Depending on the area of application, all professional sheets are divided into three categories. In the first case, the sheets are used only for roofing and are marked with the letter “H”. In the second case, the corrugated sheeting is intended for vertical installation during the construction of fences and walls - it is marked with the letter “C”. Finally, in the third case, the sheet can be used for both roofs and vertical structures - it is simply labeled “NS”. In addition, there is a profiled sheet with alternating wide and narrow stripes - it is labeled as MP, and it can be used in both roofing and wall work.

| Table of main characteristics of steel corrugated sheets | |||

| Drawing | Corrugation height, mm | Metal thickness, mm | Standard |

S21 wall | 21 | 0,5 – 0,8 | GOST 24045-2016 |

NS35 roofing wall | 35 | 0,5 – 0,8 | GOST 24045-2016 |

H60 roofing | 60 | 0,7 – 1,0 | GOST 24045-2016 |

The industry produces corrugated sheets in sizes that satisfy almost any needs of developers. In length “H” profiles are produced from 3 to 12 meters with a difference of 250 mm between types. “C” profiles have a difference of no more than 300 mm with a total length of 2.4 to 12 meters. In this case, it is allowed that the length of the profiled sheet is determined by agreement between the manufacturer and the customer.

The height of the profile (corrugation) is indicated in a short marking - usually the letter is followed by a number in millimeters. Accordingly, C21 has a height of 21 mm. Corrugations are regulated for roofing coverings in height from 15 to 160 mm, and for wall coverings from 8 to 44 mm, although in the latter case an increase is allowed by agreement with the customer.

The width can vary from 1200 mm for C8 to 653 for profiled sheet H114. In addition to the total width, there is a working width, which is obtained during the process of laying the sheet on the surface when the outer corrugations coincide, forming a rigid connection into the lock. The thickness of the sheet is greater for type “H” - it is in the range of 0.5 - 0.9 mm. “NS” and “C” have 0.55 – 0.8 mm and 0.55 – 0.7 mm, respectively. However, today “C” type corrugated sheets with thicknesses of 0.45 and even 0.4 mm have appeared on the market. For H60, the thickness can reach even 1.2 mm. Thus, the size range largely depends on the manufacturer and the needs of a large customer.

Corrugated sheeting can be protected with a special polymer coating of any color, or it can simply be galvanized. The color of the coating on different sides of the sheet may be different. The manufacturer is recommended to produce sheets with a capillary groove to remove unnecessary moisture.

What is a profiled sheet

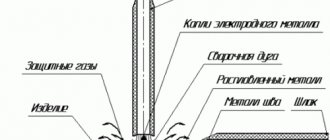

Profiled sheet is a construction sheet material made from thin sheet steel. A relief is formed on the workpiece by cold stamping, and then a protective coating is applied. The relief is called a profile. This is where the name of the material came from - corrugated sheet. That is, a sheet with a profile. You can also find such a name as corrugated sheeting. Some people think that corrugated sheets and corrugated sheets are different materials and there is a difference between them. But no. No difference. It’s just that GOST describes two brands as “for flooring.” This is apparently where the name corrugated sheet came from.

“Bent steel sheet profiles with trapezoidal corrugations for construction” - name according to GOST 24045-2016. Conventionally, we can say that if it is necessary to cover the roof, we choose roofing profiles (corrugated sheeting), and if it is necessary to sheathe the walls, we choose wall profiles (corrugated sheeting).

In general, this material has many names. You can find a “sheet profile”, a metal profile. Less common is a “profile sheet”. There is also a name from the catalogs - profiled steel sheet. It's all about the same material.

This is what a corrugated sheet with a colored coating looks like

So, a profiled sheet is a steel sheet with a formed relief. A protective multilayer coating is applied to it. The number of layers and types of coatings differ and affect the final characteristics of the product. For durability, resistance to fading, high or low temperatures, chemical and mechanical influences. In general, many important properties depend on the coating and the quality of its application.

What is a professional sheet? This is sheet metal with a protective coating and a specially shaped profile

There are corrugated sheets for different purposes and they differ in relief. In the sense that the height and width of the wave, the distance between the peaks are different, and the shape is always trapezoidal. This is stated in GOST 24045-94. Only in some types (with increased load-bearing capacity) protrusions - shelves - are added on the side faces, and additional grooves are formed in the ridge and recess. However, the profile shape is trapezoidal.

Domestic manufacturers of profiled sheets

Finding an inexpensive but high-quality profiled sheet from a domestic manufacturer can be problematic. There are too many companies that provide their products on the construction market of this inexpensive building material for sale. To select high-quality metal sheets when constructing a fence in the budget price segment, you need to consider both suppliers of galvanized steel and the equipment used to produce metal profiles.

