What type of welding are they used for?

Most welding technologies are produced using this equipment. These include MMA (manual arc welding with a coated electrode), MIG (fusion gas welding), TIG (non-consumable electrode argon arc welding). The use of rectifiers makes it possible to weld not only ferrous metals, but also stainless, heat-resistant and heat-resistant high-alloy steels, cast irons, non-ferrous metals, aluminum and titanium alloys.

What electrodes are used

Welding can be done with any type of electrode:

- DC welding electrodes (for example: UONII-13/55 or UONI-13/55);

- universal electrodes (for example: ANO-4, MR-3 or OZS-12);

- special electrodes.

Device classification

There are different main types of welding rectifiers, as there are several ways to classify them.

If we consider the design of the power section, it can be divided into the following

- thyristor models;

- versions with a saturating choke;

- inverters;

- modifications regulated by a transformer;

- devices controlled by a transistor.

When selecting rectifiers, you need to focus on the upcoming welding technology. For example, if work will be carried out in a gas protective environment, submerged, models with strict external indicators are used. They assume that the voltage is adjusted by magnetic, turn, phase and pulse methods.

Classic manual arc welding technology involves the use of rectifiers with falling external indicators. They are based on increasing the resistance of transformers or on current feedback. Universal devices are also presented that combine rigid and falling external characteristics.

Other parameters that allow you to classify a device can be presented in the following list:

- Output current. The higher this indicator, the thicker the walls of the workpiece can be. Small currents are only sufficient to work with thin metal plates. High strength significantly expands the operational scope, allowing not only to weld metal, but also to cut it.

- Adjustment accuracy class. It is better for professionals to choose devices that allow extremely accurate adjustment of performance indicators.

- Number of exits. Professional models often require several outlets on the body for installing electrode holders. It turns out that several welders can use one device at the same time. This eliminates the need to purchase additional devices, but increases the dimensions.

- Cooling system efficiency. Household models are rarely equipped with an expensive and efficient cooling system, as they are aimed at short-term and not too complex work. Professional analogues operate uninterruptedly for much longer.

Watch a video review of the welding rectifier VD-201 AD AC DC:

Let's sum it up

So, we figured out what a welding rectifier is. Despite its recent appearance, it is already in high demand both among welding professionals and those who use this technology from time to time.

Expanding the functionality of the welding machine, improving the quality of the resulting seam - there are many advantages to using it, which contributes to its popularity.

The lineup

The company that produces this welding equipment offers a wide selection of devices of various modifications. The “VD” category of devices can be presented in various designs, depending on the requirements. Each new model is assigned its own article number, expressed in letter form.

1. VD-306I - inverter-type device, average cost 26,000 rubles.

The functionality of the inverter, which affects the operation of the welding arc, deserves special attention. The model is equipped with the following operating modes:

- “hot arc start”;

- "arc force";

- "anti-sticking".

Video:

2. VD-306D. These representatives of the “VD” family have found their application mainly in industrial production.

Such devices are distinguished by a high degree of reliability and unpretentiousness in difficult operating conditions. Equipped with thermal protection of the transformer and rectifier unit. Requires power supply with mains voltage 380V. The maximum output power is 25 kW. Cost - 110,000 rubles.

3. VD-306M1. Using this type of welding equipment, you can carry out work in AC or DC mode.

The maximum power of such a device is 24 kW, regardless of the welding mode. The main area of application is the industrial sector. Price - 45,000 rubles.

4. VD-306Sh. This type of rectifier can be connected to both industrial and domestic networks.

The maximum output power value is 23 kW. The average cost is 35,000 rubles.

Manufacturer companies, cost

Initially, the production of such equipment was launched at the JSC Electric Machine Building enterprise in Simferopol. Currently, the market is witnessing the emergence of an increasing number of enterprises focused on the production of devices of the “VD” series.

To answer the question: where is the VD-306 welding rectifier produced, just go to the website, which provides a list of the most common enterprises producing similar products.

The prices of the welding rectifier VD-306 today are within 30,000 rubles. The cost varies depending on the popularity of the manufacturer and component parts supplier.

PS Despite the fact that welding rectifiers VD-306 are somewhat inferior in some respects to their modern analogues, it should be noted that, other things being equal, such equipment is the best in its class in terms of price-quality ratio.

Precautionary measures

Welder protective equipment

Before operating the VD 306, you should carefully study the state standards for welding work and the use of electrical installations. This device is strictly prohibited from being used inside tunnels, wells, or metal tanks. Do not use the device without the protective casing. If the welding unit is connected to an electrical network, then it is prohibited to move it.

During operation, a person must not touch the metal elements of the unit and the electrodes. The welder should be unplugged before removing or installing the welding rod.

Cleaning the seams should be done after the metal has completely cooled. This work must be performed with special glasses. The welding itself must be carried out using a special mask, which protects the welder’s face from molten metal particles.

Video on the topic: Repair of welding machine VD 306

Publications on the topic

How to independently repair inverter-type welding machines

The procedure for making a semi-automatic welding machine with your own hands

The process of making a spotter with your own hands from a welding machine

Welding safety

When using the device, observe the following rules:

- Before starting welding, study the requirements of GOST and SNiP regarding the work process.

- Employees who do not have a certificate are not allowed to use the device.

- Do not operate the rectifier in tunnels, collectors, unventilated or gas-filled areas.

- Remove the protective casing only after disconnecting from the electrical network. Operating an open unit greatly increases the risk of electric shock.

- Do not move equipment connected to the network.

- When replacing the electrode, the power cable is disconnected from the outlet.

