We recommend purchasing:

Installations for automatic welding of longitudinal seams of shells - in stock!

High performance, convenience, ease of operation and reliability in operation.

Welding screens and protective curtains are in stock!

Radiation protection when welding and cutting. Big choice. Delivery throughout Russia!

What is metal surfacing

This is a procedure that is used to restore the shape and material of worn-out products and mechanisms. Using surfacing technology, it is possible to create a strengthening layer of metal on the surface and bimetallic structures.

Deposition is a type of welding technology. It is based on the same principles as classical welding. To process and protect the surfaces of products, various types of surfacing are used, which differ from each other in the methods of deposition and the composition of the welding medium.

Using this technology, you can work with structures of various compositions: copper, bronze, cast iron, as well as alloys (nickel, chrome, cobalt).

Non-consumable electrodes and their types

Today, in the manufacture of metal structures using the described method, the following types of electrodes are used:

- tungsten _ The most common type used in non-consumable electrode welding. It is a rod with a diameter of 1-4 mm. Tungsten has a very high melting point, which makes it possible to use this material for the manufacture of electrodes. They are divided into standard, yttriated, lanthanated, thoriated;

- coal _ Often used for welding products made of non-ferrous metals and steels with small wall thickness and for air-arc cutting of metals. They are used both with and without an additive, and can be folded along the welding line or fed directly into the weld pool. The welding process when using these materials is carried out at a current of no more than 580 A;

- graphite _ These electrodes are especially actively used when working with copper cables. They are perfectly adapted to processing, resistant to temperature influences and are not subject to rapid wear. Thanks to all these qualities, they are very common in the domestic market.

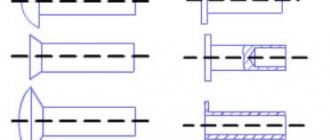

Non-consumable electrode welding diagram

Features of surfacing technology

The advantages of surfacing are that it allows you to obtain reliable adhesion of the metal to the base, as well as the necessary physical and technological parameters. The first is achieved through high-quality preparation of the product, and the second through the correct selection of materials for the work.

The essence of surfacing is that it is necessary to uniformly apply narrow strips of molten metal to the surface so that they join into a continuous thick layer, ranging in size from a tenth of a millimeter to ten millimeters.

Types of surfacing

The surfacing technology must ensure the quality of the deposited layer and minimal impact on the metal to avoid its deformation. Different types of procedures have different processing methods and material consumption. Let's consider the main types of metal surfacing on parts.

1. Gear teeth.

A gear is a part of many mechanisms and machines used in various fields. The most common defects of this part are: wear along the length and thickness, the formation of cracks or scratches, chipping, and broken teeth.

The most effective method of restoration is metal surfacing. It is performed in several stages:

- First you need to cut out the parts with defects.

- Then you need to drill several holes and make a thread in the gap.

- Make pins and insert them into the seats.

- Make a deposition using electric welding and form a tooth from the metal.

The teeth can be repaired using an additive in the form of flux-cored wire, automatically. Before use, the product must be cleaned of dirt.

2. Ends of rails.

High-speed trains need high-quality rail tracks. Shocks or improper use will cause deformation, bending and dents. The rails can be returned to their original position using fusion.

To begin, take the broken rail and remove all the exfoliated and flattened material from it using sandpaper or a chisel. Then the ends of the rails are heated. For this purpose, various surfacing methods are used:

- Manual arc. It is performed by placing rollers on the rails lengthwise, diagonally or crosswise. Or the second option is to use fusing of a bundle of electrodes.

- Semi-automatic electric arc. It involves the use of self-shielding flux-cored wire. This method is characterized by high quality and productivity.

3. Planes and cylinders.

To restore products, the following surfacing methods are used:

- Coated electrodes. This method involves the use of rollers along closed circles or a helical line. The first option is suitable for long products of small diameter. The second involves turning the product over during operation. The third is convenient in the case of mechanized surfacing and uniform rotation of the part.

- Automatic submerged surfacing. The result is a wear-resistant layer. The method is carried out using welding or flux-cored wire. Deposition occurs along a helical or generatrix line.

Planes are simple surfaces of large area. They are restored using narrow rollers by soldering in several layers or by placing them so that they overlap 30-40% of the width of the previous one.

4. Stamps and metal-cutting tools.

Restoration of products is carried out in three ways: manual, automatic or semi-automatic arc surfacing. In the first case, electrodes are used. In the second and third - paste, flux and alloyed wire.

5. Stainless steel.

In this case, rods made of high-alloy wire are used. They allow you to obtain a joint that is resistant to rust and does not scuff. The method requires preheating the part and subsequent heat treatment.