In our review of corrugated sheeting manufacturers, we presented the best companies that produce, among other products, corrugated sheets. When compiling the rating, both the production capabilities of the companies, their presence on the market, and the range of products were taken into account. And of course, the quality of the materials produced. The rating was also influenced by the assessments of consumers who had already used the product and had become familiar with all the declared characteristics over the years of operation.

Metal Profile

The largest manufacturer. Offers an exclusive catalog of materials

Country: Russian Federation

Rating for 2022: 4.8

The company has 18 manufacturing plants in different regions of the CIS. Thin-sheet wall coverings, materials for roofing, fencing, metal tiles, corrugated sheets, and so on are produced.

In 2001, the authoritative Forbes magazine included Metal Profile in the list of the 200 largest non-public companies.

The factories also produce products that have no analogues on the Russian market - unique treatments PURETAN, PURMAN and others.

Profiled sheets in the economy segment have a huge selection of colors and sizes. In the catalog you can see:

- sandwich panels;

- drainage systems;

- metal tiles;

- steel cladding;

- designs for facades that are ventilated.

Thanks to a laboratory on the production site and a staff of professional engineers, new unique products with improved characteristics are developed, and a long-term warranty is provided (50 years).

UZKM (Ural Roofing Materials Plant)

The highest standards of precision in the geometry of manufactured products. Strict control over production is exercised.

Country: Russian Federation

2022 rating: 4.8

The plant produces on the market various types of galvanized corrugated sheets, as well as processing from polymer raw materials (plastisol, pural and polyester).

Exclusively domestic material is used. At each stage of production there is a strict quality check and compliance with standards. The work uses modern professional equipment. This guarantees the production of high-quality products with precise geometry, as well as individual dimensions.

The main advantage of roofing materials from this manufacturer is the excellent quality of the sheets at a low cost.

The inexpensive product is characterized by increased wear resistance, as well as resistance to external factors and mechanical damage.

The decorative properties of profiled sheets and the use of various technologies for their processing help to significantly improve the appearance of buildings and structures.

Pocroff

The company specializes in Finnish rental technology. Uses domestic and imported materials. Strict product quality control.

Country: Russian Federation

2022 rating: 4.9

- one of the largest manufacturing companies in Russia. It has been on the market for more than 20 years and produces:

- roofing for roofs;

- materials (wall, roofing) for installation of fences and fences;

- wall covering.

Production is located in five cities, which allows us to significantly increase the sales market.

To produce budget profiled sheets, raw materials purchased from. When renting corrugated sheets from European manufacturers, Finnish technology is used.

Inexpensive products from Pokroff are well suited for the construction of cottages and country houses. The sheet material is galvanized and treated with polyester. The service life is more than 15 years, it is light in weight, convenient to store and transport. It will also last a long time in aggressive environmental conditions.

Neva Steel

Country: Russian Federation

2022 rating: 4.9

This manufacturer has been producing sheet material and metal tiles for more than 20 years. The advantages of the product are:

- use of high quality rolled steel (Zalzgitter, ArcelorMittal, Ruukki, Corus);

- a wide range of polymer processing, so not only standard samples are available for order, but also with imitation wood, natural stone or aged copper.

They produce 3 types of profiled sheets of various colors for the construction of fences, as well as for roofing:

- carrier;

- wall;

- roofing

The products are resistant to mechanical loads, light in weight, convenient to store, transport and install. Budget material can reduce construction costs by up to 20%.

Grand Line

Active development of the trading network.

Country: Russian Federation

Rating for 2022: 5.0

The Grand Line company has 9 factory production facilities in Russia.

Sheet material (roofing, walling, load-bearing) is used for the construction of fences, as well as roofing. We produce building materials for prefabricated structures, wall cladding and installation of floors.

The range includes budget galvanized corrugated sheets; polymer processing technologies are used, which increases service life and decorative properties. You can also find PVC products in the manufacturer's catalog.

Remember that a fence built using metal profiled sheets is a single structure. Damage to any part of it can provoke deformation of neighboring elements. When installing a fence, do not forget to do it at a distance from newly planted trees. As they grow, they can damage the fence, and you will have to spend money on restoration and change the geometry.

Brands of corrugated sheets

Typically, corrugated sheets are made of sheet steel with zinc and aluminum-zinc coating. If they use an aluminum-zinc coating, they put AC in the marking, if they use zinc, they don’t put anything. If zinc is applied electrolytically, then EOTS is installed. The sheet can also be coated with a layer of aluminum (letters AL in the marking) or aluminum-silicon (AK). These coatings provide better protection, but are expensive.

