What's the pressure?

According to GOST, pressure is determined at a temperature of + 20⁰C. Limit value 19 kgf/cm2. Typically, acetylene in cylinders has 14 - 16 kgf/cm2.

Gas pressure depends on temperature changes. For example, 19 kgf/cm2 at 20⁰ when cooled to -4, a total of 13.4 kgf/cm2, at 35⁰ a critical value of 26 kgf/cm2 is reached. Therefore, a pressure reserve is created in case of heating.

You can determine the amount of gas filled by a simple calculation. You need to subtract the weight of the empty cylinder from the weight after refueling and multiply by 1.09 - that’s how much a liter of gas weighs.

Cylinder explosion

The main disadvantage of acetylene is its explosiveness. Gas can detonate for many reasons:

- achieving a critical mass of gas;

- high pressure;

- residue in the flammable gas cylinder;

- contact with lubricant or calcium carbide;

- electrification of the neck by the gas itself, passing at high speed;

- heat;

- leakage and air connection;

- impacts on the weakened walls of the container.

The gas becomes explosive if it is collected in large volumes and when the acetylene pressure in the cylinder exceeds 2 kg/cm2. To reduce the risk of spontaneous explosion, a special porous mass is placed inside the gas container. It divides all the gas into small particles, allowing it to move freely. Pure acetylene can be pumped with a maximum pressure of 25 kg/cm2.

How much is 40l?

The volume of acetylene in a fully filled gas container is calculated using a simple formula:

40 × 15 × 9.2 = 5520 l;

Where: 40 l – cylinder volume;

15 kg/cm2 – pressure;

9.2 gas solubility coefficient in acetone;

5520 l = 5.5 m3 amount of acetylene.

This formula calculates the amount of acetylene that can be filled into any size cylinder. In the formula, only 40 – the number of the container’s volume – changes to 5, 10 and others .

How does an acetylene cylinder work?

Powering gas welding and cutting stations with acetylene from acetylene generators is associated with a number of inconveniences, so powering stations directly from acetylene cylinders is now widespread. They have the same dimensions as oxygen ones (Fig. 17, b). An acetylene cylinder is filled with a porous mass of activated charcoal (290 - 320 g per 1 dm3 of cylinder capacity) or a mixture of coal, pumice and infusorial earth. The mass in the cylinder is impregnated with acetone (225-300 g per 1 dm3 of cylinder capacity), in which acetylene dissolves well. Acetylene, dissolving in acetone and being in the vapor of the porous mass, becomes explosion-proof, and it can be stored in a cylinder under a pressure of 2.5-3 MPa. The porous mass must be soft and have maximum porosity, behave inertly towards the metal of the cylinder, acetylene and acetone, and not produce sediment during operation.

Rice. 17. Oxygen (a) and

acetylene (b) cylinders

Acetone (CH3COCH3) is one of the best acetylene solvents; it impregnates the porous mass and dissolves it when filling cylinders with acetylene. Acetylene delivered to consumers in cylinders is called dissolved acetylene.

The nominal pressure of acetylene in the cylinder is 1.9 MPa. The pressure of acetylene in a fully filled cylinder changes with temperature:

Temperature,

0 C -5 0 5 10 15 20 25 30 35 40

Pressure, MPa 1.34 1.4 1.5 1.65 1.8 1.9 2.15 2.35 2.6 3

The pressure of filled cylinders should not exceed 1.9 MPa at 20 0C.

When the valve of the cylinder is opened, acetylene is released from the acetone and enters in the form of a gas through the reducer and hose into the burner or cutter. Acetone remains in the pores of the porous mass and dissolves new portions of acetylene during subsequent fillings of the cylinder with gas. To reduce acetone losses during operation, it is necessary to keep acetylene cylinders in a vertical position. At normal atmospheric pressure and a temperature of 20 0C, 28 kg (l) of acetylene are dissolved in 1 kg (l) of acetone. The solubility of acetylene in acetone increases (approximately directly proportional) with increasing pressure and decreases with decreasing temperature.