- During work, use protective equipment - work suit, gloves, welding mask.

Malfunctions and their solutions

The rectifier is equipped with high voltage windings, which are considered the weak point of any welding equipment. If used incorrectly, they burn out completely or partially. In such cases, replacement or rewinding is required. Malfunctions also affect the control board.

The following components are especially likely to fail:

- rectifier bridge diodes;

- paths;

- control unit transformers.

First of all, check the diode bridge. The component is quite reliable, but if used incorrectly, it fails. If the tracks burn out, the board will have to be replaced; repair in this case is impossible. This method is not considered the best solution; new electronic components are expensive.

Therefore, they try to restore the existing block:

- use a universal tester to call device components, the failure of which could render the device inoperable;

- replace failed parts;

- they launch the device and test it.

Design and principle of operation

The general view of the rectifier and its overall dimensions are shown in the figure.

Designations

- “1” – overload sensor indicator;

- “2” – network power indicator;

- “3” – socket for connecting heating, when working with protective gas;

- “4” – socket for connecting the control unit of the semi-automatic device;

- “5” – place for installing the control unit of the semi-automatic device;

- “6” – Control unit of the device;

- “7” – button to enable/disable remote control;

- “8” – current indicator;

- “9” – voltage indicator;

- “10” – selection of external characteristics “hard/falling”;

- “11” – welding mode switch;

- “12” – regulator of output parameters;

- “13” – button to turn on the cooling system fan;

- “14” – button to turn off the cooling system fan;

- “15” – connection point for welding cables;

- “16” – connection point for grounding cables;

- “17” – toggle switch of the automatic switch;

- “18” – area for connecting network cables;

- “19” – handle for moving on the production site.

The electrical circuit diagram looks like this:

By its design, the VDU 506 welding machine is a step-down transformer with a semiconductor block that rectifies the incoming current. During operation, the diodes of the unit are subjected to heavy load, which causes an increase in temperature.

To remove heat, the devices have a cooling system, which consists of radiators and a fan. The rectifier benefits from smooth adjustment of the welding current. If necessary, it is possible to supply a special remote control for remote adjustment of the welding process.

The factory set of supplied equipment includes:

- Straightener with handle and wheels for transportation.

- Set of current inserts.

- Passport with instructions from the manufacturer.

How to make a straightener?

If you have minimal technical knowledge, making a welding rectifier with your own hands is not difficult. We first select a ready-made transformer with a step-down effect of the required range. Most often this is very difficult to do, and you have to wind it yourself. Detailed instructions for assembling the rectifier.

Welding rectifier circuit

We propose to make the simplest homemade welding diode rectifier. It must be assembled using a bridge circuit and mounted on a radiator so that the device is cooled all the time. The fact is that powerful diode lamps (VD type). To ensure a falling or hard characteristic, it is necessary to include a special inductor in the circuit. Next, a rheostat is attached to ensure smooth adjustment of the operation of the rectifier.

The electrical circuit of the rheostat is quite simple, you can wind it around the core with your own hands, you only need a simple copper or aluminum wire. But before work, you need to calculate the required resistance: the voltage adjustment depends on the diameters of the turns.

To make the task easier, you will definitely need not only a detailed instruction manual, but also a circuit diagram.

Areas of use

The significant weight makes the device an unacceptable option for home work, despite the simplicity and reliability of the design. Welding inverters will cope much better with simple tasks in a summer cottage or garage. In addition, the cost of the rectifier is quite high for the average user.

Therefore, these devices are successfully used at various industrial enterprises that require the connection of thick-sheet products with deep welding of the seam. As practice shows, subject to timely maintenance and compliance with safety requirements, the device can operate for 20 years or more.

Features of use

The rectifier is formed by several blocks, the operation of which converts the incoming voltage to increase the current.

The main task of the module is to generate high-power direct current, which provides the following operational capabilities:

- Welding with any electrodes, regardless of the type of coating. The presence of the coating contributes to stable burning of the arc, the metal does not spatter, the seam is more even and durable, requiring minimal modification.

- Expanding the capabilities of the welding machine. Adjusting the current allows you to work effectively with parts with a wall thickness of 5 centimeters and with millimeter plates. Also, the device can be used not directly for welding, but for melting an edge in order to adjust its geometry.

- It becomes possible to use non-consumable electrodes (for example, tungsten-based), which require the additional use of filler wire.

- The arc welding rectifier expands the list of materials with which effective work can be carried out. It is possible to weld parts made of stainless steel, cast iron, steel with low carbon content and other “complex” alloys.

- The device helps not only to cook, but also to cut metal. To do this, the maximum current values are set, forming a very powerful arc that cuts through the material.

Some experts may note that to carry out the specified range of work, you can use a conventional transformer, but practice shows that a rectifier is much more technologically advanced and convenient, in addition, it helps reduce the overall consumption of electrodes.

Interesting video, converting the AC welding machine WELDER 160C to direct current:

General information

This device is characterized by a variety of work performed. Depending on the type of design, the rectifier can be used in the following types of welding work:

- Electric arc welding. Coated electrodes are used as filler material.

- Work in a protective gas environment. In this case, the equipment is equipped with a feeding mechanism of the PDGO-510 type.

- Submerged arc welding. For operation in semi-automatic mode. In these works, the filler material is flux-cored wire.

- Work as a manipulator. Some models are equipped with a rectifier as a current source.

Common options for rectifier devices

Among the models of rectifier devices for welding on the market, the VDM 1202C device can be distinguished - it has a high current-voltage property. 1202C is used for arc welding in the construction and energy sectors.

