Reinforced concrete structures in construction are the strongest, which is why they are used in the construction of house foundations, load-bearing beams and floor slabs, bridges, columns and other critical objects. Without reinforcement, concrete poorly resists tensile and bending loads, which cause its destruction. This problem is solved simply - they “stuff” the concrete with steel rods, which serve as a rigid frame in its body. The reinforcement, the weight of which is necessary for design calculations and determining the required amount of material, can have different shapes and cross-sectional diameters.

Samples of reinforcement of different diameters Source permglavsnab.ru

Why and how to determine the weight of reinforcement

Most private developers wondered how much 12 mm reinforcement weighs per meter - it is what is most often used for pouring foundations, monolithic basement walls, and armored belts. The answer to this helps solve at least two problems.

- Determination of the carrying capacity of the vehicle required to deliver materials to the construction site.

Not all developers use delivery services, and not all small sellers provide such a service. If you don’t need so many rods, it’s cheaper to pick them up yourself, but you need to know whether the load will be excessive for the car. Since the standard length of the reinforcement is 6 or 12 meters, many people cut it in half right on the spot and transport it on a trunk or in a trailer. Or they select short rods from unmeasured lots.

The number of short rods in unmeasured batches can reach 7% Source prom.st

See also: Catalog of companies that specialize in the design and installation of metal structures (canopies, greenhouses, etc.)

- Determination of reinforcement footage in ton.

Large volumes of rolled metal are sold using not meters or pieces as a unit of measurement for calculations, but a ton. If you know how many linear meters of reinforcing bars are contained in one ton, it will not be difficult to calculate the weight required for ordering and purchasing.

In theory, knowing the diameter of the required products and the density of the steel alloy from which they are made, you can independently calculate their weight. But in practice, such calculations will have a large error, since the reinforcement bars do not have a constant cross-section, but a periodic one, with longitudinal and transverse stiffeners. And they have two diameters - minimum and maximum.

Reinforcement cross-section - drawing Source ugmk.com

But there is no need to do this. A table compiled on the basis of GOST 5781-82 will help you find out how much the reinforcement weighs. This document regulates all parameters of these metal products. Their mass depends primarily on their diameter.

- The thinnest rods have a diameter of 6 mm and the weight of one linear meter is slightly more than 220 grams.

- The thickest 80 mm reinforcement is much heavier - more than 39 kg per linear meter.

The larger the diameter and denser the reinforcement pattern, the more important it is to know how much a meter of reinforcement weighs. The mass of the metal frame must be taken into account when calculating the load on the base, and an error can lead to unpredictable consequences.

What does reinforcement class mean?

Based on the fact that the very essence of reinforced concrete is a combination of a reinforcing frame inside with concrete pouring, products of different shapes and with different loads placed on them should use reinforcing bars of different cross-section and composition as reinforcement. Classification of reinforcement is a way to unify and simplify the processes of manufacturing reinforced concrete.

To facilitate orientation in the types of reinforcement, there are tables of classes, thanks to which the selection of the required cross-section and metal composition of the rod is carried out.

The main parameters indicated in the tables:

- Weight (mass)

- Applicable diameter limit

- Load and resistance that the bar can withstand

- Possibility of integration into stressed parts of a structure

- Relative extension

| Class | Rod diameter, mm | Tensile strength, MPa | Relative extension, % | steel grade |

| AI (A240) | 6-40 | 373 | 25 | St3kp, St3ks, St3sp |

| AII (A300) | 10-40, 40-80 | 490 | 19 | St5sp, St5ps, 18G2s |

| AII (Ac300) | 10-32, (36-40) | 441 | 25 | 10GT |

| AIII (A400) | 6-22, 6-40 | 590 | 14 | 35Gs, 25G2s, 32G2Rps |

| AIV (A600) | (6-8),10-18, 10-32, (36-40) | 883 | 6 | 80С, 20ХГ2Ц |

| AV (A800) | (6-8), 10-32, 36-40 | 1030 | 7 | 23ХГ2Ц |

Pay attention to the first (left) column.

It contains old and new designations. The first also means the Soviet GOST 5781-75 (which, nevertheless, can often be found in reference books). In order not to be disoriented, you need to know the compliance of old GOSTs and updated ones. Numerical and letter values according to the current GOST 34028-2016 are indicated in brackets. Let's look at the presented labeled samples in more detail:

- A 240 is a smooth-profile reinforcement of class A1, which does not have corrugated hooks on the outer edge in the form of a “spiral” or “herringbone” with a longitudinal edge. This smooth profile is used for the manufacture of non-stressed reinforcing mesh in reinforced concrete products not intended for load-bearing structures, or as clamps. Their adhesion to concrete is weak and their strength is low.

