each other using standard clamps. 3.9. If you need to leave your workplace, you need to stop the press and turn off the air supply. 4. Safety requirements in emergency situations. 4.1. If an emergency occurs, stop work, turn off the machine (cut off the air supply), leave the danger zone, and report the accident to your immediate supervisor. 4.3. In the event of an accident or injury at work, take measures to provide pre-medical assistance to the victim, and keep the situation as it is for investigation. what it was like at the time of the incident, if it does not threaten the life and health of surrounding workers, does not lead to an accident and does not disrupt the continuity of the production process: report the incident to the immediate supervisor. 4.4. In case of electric shock, the victim must be provided with the following assistance: - free him from wires and live parts using dielectric materials: - provide the victim with access to fresh air; - call a paramedic: - report the incident to the immediate supervisor: - until the paramedic arrives, the victim must be given artificial respiration. 5. Safety requirements upon completion of work. 5.1. Turn off the machine (cut off the air supply). 5.2. Put the workplace in order and hand it over to a shift worker or foreman. 5.3. Inform the shift worker or foreman about any malfunctions noticed during work. 5.4. Take off your work clothes and put them in a closet for storing work clothes. 5.5. Wash your hands and face with warm water.

Similar articles:

OJSC Chelyaboblkommunenergo will pay a large fine for violations of labor protection requirementsIn the section - Occupational Safety NewsInspectors of Rostrud in the Chelyabinsk region conducted an unscheduled inspection of Chelyaboblkommunenergo OJSC (a branch of the Ashinsky Heating Networks). Control measures were carried out in connection with the investigation of a serious… | Obneftegazgeologiya eliminated hazardous wasteIn the section - Occupational Safety NewsEmployees of the environmental prosecutor's office of the Khanty-Mansi Autonomous Okrug-Yugra established that OJSC Obneftegazgeologiya in the period from 2009 to 2014. stored in 19 sludge pits at well pads of the Tailakovskoye field... |

Faulty equipment causes accident at paper millIn the section - Occupational Safety NewsOn August 1 of this year, a repairman was seriously injured at the production of the Balakhninsky paper mill of Volga JSC. The incident occurred during scheduled maintenance work on the press section of the papermaking… | Rostechnadzor inspected enterprises that do not produce commercial petroleum products, but carry out export suppliesIn the section - Occupational Safety NewsThe Federal Service for Environmental, Technological and Nuclear Supervision (Rostechnadzor) reports that, as part of the execution of the instructions of the Deputy Chairman of the Government of the Russian Federation Arkady... |

Pipe bender operation

- The machine must be well grounded, the wire must be at least 4mm2 flexible copper cord. Do not access power supply voltage exceeding the specified range, cannot be connected or disconnected while charging, cannot test the control circuit with tramegger, otherwise the device may be damaged.

- When inserting and removing the connector, do not pull on the wire or cable in case of welding.

- Limit switches, encoders, etc. must not be touched with hard objects.

- There is no sharp object collision display block.

- The electrical cabinet must be placed in a ventilated place and is prohibited from operating in dust and corrosive gases.

- No personal loading or switching of PC input and output terminals.

- When changing the machine's power source, the motor must be re-confirmed.

- The machine should be kept clean, special attention should be paid to the clamping block, sliding block and other sliding grooves to ensure that there are no foreign objects on it.

- Lubricate the chain and other sliding parts regularly.

- The power supply must be turned off during cleaning and maintenance.

- 11, Preparation: Before starting, check whether the oil level is consistent with the oil level line, all lubrication points, trunk to confirm the engine rotation, check whether there is any abnormal sound on the oil pump, check whether there is any leakage in the hydraulic system after the boot (Angle sensor cannot add oil during operation);

- Pressure adjustment: Adjust the pressure using the solenoid bypass valve to ensure the system pressure reaches the required operating pressure, usually not higher than 12.5 MPa.

- Mold adjustment: Mold setting required to center the mold and clamping block, the clamping block can be adjusted by bolts; to center the acceleration block and matrix, the acceleration block is adjustable; Center the rod head and die, loosen the bolt shank, adjust the center and tighten the bolt.