In the welding process using device 1202, any type of electrode can be used, both DC products and universal or special ones.

According to experts, the VDM 1202 device is considered reliable, high-quality and durable.

A feature of rectifiers with doubling voltage power is the ability of capacitors to accumulate and save electricity.

At the moment, the price of a rectifier for welding 1202 is about $1000.

Rectifier devices VDU 506C are intended for the assembly of arc welding units and semi-automatic devices, for arc welding carried out by hand using coated electrodes.

VDU 506S, assembled with a semi-automatic device, is used during semi-automatic welding using consumable wire in a shielding gas environment. VDU 506S is an analogue of devices of the VDU 506 type, their production was carried out in Lithuania and in Russia.

Unlike model 506, version 506C has a light weight of 250g and smaller dimensions - 740x600x920.

In turn, the VDU 506 rectifier is capable of welding with simple electrodes, working in a protective gas environment, and welding with powder material.

And also the ability to cut molten metal with your own hands.

The welding rectifier VD 301 UZ is used to maintain the electric arc during do-it-yourself arc welding, for cutting and welding metal products.

Russian production has provided the VD 301 UZ model with effective operating properties; the VD 301 UZ can be used in various climatic conditions.

The version of the rectifying device for welding VD 306 C1 is designed for manual welding using direct current for welding various types of steels, including corrosion-resistant ones.

The material used for the transformer winding is copper. The VD 306 C1 is operated from 380V, at the moment the price for the rectifier device 306 reaches $300.

VD 313 UZ is used for manual welding of steel products using coated electrodes. The VD 313 rectifier has a simple but reliable design. In terms of mobility, the 313 model competes with the VD 306.

The welding rectifier VD 313 UZ is equipped with a shunt control device, due to which the period of change in the welding mode is reduced.

The classic rectifier VD 401 is indispensable for supplying direct current to a welding electric arc, for welding and cutting metals, and is also used for manual welding.

The rectifier model for welding VD 401 is powered by a 3-phase network. The design consists of a power type transformer, an equalizing block, a magnetic shunt, a cooling system, an auto switch and a housing.

The 401 welding rectifier is intended for use in enclosed but naturally ventilated spaces. The use of VD 401 in hazardous areas is prohibited.

The VD-16-Ch rectifier is used for manual electric arc welding on direct current. VD-16-Ch has a protective sensor against overload, and VD-16 can be used at temperatures from -10 to +40ºС.

The operation of the VD-16 under the influence of prolonged vibrations, rain and snow is prohibited; it is also prohibited to operate the VD-16 in a chemical environment.

An AC rectifier, single-phase or three-phase, is the most unpretentious, cheap and reliable device for welding a variety of metal structures. It works great outdoors in very low and high temperatures and in unstable input voltage conditions. The main disadvantage is the large weight of the welding rectifier, which is due to its design. But homemade devices flawlessly perform their functions, and factory models continue to perform their difficult service without fail. We will talk about them thoughtfully and in detail.

Technical characteristics of welding rectifier VDU-506

Welding rectifier VDU-506 is a universal rectifier with thyristor control. Its versatility is manifested in its ability to provide:

- welding with coated electrodes;

- welding in shielding gases;

- flux cored wire welding;

- submerged arc welding;

- air arc cutting.

The rectifier is designed both for completing manual arc welding stations with piece metal electrodes, and for equipping semi-automatic machines of the PDG type for mechanized welding in a shielded gas environment of products made of low-carbon, low-alloy, carbon and corrosion-resistant steels on direct current. The straightener is adjustable and has a hard and falling external characteristic.

The rectifier is connected to a three-phase 380 V network and consumes 62 A from it at full load. The range of welding currents and operating voltages is quite wide: 50–500 A, 18–50 V.

| supply voltage, V | 3x380; 3x220 |

| rated welding current, A | 500 (PN=60%); 390 (MON=100%) |

| limits of welding current regulation, A | |

| for tough specifications | 60–500 |

| for falling characteristics | 50–500 |

| operating voltage regulation limits, V | |

| for tough specifications | 18–50 |

| for falling characteristics | 22–46 |

| open circuit voltage, V, no more | 85 |

| rated power, kVA, no more | 40 |

| welding cycle duration, min | 10 |

| overall dimensions, mm (LxBxH) | 820x620x1100 |

| weight, kg | 300 |

Expert comment:

By purchasing VDU-506, you receive:

- DC arc welding Welding from a rectifier is stable and stable, the technological effect in terms of the quality of seam formation and low spatter corresponds to the best samples. The rectifier ensures easy ignition and stable arcing at any current within the control range. The rectifier can work according to a given program with a manipulator or as part of a robotic complex. For this purpose, there is a special connector through which a standard signal (0–10 V) is supplied.

- Ease of use Smooth regulation of welding current (at falling) and voltage (at rigid external characteristics) is carried out by a resistor on the control unit (local regulation), as well as from a semi-automatic device or automatic device (remote regulation). The rectifier is equipped with a remote control for remote activation and regulation of welding current.

- To move within the welding area, the rectifier is mounted on a four-wheeled trolley with two handles. There are special handles with holes for lifting the rectifier.

- Transformer Features:

- designed for operation at ambient temperatures from –10 °C to +40 °C;

- versatility;

- ease of use;

- high arc stability;

- smooth regulation of welding current and voltage over the entire range without switching for each type of external characteristics;

- high technological properties;

- reliability and trouble-free operation.

