Industry has been successfully using vacuum for a long time, for example in vacuum dryers. But in handicraft production, as well as in everyday life, there are many tasks for it.

All you need to use it is a sealed container (with the advent of polymer materials, this has ceased to be a problem) and a special pump, through which you can completely or partially pump out the air.

You can buy such a device, but it is not the only option. Due to the simplicity of its design, you can easily make a vacuum pump with your own hands, saving money for other useful purchases. We will talk about how to do this in this material.

DIY vacuum pump from a car compressor

You can make a manual vacuum pump with your own hands from a regular car or bicycle pump using a very simple technique. Here is the “recipe for magic”:

- After unscrewing the cover installed on top of the pump sleeve, remove the rod with the cuff.

- Disconnect the cuff by unscrewing the screw that holds it, and then screw it back, only with the other side. After this we return the rod to its place.

- All that remains is to connect a plastic check valve to the tube through which the pump in its previous life pumped air (now it is a suction tube). This product is very cheap, it is sold in a spare parts store for pumping and compressor equipment. The valve must be installed correctly: it must allow air into the pump sleeve, and not vice versa. To check in which direction the valve allows air to flow, simply blow into it.

We tightly place a tube made of durable material onto the free end of the valve (so that it is not compressed by atmospheric pressure), after which the pump can be considered ready.

As you can see, the manufacturing process of a hand vacuum pump is extremely simple. Using such a device, you can create a sufficient vacuum in a bag of clothes or a food storage container in several steps.

Indications for use

A pump (or vacuum pump) is a modern cylindrical device designed to improve the quality of sexual life.

There are several indications for its use:

- The need to increase the volume or length of the penis.

- Partial or complete absence of erection.

- Insufficient degree of elasticity of the penis during sexual intercourse.

- Impotence.

The principle of operation is that the device creates high pressure in the groin area of a man. This leads to increased blood flow, stretching of the cavernous bodies and, accordingly, to an enlargement of the penis. Ready-made equipment can be purchased at a price of 3,000–5,000 rubles. It is much more profitable to create a vacuum pump for the penis with your own hands.

DIY vacuum pump from a hospital syringe

In the previous section, we learned how to make a very practical vacuum pump, but at the same time we were left without a conventional pump, which not everyone is ready to accept.

If you cannot afford such luxury or your religion prohibits you from disassembling car pumps, use a regular medical syringe as a pump.

For just a few rubles you can buy it at any pharmacy.

We begin to master the secret technology:

- In addition to the syringe, prepare two plastic check valves and a short silicone tube of such a diameter that the valves fit tightly into it.

- Use a needle or awl to make a small hole in the middle of the silicone tube. Its diameter should not be too small so that the nozzle from the syringe can be pushed into the hole, but not too large so that the nozzle fits as tightly as possible.

- Insert the syringe into the finished hole.

- Now you need to insert a check valve into the silicone tube at both ends. One is installed in such a way that it lets air into the tube, the other, on the contrary, must release air from it. We will call the first valve the suction valve. A rigid tube must be attached to it, through which the vacuum pump will be connected to a container, bag of clothes or other object.

By moving the syringe piston back and forth, we, although not immediately (the volume of the syringe is not too large), will be able to create the necessary vacuum.

A device such as an uninterruptible power supply is necessary to insure devices during a power outage. Uninterruptible power supply for a heating pump - features of choosing a device and the cost of the unit.

Let's look at the operating principle of a heat pump for heating a house here. How effective is this system?

Most often, circulation pumps are purchased for private homes, and if in your village there is no service nearby for the maintenance of such devices, then you need to master some types of repairs yourself. Here https://microklimat.pro/otopitelnoe-oborudovanie/otopitelnye-pribory/remont-cirkulyacionnogo-nasosa-svoimi-rukami.html some instructions and tips for repairing pumps are given.

How to make a penis pump: description of the assembly process

It will take 30-50 minutes to create a pump at home.

- In the bottle, carefully cut out a hole for the penis in the center of the cap. The size corresponds to the width of the erect penis.

