Today, aluminum is used in almost all industries, from the production of food utensils to the creation of spacecraft fuselages. For certain production processes, only certain grades of aluminum are suitable, which have certain physical and chemical properties.

The main properties of the metal are high thermal conductivity, malleability and ductility, resistance to corrosion, low weight and low ohmic resistance. They are directly dependent on the percentage of impurities included in its composition, as well as on the production or enrichment technology. In accordance with this, the main grades of aluminum are distinguished.

Types of aluminum

All metal grades are described and included in a unified system of recognized national and international standards: European EN, American ASTM and international ISO. In our country, aluminum grades are defined by GOST 11069 and 4784. In all documents, aluminum and its alloys are considered separately. At the same time, the metal itself is divided into grades, and alloys do not have specifically defined signs.

In accordance with national and international standards, two types of microstructure of unalloyed aluminum should be distinguished:

- high purity with a percentage of more than 99.95%;

- technical purity, containing about 1% impurities and additives.

Compounds of iron and silicon are most often considered as impurities. The international ISO standard has a separate series for aluminum and its alloys.

Chemical composition of aluminum alloys

| Aluminum alloys | |||||||||||||

| Brand | Mass fraction of elements, % | Density, kg/dm³ | |||||||||||

| GOST | ISO209-1-89 | Silicon (Si) | Iron (Fe) | Copper (Cu) | Manganese (Mn) | Magnesium (Mg) | Chromium (Cr) | Zinc (Zn) | Titanium (Ti) | Other | Aluminum no less | ||

| Every | Sum | ||||||||||||

| AD000 | A199.8 1080A | 0,15 | 0,15 | 0,03 | 0,02 | 0,02 | 0,06 | 0,02 | 0,02 | 99,8 | 2,7 | ||

| AD00 1010 | A199.7 1070A | 0,2 | 0,25 | 0,03 | 0,03 | 0,03 | 0,07 | 0,03 | 0,03 | 99,7 | 2,7 | ||

| AD00E 1010E | EA199.7 1370 | 0,1 | 0,25 | 0,02 | 0,01 | 0,02 | 0,01 | 0,04 | Boron:0.02 Vanadium+titanium:0.02 | 0,1 | 99,7 | 2,7 | |

Aluminum grades

The technical type of material is divided into certain grades, which are assigned to the relevant standards, for example AD0 according to GOST 4784-97. At the same time, the classification also includes high-frequency metal, so as not to create confusion. This specification contains the following grades:

- Primary (A5, A95, A7E).

- Technical (AD1, AD000, ADS).

- Deformable (AMg2, D1).

- Foundry (VAL10M, AK12pch).

- For deoxidation of steel (AV86, AV97F).

In addition, there are also categories of alloys - aluminum compounds that are used to create alloys from gold, silver, platinum and other precious metals.

Primary aluminum

Primary aluminum (grade A5) is a typical example of this group. It is obtained by enriching alumina. The metal is not found in nature in its pure form due to its high chemical activity. Combining with other elements, it forms bauxite, nepheline and alunite. Subsequently, alumina is obtained from these ores, and from it, using complex chemical and physical processes, pure aluminum is obtained.

GOST 11069 establishes requirements for grades of primary aluminum, which should be marked by applying vertical and horizontal stripes with indelible paint of various colors. This material has found wide application in advanced industries, mainly where high technical characteristics are required from raw materials.

Properties of winged metal

Aluminum has the unlucky number 13 in the periodic table. However, this did not affect the happy fate of the metal.

This lightweight silver metal can be easily machined and cast, and has great ductility.

A rare ability - to quickly form oxide films on the surface of pure metal. But these films do not protect against corrosion very well. Chemical and electrochemical oxidation is more reliable. The formula of the oxide film is A12Oz.

Chemical and physical characteristics of aluminum:

- density 2.7 g/cm3;

- melting point 660°C;

- non-ferrous metal boils at a temperature of 2518°C;

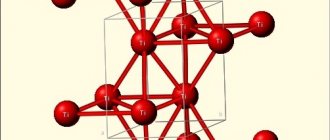

- the structure of the crystal lattice is face-centered, cubic;

- oxidation state 0; +3.