Instructions for labor protection when working on pipe bending machines

Instructions for labor protection when working on pipe bending machines and devices

1. General provisions.

1.1. These instructions are intended for those working at the enterprise.

1.2. The following persons are allowed to perform work:

- At least 18 years of age;

- Passed a medical examination;

- Have completed introductory training on labor protection, as well as training on labor protection in the workplace;

- Trained in safe workplace practices for the work performed.

1.3. The worker is obliged:

- Comply with internal labor regulations.

- Comply with the requirements of these instructions;

- Have with you a certificate confirming your knowledge of safe methods and techniques for performing work in your main and related professions. Periodically, at least once a year, undergo regular labor safety knowledge testing according to the approved schedule;

- Know the design and conditions of safe operation of the machines and equipment on which he has to work;

- Inform the work manager about malfunctions that make it impossible to carry out the work safely;

- Use special clothing and personal protective equipment provided for by the standards approved by the head of the enterprise.

- Do not allow unauthorized persons to be present at the workplace;

- Be able to provide first aid and, if necessary, provide it to victims of industrial accidents, if possible keeping the situation at the scene unchanged and reporting the incident to the manager;

- Comply with fire safety requirements and do not light an open fire without the special permission of the work manager;

- Periodically undergo a medical examination within the time limits prescribed for this profession.

1.4. The worker must know the dangerous and harmful production factors present at this workplace:

- Possibility of injury from electric shock in the absence or malfunction of grounding devices;

1.5. When moving around the city on the way to and from work, the employee is obliged to comply with traffic rules as they relate to pedestrians, and when transported to work by transport as they relate to passengers.

1.6. When performing any work, an employee must have a healthy sense of danger and be guided by common sense. In the absence of these qualities, he is not allowed to work independently.

2. Labor safety requirements before starting work.

2.1. Before starting work, the employee must:

- Receive instructions from the work manager on safe methods, techniques and sequence of performance of the production task;

- Put on the special clothing required by the regulations, put it in order, fasten all the buttons so that there are no hanging ends;

- Make the workplace safe;

3. Labor protection requirements during work.

Necessary:

Clear the area around the machine with a radius of at least 2 meters;

Install the protective casing over the gears of the mechanism;

Change rollers only after the machine has completely stopped and the electric motor has been disconnected from the mains;

Hold onto the pipe being processed no closer than 400 mm from the working roller.

3.32.8. When working on machines for cutting and rolling pipes, you should:

Carry out thread cutting only after making sure that the part is securely fastened in a vice or clamp;

Before starting the machine, install a casing covering the rotating die;

When cutting threads on long pipes, support their free ends using a special stand;

Be careful not to touch the rotating die head;

Measure threads only after the machine has completely stopped.

4. Labor protection requirements upon completion of work.

4.1. Upon completion of work, the employee must do the following:

- Tidy up the workplace;

- Remove tools and accessories to specially designated storage areas;

- Report all noticed malfunctions and deviations from the normal state to the work manager;

- Bring the workplace into compliance with fire safety requirements;

- Leave special clothing and special shoes in the “dirty” locker room, wash and change.

5. Action in case of accident, fire, injury.

5.0. If voltage appears on the machine body, immediately turn off the general switch.

5.00. If there is a danger of injury to workers, or if there is smoke, a burning smell, or unusual noise, stop work immediately. notify the current manager. Turn off the machines from the control panel or the nearest “Emergency shutdown button”.

5.1. Be careful when detecting explosive objects (grenades, shells, mines, etc.). If you find these items, stop work, mark the location and notify the work manager about their discovery.

5.2. In the event of a fire at stationary facilities, call the fire brigade, notify the work manager and take measures to eliminate the source of fire.

5.3. If a worker is struck by an electric shock, release the victim from its action as quickly as possible (the duration of the current determines the severity of the injury), to do this, quickly turn off the switch or other device.

5.4. If it is impossible to quickly disconnect the electrical installation, take measures to free the victim from live parts:

- when freeing the victim from live parts or live wires up to 1000 V, use a rope, stick, board or other dry non-conductive objects, or pull the victim by the clothes (if they are dry and falling away from the body), for example, by the tails of a jacket or coat, by the collar , while avoiding touching surrounding metal objects and parts of the victim’s body not covered by clothing:

- if the victim touches a wire that lies on the ground, then before approaching him, place a dry board, a bundle of dry clothes or some kind of dry, non-conductive stand under your feet and separate the wire from the victim using a dry stick, board . It is recommended to operate with one hand, if possible;