Attention! The power source can be supplied at the consumer's request for a voltage of 220 or 380 V. At the user's request, the rectifier is equipped with a semi-automatic welding machine or automatic machine.. et.ua

et.ua

Advantages and disadvantages

Modern welding machines are distinguished by good functionality and high power in a modest size. The most compact models are inverter. Experts place them in a separate group. The transformer in such devices occupies no more than a fifth of the total volume.

The main difference between other rectifiers and transformers is that they can generate direct current, while this function is not available for transformers. It is this feature that is the foundation of a large list of advantages of devices with rectifiers:

- the electrode heats up much faster when direct current is applied to it instead of alternating current;

- Unproductive electricity consumption is significantly reduced and, accordingly, the efficiency value increases;

- the arc is characterized by combustion stability;

- uniform melting of consumables is accompanied by a minimum amount of melt splashes. This reduces the likelihood of injury among welders;

- arc stability makes it possible to better control the seam. It turns out to be as smooth and durable as possible;

- The functionality of a welding machine with a rectifier is richer than that of an analogue with a transformer;

- consumption of filler material is reduced. The savings become more noticeable the larger the amount of work performed.

In addition to the advantages, rectifiers also have disadvantages:

- it was not possible to completely eliminate power loss;

- devices with rectifiers perform worse than transformer ones in the event of a drop in network voltage;

- very sensitive to short circuits in the power supply network. They fail at the slightest short circuit in the wiring;

- Most models are not recommended for use in conditions of increased dust or humidity.

Preparation for use and welding

Before you start welding metal, you need to prepare the device for work. To do this, you should perform a number of actions, such as:

Front panel of welding rectifier VD-306

- Remove dust particles from the housing and live parts. You can do this with compressed air;

- Connect the cables to the appropriate connectors;

- Connect the grounding cable;

- Connect the power cord to a three-phase network.

After turning on the unit, it is necessary to determine whether the forced cooling fan is rotating. If there is no rotation, you must turn off the device.

Immediately before starting welding, you should configure the rectifier VD 306. The current strength is regulated by the control handle. The installation should be adjusted based on the thickness of the metal workpieces and the diameter of the welding rods. During the working process, the current strength can be controlled thanks to the built-in ammeter.

Sequencing

When the necessary tools and materials are prepared, you can begin to manufacture the throttle for welding. The algorithm of actions is as follows:

- disassemble the transformer, clean the coils from traces of old windings;

- make gaskets from fiberglass, cardboard impregnated with bakelite varnish, or other suitable dielectrics, which will subsequently play the role of an inductive (air) gap. They can simply be glued to the corresponding surfaces of the coils. The thickness of the gasket should be 0.8-1.0 mm;

- wind a thick copper or aluminum wire onto each coil. You should focus on a round wire made of aluminum with a cross-section of 36 mm or copper with a similar ohmic resistance. Each “horseshoe” is covered with 3 layers of 24 turns each;

- lay a dielectric material between the layers - fiberglass, cardboard impregnated with bakelite varnish or another dielectric. The gaskets must be reliable, since a choke of this design is prone to self-breakdown between windings. If the resistance between the windings is lower than the air resistance between the electrode and the additive, then a breakdown will occur between the windings, and the welding device will be irreversibly damaged.

Winding must be done evenly, without overlaps, strictly in the same direction, so that the “bridge” between the coils is on one side of the future inductor, and the input and output contacts are on the other.

In case of an error, the jumper can be installed askew

It is important that its installation turns coils with different winding directions into coils with the same direction in fact

Malfunctions and their solutions

The rectifier is equipped with high voltage windings, which are considered the weak point of any welding equipment. If used incorrectly, they burn out completely or partially. In such cases, replacement or rewinding is required. Malfunctions also affect the control board.

The following components are especially likely to fail:

- rectifier bridge diodes;

- paths;

- control unit transformers.

First of all, check the diode bridge. The component is quite reliable, but if used incorrectly, it fails. If the tracks burn out, the board will have to be replaced; repair in this case is impossible. This method is not considered the best solution; new electronic components are expensive.

We recommend reading Types of welding machines

Therefore, they try to restore the existing block:

- use a universal tester to call device components, the failure of which could render the device inoperable;

- replace failed parts;

- they launch the device and test it.

Welding rectifier: operating principle and characteristics

The principle of operation of the welding transformer is that it operates on alternating current 220/380 V with a reduction in voltage in the secondary winding, and the rectifier device implies the presence of a powerful diode bridge after the secondary, step-down winding of the transformer. This design solution provides advantages when adjusting the welding current and can be organized according to the following schemes:

- single-phase rectification, more suitable for domestic conditions and is relatively simple;

- three-phase rectification makes it possible to reduce ripple in the primary and secondary windings;

- rectification circuit using a six-phase system, allowing you to organize a multi-station welding station.

In addition, the arc welding rectifier, which allows achieving stable melting of the coated electrode and the workpieces being connected, may differ in the methods of regulating the output characteristics, namely:

- transformer regulation is achieved by changing the winding connection diagram;

- adjustment of characteristics using a throttle and a powerful rheostat;

- thyristor or transistor regulation with a ring, three-phase or six-phase rectification circuit.

Using the product brand and instruction manual, you can determine the current-voltage characteristics of a particular product, which can be incident, flat and rigid, or combined. For example, the VD 306 rectifier is designed as a device with a falling characteristic, and the devices of the VDG and BC series have a rigid characteristic and are designed for welding in shielding gas with consumable electrodes.

Thus, the VSVU-160 rectifier is designed for welding with non-consumable electrodes, therefore, before purchasing the unit, you must first familiarize yourself with the instructions and technical characteristics of the model. At the same time, the VSVU has all the properties of a universal device.