Basically, such reinforcement is used when reinforcing plaster in walls, when the plaster mortar is spread with a trowel and then leveled with tools designed for this purpose, and when pouring floor screeds. In addition, smooth reinforcement can be used as thick wire for tying together large-sized metal structures - because only such rods, acting as fastening wire, can reliably fix frames made from profiles with a diameter of 40 mm or more.

- A300 and Ac300 are class 2 fittings. It has a corrugated profile, with a rod diameter starting from 10 and ending with 80 mm. Adhesion to concrete is higher. Application - in the construction of low-rise buildings (with the number of floors not exceeding 3).

- A400, or AIII – class 3 fittings. The most popular profile that can be used in capital (including multi-story) construction and to solve almost all construction problems. It has a unique combination of stress resistance and strength; there is always a corrugation on the surface. It is durable, strong, and the cost is only slightly higher than the cost of the A1 and A2 brands (A 240, A 300 and Ac 300). A3 is a hot-rolled profile with a periodic surface.

- A600 Corrugated fittings class 4. It has slightly greater strength and stress resistance characteristics than A 400, and the metal contains alloying additives that increase the durability of reinforcement structures inside reinforced concrete, or another indicator of carbon content. Such rods are joined into a reinforcing mesh by welding. A600 is mainly used in support blocks or foundation slabs, as it is stronger and more durable.

Classes V and VI fittings are practically not used in civil engineering, and are used mainly for the construction of large hydraulic structures, airfields receiving large-capacity aircraft, dams for large reservoirs and other strategic objects.

The main types of profiles (except for class A 240, smooth and need no introduction):

a) circular; b) double-sided crescent; c) crescent-shaped quadrilateral

Weight table

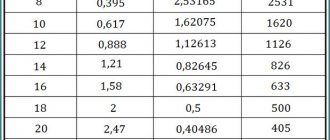

In accordance with the current standard, reinforcement of classes A240, A400 and A500C is used in construction. All weight values in 1 linear meter, in a rod 11.75 m long and in 1 ton of timber are summarized in the table. The error is acceptable, but insignificant, no more than a few percent.

Summary table for all diameters Source vezetnerud.ru

Mechanical properties of reinforcing steel.

Reinforcing steel class

Yield strength, N/mm 2

Tensile strength, N/mm 2

Relative extension, %

Uniform elongation, %

Impact strength, MJ/m 2

Cold bending test (c-thickness of mandrel, d-diameter of rod)

| A500C price from 38200 ₽/t | 35gs price from 36300 ₽/t | 25g2s price from 37300 ₽/t | A240 price from 35700 ₽/t |

Examples of calculations

To find out how much 1 meter of 12 mm reinforcement weighs, just find this diameter in the first column. The following gives the mass of 1 l.m. – 888 grams. And there are only 1126 meters in a ton, or, if you divide this value by the length of the rod, almost 96 pieces.

The design documentation may only indicate the diameter and weight of the reinforcement without indicating the footage. When purchasing individually, you will have to calculate how many pieces you need. For example, you need to buy 1.5 tons of 16 mm reinforcement to install a strip foundation.

- We find from the table how much 1 meter of reinforcement weighs - it is 1.58 kg.

- We convert 1.5 tons into kilograms, multiplying by 1000 - 1500 kg.

- Divide 1500 by 1.58 and we have 950 m.

- Or divide 1500 by 18.56 (the weight of one bar) and get 81 pieces.

These simple calculations will allow you not only to avoid making mistakes when purchasing, but also to check the amount of material delivered to the site.

When you need to find out how much a certain number of rods will weigh, do the opposite: multiply the weight of the rods of the required diameter by their number or footage. For example, you need to buy 30 rods, the thickness of the reinforcement is 20 mm. With a mass of one rod of 29 kg, the total weight will be 30 x 29 = 870 kg.

Fittings according to purpose

When creating a reinforcing frame, reinforcing bars occupy a strictly defined place. There are types of fittings that differ in their position and purpose.

Working fittings

Working reinforcement is laid along the longest structural elements. For strip foundations, floor slabs and load-bearing beams it occupies a horizontal position, and in piles and columns it occupies a vertical position. In this case, it is able to take on tensile loads, thereby increasing the strength and durability of the entire part. Rods of this class always have a variable cross-section. They form the basis of the frame.

Distribution

Distribution fittings are considered auxiliary. It is responsible for connecting the main rods into a common frame with a spatial structure. In this case, the loads are optimally distributed between several elements, which reduces the risk of damage to any of them. Such rods can occupy horizontal and vertical positions. The optimal shape for them is corrugated, although in the least critical parts it is allowed to use smooth rods or pieces of pipes.