- if the victim convulsively squeezes one current-carrying element (for example, a wire) in his hand, separate the victim from the ground by pushing a dry board under him, pulling his legs off the ground with a rope, or pulling him by his clothes. Observe the safety measures described above;

— when dragging the victim by the legs, do not touch his shoes or clothes if your hands are not insulated or poorly insulated, because shoes

and clothing may be damp and conduct electrical current. To insulate your hands, especially if you need to touch the victim’s body that is not covered by clothing, wear dielectric gloves; if they are absent, wrap your hands with a scarf or use any other dry clothing;

- if it is not possible to separate the victim from live parts or disconnect the electrical installation from the power source, then cut the wires with an ax with a dry wooden hatchet or cut them with a tool with insulated handles (pliers, wire cutters). Cut and cut the wires in phases, i.e. each wire separately. You can also use a non-insulated tool, but you need to wrap its handle in dry woolen or rubberized material;

- if the damage occurs on a power line, resort to short circuiting all the wires; to do this, throw a wire, metal cable or bare wire over them. Before shorting the power line wires, ground one end of the thrown wire (connect to a metal support, grounding descent, etc.).

Make sure that the thrown wire does not touch the victim or people providing assistance.

5.5. If the affected person is conscious, but is frightened, confused and does not know that in order to free himself from the current he needs to get off the ground, with a sharp shout of “jump” force him to act correctly.

5.6. If a fire occurs in electrical installations, the first person to notice the fire must report it to the fire department, the person responsible for electrical equipment, and the shop manager.

5.7. If a fire occurs in the electrical installation itself or near it, first of all, before firefighters arrive, disconnect the electrical installation from the network. If this is not possible, try cutting the wires (sequentially, one at a time) with a tool with insulated handles.

5.8. When extinguishing a fire under voltage, use carbon dioxide manual fire extinguishers of the OU-2, OU-5, OU-8 type or stationary type OSU-5, as well as carbon dioxide-bromoethyl fire extinguishers OUB-Z, OUB-7, but do not touch wires and cables, electrical installation housings . You can use dry, clean sand for extinguishing. When using fire extinguishers OP-1 and OP-2, do not direct the powder stream at hot objects: an explosion is possible.

5.9. Do not use chemical foam or chemical air foam fire extinguishers to extinguish a fire in an energized electrical installation.

Providing first aid

5.10. Electric shock. After freeing the victim from the action of the electric current, place him on a mat and cover him warmly, quickly, within 15-20 s, determine the nature of the required first aid, arrange for a doctor to be called and take the following measures:

- if the victim is breathing and conscious, place him in a comfortable position and unbutton his clothes. Before the doctor arrives, provide the victim with complete rest and access to fresh air, monitor his pulse and breathing. Do not allow the victim to get up and move, much less continue working, until the doctor arrives;

- if the victim is unconscious, but his breathing and pulse remain stable, constantly monitor them, let him sniff ammonia and spray his face with water, ensuring complete rest until the doctor arrives;

- in the absence of breathing, as well as rare, convulsive breathing, cardiac arrest (lack of pulse), immediately perform artificial respiration, closed cardiac massage.

Start artificial respiration and cardiac massage no later than 4-6 minutes after the cessation of cardiac activity and breathing, because after this period, clinical death occurs. Do not bury the victim in the ground under any circumstances.

5.11. Carry out artificial respiration “mouth to mouth” or “mouth to nose” as follows. Lay the victim on his back, unfasten clothing that is restricting breathing, and place a cushion of clothing under his shoulder blades. Maintain open airways that may be blocked by a sunken tongue or foreign contents. To do this, tilt the victim's head back as much as possible, placing one hand under the neck and pressing the other on the forehead. In this position, the mouth usually opens and the tongue moves to the back of the larynx, ensuring patency of the airway. If there is foreign content in the mouth, turn the victim's shoulders and head to one side and clean the mouth and throat with a bandage, handkerchief, or the edge of a shirt wrapped around the index finger.

If the mouth does not open, then carefully insert a metal plate, tablet, etc. between your back teeth, open your mouth and, if necessary, clean your mouth and throat.