Classification and labeling

All versions of welding rectifiers are divided according to the following parameters:

- According to the phase of the current used: single or three phase. The former are compact, but do not allow smoothing out significant voltage ripples and obtaining significant processing currents at the output, therefore they are used mainly for welding machines for household use.

- According to the method of controlling the strength of the welding current.

- According to the type of current-voltage characteristic.

- According to the current rectification circuit. It can be single-phase (used in low-power devices), three-phase or six-phase (the latter is used in high-power units exceeding 1000 kVA). In turn, three-phase rectification can be implemented using bridge or ring circuits.

- Depending on the number of posts served - single-post or multi-post.

The marking of welding rectifiers is regulated by the requirements of GOST 13821-77 (for single-station units) and GOST 18142-85 (for semiconductor units). It includes the letters VD (arc rectifier), the third letter U (universal), or M - multi-station. This is followed by the value of the welding current in amperes multiplied by 10, and (optionally) the series number. Thus, for example, the universal welding rectifier type VDU-504 is designed to produce direct current up to 500 A.

GOST 13821-77 establishes the following relationships between the energy characteristics of a welding rectifier and the duration of its continuous operation. In particular, in the range of welding currents 400...630 A, the minimum operating voltage cannot be less than 24...25 V, and duty cycle - more than 60%. At currents of 800 A or more, the minimum voltage is 26...34 V, and duty cycle can reach 100%.

Advantages and disadvantages

Modern welding machines are distinguished by good functionality and high power in a modest size. The most compact models are inverter. Experts place them in a separate group. The transformer in such devices occupies no more than a fifth of the total volume.

The main difference between other rectifiers and transformers is that they can generate direct current, while this function is not available for transformers. It is this feature that is the foundation of a large list of advantages of devices with rectifiers:

- the electrode heats up much faster when direct current is applied to it instead of alternating current;

- Unproductive electricity consumption is significantly reduced and, accordingly, the efficiency value increases;

- the arc is characterized by combustion stability;

- uniform melting of consumables is accompanied by a minimum amount of melt splashes. This reduces the likelihood of injury among welders;

- arc stability makes it possible to better control the seam. It turns out to be as smooth and durable as possible;

- The functionality of a welding machine with a rectifier is richer than that of an analogue with a transformer;

- consumption of filler material is reduced. The savings become more noticeable the larger the amount of work performed.

In addition to the advantages, rectifiers also have disadvantages:

- it was not possible to completely eliminate power loss;

- devices with rectifiers perform worse than transformer ones in the event of a drop in network voltage;

- very sensitive to short circuits in the power supply network. They fail at the slightest short circuit in the wiring;

- Most models are not recommended for use in conditions of increased dust or humidity.

How does a welding rectifier work and on what principle does it function?

The welding rectifier is designed from several blocks, inside of which the incoming voltage is reduced and converted while simultaneously increasing the value of A. The design of the welding rectifier allows you to understand the basic principles of its operation.

The design of the unit consists of the following elements:

- three-phase transformer that reduces the incoming voltage;

- diodes that pass current in one direction, as opposed to conductors of electric current, which can conduct current equally well in both directions;

- radiators and fan for cooling the structure;

- ammeter;

- voltmeter;

- current regulators.

Since the diodes heat up during operation of the unit, they require a high-quality cooling system. For this reason, cooling modules are located next to them, providing the structure with constant flow of cold air.

This eliminates the risk of overheating the diodes, increases the operating time of the rectifier and eliminates the need for interruptions in its operation.

Such units can have different characteristics and are designed for welding workpieces made of steel and non-ferrous alloys. But all types of such equipment operate on the same principle.

Diagram of a rectifier with a transformer with increased dissipation.

The welding rectifier circuit looks like this:

- alternating or mains current is supplied to the primary winding of the step-down transformer, which leads to a decrease in its standard value;

- a voltage flow with a reduced value of V and an increased current A appears on the secondary winding due to electromagnetic induction;

- the voltage is supplied to silicon diode elements, which ensure the passage of current in one direction and its stabilization;

- fluctuations in the frequency of the current are eliminated, after which a constant voltage is supplied to the area where the parts are connected.

Any DC welding machine operates according to a similar scheme, providing the welder with ample opportunities in his work.

After all, rectifiers for welding work allow welding and cutting with a stable arc to produce higher-quality seams on various metal structures by converting the current from the transformer into direct voltage inside the unit.

During operation, consumables do not splash, so significant savings occur.

Important! The voltage during operation of welded rectifiers at idle speed should not exceed a level of 48V

Types of rectifiers

There are several types of rectifiers:

- welding thyristor rectifier VD 313 SE, VD 306;

- inverter power rectifier (welding);

- throttle;

- transistor (station wagon).

What is the difference between these devices?

Thyristor power supplies are suitable for various types of arc welding electrodes and can be used for welding work on rods.

Advantages:

- Higher efficiency compared to conventional rectifiers.

- Excellent arc characteristics, much smaller spark.

- Single row current control

- Easy to implement remote control function

- Good strength against voltage fluctuations

- Suitable for outdoor use.

- This is a multi-station welding rectifier - vdm - 1201, 2x313, vdm-1202 s, 1001, selma, BC ma, 6303 s.

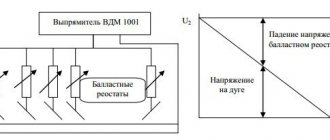

The throttle rectifier is designed for welding in the most severe operating conditions (quarries, mines, pipelines, etc.). It provides semi-automatic welding and surfacing for currents up to 650A. In semi-automatic welding, the operating voltage is adjusted in steps. The single-station welding rectifier is represented by VDU 505, 504, VDU 506, DUGA professional and DUGA industrial.