6. Cast iron and its alloys.

Electrodes of various brands are used for surfacing cast iron and its alloys. Some of them are universal and suitable for all types of alloys.

7. Copper and its alloys.

Deposition of pure copper products is carried out using Komsomolets-100 electrodes or filler rods. The products are preheated to a temperature of 300 to 500 degrees. If the temperature reaches more than 500 degrees, then the deposited layer is subjected to forging. Surfacing is carried out using direct current. The result is a material with increased wear resistance.

N.V. Khramtsov

Metals and welding(lecture course)

Introduction

Humanity has been familiar with metals since ancient times. Tools, household utensils and jewelry were mainly made of metal. The development of materials proceeded in the sequence: stone, gold, silver, copper (bronze) and iron, therefore, according to the material of tools and weapons, the historical periods of human development are divided into the Stone, Bronze and Iron Ages. Therefore, we are currently living in the Iron Age. The natural resources of metals are enormous, so the share of iron (by weight) is 1/3 of the entire globe, and in its surface layer (up to 1 km) there are 5% iron, 8% aluminum, 28% silicon, 47% oxygen and only 0 .0000005% gold and 0.00001% silver. The reserves of only explored iron deposits will be enough for humanity for more than the next two centuries.

There is an average of about 4 tons of iron per person in the world, from which building structures, pipelines, cars, tractors, trucks and cars, household appliances, tools, etc. are made. Parts made of steel and cast iron predominate in machines and building structures. Rarer and often more expensive metals and alloys are mainly used in radio electronics and for jewelry.

Due to such a widespread use of metals in our practical activities, the role of knowledge about metals is extremely important.

, about the technology of manufacturing and repairing parts and structures.

A person who knows metals and knows how to process them has always enjoyed respect and honor

among all peoples of the world. So the only “working” god in many religions were blacksmiths: Hephaestus among the Greeks, Svarog among the Slavs, Vulcan among the Romans. In England, many successful blacksmiths even became lords.

An ancient legend tells that King Solomon, upon completion of the construction of the Jerusalem Temple (XI century BC), decided to glorify the best builders and invite them to the palace, and during the feast, give up his royal throne to the best of the best - the one who did especially a lot for the construction of the temple . When the invitees arrived at the palace, one of them quickly ascended the steps of the golden throne and sat down on it. His action caused amazement among those present.

-Who are you and by what right did you take the throne? - the angry king asked menacingly.

The stranger turned to the mason and asked him: Who made your tools?

“Blacksmith,” he answered.

The one sitting on the throne turned to the carpenter, joiner: -Who made your tools?

“Blacksmith,” they answered.

And everyone to whom the stranger addressed answered:

-Yes, the blacksmith forged our tools with which the temple was built.

And the king agreed with the blacksmith’s arguments that none of the builders present could have completed their work without the tools made by the blacksmith, and the blacksmith himself deserves the greatest honor among the builders

.

Currently, without a car and driver, without an excavator and excavator operator, without a crane and crane operator, without a mechanic, turner, welder and other workers associated with the manufacture, operation and repair of machines and metal structures, it is impossible to imagine a modern construction site.

In his practical activities, a civil engineer is continuously associated with the use of metals in building structures, with the organization of workers’ labor and the technology of rational use of machines. To effectively manage production, you need to “understand” metals and know the basics of their processing technology, the design features of machines, and the features of their operation and repair.

1. Metals and alloys.

Most (3/4) of all chemical elements of D.I. Mendeleev’s periodic table are metals. Their properties differ from non-metals: they combine high strength and hardness with good ductility, have casting properties and the ability to be machined, conduct heat and electricity well, but do not transmit X-rays well and reflect light waves. These properties are determined by the peculiarities of the intra-atomic structure of metals.

Metal surfacing methods

The surfacing method should be as simple, fast and safe as possible to implement, and also prevent metal deformation. Let's look at the main methods, the most common.

1. Electric arc.

For it, classic electric arc equipment is most often used. It can be manual or mechanized. The first option involves the use of conventional DC inverters and rectifiers, in which the plus is connected to the electrode, and the minus to the product itself. This simple assembly reduces the level of overall heating and melts the base layer shallowly. If you add a special additive mixture, you can evenly increase the surface strength.

Mechanized surfacing is carried out using semi-automatic welding machines with solid or flux-cored wire. The main advantages of this method are a high level of productivity and joint quality. If you first sand and clean the area, the seam will be perfectly smooth.

2. Vibro-arc.

This method is used to work with non-ferrous metals up to 1 mm thick and with virtually no heating of the top layer of the product. During the procedure, the electrode moves with an amplitude of 0.3-3 mm and a frequency of up to 100 Hz. As a result, an arc is created for one-fifth of the total time and a small amount of metal is exposed to the surface. The depth and thermal impact on the part are minimal.