After this, position yourself on your knees on either side of the victim’s head and, holding your head back, take a deep breath and, pressing your mouth tightly (through a handkerchief or gauze) to the victim’s open mouth, strongly blow air into it. In this case, cover the victim’s nose with your cheek or the fingers of your hand on the forehead. Make sure that the air gets into the lungs and not into the stomach, this is detected by bloating and lack of expansion of the chest. If air gets into the stomach, remove it by quickly pressing the area of the stomach between the sternum and the navel for a short time.

Take measures to clear the airways and repeat the blowing of air into the victim’s lungs. After insufflation, free the victim’s mouth and nose so that air can freely escape from the lungs. For a deeper exhalation, lightly press on the chest. Make each air injection every 5 seconds, which corresponds to the rhythm of your own breathing.

If the victim’s jaws are clenched so tightly that it is impossible to open his mouth, then perform artificial respiration using the “mouth to nose” method, i.e. blow air into the victim's nose.

When the first spontaneous breaths appear, time the artificial breath to coincide with the beginning of the spontaneous breath.

Carry out artificial respiration until deep and rhythmic breathing is restored in the victim.

5.12. Perform external cardiac massage in case of cardiac arrest, which is determined by the absence of a pulse, dilated pupils and cyanosis of the skin and mucous membranes.

To carry out external cardiac massage, lay the victim with his back on a hard surface or place a board under him, free the chest from clothing and raise his legs by about 0.5 m. Position yourself on the side of the victim and determine the place of pressure, to do this, feel the lower soft end of the sternum and The pressure point is determined along it 3-4 cm above this place. Place your palm on the place of pressure so that your fingers do not touch the chest, place the palm of your second hand at a right angle to the back of the palm of your first hand. Apply a quick (push) and strong pressure on the sternum and hold it in this position for about 0.5 s, then quickly release it, relaxing your hands, but without removing them from the sternum. Massage the heart approximately 60 - 80 times per minute. Perform heart massage until your own (not supported by massage) regular pulse appears.

5.13. If it is necessary to simultaneously perform artificial respiration and cardiac massage:

- if one person is providing assistance, then after two deep injections, do 15 compressions on the chest, then again two deep injections and 15 compressions on the sternum, etc.;

- if two people are providing assistance, then one makes one blow, and the second after 2 seconds makes 5-6 pressures on the sternum, etc.

5.14. Carry out artificial respiration and cardiac massage until the vital functions of the body are completely restored or until a doctor arrives.

5.15. Injuries. Lubricate abrasions, injections, and small wounds with iodine or brilliant green and apply a sterile bandage or cover with a strip of adhesive plaster. For a large wound, apply a tourniquet, lubricate the skin around the wound with iodine and bandage with a clean gauze bandage or a sterile bandage from an individual bag.

If a bandage or bag is not available, take a clean handkerchief or rag, add iodine to make a spot larger than the wound, and apply it to the wound.

Apply the bandage so that the blood vessels are not compressed and the bandage stays on the wound. If you are injured, get an anti-tetanus injection at a medical facility.

5.16. Stop bleeding. When stopping bleeding, lift the wounded limb up or position the damaged part of the body (head, torso, etc.) so that it is on an elevation and apply a tight pressure bandage, if during arterial bleeding (scarlet blood flows in a pulsating stream) the blood does not stop, apply a tourniquet or twist. Tighten the tourniquet (twist) only until the bleeding stops. Mark the time of application of the tourniquet on a tag, piece of paper, etc. and secure it to the harness. The tourniquet can be kept tightened for no more than 1.5 - 2 hours. In case of arterial bleeding, take the victim to a doctor as soon as possible. Transport him in a comfortable and, if possible, fast vehicle, always with an accompanying person.

5.17. Bruises. For bruises, apply a tight bandage and apply cold packs. If there are significant bruises to the torso and lower extremities, take the victim to a medical facility.

Bruises in the abdominal area lead to ruptures of internal organs. Immediately take the victim to a medical facility at the slightest suspicion. Do not give such patients anything to drink or eat.

5.18. Bone fractures. If the fracture is closed, give the limb a comfortable position, handle it carefully, do not allow sudden movements, and apply splints. Apply splints on both sides, place cotton wool under them so that the splints do not touch the skin of the extremities, and be sure to grab the joints above and below the fracture sites. Splints can be placed over clothing. In case of an open fracture, stop the bleeding, smear the edges of the wound with iodine, bandage the wound and apply splints. Do not touch or push any protruding bone fragments into the wound with your hands. If tires are not available, use plywood, boards, fork holders, etc. As a last resort, tape the broken leg to the healthy leg and the arm to the chest.