Circuit: Throttle rectifier

In addition to the main choke, the welding arc power supply system has another one built into the parametric section, which can significantly improve the quality of the weld due to the stabilization of welding. As a rule, in addition to the main power winding, an auxiliary winding is also used, which serves to regulate the inductance of the inductor and, thereby, controls the peak point during a short circuit or voltage surges.

The inverter rectifier is used to convert incoming alternating current into direct current, represented by models esab, man,. This current switches on and off very quickly, creating a pulsed, high-frequency DC current. Typical frequencies range from 10,000 to 20,000 Hz, but data up to 100,000 Hz is possible. The inverter, like the entire welding rectifier, needs to be checked every six months. The welding inverter rectifier is represented by the models electron 125, sun 600, 318m1, arc, neon (naks), afterburner, power, paton, terminator and anode (USSR).

Video of economical operation of a welding rectifier

Transistorized welding power sources have been developed for precise control of welding parameters. The speed of operation and response of transistors is very fast, hence such power sources can be adjusted to give any desired I-V reading between direct current and constant type voltage. In addition, the control system can be programmed to set the variable current and voltage during the actual welding operation. These technical features make the universal transistor welding rectifier particularly attractive for welding pipes, ventilation passages and shafts. Welding can be carried out using free-standing electrodes.

Almost every master has gasoline welding rectifiers (Esva, Loris). These are quite convenient portable devices, with which it is convenient to carry out work on the road or in the open air. There are very good reviews about the fubag welding rectifier, and its characteristics indicate that the device is also suitable for use in a local power supply network. In addition, these devices are often equipped with a portable charger.

If we distribute rectifiers by area of application, we get the following table:

| Application area | Rectifier name |

| For surfacing metal under a flux layer | vdu |

| For simultaneous power supply of several welding stations | VKSM |

| Used to power the welding machine when working with structural and alloy steels. Widely used in public utilities, everyday life, small workshops and workshops. | VDMSH |

| In cold car engines, an arc frequency universal device is often used. | VDUCH and VDC |

Maintenance and basic faults

New converters must be purged before being connected to the network. It is better to do this with a household hairdryer on medium heat setting. It is necessary to eliminate accumulated dust and possible moisture; it reduces the resistance of the copper windings of the built-in transformer. The purging is repeated once a quarter.

After long-term storage (up to a year) of the converter, before use it is useful to “pump” the semiconductors - let the rectifier operate in different modes, starting with the minimum. After a two-hour “break-in” the device will work stably and will not fail during welding

It is important to ensure that the fan is working properly; the equipment should not overheat

Possible malfunctions of the welding rectifier and methods for eliminating them:

The device does not turn on when connected to the network. Is it possible:

- if the core of the power conductor is broken, the contacts in the plug rattle - check the cable, change the plug;

- there is no voltage in the network - you need to check the input switch;

- one of the nodes has failed - it’s time to take the converter to a service center or repair the devices yourself;

- The life of the semiconductor elements has been exhausted - the circuit needs to be re-soldered.

The melting electrode sticks, and the converter hums - you need to:

- check the serviceability of the semiconductors and capacitor;

- make sure that there is no sag in the power supply network;

- check the integrity of the inductor winding.

The converter turns off spontaneously during operation - this happens:

- if overheating, check the serviceability of the fan or cooling system;

- break through the winding of the built-in transformer - remove the old one and make a new one.

The device stops providing power to the required parameters - you need to touch the case, how hot it is, check the air supply to the fan, and give the generator a rest.

The no-load and operating current voltage jumps - check:

- regulator knob;

- primary winding fuses;

- the tightness of the terminal contacts at the starter.

Converter circuits are specified in the operating instructions. Repairing devices requires electrical knowledge and soldering skills. It is better to take the device to a service center. They will accurately determine the cause of the breakdown and eliminate it.

Instructions for Welding Machine ETA VD-306B - free instructions in Russian, forum

If the instructions are not complete or you need additional information on this device, if you need additional files: drivers, additional user manual (manufacturers often make several different technical help documents and manuals for each product), the latest firmware version, then you can administrators or to all users of the site, everyone will try to quickly respond to your request and help as quickly as possible.

Your device has the following characteristics: Device type: welding rectifier, Welding types: manual arc welding (MMA), Welding current (MMA): 60-300 A, Number of power phases: 3, Type of output current: constant, Power: 21 kV?A , see the next tab for full specifications.

| ETA_VD-306B_0.pdf | User guide |

| ETA_VD-306B_1.pdf | Download certificate of conformity |

| Download Report broken link |

Useful files and software

For many products, various additional files may be needed to work with ETA VD-306B: drivers, patches, updates, installation programs. You can download these files online for a specific model ETA VD-306B or add your own for free downloading by other visitors.

| No files found |

Instructions for similar welding machines

If you have not found files and documents for this model, you can look at the instructions for similar products and models, as they often differ in slight changes and are complementary.

Reviews about ETA VD-306B

Be sure to write a few words about the product you purchased so that everyone can read your review or question. Be active so that as many people as possible can find out the opinions of real people who have already used ETA VD-306B.