With the help of metallic aluminum (its interaction with metal oxides), difficult-to-reduce metals are obtained. This method is called aluminothermy.

| Properties of the atom | |

| Name, symbol, number | Aluminum (Al), 13 |

| Group, period, block | 13, 3, |

| Atomic mass (molar mass) | 26.9815386(8)[1] a. e.m. (g/mol) |

| Electronic configuration | [Ne] 3s2 3p1 |

| Electrons by shell | 2, 8, 3 |

| Atomic radius | 143 pm |

| Chemical properties | |

| Covalent radius | 121 ± 4 pm |

| Van der Waals radius | 184 pm |

| Ion radius | 51 (+3e) pm |

| Electronegativity | 1.61 (Pauling scale) |

| Electrode potential | −1.66 V |

| Oxidation states | 0; +3 |

| Ionization energy | 1st: 577.5 (5.984) kJ/mol (eV) 2nd: 1816.7 (18.828) kJ/mol (eV) |

| Thermodynamic properties of a simple substance | |

| Thermodynamic phase | solid |

| Density (at normal conditions) | 2.6989 g/cm³ |

| Melting temperature | 660 °C, 933.5 K |

| Boiling temperature | 2518.82 °C, 2792 K |

| Ud. heat of fusion | 10.75 kJ/mol |

| Ud. heat of vaporization | 284.1 kJ/mol |

| Molar heat capacity | 24.35[2] 24.2[3] J/(K mol) |

| Molar volume | 10.0 cm³/mol |

| Crystal lattice of a simple substance | |

| Lattice structure | cubic face-centered |

| Lattice parameters | 4.050 Å |

| Debye temperature | 394 K |

| Other characteristics | |

| Thermal conductivity | (300 K) 237 W/(m K) |

| Sound speed | 5200 m/s |

| CAS number | 7429-90-5 |

Aluminum has one stable isotope, 27Al.

Microstructure of aluminum on the etched surface of an ingot, 99.9998% purity, visible sector size about 55×37 mm

Not true, but well thought out

There is a story circulating in print media, and now on the Internet, about a peasant who had “seditious conversations about flying to the moon.” A peasant (or tradesman), according to some information from Petrov, according to others from Nikiforov, was exiled to the Kyrgyz village of Baikonur" Allegedly, news of the fact was published in the Moscow provincial news" in 1848. Now, when more than a dozen satellites and stations have gone into space from the Baikonur cosmodrome, this fact looks prophetic and mystical.

But this is not true. Meticulous readers rummaged through the files of this newspaper, and did not find such a note. It's just a beautiful legend.

Aluminum alloys, pros and cons

Code symbol indicating that aluminum can be recycled

It is not practical to use pure aluminum in building structures. Its strength characteristics are “so-so”. But aluminum alloys are a different matter. About 60 alloys are now known and used. You can choose for any need, for every taste.

Classification of alloys is carried out according to composition, properties, and ability to heat treatment.

Additives of copper, magnesium and manganese, zinc significantly improve the characteristics of the alloy in comparison with pure metal. Aluminum is most often alloyed with these metals. Titanium, lithium, vanadium, cerium, scandium, and some rare earth elements are used less frequently for alloying, but the properties of these alloys are also in demand in industry.

Duralumin

Duralumins are alloys of aluminum with copper (4%), magnesium (0.5%) and small amounts of iron, manganese, and silicon. The disadvantage of duralumin is its susceptibility to corrosion; it is dealt with using anodizing, plating, aviation primer, and painting.

Demanded properties of the alloy: good static and fatigue strength, high fracture toughness.

Widely used in parts and structures where the mass of the product plays an important role. The main consumers of the alloy are aviation, shipbuilding, and astronautics.

For the curious: duralumin was invented in 1909. The “dad” of the alloy is A. Wilm.

Alloy 7075

It was developed by Sumitomo Metal Corporation (Japan) in the strictest confidence.

It is a compound of aluminum with zinc (up to 6%), magnesium (2-2.5%), copper (up to 1.5%). Titanium, silicon, manganese, chromium, and iron are added to the same alloy. These additives amount to no more than 0.5%, but they contribute to the properties of the alloy.

The alloy is comparable in strength to steel, but is three times lighter.

Alloy modifications:

- 7075-0;

- 7075-06;

- 7075-T651;

- 7075-T7;

- 7075-ASR.

The alloys are resistant to corrosion and can be polished well.

Used in the production of rifles for the army and citizens. The automotive, aviation, and marine industries actively use the alloy. Its disadvantage is the rather high price.

There are many different alloys

There are quite a lot of alloys in Russia with different properties:

- D1, D16, 1161, 1163 - aluminum, magnesium, copper;

- AMG1 - AMG6, aluminum and magnesium alloy;

- AD31, AD33, AD35, AB - aluminum, silicon, magnesium. The list is easy to continue.

Old age is a joy

Old age is not always a bad thing. Metal is like a person or wine; with age, the properties of aluminum change; he gets better, stronger, stronger.

Natural aging of metal occurs under normal conditions; we can say that the metal is “ripening.”

Artificial aging occurs during heat treatment and plastic deformation.