If the collarbone or scapula is fractured, place a tight cotton swab in the axillary area on the damaged side, and hang your hand on a scarf. If you have broken ribs, bandage your chest tightly or use a towel to cover it as you exhale.

If the spine is fractured, carefully lay the victim on boards or plywood, making sure that the torso does not bend (to avoid damage to the spinal cord).

If a bone is broken, take immediate measures to transport the victim to the nearest medical facility.

5.19. Dislocations. In the event of a dislocation, ensure the immobility of the injured limb, apply splints without changing the angle that formed in the joint during the dislocation. Dislocations should only be adjusted by doctors. To deliver the victim to a medical facility, place him on a stretcher or in the back of a car, and cover the limb with rolls of clothing or pillows.

5.20. Burns. In case of a thermal burn, remove clothing from the burned area without tearing off the stuck parts of clothing, cover the area with sterile material, place a layer of cotton wool on top and bandage it. When providing assistance, do not touch the burned areas or puncture the blisters. Do not lubricate the burned surface with ointments or cover it with powders. In case of severe burns, take the victim to the hospital immediately.

In case of an acid burn, take off your clothes and thoroughly, for 15 minutes, rinse the burned area with a stream of water, then rinse with a 5% solution of potassium permanganate or a 10% solution of baking soda (a teaspoon per glass of water). After this, cover the affected areas of the body with gauze soaked in a mixture of vegetable oil and lime water, and bandage it.

For alkali burns, treat the affected areas for 10–15 minutes. rinse with a stream of water, and then with a 3-6% solution of acetic acid or a solution of boric acid (a teaspoon of acid per glass of water). After this, cover the affected areas with gauze soaked in a 5% acetic acid solution and bandage it.

5.21. Frostbite. In case of first degree frostbite (the skin is swollen, pale, bluish, and loses sensitivity), bring the victim into a cool room and rub the skin with a dry, clean cloth until it becomes red or feels warm, lubricate it with fat (oil, lard, boric ointment) and apply an insulated bandage. Give the victim hot tea and move him to a warm room.

In case of frostbite of II-III degree (blisters with bloody fluid appear on the skin, and it acquires a purplish-bluish color - II degree; layers of skin and underlying tissues become dead, the skin becomes black - III degree; complete necrosis of the skin and tissues - IV degree) on Apply a dry bandage to the affected skin, give the victim a drink of hot tea or coffee and immediately send to the nearest medical facility.

5.22. Heat and sunstroke. At the first signs of illness (headache, tinnitus, nausea, rapid breathing, severe thirst, sometimes vomiting), place the victim in the shade or bring him into a cool room, free the neck and chest from constricting clothing; if the victim is conscious, give him cold water to drink; periodically moisten your head, chest and neck with cold water, and sniff ammonia. If the victim is not breathing, perform artificial respiration in accordance with paragraph 4.11 of these instructions.

5.23. Poisoning with pesticides, mineral fertilizers, preservatives and their breakdown products, toxic gases. First of all, take the victim out of the contaminated area and free him from clothing that restricts breathing and respiratory protection. Take first aid measures to stop the poison from entering the body:

through the respiratory tract - remove the victim from the danger zone to fresh air;

through the skin - thoroughly rinse the drug with a stream of water, preferably with soap, or, without smearing or rubbing it on the skin, blot it with a piece of cloth, then wash with cold water or a slightly alkaline solution; if poison gets into your eyes, rinse them thoroughly with water, 2% solution of baking soda or boric acid;

through the gastrointestinal tract - give several glasses of water (preferably warm) or a slightly pink solution of potassium permanganate to drink and induce vomiting by irritating the back of the throat. Repeat this procedure 1-3 times. Vomiting can be induced with mustard (1/2 - 1 teaspoon of dry powder per glass of warm water), salt (2 tablespoons per glass of warm water) or a glass of soap solution. Do not induce vomiting in an unconscious or convulsive victim. After vomiting, give half a glass of water with two to three tablespoons of activated charcoal, and then a saline laxative (20 g of bitter salt in half a glass of water), do not give castor oil as a laxative; in case of acid poisoning, give a solution of baking soda (1 teaspoon per glass of water), milk or water to drink; In case of alkali poisoning, give milk, lemon juice or vinegar water to drink.