- On the other side of the bottle we cut a hole for the tube.

- We place its edge in the hole and treat it with sealant.

The manufactured pump lasts 2-3 years, not inferior in properties to the conveyor version. The following video describes the self-assembly process of the pump:

Aquarium pump modification

Having an aquarium with fish in your home not only helps calm your nerves, but also allows you to successfully solve the problem of creating a homemade vacuum pump. Yes, not a simple one, but with an electric drive.

All you have to do for this is to slightly change the design of the aquarium compressor, namely, swap its valves. This is not difficult to do, since they are installed on detachable mounts.

Aquarium compressor

During operation of the compressor, condensation may accumulate in it, to remove which it is recommended to drill a hole.

The most common mistakes

Assembling correctly is not a difficult task. Beginners make mistakes in the methods of processing the device, choosing components and exercises.

Mistake #1 – Incorrectly selected seal

Refusal of the seal or incorrect selection of the hole size leads to the suction of the testicles into the cylinder. This should not be allowed, as there is a high risk of injury.

Mistake #2 – The tube is not secured

Mistake #3 – Plastic lid

We construct a vacuum pump with a rubber cover. The plastic rubs and puts pressure on the penis during an erection.

Mistake #4 – Narrow tube

We do not use material with an internal diameter of less than 2-3 mm . It bends and air does not enter the cylinder.

Liquid ring pump

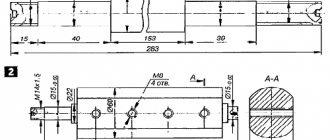

Anyone who is willing to spend a little more labor and money on fees for a familiar turner and welder can take on the manufacture of a vacuum pump with a liquid piston (the second name for water ring-type units). Such a pump is a pipe in which an impeller with radial blades is installed with some displacement relative to the axis.

The pump is partially filled with water, and the impeller shaft is driven by an electric motor.

At the same time, the impeller blades also impart a rotational movement to the liquid, as a result of which it is pressed by the resulting centrifugal force against the walls of the housing and forms a rotating ring.

Between the liquid ring and the rotor (impeller) bushing, a crescent-shaped cavity is formed (recall that the wheel is mounted eccentrically), which plays the role of a working chamber.

The blades divide it into several parts, and their volume either increases or decreases as the wheel rotates. At the beginning of the cycle (increase in volume), the cell sucks in the pumped gas, at the end (decrease in volume) it is compressed, that is, it is pumped.

In this case, the heat released in the compressed gas “goes” into the water, so that its temperature remains almost constant (isothermal compression). The water gradually heats up more and more, so it has to be changed periodically.

Water enters the pump from the tank through the hydraulic seal of the rotor shaft or through the suction pipe. Then it, like the compressed gas contained in it, is discharged through the outlet (discharge) openings.

As you can see, the liquid ring pump is designed quite simply. In addition to the materials (pipes for making the housing, end caps and shaft, steel sheet for making the wheel, blades and tank), you will need bearings and an electric motor. The impeller is installed so that it does not come into contact with the housing and end covers. Thus, there is no friction between any parts of the pump, which means there is nothing to wear out.

Water ring pump

Pressing of bearings is carried out using a special tool - a puller. You can also make it yourself. The required force in any puller, regardless of its design, is created by tightening the thread. The simplest option is two plates with holes for the studs. We rest one plate against the end of the shaft, and install the other behind the bearing.

Having inserted the studs into the holes of the plates, you need to tighten the nuts on them one by one and gradually, as a result of which the second plate will be attracted to the first, and at the same time press the bearing onto the shaft. Before starting the operation, it must be lubricated with lithol.

A liquid ring pump can pump out gases with a high content of dust, sand or moisture without consequences. In this case, all the debris remains in the water, that is, in parallel with pumping, gas filtration occurs. However, during prolonged operation under such conditions, the ends of the impeller may wear out. In this case, it will be enough to restore the required clearances by installing gaskets between the housing and the end covers.

The liquid ring pump belongs to the oil-free category. This means that its working mechanism does not require lubrication. Only a small amount of it needs to be injected into the bearings. High precision in the manufacture of individual parts is not required.

