Any concrete structure has a reinforcing frame, which is traditionally made of steel elements. Relatively recently, fiberglass reinforcement began to be used for these purposes, the use of which to strengthen the foundation, if we take into account the reviews of experts, is an excellent solution.

Reinforcement of strip foundations with fiberglass reinforcement

Types of plastic fittings

There are several types of reinforcement, depending on what material it is made from:

- Fiberglass. It began to be used back in the days of the Soviet Union. At that time, there was a rapid development of printed circuit editing in the field of radio electronics. The boards were then made from PCB. The peculiarity of this material is its woven base, bonded with artificial resin. Gradually fiberglass replaced fabric. Thanks to this, it was possible to expand the scope of application of fiberglass. They began to make furniture and household goods from it. The material has even found its place in aircraft manufacturing and the military industry. Over time, it was introduced into construction. Frames for the foundation began to be made from fiberglass reinforcement. They are suitable for conditions where other materials would deteriorate quickly. To create fiberglass, glass and epoxy resin are used.

- Basalt-plastic. This material is easier to make than fiberglass. Only basalt is enough for it. The popularity of such reinforcement is associated with its high level of strength and elasticity. It conducts less heat, but is heavier.

- Carbon fiber. This is an expensive material that requires carbon fiber and resins. The high price is due to the peculiarities of carbon fiber production. It forms the basis of the material. To obtain it, all temperature parameters and processing time must be strictly observed, since organic fibers are used as raw materials. The use of this material is possible in different areas of life. This plastic foundation reinforcement is very elastic, but the downside is its fragility. Therefore, if you plan to build a more durable and stressed structure, choose another option.

The first option is the most popular, since its price is not high and its performance properties are quite acceptable.

What is reinforcement made of composite materials?

Composite reinforcement is an excellent alternative to traditional products for similar purposes made from metal. Today, the following options for reinforcing products are presented on the construction market:

- from staple fiberglass, produced from inorganic glass by melting it (fiberglass of this type has good thermal insulation and reinforcing characteristics, which predetermined the main areas of its application: thermal insulation boards, glass wallpaper for wall decoration, canvases for reinforcement, individual fibers are produced from staple fiberglass, with the help of which concrete screeds and plastered surfaces are strengthened);

- with materials used as binding elements (thermosetting resins of the non-curing type, the most famous of which are epoxy and epoxy-diane);

- with additives, the use of which makes it possible to increase the ductility and strength characteristics of reinforcement made from composite materials.

One of the stages of creating non-metallic reinforcement: feeding and unwinding of roving

The fittings, made of composite materials, are available in two versions.

With special corrugation on the surface

The technology for obtaining such a surface is as follows. A fiberglass thread is wound onto a smooth rod of composite material, which forms the corrugation elements. Then the surface of the rod with the thread wound on it is covered with a thin layer of resin made of a polymer material. A reinforcing bar with such corrugation, due to the increase in the contact area, is much better bonded to the concrete mortar, strengthening it well. These rods are used to reinforce foundations and other massive concrete structures.

An improved type of fiberglass reinforcement

with a conditionally smooth profile.

In order to ensure good adhesion of such a rod to the concrete solution, a powder is applied to its surface, which is fine sand. Due to the complex technological process of manufacturing such reinforcement, its cost is slightly higher than the price of other types of composite reinforcing products.

Composite reinforcement coated with quartz sand

Comparative parameters of products made of fiberglass, basalt and carbon fiber will help you better navigate the characteristics of reinforcing elements made of composite materials.

- The modulus of elasticity for products made from fiberglass is 55,000 MPa, and for products made from basalt fibers – 78,000 MPa.

- The tensile strength of reinforcing products made from fiberglass is 1250 MPa, and that of reinforcement made of basalt fibers is 1450 MPa.

- The advantage of fiberglass reinforcement is its cost, which is approximately 15% lower than the price of products made from basalt fiber.

Reinforcement made of composite materials can be supplied to the customer either as cut rods, the length of which is 6 m, or in coils, in each of which 50 to 100 meters of products can be wound. The diameter of non-metallic reinforcement bars can range from 4 to 18 mm.

Fiberglass reinforcement in coils of 50 meters

How to produce

Composite rods are made in three ways:

- Needletrusion. During the procedure, individual fibers are twisted into one and at the same time impregnated and braided. Since such technological lines operate at high speed, the process does not require large financial costs, which also affects the price. In order for the reinforcement to acquire a characteristic relief, it is wrapped with threads and a periodic profile. The thickness of the rods depends on the number of threads. This manufacturing method allows us to obtain products that have good adhesion to concrete.

- Plaintrusion. First, the main rod is formed, after which it is wrapped in a spiral in two directions.

- Pultrusion. This is the oldest technique. First, the fiber is formed and impregnated, and when it hardens, it is pulled through a spinneret. This system operates at the polymerization temperature of the plastic and allows the final forming and stretching of the reinforcement. The cost of the material obtained by this method is higher, and the production speed is low.

There are smooth or profiled products.

Specifications

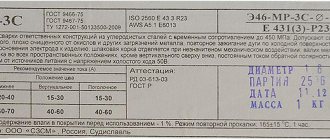

The production of glass fittings takes place in accordance with GOST 31938-2012. The document specifies what size the products should be, their appearance, raw materials, environmental safety and other parameters.

A plastic frame, like a metal one, is used to fasten the monolith in order to increase its ability to withstand loads. This allows you to increase the service life of the building.

The functions of such reinforcement do not differ from steel, and it has the same indicators:

- The weight of the products is 0.02-0.42 kg per meter.