Characteristics of ETA VD-306B

Text describing the characteristics of the device.

| Main characteristics | |

| Device type | welding rectifier |

| Welding types | manual arc welding (MMA) |

| Welding current (MMA) | 60-300 A |

| Number of power phases | 3 |

| Output current type | constant |

| Power | 21 kV?A |

| Electrode diameter | 2-5 mm |

| additional characteristics | |

| Dimensions, LxWxH | 690x360x640 mm |

| Weight | 86 kg |

Breakdowns of welding machines

Here is a list of the most frequent and common breakdowns and malfunctions of Welding machines. If you have such a breakdown, then you are lucky, this is a typical malfunction for ETA VD-306B and you can find out how to fix it and they will quickly answer you, or read the questions and answers below.

Name of the breakdown Description of the breakdown Action

| Spontaneous shutdown of the welding machine | |

| Transformer humming loudly | |

| Excessive heating of the welding machine | |

| Low welding current | |

| Poor adjustment of welding current | |

| Sudden breakage of the welding arc and inability to ignite it again | |

| High current consumption from the network when there is no load | |

| The car radio won't turn on at all | |

| A9 (not AL9, namely A9) | Error code A9 lights up and that’s it. The device is not working. |

| no arc current adjustment | The arc current setting display has zeros and does not respond to rotation of the current setting adjustment potentiometer. |

| Transistor RJH60F7 burned out | |

| Lack of primary impulse | |

| FUBAG TS-MIG 190 | smoke came from the main transformer |

| craton wt 180 | switch is faulty |

| Transistor burnt out, unclear marking 1D22AY first line and third 90C please tell me the full marking | Turned it on and the device fired |

| doesn't work like a semi-automatic | the solenoid valve fails for the second time |

| No arc | We turn on everything, it works, no Adyghe |

| No current at the output terminals of the starting charger | |

| FGH60N60SMD transistors burned out | |

| TIG mode does not work | |

| no voltage at output | the fan is running |

| no gas supply to the welding zone | The control for turning on the gas supply valve does not work |

| fan doesn't turn on | |

| All wires were disconnected from the board | Now we don’t know where to go |

If not a single breakdown from the list above fits the description for your case, then you can add your own breakdown and technicians from service centers or simply website visitors will be able to advise you. It's free!

Services specializing in the repair of Welding machines

Our database currently contains 18,353 services registered in 513 cities in Russia, Belarus, Kazakhstan and Ukraine.

Services selected by users

Source: https://infotehnic.ru/product/570203

terms of Use

According to the instructions, operation of the welding rectifier is possible only if the following conditions are met:

- The work is carried out in enclosed spaces with a functioning ventilation system. Work outdoors is permitted only in normal weather conditions.

- The level of dust in the working area should not exceed the maximum permissible concentration adopted for industrial premises.

- The temperature range is from -10 to +40 Cº.

- The working area is located at an altitude of up to 1000 meters above sea level.

- The humidity level of the production area should not exceed 80%.

During operation, the device should not be subjected to external mechanical influences.

Peculiarities

There is a myth that a welding rectifier cannot be used indoors. But this does not apply to the VDU 506 model. It feels great in the presence of natural ventilation (cracks, open windows, etc.). And even more: this device is capable of operating at very low temperatures down to -40 degrees.

However, this rectifier is not intended for welding in explosive atmospheres. The released vapors and gases can damage the welding machine or completely destroy it.

We are accustomed to thinking that a transformer and rectifier are difficult-to-use devices. This is largely true. But the VDU 506 model does not have many disadvantages. The arc ignites easily and burns stably, provided that you have provided sufficient voltage in the network to power the device. All this is possible thanks to improved characteristics. We can say that VDU 506 is a significantly modified version of the classic rectifier.

Basic malfunctions and maintenance of welding machines

Before connecting to the network for the first time, new converters must be purged. An ordinary household hair dryer is suitable for these purposes. It is turned on at maximum speed at an average warm-up level. This is done in order to dry any possible accumulation of moisture inside and remove dust that reduces the resistance of the copper winding. Blowing should be repeated approximately once a quarter.

If there was a long break in the operation of the equipment (up to 1 year), then before turning it on you need to “pump” the semiconductors. The essence of the procedure is to let the rectifier operate in different modes, starting with idle. This “break-in” lasts approximately two hours. After this, the welding machine will work flawlessly and stably under different conditions. It is necessary to monitor the condition of the main components and prevent the equipment from overheating.

The most common malfunctions of welding equipment and ways to eliminate them:

- The equipment does not work when connected to the power supply. Possible reasons:

- fracture of the supply wiring strand. In this case, the contacts in the plug “dangle”. The plug needs to be replaced;

- no voltage in the network. You should check the switch at the entrance and make sure it is turned on;

- One of the system nodes has failed. It will be very difficult to repair it yourself without proper training. It is better to take the device to a workshop;

- The semiconductor resource has been exhausted. The circuit needs to be re-soldered.

- The electrodes stick and at this moment the hum of the converter is heard. What you can do:

- check the serviceability of the capacitor and semiconductors;

- measure the performance of the power supply network and make sure that the voltage corresponds to the nominal value;

- make sure the throttle wiring is intact.

- During operation, the inverter switches off unexpectedly. This may happen:

- in case of overheating. You should make sure that the cooling system and fan are in good working order;

- if the integrity of the winding of the built-in transformer is damaged. You need to replace the old one with a new one.

- The voltage is unstable when operating under load or at idle speed. You should check:

- regulator knob;

- fuse installed on the primary winding;

- reliability of starter terminal contacts.

If the welding machine no longer maintains the required operating parameters, overheating may be the likely cause. To verify this, just touch the body. If it is hot, then you need to give the generator a break and check how freely air flows to the fan.

Design features and operating principle

Three-phase step-down transformer provides falling external characteristic

The rectifier consists of units and parts:

- frame;

- control Panel;

- winding;

- rectifier;

- stabilizer;

- circuit breakers;

- fan.