For vibratory arc surfacing, semi-automatic machines with special electromechanical devices with intermittent wire feed (1.6-2 mm) are used. The procedure must be carried out in a safe environment consisting of gas, solution or foam that is safe for health.

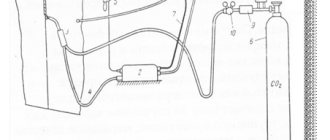

3. Gas flame.

This method is considered the simplest and most accessible. Acetylene or propane-butane mixture is used as a heat source; as an additive - rods or wire; for fluxes - a mixture of boric acid or borax.

Small parts are welded immediately, and large parts are first heated to a temperature of 500 degrees. Powders can be used as useful additives; they can be introduced into a flame stream, which can settle on the surface in small drops.

For gas-flame fusing, plasmatrons are required - special welding machines equipped with a powerful torch. Additives are supplied only in an automated manner, as this is unsafe for humans. Not only powders, but also granules can be used as additives.

The advantages of the method are shallow welding and a uniform structure of the joint layer. The disadvantage is the high cost of the method and heating the plasma to high temperatures.

4. Plasma.

It is performed on special devices equipped with a gas burner. A flow is formed in it, reaching a temperature of several tens of thousands of degrees. Powder or granular mixtures can also be used as additives.

5. Electroslag.

This thermal process uses a slag bath - a container with a catalyst, which moves along the workpiece. An electrode or additive in the form of a granular composition is placed in this vessel. Then the temperature is increased under flux and slag. In this case, the materials become a kind of protective shield that protects the work area from harmful gas effects.

The slag bath is located vertically: thus, air bubbles do not have time to form pores and do not float up. As a result, there is no heat loss or splashing. The advantage of this method is that it is an affordable option. But the disadvantage is labor intensity and the inability to work with small-sized parts and complex configurations.

6. Laser.

Flux or powder is used as an additive; they are melted using a focused laser beam. The laser is emitted from a special head using a nozzle (heats the gas flow) or an injector (injects a useful additive).

The method allows you to ensure the most accurate result and stable quality coating. The method is used only in very critical cases, as it is the most expensive to use.

7. Induction.

The principle of the method is to melt the filler material and the upper metal layer using vortex flows that are induced on the surface. To do this, a flux additive is applied to the product area. Then an inductor made of several turns of a tube with high-precision voltage is located above it.

The depth of deposition depends on the frequency of the inductor current: the higher it is, the lower the depth. This method is considered the most productive and provides minimal heating of the metal.

8. Electric spark.

The procedure is carried out using short-term current discharges and the application of an ultra-thin coating. Surfacing is carried out using a special installation. The electrode must be set to the plus sign, and the workpiece to the minus sign. When current discharges, the particles are torn out and welded into a dense, finely porous seam.

The method is considered affordable and convenient, due to the almost complete absence of surface heating. No oxidation or deformation is observed during the procedure. Thus, the product receives a long service life.

Fluxes, powdered materials and cast rods

3.1 Fused fluxes

All fused fluxes developed for welding steels are also suitable for surfacing. Taking into account the specifics of surfacing - obtaining a minimum proportion of base metal in the deposited metal, special surfacing fluxes are usually pumice-like (Table 8).

Table 8. Fused fluxes for surfacing

| Stamps | Characteristic |

| AN-70 | Pumice-like low-silicon manganese-free flux for surfacing medium- and high-alloy steels has a low oxidizing ability, which causes a weak dependence of the composition of the deposited metal on the surfacing mode. AN-70 flux is “shorter” and more refractory than AN-20, so it can be used to fuse cylindrical surfaces of significantly smaller diameter than with AN-20 flux. Slag is easily separated from the surface at temperatures up to 800 °C |

| AN-28 | Pumice-like flux, low-silicon, manganese-free, intended for surfacing steel and cast iron strips |

3.2 Ceramic fluxes

Alloying of the deposited metal through ceramic fluxes is less effective than with flux-cored wire; the required quality of the deposited metal is achieved in an even smaller range of mode parameters. In addition, the content of metal components in it cannot exceed 25...30% due to arc shunting and disruption of arc discharge stability; however, in some cases this method may be more accessible to use (Table 9).

