A caliper is a tool for taking precise dimensions of various parts both outside and inside, measuring the diameters of holes, their depths, etc. They are used in various fields: repairing machine parts and various equipment, processing products from different materials, construction, etc. , when precise data is needed, down to tenths and even hundredths of a millimeter. This device allows you to make such measurements, unlike an ordinary ruler or tape measure.

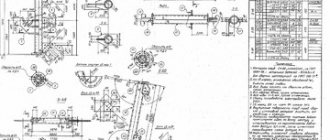

Vernier caliper design

Understanding the design features of this device is necessary in order to understand how to use it correctly. The caliper consists of the following parts.

- Fixed bar or ruler (bar). It represents the basis of the structure. There is a scale on it.

- A movable bar that can move along the bar. This bar has a vernier scale. It allows you to get very accurate measurements, namely, it counts fractions of a millimeter.

- Upper and lower lips. These are moving parts that allow you to measure an object and find out the dimensions both outside and inside. When the jaws are perfectly aligned, the zero marks on both scales should exactly match.

- Locking or clamping screw. It is required to fix the bar.

- Depth gauge. A thin retractable bar that can be used to measure depth. Electronic measuring devices are also equipped with batteries and a mobile mechanism.

In addition, there are models in the upper part of which there is a movable inch measuring scale. They are easy and convenient to use.

What can experts advise?

Sergey Voronenkov, master installer: As a rule, pipes made of steel intended for installation of water supply systems are characterized by their inner diameter. You can often hear from professionals about half-inch or inch pipes. This means that their internal diameter is 12.7 mm or 25.4 mm. But the outer diameter is the province of the plumber and plumber. Simply because most plumbing systems today are installed using a threaded connection. In turn, the thread is cut on the outside of the pipe.

Viktor Ivanovich Petrov, plumber: The use of a metal measuring tape during measurements is less preferable. Metal cannot ensure a tight fit of the tape measure to the pipe, which is why the error will be too large. The result will be much more accurate if you use the so-called flexible tailor's meter.

Types of calipers

There are three main types of such devices. Their use for a certain type of work is determined by its characteristics.

- Vernier or analog calipers. Measurements are made on a vernier scale. These power tools are simple and inexpensive. They are the most common.

- Dial or pointer calipers. To measure, instead of a scale, they have a dial that shows the results and does not require calculations. Their cost is higher than analog models. They are easy to use.

- Digital or electronic calipers. These are devices that have liquid crystal digital displays with rechargeable batteries. The use of such devices allows you to obtain the most accurate results. They show data in both millimeters and inches.

In addition to those listed, there are also models of special-purpose calipers. They are used for special jobs. For example, ШЦЦП, which measures parts with protrusions, or ШЦЦП - a design for measuring the tread pattern of tires, etc. These devices are not sold in regular stores; if necessary, they can be purchased on special websites. They are used by professional craftsmen.

All types of calipers have their own designations depending on the specific application.

- Vernier caliperSHTs-1. They measure parts, their external and internal dimensions using two pairs of sponges. It can also be used when measuring the size of a hole using a depth gauge.

- ShTs-1S. Such devices are equipped with arrow heads, making the measurement process simplified.

- Shtsk. Designs with a dial scale with a spring mechanism. It can be used for measurements when perfect accuracy is not required.

- SCT-I. Devices equipped with carbide-coated jaws to prevent surface abrasion. They are resistant to wear and can be used for a long time.

- SHTs-II. In addition to the jaws, such devices also have a mechanism for feeding the frame. Thanks to this, markings can be applied.

- SHTs-III. This device is large in size. The jaws on it are one-sided. Not suitable for depth measurement.

- SCC. A device with a digital scale from which readings are taken.

Each type of caliper is manufactured in accordance with the currently valid GOST 166-89 and is marked accordingly.

GOST 166-89 Calipers. Specifications

1 file 998.54 KB

Measurement order

Now let's talk about how a caliper works. Before you start using it, you need to prepare the device and the part being measured: clean the surface of dirt to ensure maximum accuracy. The jaws need to be brought together tightly and the size of the gap between them needs to be assessed. If the design is working properly, then it will be minimal.

Next, the movable frame must be moved so that its first mark coincides exactly with the zero mark on the rod scale. If this is not taken into account and implemented, the results will not be accurate. If you cannot match these marks, then the caliper is faulty and is not recommended to be used. Only after making sure that the structure is completely prepared can you begin to work.