The cooling system is forced, the fan turns on automatically along with the equipment. On the body of the device there are:

- push-button switch;

- control panel with digital display and adjustment knobs;

- ammeter;

- network connector;

- welding cable connectors;

- warning lamp;

- ground bolt.

Rotating handles allow you to smoothly adjust the current strength and other parameters. In case of overheating, the rectifier automatically switches off.

Contents of delivery

The VD series welding rectifier is supplied complete with:

- current converter;

- passport;

- power cable.

The new device is packaged in cardboard boxes. They indicate the model and technical characteristics of the rectifier. Additionally, holders for coated and non-consumable electrodes may be included.

Varieties

Comparative characteristics of the welding machine VD 306 in various design changes.

| Options | VD-306B | VD-306M UZ | VD-306 UZ |

| Dimensions, mm | 690×360×640 | 1 040×360×315 | 660×565×510 |

| Weight, kg | 87 | 65 | 104 |

| Rated current, A | 300 | 315 | 315 |

| Operating mode, % | 25 | 55 | 65 |

| Current regulation limits, A | from 25 | from 30 | from 30 |

| No-load current, A | 70 | 75 | 80 |

All rectifiers listed in the table have the same indicators:

- 3 phases;

- industrial voltage 380 V;

- working – 32 V;

- smooth adjustment.

The digital display and stepless control allow you to precisely adjust the equipment to the required mode.

Unacceptable operating conditions

Considering the design of the device, the welding transformer VD 306 is prohibited from operating in rooms where the atmosphere contains:

- dust;

- vapors of caustic substances;

- fire hazardous atmosphere;

- substances that destroy insulating materials.

Important! Working in conditions harmful to the machine leads to the destruction of the equipment and endangers the health of the welder.

For modifications

- transformer;

- rectifier;

- magnetic shunt;

- emergency shutdown system;

- fan;

- casing

The VD-306 rectifier feeds the electric arc and operates with a direct current output. Performs surfacing and welding. Connects to industrial current 380V.

Operating parameters of VD-306:

- current 315 A;

- mode 60%;

- voltage from 32 V;

- welding current limits 30 – 315 A;

- the adjustment is smooth.

The rectifier is packaged together with a 3 m cable and a passport in the usual version and with ultrasonic climate protection. Protection degree IP22. The ground clamp is located on the base of the chassis.

The presence of a welding choke in the design of the rectifier makes it possible to weld high-alloy steels with a non-consumable electrode in an argon environment with or without the use of filler wire.

Setting modes and circuit

Opening and closing the magnetic shunt changes the inductive leakage. The shift is made by rotating the handle on the top of the body. The current value required for operation is set depending on the electrodes used and the type of metal being welded.

Current is supplied to the primary winding, then the inductor forms a saturated electromagnetic field. It creates an excitation current, which stabilizes and passes through the rectifier to the holder, forming an arc.

Another rectification circuit is also used, using diodes or thyristors in continuously variable welding machines

Welding rectifier VD 306 C1

The welding machine VD 306 C1 is designed to supply a welding arc with direct current for manual arc welding, surfacing and cutting of metals when powered from a three-phase alternating current network. Welding is carried out in open areas or indoor areas equipped for welding. It consists of a step-down welding transformer with a movable primary winding, a silicon rectifier unit with a fan, starting and protective equipment. Welding rectifier VD-306 S1 (380 V) is recommended for use in industrial enterprises.

| Features and advantages of VD-306 SELMA |

- All components of the rectifier are mounted on the trolley frame and protected by a sheet metal casing.

- The voltage required for the welding process, the falling external characteristic of the rectifier and the regulation of the welding current are provided by a three-phase transformer with increased magnetic dissipation.

- The rectifier has two ranges of regulation of welding currents.

- Within each range, smooth regulation of the welding current is carried out by changing the distance between the windings of the welding transformer.

- The external characteristics of the rectifier have a steeply falling working part with small multiples of the short circuit current (1.2-1.4) from the welding current at the rated operating voltage.

| Technical characteristics of VD-306 S1 |

| Supply voltage | 3x380 V |

| Rated network frequency | 50 Hz |

| Rated welding current | 315 A |

| Welding current adjustment range | 45-315 A |

| Duration of load | 60 % |

| Rated operating voltage | 22-36 V |

| Open circuit voltage | 71 V |

| Welding current control method | stepped, smooth |

| Power consumption | 24 kVA |

| Transformer windings | AL |

| Number of posts | 1 |

| dimensions | 610x710x640 mm |

| Weight | 127 kg |

| Design features of VD-306 S1 |

- A lead screw guide is passed through the upper yoke of the transformer.

- When the screw rotates, the primary winding moves and thereby changes its distance from the secondary winding.

- The conversion of alternating current into direct (welding) 1.A is carried out using a rectifier unit consisting of 6 diodes assembled using a three-phase bridge rectification circuit.

- Cooling of the welding rectifier is air, forced.

- To connect the rectifier to the power supply network, there is a plug connector on the front grille of the housing; for connecting the welding cable, there are also two power connector sockets, marked with “+” and “-” signs.

- On the front panel of the case there is a welding current range switch, control devices and control buttons.

| WE DELIVERY CONVENIENTLY Free delivery to the transport company | FAIR TRADE 100% guaranteed exchange of goods and money back | WE DO NOT Abandon OUR OWN We conscientiously carry out service and maintenance according to regulations | LOW PRICE GUARANTEED Found it cheaper? Let's reduce the price! |