Table 9. Ceramic fluxes for surfacing

| Brand | Weld metal | Recommended wire | Operating conditions of welded parts | |

| Type | Hardness | |||

| FK-45/5Х10В5ФМ | 45Х10В5ФМ | HV 540 | Sv-20Х13 | Intensive wear at temperatures up to 600 °C (tools for hot metal forming) |

| ZhSN-5 | 20Х6МФ | HRC 36 HRC 42 HRC≥48 HRC 54 | Sv-08A Sv-08GA Sv-12GS Np-30HGSA | Intensive wear due to metal-to-metal friction, cyclic heat changes, high pressures (rolling rolls, roller conveyor rollers, brake pulleys) |

| ANK-18 | 30Х3Г1 | HV 400 HRC 50 HRC 50 | Sv-08 Sv-08A Np-30HGSA | Metal-to-metal friction (parts of road equipment, construction, agricultural and lifting machines) |

| ANK-19 | 60Х4ГС | HRC≥50 | Sv-08 A, Sv-08 | Abrasive wear (knives and road wheels of bulldozers, flat workpieces of bunkers) |

| ANK-40 | 25X1GS | HB 250 | Sv-08A, Sv-08 | Metal-on-metal friction |

Note. Fluxes FK-45/5Kh10V5VFM, ZhSN-5, ANK-40 are recommended for surfacing with direct current of reverse polarity, fluxes ANK-18, ANK-19 are recommended for surfacing with direct current of reverse polarity and alternating current.

Equipment used

Surfacing equipment operates using the same heating sources and methods as welding equipment. It differs in that it has auxiliary devices that ensure the supply and distribution of additives over the surface of the product.

For surfacing, welding devices are often used, which can be supplemented with the necessary devices and equipment. Surfacing equipment is divided according to the shape of the working surfaces: for bodies of revolution, for flat parts, for complex profiles.

The additive is applied using classical methods (for example, spraying, rods, wire) or special ones (centrifugal distribution, spiral laying, etc.).

Surfacing equipment is equipped with devices for preheating the product (from 500 to 700 degrees). The market offers small-sized units for home use that work with metals up to several millimeters thick.

Disadvantages and advantages

Among the advantages of this connection method are:

- high welding speed;

- upon completion of welding work, the seam does not require additional processing;

- ease of mastering welding techniques using this method;

- connection strength due to the use of argon as a shielding gas;

- the metal does not deform during welding , since it is heated over a minimal area;

- a large number of welded metals.

Disadvantages include:

- inconvenience of welding parts at an acute angle due to the shape of the welding torch;

- it becomes difficult to perform work in drafts or outside in windy weather , since the correct supply of protective gas to the seam formation zone is disrupted;

- metal requires careful preparation before the welding process.

Consumption of materials

To determine the cost of the finished product, it is necessary to correctly calculate the consumption of materials used in the deposition process. Calculations are carried out in accordance with the standards adopted for each type of material. The exact quantity of consumables will allow you to create stocks of materials and ensure continuity of the process.

Calculation of metal during welding is the main indicator, which is determined using a special formula. The mass is calculated from the consumption of 1 meter of weld. Use the formula:

G = F * y * L, where:

F – cross-sectional area of the weld (in mm2);

y – specific mass of metal (g/cm3);

L – the length of the weld is 1 meter.

The master will be able to independently calculate the mass of metal deposited during the welding process.

Calculation of electrodes for surfacing is a significant quantitative parameter for which no calculations are required. Each grade of materials has its own indicator for 1 kg of surfacing. It varies from 1.4 kg to 1.8 kg.

There is no need to calculate the mass of the deposited weld. According to government standards, each weld shape has an average rating. In this case, the form must be made of low-alloy or carbon steel, and also be made using the manual electric arc method.

Flux

The flux is prepared as follows: for 10 parts by weight of AN-348-A flux, take 0.5 parts of powdered graphite and 0.4 parts of powdered ferrochrome No. 6 and, after mixing them thoroughly, pour 0.5 parts of liquid glass into the mass. Graphite (EUT-1, EUB or EUN) must first be sifted through a sieve with a mesh size of 0.05-0.07 mm. Ferrochrome is sifted through a sieve with about 1000 holes per 1 cm2. Then the mass is mixed again until it is all moistened. The prepared mass is placed in an electric oven and calcined for 3-3.5 hours at 550-600°C. After cooling, the flux is thoroughly broken into powder and sifted through a sieve with 9 holes/cm2.

To the resulting mass add 10 parts of separately calcined and sifted pure flux AN-348-A and the entire mass is thoroughly mixed. In this form, the flux is used for surfacing steel parts that require high hardness of the surface layer. If class 2 spring wire is used as an electrode wire, then when surfacing parts under a flux of the specified composition, the metal hardness reaches 52-62 HRC. To ensure such hardness when surfacing with Sv-08 welding wire, the flux must have a slightly different composition: (in percent by weight) standard flux AN-348-A - 95.5; powdered graphite - 2.5; ferrochrome No. 6 powder - 2.

The prepared flux should be stored in a dry place. In case of a long break in work and the flux is moistened, it must be calcined before use.