If possible, bring the victim into a warm room. If you are unconscious, use heating pads, but with great caution; in case of poisoning with DNOC, nitrafen, sodium pentachlorophenol and sodium pentachlorophenolate, heat is contraindicated; carry out cold procedures - cool baths, wet wipes, cold compresses, ice packs. If breathing weakens, let's sniff ammonia; in cases of cessation of breathing or cardiac activity, perform artificial respiration or closed cardiac massage. If there are convulsions, avoid any irritation and give the patient complete rest. If irritating substances, such as formaldehyde, enter the body, give the victim an enveloping agent (an aqueous solution of starch) to drink. Do not give milk, fats, alcoholic drinks. In case of skin bleeding, apply tampons moistened with hydrogen peroxide; in case of nosebleeds, lay the victim down, lift and slightly tilt the head back, apply cold compresses to the bridge of the nose and the back of the head, insert tampons moistened with hydrogen peroxide into the nose. For poisoning with organophosphorus compounds, accompanied by salivation, lacrimation, constriction of the pupils, slow breathing, slow pulse, muscle twitching, give belladonna preparations: 3-4 tablets of besalol (becarbon) or 1-3 tablets of bellalgin.

In all cases of poisoning (even mild ones), immediately refer the victim to a doctor or paramedic.

In case of poisoning with poisonous gases (headache, tinnitus, dizziness, dilated pupils, nausea and vomiting, loss of consciousness), immediately take the victim into fresh air and provide oxygen for breathing using a rubber cushion or an oxygen cylinder. If there is no oxygen, lay the victim down, elevate his legs, give him cold water or a lot of milk to drink, and sniff cotton wool soaked in ammonia. If breathing is weak or stops, give artificial respiration until a doctor arrives or breathing is restored.

5.24. Eye damage. If your eyes become clogged, wash them with a 1% boric acid solution, a stream of clean water, or a damp cotton (gauze) swab. To do this, position the victim’s head so that you can direct the jet from the outer corner of the eye (from the temple) to the inner. Don't rub your clogged eye. If acid or alkali splashes into your eye, rinse it for 5 minutes. clean water. After rinsing, cover the eye with a bandage and send the victim to a doctor.

Developed by

Agreed

Safety precautions when operating a pipe bender

- Please note that when the pipe bending machine is moving, the body cannot enter the rotation area of the rotating arm.

- While the pipe bender is operating, all personnel should not enter the area of the rotating arm and pipe fittings.

- The hydraulic system of the pipe bender uses ordinary hydraulic oil YA-N32 (original number 20). Typically, the oil is changed once a year, and the filter must be cleaned at the same time.

- When adjusting a pipe bender (or die), the adjustment must be made with a regulator. One person sets up the machine, while the other works on the control cabinet.

- When adjusting the pipe bender or driving an empty vehicle, remove the mandrel.

- The hydraulic system pressure should not exceed 14 MPa.

- When adjusting the cylinder speed manually, the rotating arm must be rotated more than 900°. The adjustment speed is synchronous with the linear speed of the edge of the rotary elbow. It is forbidden to push the speed more than the edge of the rotating mold in the manual state.

- After a while, a regular machine should check the chain tension and maintain its elasticity and stability.

- Automatic operation in core bending mode, return to the previous bent arm, the operator must ensure that the core head is in the pipe, or ensure that the core shaft is not blocked when bending the arm back, otherwise the core head or core rod may be bent or broken .

- After work, turn off the power, do a good job of cleaning and lubricating.

Types of pipe bending machines

Today, all pipe bending devices that are used in various enterprises can be classified according to one main indicator - design. Depending on the design features, the following types of pipe bending machines are distinguished:

- Manual. Such devices are used in small enterprises and involve the application of physical effort when bending pipes. As a rule, such compact machines are portable and are used in the construction industry. It is worth noting that the mobility of such machines allows them to be used directly on construction sites.

- Hydraulic. Devices operating from a hydraulic drive are very similar (in design) to manual machines, but can be either portable or stationary. The main difference between such machines and manual models is the presence of a hydraulic booster. This element allows you to process products with cross-sectional dimensions up to 20 mm without the use of significant physical effort.