Profiled steel sheet with a protective coating - this is corrugated sheeting

In addition to various “primary” coatings, rolled steel sheets are used in various thicknesses. In combination with different profiles, it has different load-bearing capacities, accordingly, it has different purposes and areas of application. According to their purpose, profiles are divided into types (GOST 24045-2016):

- N - for load-bearing covering decks that support the weight of the roof with insulation and the load of climatic influences;

- NS - for flooring and wall fences;

- C - for wall fences that perform load-bearing and enclosing functions.

Sometimes there is such a decoding of the designations of corrugated sheets, where type H is load-bearing (for load-bearing covering decks that bear the weight of the roof with insulation and the load of climatic influences). He is the heaviest, the toughest. Roofs with high snow and wind loads are made from this corrugated sheeting.

Brands of corrugated sheets and their purpose

NS - load-bearing wall. Another name is universal. Less “hardy”, but can be used on the roof with low loads on it. It is also possible to build load-bearing walls from it (with sufficient thickness and depth of the relief). He is often “allowed” onto fences that do not have crossbars between the posts.

C - wall profiled sheet. Used for cladding frame walls. It is used in the construction of garages from corrugated sheets and utility rooms. The same type, but of sufficient thickness, can be attached to the fence if there are crossbars between the posts. This material is not recommended for roofing. Unless there is almost no snow and wind. And then, the sheathing should be frequent, with small gaps.

Peculiarities

Roofing corrugated sheeting always meets more stringent requirements than the wall version of this material. But it is used in a variety of cases. It’s one thing when you need to cover the roof of a solid cottage, another when decorating a private house, and a third when work is being carried out on a temporary structure. You always need your own approach. In any case, corrugated roofing is superior to many other materials in such parameters as:

- protection against corrosion;

- ease of transportation and installation;

- light weight and versatility in use;

- environmental Safety;

- minimum care requirements.

But users will have to reckon with possible difficulties. Only when using reliable sound insulation can the “loudness” of a professional sheet be overcome

It must be transported with great care, because the material deforms very easily.

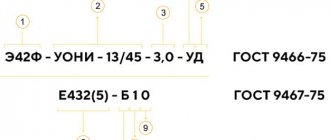

Profiled sheet marking and its interpretation

The marking of corrugated sheets is also described in GOST. It contains all the necessary data, except weight. And so, there are all the sizes of the corrugated sheet, the name of the protective coating on both sides. But in order to read the transcript, you need to know in what position which symbols represent what. Appearance of the corrugated sheet markings in the figure.

How to decipher the markings of a profiled sheet and where its dimensions are indicated

The first position is the sheet type. It is stated in the previous paragraph: C - wall, NS - universal, N - for flooring. The specific scope of application is not indicated, but this information is usually provided by manufacturers.

Sheet dimensions and material

The second position will not raise many questions either. Here are the dimensions of the corrugated sheet in millimeters. Only the order of magnitude is unusual. First the height is indicated. This refers to the profile height. Then comes the width and thickness of the metal sheet. The length is not specified; it is usually discussed upon delivery, as it can vary within wide limits. For example, H44-1000-0.8. This is a load-bearing profile with a wave height of 44 mm, a sheet width of 1000 mm, made of a metal sheet 0.8 mm thick.

This type of profiled sheet is recommended for fences. Please note that the higher the profile height, the stiffer the fence will be. Well, the thickness of the sheet also plays a role.

In the third position there are letters by which you can determine the material of the workpiece. That is, what primary protective coating was applied to the metal sheet:

- If the steel is galvanized, it costs nothing.

- Electrolytic galvanization - EOTS.

- Aluminum-zinc coating - AC.

- Aluminum coating - AL.

- Aluminum ceramic - AK.

For example, N57-750-0.8 AL. Everything is clear with the dimensions of the corrugated sheet: sheet height 57 mm, width 750 mm, steel thickness 0.8 mm. The letters AL indicate aluminum coating. This is probably also understandable.