Assembly

The task of mounting reinforcement is to ensure that the shape of the reinforcing frame remains unchanged during transportation, placement in formwork and pouring with mortar. For these purposes, rods with any surface structure are used.

1. Working.

2. Distribution.

3. Assembly room.

Weight of composite reinforcement

Nowadays, fiberglass reinforcement bars are increasingly being used instead of steel reinforcing bars. They have a lot of advantages, including light weight. In addition, fiberglass has better tensile strength than steel, which allows the use of products with a smaller diameter. For example, an 8 mm composite rod is equivalent in its physical and mechanical characteristics to a 12 mm steel rod. Accordingly, the load decreases even more noticeably.

Table for determining the equivalent diameters of steel and composite reinforcement Source luxkompozit.ru

Compare how much a meter of 12 mm steel alloy reinforcement weighs (890 g) and a meter of fiberglass rod with a diameter of 8 mm (110 g). The difference is 8 times.

Briefly about the main thing

When starting construction and ordering materials for it, it is important to be able to calculate them correctly and control delivery, without allowing suppliers to deceive you. To do this, you need to know how many kilograms of cement are in a bag, how many boards are in a cubic meter, how many kg are in 1 meter of reinforcement with a diameter of 12 mm. Such knowledge can be very helpful in calculating loads on building structures and in solving transportation issues. In the case of fittings, everything is simple - you just need to look at the table and find the necessary data in it.

Main categories

The following classes of fittings are popular in Russia: A240, A400, A500C, AT800. Below we will look at them in detail.

A240 (AI)

Reinforcement of this type is made from carbon steels, which additionally contain small amounts of manganese, nickel, chromium, and copper. Brand A240 - smooth fittings. If the cross-sectional diameter is less than 12 millimeters, then A240 can be in the form of large coils held together with wire. Spare parts with a diameter of more than 12 millimeters are made in the form of separate rods of short length (up to 5 meters). The brand is used for the construction of small lightweight structures. It can also be used to reinforce small objects - compact columns, curbs, partitions, walls.

A400 (A-III)

A400 class rods have a round cross-section with a corrugated surface. Corrugation on spare parts appears due to small protrusions, which are located at an angle of 40-45 degrees relative to the central axis of the reinforcement. A400 is made from carbon steel, which includes a large number of filler components. The main additive component is manganese, which makes the alloy more durable and reliable. In addition to manganese, the alloy also includes other components - chromium, nickel, copper. The presence of stiffening ribs provides better adhesion of the A400 to the concrete composition.

Therefore, durable composite parts based on reinforced concrete are often made from the A400 brand - walls, floors, ceilings, inclined surfaces, vertical pillars, beams, bridges. Another area of application is road pavement reinforcement. Welding can be used to connect A400 parts to each other, but it is recommended to do butt welding using the butt welding method or using spot welding machines. Alternative welding technologies are less reliable, and the resulting structure will have low bending strength. This negatively affects the shelf life of the reinforced concrete product.

A500C

The A500C brand appeared on the Russian market relatively recently - in the 90s. Reinforcement of this type undergoes a number of auxiliary technological treatments (hot rolling, thermal hardening). These treatments significantly increase the physical properties of the material - elasticity, strength, stretching. Also, the A500C brand has poor contact with water and air, since it is chemically inert. Interestingly, grade A500C is smelted from ordinary steel containing an average amount of carbon and a minimum amount of alloying additives.

This makes the material cheaper to produce, which will be very useful for the builder. The A500C brand tolerates welding well, and can be joined using almost any welding method - overlap, butt, cross-overlay, and so on. The brand can be used for the construction of both large and small buildings based on concrete. These can be elements of a house or the entire house, bridges, hanging structures, medium-sized hangars, support poles, power lines. The only major drawback of the A500C is the deterioration of physical properties at low temperatures (below -30 degrees). Therefore, parts of this type are not recommended for use in the Far North.

AT800

The AT800 brand belongs to the class of heavy-duty reinforcements that have undergone hot rolling and thermomechanical hardening. The surface of the material is usually corrugated, although smooth varieties of the AT800 brand are also available. The brand is used for the construction of large massive structures based on reinforced concrete. These can be multi-story buildings, bridges, hangars, and so on. Thermo-mechanical hardening performs the following functions:

- Increasing ductility while maintaining the strength of the material (ductility increases by 20-30%).

- Increased fatigue strength, which allows spare parts to retain their shape even during long-term use.

- Improving anti-corrosion properties, minimizing the risk of cracking of the material upon contact with chemicals.