- Electrical. They are large in size and operate on electricity. When bending a part, such stationary machines provide high angle accuracy. It is also worth noting that an electric industrial pipe bender can bend products with large cross-sections and thin walls.

Hand-held devices are used in everyday life to work with small-diameter pipes

All electric pipe bending machines are divided into three main types, depending on how automated they are. Consider these types:

- manual;

- semi-automatic;

- automatic with numerical control program (CNC).

Machines with a computerized control system are the most functional of all. Thanks to the CNC system, it becomes possible to program the parameters of the angle and bending radius of the part. Such devices can operate in a fully automatic mode, where all processes are controlled by a computer program (including part delivery and mandrel adjustment).

It is worth noting that pipe bending machines for regular and profile pipes are different. Manual pipe benders are quite inexpensive, however, they are much less productive than electric models.

Regularization of pipe bend type

The design and exhaust pipe avoid large circular arc, any curve, bending of composite material and circular arc greater than 180°.

Too large a circular arc not only increases the workload, but is also limited by the size of the pipe bender;

The arbitrary bending and combination bending design is unreasonable, making mechanization and automation much more difficult, making it difficult for operators to relieve heavy manual labor. Due to the arc of more than 180°, the pipe bender cannot discharge.

Bending speed of pipe bending machine

The main influence of bending molding speed on molding quality is:

If the speed is too high, it is easy to cause the curved part of the ducts to flatten, the roundness cannot meet the requirements, causing the ducts to lacing and breaking;

If the speed is too slow, it is easy to cause the catheter and the pressure block to shrink to slip, the large pipe tube will easily become the channel part of the sink.

To determine the maximum bending speed of a machine, the best final bending speed should be 20-40% of the pipe bender's maximum bending speed.

Advantages of modern pipe bending machines

Previously, special equipment was used to bend pipes, which was large in size and operated on the principle of induction heating. Induction heating meant raising the temperature of the part at the bending point to the desired level (until the metal became plastic enough to bend).

Today, industrial development allows us to produce more advanced equipment, which differs from old pipe bending machines and has the following advantages:

- more compact dimensions compared to older devices. The size of a modern pipe bending machine allows you to do without organizing a capital foundation for the installation of equipment;

- The minimum height for loading the part is no more than 140 cm from the floor. This indicator is not affected by the diameter of the product;

- reduction in energy consumption compared to old pipe benders. New models do not require heating pipes;

- lack of contamination, which was observed in old induction machines;

- the temperature near modern pipe bending equipment is very comfortable;

- in addition, during operation of such equipment the noise level is reduced, which is also a big advantage;

- high bending speed, which allows you to cope with large volumes of work. For example, a modern pipe bending machine is capable of bending a part with a cross-section of 400 mm and a wall thickness of 25 mm in a very short period of time (2-3 minutes).

Large volumes of work require high bending speed, which can only be provided by professional equipment.

Standardization of pipe bending radius

The bending radius should better achieve "one pipe and one die" and "multiple pipes and one die".

For a pipe, or have multiple bending positions, or have multiple bending angles, the bending radius can only be one, because the module of the pipe bending machine will not be changed during the bending process, which is the "pipe corresponding to the die. "

Although for "multiple pipes with one die" this means that a pipe with the same diameter should try to use the same bend radius, and also use the same modules to bend pipe with different shapes, this helps reduce the number of modules. .

Why do you need a pipe bending machine?

Conventional and profile pipes are used in various fields:

- installation of pipelines of various configurations;

- execution of frame structures in the construction industry;

- for organizing fencing;

- in the automotive industry;

- in the furniture industry;

- as decorative elements of the interior.

The above options for using pipes in most cases require bending them. When installing a pipeline structure, you can use fittings to connect individual sections of communication. However, the node obtained as a result of joining two pipes is considered a problem area and the risk of a leak increases in direct proportion to the number of such nodes. Therefore, it is much safer to bend the pipe at the desired angle, without compromising its integrity. Special pipe bending equipment is used to bend pipes.

Helpful information! Pipe benders are used both in private cases and in industrial enterprises. It is worth saying that these devices bend pipes at an angle of up to 180°.

The drive system for such equipment can be different:

- hydraulic;

- electromechanical.

Pipe bending equipment with hydraulic drive can be used in production and at home

A pipe bending machine is a popular and widespread equipment that is used today in many areas of human activity. If necessary, you can assemble such a machine yourself.