Paintwork

The fourth and fifth positions reflect the type of paint coating applied. All types of paints and primers that GOST allows are shown in the table. It also shows resistance to chemical attack depending on the type of primary protective coating on the metal.

| Name and designation of paint | Primer designation | Coating thickness in microns | Resistance to aggressive environments when applied to zinc coating | Resistance to aggressive environments when applied to aluminum-zinc coating | Resistance to aggressive environments when applied to aluminum coating |

| Without cover | non-aggressive | slightly aggressive with restrictions | slightly aggressive with restrictions | ||

| Enamel GF-2017 | 10-12 microns | non-aggressive | slightly aggressive with restrictions | slightly aggressive with restrictions | |

| Polyester silicone enamels ML-1202 | EP-0200 | 25-34 microns | slightly aggressive | slightly aggressive | slightly aggressive |

| Acrylic silicone enamels AS-1171, AS-5122 | EP-0200 | 25-30 microns | slightly aggressive | slightly aggressive | slightly aggressive |

| Organodisperse paints OD-HV-221 | AK-0138 | 40-50 microns | slightly aggressive | slightly aggressive | slightly aggressive |

| Epoxy primer EP-0140 | 70-80 microns | slightly aggressive | slightly aggressive | slightly aggressive | |

| Polyvinyl chloride plastic compounds PL_HV-122 | AK-0138 | 180-220 microns | slightly aggressive | non-aggressive with restrictions | non-aggressive with restrictions |

But the standard was developed a long time ago, and GOSTs are rarely updated. During this time, polymer coatings that were more reliable than paints appeared. Roughly speaking, polymer-coated corrugated sheets are not standard. But polymer-coated sheets are more resistant to fading, better withstand weather conditions and ultraviolet radiation, and are more resistant to mechanical stress. So that's not to say they're bad. Expensive. Yes. But in terms of performance characteristics it is better.

The coating cannot be determined by its appearance. You can only distinguish galvanized from painted

These other coatings can be:

- Pural. Designated PUR. High resistance to mechanical stress and abrasion.

- PVDF. Polyvinylidene fluoride. High resistance to ultraviolet radiation. Good for roofs.

- PVC (or PVC). Polyvinyl chloride. High degree of corrosion protection. Good in regions close to the sea.

- AC. Acrylic. The most inexpensive of polymer coatings. In relation to the above, it is inferior in resistance to fading and degree of protection.

In general, we examined the markings of the corrugated sheet and what it hides. The most interesting thing is that usually only the first two positions are indicated. For example, C 18-100-0.9, NS 44-100-0.6. The rest must either be looked at in the description or found out from sellers and dealers.

Sheet dimensions and weight

In general, enterprises produce profiled sheets not only in accordance with GOST, but also in accordance with technical specifications. Specifications are technical conditions in which the manufacturer sets down its dimensions and quality requirements. Registering them is not that difficult. But this is not GOST and anything can be there. If you see specifications on the labeling or in the accompanying documents, it is better to read it so that there are no surprises. And the standard does not have many profiles and sizes of corrugated sheets, which is why specifications are used. Consumers demand other sizes and profiles. The table shows the grades and sizes of corrugated sheets according to GOST, and the figure also includes drawings and appearance. By the way, sheet thickness with * is not a standard.

Drawing of the profiled sheet and appearance, sheet width and thickness

| Designation of profiled sheet | Width, mm | Metal thickness, mm | Weight of 1 meter long, kg | Weight per square meter, kg |