There are different types of heat treatment. The choice depends on the purpose of the future alloy.

| Type of heat treatment | What does heat treatment provide? |

| Hardening with full artificial aging | High strength of the alloy, but some reduction in ductility |

| Hardening with stabilizing aging | Good strength, fairly high structural stability |

| Hardening followed by softening tempering | Good ductility, but reduced alloy strength |

| Artificial aging | Increases the strength of the alloy, improves machinability |

| Annealing | Increasing ductility, reducing residual stresses of the metal |

| Hardening | Improves strength characteristics |

| Hardening and incomplete artificial aging | Increases strength while maintaining ductility |

Technical aluminum

Technical aluminum is a material with a percentage of foreign impurities of less than 1%. Very often it is also called undoped. Technical grades of aluminum according to GOST 4784-97 are characterized by very low strength, but high corrosion resistance. Due to the absence of alloying particles in the composition, a protective oxide film quickly forms on the metal surface, which is stable.

Grades of technical aluminum are distinguished by good thermal and electrical conductivity. Their molecular lattice contains virtually no impurities that scatter the flow of electrons. Thanks to these properties, the material is actively used in instrument making, in the production of heating and heat exchange equipment, and lighting items.

Wrought aluminum

Deformable aluminum includes a material that is subjected to hot and cold pressure treatment: rolling, pressing, drawing and other types. As a result of plastic deformations, semi-finished products of various longitudinal sections are obtained from it: aluminum rod, sheet, strip, plate, profiles and others.

The main grades of deformable material used in domestic production are given in the regulatory documents: GOST 4784, OCT1 92014-90, OCT1 90048 and OCT1 90026. A characteristic feature of deformable raw materials is the solid structure of the solution with a high content of eutectic - the liquid phase, which is in equilibrium with two or more solid states of matter.

The scope of application of deformable aluminum, like that where aluminum rod is used, is quite extensive. It is used both in areas requiring high technical characteristics of materials - in ship and aircraft construction, and on construction sites as an alloy for welding.

Aluminum alloys

The most common elements in aluminum alloys are copper, manganese, magnesium, zinc and silicon. Less common are alloys with titanium, beryllium, zirconium and lithium.

Aluminum alloys are conventionally divided into two groups: cast and wrought.

To make casting alloys, molten aluminum is poured into a mold that matches the configuration of the resulting product. These alloys often contain significant silicon impurities to improve castability.

Wrought alloys are first cast into ingots and then shaped into the desired shape.

This happens in several ways depending on the type of product:

- By rolling, if necessary, to obtain sheets and foil.

- By pressing, if you need to obtain profiles, pipes and rods.

- Molding to obtain complex shapes of semi-finished products.

- Forging, if you need to obtain complex shapes with increased mechanical properties.

Cast aluminum

Aluminum foundry grades are used for the production of shaped products. Their main feature is the combination of high specific strength and low density, which makes it possible to cast products of complex shapes without cracking.

According to their purpose, foundry grades are conventionally divided into groups:

- Highly hermetic materials (AL2, AL9, AL4M).

- Materials with high strength and heat resistance (AL 19, AL5, AL33).

- Substances with high anti-corrosion resistance.

Very often, the performance characteristics of cast aluminum products are increased by various types of heat treatment.

Application area

This metal is actively used in the metallurgical, electrical, and mechanical industries. Let's take it in order.

As mentioned earlier, aluminum can be used to make a lightweight metal structure with a high strength coefficient. This is very beneficial in that the costs of foundations for the building, as well as the purchase of durable supports, are eliminated. Another product is very thin hot-rolled sheets, which are actively used in the chemical industry. Due to its inertness to alkalis and other chemicals, aluminum is a priority metal for room cladding.

The second area of application is electrical. It has long been known that aluminum can completely replace copper, as it is an excellent conductor of electricity. Take, for example, electronics in a car. If you replace all copper wires with aluminum, the total weight of the car will decrease by 12 kilograms. This greatly simplifies the task in mechanical engineering. By the way, this metal is often used in mechanical engineering, in the manufacture of small parts for cars and trucks. Thanks to its low weight and high strength, you can significantly reduce the overall weight of the car while maintaining all the performance characteristics.

Mechanical. Each person has his own personal gadget, electronic device or other device. But few people know that every phone contains a small amount of aluminum, which allows it to maintain the functionality of the device, as well as the battery life. Microcircuits, battery contacts - everything is made of this metal.

In addition, it is used in various mechanisms such as a crane or a heavy truck.

It is worth noting that blacksmiths recommend this metal for decorating and cladding buildings. Due to its high malleability, any product can be made from aluminum at minimal cost.