To fully utilize the cylinder capacity, it is recommended to store empty acetylene cylinders in a horizontal position, which promotes uniform distribution of acetone throughout the entire volume, and with the valves tightly closed. When acetylene is removed from the cylinder, it carries away some of the acetone in the form of vapor. This reduces the amount of acetylene in the cylinder during subsequent fillings. To reduce the loss of acetone from the cylinder, acetylene must be withdrawn at a rate of no more than 1700 dm3/h.

To determine the amount of acetylene, the cylinder is weighed before and after filling with gas and the amount of acetylene in the cylinder in kilograms is determined from the difference.

EXAMPLE

The mass of the cylinder with acetylene is 89 kg, empty - 83 kg, therefore, the amount of acetylene in the cylinder is equal to: by weight 89-83 = 6 kg, by volume 6: 1.09 = 5.5 m3 (1.09 kg/m3 - density acetylene at atmospheric pressure and temperature 20 ° C).

The mass of an empty acetylene cylinder consists of the mass of the cylinder itself, the porous mass and acetone. When taking acetylene from a cylinder, 30-40 g of acetone per 1 m3 of acetylene is consumed along with the gas. When removing acetylene from a cylinder, it is necessary to ensure that the residual pressure in the cylinder is at least 0.05-0.1 MPa.

The use of acetylene cylinders instead of acetylene generators provides a number of advantages: compactness and ease of maintenance of the welding installation, safety and improved working conditions, increased productivity of gas welders. In addition, dissolved acetylene contains fewer impurities than acetylene obtained from acetylene generators.

The reasons for the explosion of acetylene cylinders can be sharp shocks and impacts, strong heating (over 40 ° C).

Refueling

Acetylene is produced by combining water and carbide . Acetylene cylinders are filled through the neck, determining its quantity by weight. Standard full cylinder 65 kg, empty 53 – 58 kg. The weight of the container with filler is indicated at the marking on the neck and is determined by weighing.

The acetone partially evaporates along with the gas. At each refill, add 130 - 150 ml.

If you fill a 5 liter container from a 40 liter cylinder, the gas in it will run out very quickly. In order for acetylene to dissolve in acetone, high pressure must be created. When pumping at home, it is impossible to create it .

Storage of gas cylinders

The cylinders are intended for gas supply to individual (mobile) posts and for equipping gas discharge ramps. Cylinders for GPOM (gas-flame processing of metal) must comply with the requirements of the “Rules for the Design and Safety of Pressure Vessels”. They are painted in different colors depending on the type of gas. The name of the gas stored in it is written in paint on the cylinder.

The upper spherical part of the cylinder is not painted; passport data is printed on it: cylinder type, cylinder serial number, manufacturer's brand, cylinder weight, cylinder capacity, operating and test pressure, date of manufacture and next test, quality control department and Rostekhnadzor stamp.

Oxygen cylinders . Compressed gaseous oxygen is stored and transported in hollow, seamless cylinders in accordance with GOST 949-73, type 150 and 150A (the numbers 150 indicate the pressure, and the letter “A” indicates that the cylinder is made of alloy steel) with a capacity of 40 liters.

The maximum amount of oxygen in a cylinder of this type at the highest pressure is 8 kg or 6 m3. The highest oxygen pressure in a cylinder is 15 MPa (150 kgf/cm2), and oxygen cylinders are tested at a pressure of 22.5 MPa (225 kgf/cm2). The outer diameter of the cylinder is 219 mm, wall thickness is 8 mm, length is 1390 mm, weight is 70 kg.

Cylinder color: blue.

The neck of the cylinder is equipped with a conical thread into which a brass valve is screwed. A plastic or metal cap is screwed onto the top of the cylinder neck to protect the valve from contamination and damage. At the bottom of the cylinder there is a shoe to give the cylinder vertical stability.

Oxygen cylinders must be degreased. It is always necessary to remember that oxygen cylinders and their fittings, including the reducer, must be protected from contamination with oil or fats, the slightest traces of which can spontaneously ignite in an oxygen environment and therefore pose a danger to the integrity of the cylinder. The residual pressure in the cylinder supplied from the consumer for filling must be at least 0.05-0.1 MPa (0.5-1.0 kgf/cm2).