| N-75-750-0.7 | 750 | 0,7 | 7,4 | 9,8 |

| N75-750-0.8 | 750 | 0,8 | 8,4 | 11,2 |

| H75-750-0.9 | 750 | 0,9 | 9,3 | 12,5 |

| Н114-600-0.8 | 600 | 0,8 | 8,4 | 14,0 |

| Н114-600-0.9 | 600 | 0,9 | 9,3 | 15,6 |

| N114-600-1.0 | 600 | 1,0 | 10,3 | 17,2 |

| H114-750-0.8 | 750 | 0,8 | 9,4 | 12,5 |

| H114-750-0.9 | 750 | 0,9 | 10,5 | 14,0 |

| N114-750-1.0 | 750 | 1,0 | 11,7 | 15,4 |

| NS35-100-0.6 | 1000 | 0,6 | 6,4 | 6,4 |

| NS35-100-0.7 | 1000 | 0,7 | 7,4 | 7,4 |

| NS35-100-0.8 | 1000 | 0,8 | 8,4 | 8,4 |

| NS44-1000-0.7 | 1000 | 0,7 | 8,3 | 8,3 |

| NS44-1000-0.8 | 1000 | 0,8 | 9,4 | 9,4 |

| S10-899-0.6 | 918/899 | 0,6 | 5,1 | 5,7 |

| S10-899-0.7 | 918/899 | 0,7 | 5,9 | 6,6 |

| S10-1000-0.6 | 1022/1000 | 0,6 | 5,6 | 5,6 |

| S10-1000-0.7 | 1022/1000 | 0,7 | 6,5 | 6,5 |

| S18-1000-0.6 | 1023/1000 | 0,6 | 6,4 | 6,4 |

| S18-1000-0.7 | 1023/1000 | 0,7 | 7,4 | 7,4 |

| S15-800-0.6 | 940/800 | 0,6 | 6,5 | 6,0 |

| S15-800-07 | 940/800 | 0,7 | 6,55 | 6,9 |

| S15-1000-0.6 | 1018/1000 | 0,6 | 6,4 | 6,4 |

| S15-1000-0.7 | 1018/1000 | 0,7 | 7,4 | 7,4 |

| S21-1000-0.6 | 1000 | 0,6 | 6,4 | 6,4 |

| S21-1000-0.7 | 1000 | 0,7 | 7,4 | 7,4 |

| S44-1000-0.7 | 1000 | 0,6 | 7,4 | 7,4 |

Everything seems clear in the table. The dimensions of the profiled sheet are indicated in the same way as prescribed in the standard: profile height, sheet width and metal thickness. Length - by agreement or according to the manufacturer's capabilities. Questions may be where the width is indicated through a fraction. For example, 1022/1000. The first number is the full width when covering walls, the second is the working width when installing on the roof. As you understand, this is a dual-use material. Can be used both on the roof and for wall cladding.

For comparison, look at what sizes of corrugated sheets they can offer, and compare with what GOST prescribes

It is worth saying that if the parameters of a profiled sheet do not comply with GOST, this does not mean that the material is bad. You need to look at the quality of the coating and the rigidity of the sheet. In any case, it is worth finding reviews on the products of a specific manufacturer. Because standard ones can be made not so well. It's all about the quality of steel and coatings.

Specifications

The technical characteristics of load-bearing profiled sheets usually include:

- Thickness;

- Profile height;

- Length, width;

- Weight.

The list of characteristics also includes the presence or absence of a polymer coating.

Thickness is an important parameter that affects the amount of load that a material can withstand. Its parameter depends on the similar parameter of the steel used to produce the product. Thickness affects weight. Accordingly, the thicker the sheet, the more it weighs.

The height of the profile also affects the ability of the corrugated sheet to withstand certain loads. The higher it is, the more durable the material is. Its value can be immediately determined by the grade of corrugated sheet. Example - H114. The numbers next to the letter H indicate the profile height in millimeters.

Length – up to 12 meters. Sheets can be sold in specific lengths: 3, 4, 5 m, etc. The assortment in certain construction stores, as a rule, is limited in this parameter. However, it is possible to use the cutting to length service. This service can be provided by a manufacturer of metal products, in particular, one engaged in the production of profiled metal sheets. Using appropriate production equipment, cutting is carried out to the length specified by the client.

Width – overall or installation. Overall or overall - the full width of the product, from edge to edge. Mounting (working) - the total width of the material, reduced by the distance required to connect/fasten the sheets to each other. This width is always less than full. The difference between the indicated parameters is approximately 50 mm. Maybe more, depending on the parameters of a particular brand of sheet. When calculating the required amount of material, you should focus specifically on the installation width. Otherwise, when using the sheets directly for their intended purpose, they may simply not be enough.

Load-bearing corrugated sheets H75, H60, NS35 and other grades are available galvanized or with a polymer coating. Available with Printech coating. Galvanized has 1 color - gray-silver. With a polymer coating and a variety of colors. The variety of colors allows you to choose the material of the desired color and harmoniously fit it into the design of the building, nearby structures, etc. Printech is a special coating that imitates the structure of wood or stone.

How to determine quality

First of all, an external inspection. The quality of application of paint, polymer or galvanization is the first indicator. There should be no sagging, drips or bald spots. GOST allows for abrasions and small scratches that do not damage the integrity of the protective layer. That is, if the scratch does not reach the metal, this is normal. This happens all the time during transportation. The main thing is that the coating is intact.

One of the indirect indicators of the quality of corrugated sheets is its weight. Reference values are indicated in GOST (available in the table). If the weight varies significantly downwards, this means that a thinner sheet or less dense (and cheaper) metal was used.

Direct evidence of the manufacturer’s reliability is the thickness of the sheet. If the declared thickness matches the actual one, this is a good sign. How to measure the thickness of a profiled sheet? Using an electronic caliper. Not such an expensive tool, but easier to use. If you have a regular one, you can take measurements using it. But keep in mind that the actual thickness - with a layer of paint or polymer - should be at least a little (several micrometers) greater than declared. This difference will be shown by an electronic device. A mechanical one will not cope with such a task.