Measuring external surfaces

When it is necessary to measure a linear dimension or outer diameter, the sequence of using the tool is as follows. First of all, the sponges need to be spread apart by moving the frame. And then press them tightly against the opposite surfaces of the part that needs to be measured, and secure the position of the frame with a screw. If the outer diameter of a cylindrical part is measured, then its axis must be exactly perpendicular to the plane of the frame. If the length of a part or product is measured, then its longitudinal axis should be located exactly parallel to the rod. These conditions must be observed when using a caliper, otherwise it is impossible to obtain accurate results.

Measuring internal surfaces

If you need to measure the diameter of the hole, the outer jaws must be set to zero. They must be inserted into the hole that needs to be measured. It is necessary to hold the caliper straight. Next, the jaws need to be spread all the way, so that they are pressed tightly against the inner walls of the part. Secure their position using the locking screw. Then readings are taken and the necessary calculations are made if a vernier caliper was used.

Depth detection

To measure the depth of the hole, you will need to move the frame and extend the depth gauge. Then insert it all the way into the hole so that the end touches the bottom. It must be positioned exactly perpendicular to the surface of the part being measured. Press against the wall. Move the bar to the end also until it stops. Using the locking screw, secure the position and remove the device.

Measuring threaded connections

A caliper can be used to measure threaded connecting parts - screws, bolts, etc. Thread diameters are determined by the protrusions. For this purpose, the screw or bolt to be measured should be installed vertically and clamped with jaws. After this, it is possible to determine the necessary indicators.

If you need to measure the thread pitch using a caliper, this is done in the following sequence. First, the height of the rod and the outer diameter of the part are measured. And then the number of thread turns is counted. By dividing the length of the rod by the number of turns, you can get the thread pitch indicator.

Less accurate, but very fast method

However, if there is no need for overly complex and precise calculations, then you can determine the diameter simply by applying an ordinary school ruler to the diameter of the pipe. You will only need to hold the ruler so that its scale coincides with the imaginary line of the pipe diameter. Small deviations in one direction or another are quite acceptable. After all, in stores, pipes, as a rule, are offered in standard sizes. If necessary, the sales consultant can adjust the diameter of the required pipe.

An ordinary ruler can help if there is no professional tool for measuring the diameter of the pipe, but do not forget about the error.

Reading results

It is not difficult to read the results obtained using a caliper. On the fixed frame (bar), where the main scale is located, determine the integer number (mm). The vernier scale shows hundredths of a millimeter. You need to find a stroke on the vernier scale on the caliper you are using that matches a certain number on the main scale. This indicator will be the value of the part size in millimeters.

Vernier scale

It happens that when measuring, a whole indicator is sufficient. If you want to set the value more accurately, you need to inspect the vernier scale. And on it you need to find the point of coincidence of the two marks. The number on the vernier scale will indicate the tenth value. By adding it to an integer, the user will receive the exact value of the part size.

By hourly indicator

When using a dial caliper, the whole number in millimeters can also be seen on the main scale. As on an analog device, it is determined by the coincidence of marks on both scales. The number presented on the dial shows a value from 0.01 to 0.99 mm, this depends on the value of the scale division. A pointer or dial caliper is a more accurate device than a mechanical (analog) one. It should be used when it is necessary to obtain perfectly accurate data.

By digital display

High-precision (up to hundredths of millimeters) readings of the results obtained when working with a digital caliper are presented on the liquid crystal display of the scoreboard. It is necessary to remember that it has different modes that show measurement results in both millimeters and inches. Such devices are also equipped with a vernier scale. It can be used if, for example, the battery runs out.

If you need to measure a very small pipe

It is usually recommended to measure the diameter of small objects using a caliper. This method is suitable when working with pipes up to 15 cm. One end (leg) of the device is pressed against one edge of the pipe, and the other against the other. In this case, special indicators on the caliper will show the outer diameter of the pipe.

A caliper is a universal tool for measuring internal and external dimensions, as well as hole depth, with an accuracy of 0.1 or 0.01 mm.

If you need to use it to measure the internal diameter, then you can press the edge of the pipe, the one that is “responsible” for its thickness, between the legs of the caliper. The pipe wall thickness is then subtracted from the outside diameter. This will be its internal diameter.

Read also: Bit for a screwdriver for heads

How to properly store a tool

To extend the life of your caliper, it must be stored properly. To do this, you should use a special case. It is recommended to periodically wipe the surface of the device with a soft cloth to remove dirt. If used frequently, it does not require additional protective measures. If you use it rarely, then you need to treat it with machine oil. It is necessary to avoid exposure to moisture and sunlight and mechanical damage - impacts, scratches, etc.

Vernier calipers are a tool that is often required by professional craftsmen and amateurs. If you need to take measurements frequently, you will need to purchase such a device. When choosing the right model, the user should be guided by the specifics of the work, taking into account the design features and cost of such tools.