Acetylene cylinders . Unlike other compressed gases, acetylene is stored in seamless cylinders type 100 with a capacity of 40 liters. The cylinders are filled with a porous mass soaked in acetone. Activated carbon BAU or cast mass made using special technology (infusor soil, crushed pumice and other porous materials) are used as a porous mass.

Acetone is used to dissolve compressed acetylene. Being in the smallest vapors of the mass and being dissolved in acetone, compressed acetylene loses its explosive properties and in this form can be completely safely stored under pressure up to 2.5 MPa (25 kgf/cm2). The average amount of dissolved acetylene is 5.5 m or 6 kg.

The maximum gas extraction from a cylinder with a porous mass is 1.0 m/hour, and from a cylinder with a cast mass—1.5 m/hour. The residual pressure in the cylinder supplied from the consumer for filling should not exceed 0.1 MPa (1 kgf/cm2) and should not be lower than 0.05 MPa (0.5 kgf/cm2).

The color of the cylinder is white.

The design of the valve for acetylene and oxygen cylinders is different, which eliminates the mistaken installation of an acetylene reducer on an oxygen cylinder and vice versa.

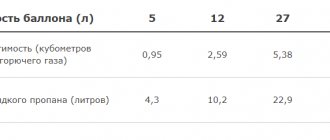

Cylinders for propane-butane . Three types of cylinders are manufactured in accordance with GOST 15860-84. For HPOM, type 3 cylinders are mainly used. The maximum operating pressure in cylinders for reduced gases is different for each of them. Thus, for propane the maximum operating pressure should not exceed 1.6 MPa (16 kgf/cm2), and for butane - 0.45 MPa (4.5 kgf/cm2).

The color of the cylinder is red.

Liquefied gases have a high coefficient of volumetric expansion, so the cylinders are filled in such a way that the vapor cushion in them is sufficient to absorb the liquid that expands when heated. The volume of gas in a 50-liter cylinder is about 11 m3.

Cylinders for other compressible gases (hydrogen, nitrogen, argon, urban, natural, etc.) are made seamless in accordance with GOST 949-73. For these gases, cylinders of type 150 and 150A are used, and for methane and compressed air, cylinders of type 200 or 200A are used.

Data on gas cylinders used in flame processing of metals

| Gas | State of the gas in the cylinder | Maximum operating pressure, MPa (kgf/cm2) | Cylinder color | Connection thread |

| Oxygen | Compressed | 15 (150) | Blue | 3/4″ pipe, right |

| Acetylene | Dissolved in acetone | 2,5 (25) | White | Attached with a clamp |

| Hydrogen | Dark green | |||

| Propane | Liquefied | 1,6-1,7 (16-17) | Red | |

| Argon grades I and II, technical | Compressed | 15 (150) | Black with white top | 3/4″ pipe, right |

| Helium | Brown | |||

| Carbon dioxide | Liquefied | 7,5 (75) | Black |

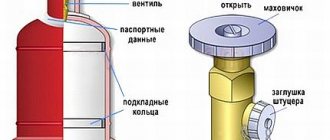

CYLINDER VALVES

Valve for acetylene cylinders . Designed for a working pressure of 2.5 MPa (25 kgf/cm2), it is made of steel and has a thread different from other valves. The balloon reducer is connected to the valve using a special O-shaped clamp, and opening and closing is done with a special socket wrench. Three types of acetylene valves are commercially produced, of which two (VBA and VAB) are with a membrane seal and one (VA) is with a gland seal.

Valve for oxygen cylinders . Designed for a working pressure of 20 MPa (200 kgf/cm2), made of brass. The VK-74 valve has a fluoroplastic seal in the valve, due to which the handwheel is rotated manually. All parts of oxygen valves must be thoroughly degreased and protected from contamination during operation. Oxygen cylinder valves can be used for nitrogen, helium, argon, carbon dioxide and compressed air.

Valve for propane-butane cylinders . Designed for a working pressure of 1.6 MPa (16 kgf/cm2). There are several models of propane-butane valves. They differ in the way they ensure tightness inside the gas cavity. For these purposes, membranes, rubber stockings, gaskets, etc. are used. All valves have a left-hand thread with a diameter of 21.8 mm (thread profile according to GOST 6357-81).