Instructions for use

Achieving the effect of exercising with a vacuum pump is possible if certain rules and safety precautions are observed. We recommend that you listen carefully to your own feelings during the procedure - if any discomfort or pain occurs, the session should be stopped immediately. This will mean that you have assembled the device incorrectly - using such a device can cause harm to the body.

As for the general rules for using a vacuum pump, they are as follows:

- Beginners are not recommended to use a vacuum pump for more than 5 minutes;

- After each use of the device, you must thoroughly wash both it and the penis;

- It is recommended to use a water-based gel lubricant during the procedure;

- Classes with a vacuum pump are not carried out at low temperatures;

- After placing the penis in the pump flask, the air must be pumped out gradually until the penis reaches a fully erect state in a vacuum;

- To avoid accidental pumping out of air, use a clothespin on the tube;

- One procedure should not take more than thirty to forty minutes.

If you follow these recommendations, it is possible to safely increase the length of the penis by 3-4 cm, and its volume by 1-1.5 centimeters.

Vacuum pump from a refrigeration compressor

Let's look at how to make a vacuum pump with your own hands from a compressor.

The compressor from an old refrigerator is an almost finished vacuum pump.

But in order to finally transform it into one, you will have to remember the skills of a home craftsman.

Here's what to do:

- Use a hacksaw to cut off the top of the compressor.

- Remove the motor suspended on springs and connect the suction and discharge lines with tubes made of oil-resistant material (sold in car dealerships) with scraps of copper tubes available in the housing.

- Now you need to make a cover for the body. The cut top cannot be used for this purpose, since the oil flowing down it will seep out. The new lid should be slightly smaller in diameter than the body so that its edges are inside it. It is recommended to solder it from brass foil, providing stiffeners with an external soundproofing coating made of linoleum. Theoretically, there is no need to equip the lid with a “blowhole”, since if all the tubes are connected tightly enough, the pressure inside the compressor will remain at atmospheric level. However, in case of unexpected depressurization, you should still install something like a breather.

- Unlike a liquid ring vacuum pump, this vacuum pump is not oil-free. There is oil inside and its level constantly drops as it is thrown out in the form of mist through the discharge pipe. To control the oil level, it is recommended to equip the pump with a homemade level gauge. It is a part of the transparent body of a ballpoint pen (installed vertically with the cap up), connected to the compressor body with an oil-resistant tube. The cap must be slightly unscrewed to allow air to pass through. For ease of use, you need to scratch transverse marks on the level gauge corresponding to the oil level - minimum and maximum.

The converted compressor must be placed in a box, which is a frame made of 25x25 mm steel angle covered with any sheet material.

To ensure that the housing does not have to be disassembled to check the readings on the oil level gauge, cut a hatch into its side wall. If the pump is located in a poorly lit place, you can also install a light bulb next to the level gauge for illumination.

Since the oil pump does not tolerate moisture and dust getting inside, it is necessary to install a filter in front of the suction pipe. If relatively dry air will be pumped out, it is enough to install a fine air filter for cars of the FT-206 type.

Refrigerator compressor

If it is assumed that the pumped-out medium will have high humidity (for example, when using a vacuum pump to accelerate the evaporation process in the distillation cube), you will have to additionally install a receiver with a sump or some special dehumidifier at the inlet.

An oil filter type FV-6 should be connected to the discharge pipe. It has a plug to drain oil condensate.

It remains to install an excess pressure relief device in the area between the discharge pipe and the oil trap filter. If you turn on the engine with excess pressure on the discharge line, it will take too long to spin up and the starting winding will burn out. The best solution is to install an electro-pneumatic valve through a tee and connect it in parallel with the engine.

When the pump is turned off, the valve will open. When switched on, voltage will be applied to its coil and it will close, so that all the forced air will flow through the oil trap.

The Vilo brand is known throughout the world. Wilo pumps: technical specifications and model overview - read about all this in the article.

Read about the features of choosing and installing circulation pumps in this material.