- The length according to the state standard should be 0.5-12 m. The parameter is measured in 0.5m increments.

Finished plastic reinforcement for the foundation must not have chips, cavities, burrs, wounds with gusts, delamination, or dents.

When reinforcing the foundation, steel rods are gradually beginning to be used more. To ensure better adhesion to concrete, they are additionally treated with sand.

The main disadvantages of metal fittings

The reinforcing frame, which is present in each foundation, eliminates the risk of destruction of the concrete structure, which can occur when it is exposed to bending and compressive loads. In the presence of such a frame, which was previously made only of metal reinforcing elements, the foundation can easily withstand serious loads that arise due to frost heaving of the soil. In such a reinforced concrete structure, cracks, delaminations and other defects that affect its reliability and durability practically do not occur.

Meanwhile, metal reinforcing elements also have disadvantages, the main one of which is that the metal does not withstand the effects of high humidity and aggressive environments (salt sea water, concrete slurry, etc.). As a result of such interaction, corrosion processes arise and develop in metal structures.

Corrosion affects the integrity of the concrete structure

The use of metal reinforcing structures is not recommended for strengthening concrete structures of those buildings whose premises are subject to requirements for radio transparency and magnetic inertness. We are talking about premises in which complex electronic equipment is installed (various research centers, laboratories, medical institutions). To strengthen the foundations and walls of such buildings and premises, only dielectric fiberglass reinforcement can be used, which appeared on the construction market relatively recently.

Comparative characteristics of steel and fiberglass reinforcement

Advantages and disadvantages

Plastic reinforcement has gained popularity in construction due to a large number of positive properties:

- The rods have increased strength. Even when exposed to tensile forces, the material can retain its properties.

- The price is affordable. A foundation made of plastic reinforcement will cost less than if you use metal rods.

- Small mass. This facilitates the work process and transportation of products.

- Reliability. There is no need to treat the material with protective coatings. It is not subject to corrosion and easily tolerates sea water, hydrochloric acid, and alkalis.

- Low level of thermal conductivity. The rods can be used for residential buildings, as they do not create cold dams. This allows you to create favorable temperature conditions in the room.

- Safety for the environment. During the production of products, sanitary standards are strictly observed, so they do not pose a danger to human life and the environment.

- Long service life. Reviews show that with the help of plastic reinforcement it is possible to improve the performance properties of the structure several times.

- Easy to cut and convenient to deliver to the job site. To obtain the required length of the workpiece, you do not need to use special tools.

- Can be installed without the use of welding equipment. Products are knitted with wire or special fasteners.

- They retain their properties even at temperatures of -70 degrees.

- They have dielectric properties. Thanks to this, the products are not destroyed under the influence of stray currents and have increased safety.

Experienced builders claim that plastic reinforcement is ideal for foundations.

The material also has negative reviews associated with some shortcomings of the filler. Such fittings have the following disadvantages:

- Low heat resistance. Polymer binders can withstand a limited temperature range, so plastic rods cannot be used everywhere.

- If they are heated to 200 degrees, the strength decreases and the flammability increases.

- Lower elastic modulus. When using composite rods, it is necessary to carry out special calculations to confirm the possibility of using this material for a load-bearing structure.

- If the reinforcement is constantly in an alkaline environment, then its strength characteristics will gradually deteriorate.

- Hard to bend. This material is difficult to obtain a radius shape. To achieve this you will have to resort to special technological techniques.

Reviews from builders about plastic reinforcement for foundations are quite high. Experts say that such rods:

- They have increased elasticity.

- Not subject to deformation.

- They do not require large financial outlays.

- Do not corrode.

- They do not respond to electromagnetic fields.

- No shielding.

Due to its positive performance properties, the composite is used in many fields. It is a serious competitor to steel.

Professional opinions

“As a design engineer, I often hear the same question from clients - is it possible to use plastic rods instead of steel for the foundation and how to calculate the replacement volume.

Having studied the materials of some factories and tested their products, I came to the conclusion that everything depends on the purpose of use. For example, fiberglass reinforcement with an equal cross-section is almost 3 times tensile strength than metal, but under the same load it will stretch 4 times more than steel. That is, at the base of the building it is absolutely useless; those who write negative reviews are right.

If the tensile strength coefficient of the material is of paramount importance, then you can buy ASP with a diameter 3 times smaller than steel (the so-called equal-strength replacement). Composite products will be cheaper in price and transportation. However, for each linear meter under load, the length of the reinforcement increases by 2.2%, that is, by 2.2 cm. This is unacceptable for most reinforced products. It turns out that for structures under load it is necessary to take not a replacement of equal strength, but a replacement with a volume 4 times larger. The price will be too high. There are other methods for calculating the risks of replacement, but the conclusion is clear in any case: the product is unprofitable, leads to a loss of structural strength, so it cannot be used to strengthen the foundation of private and high-rise housing construction.”

Dmitry, Moscow.

More information about composite rods in the article Plastic fittings - cost of 1 meter. “My construction company specializes in the construction of houses and cottages from cellular concrete, including monolithic pouring and blocks. These are aerated concrete, foam concrete, expanded clay concrete and other analogues. We have extensive experience in using composites, since we use it for reinforcing walls, but not for foundations. Plastic rods are very easy to work with, they weigh little, and can be cut with a regular knife or hacksaw. According to the technology, an armored belt should be formed every 4 rows, but the upper reinforced block (under the roof) is still made of metal for greater reliability and strength. This tactic is justified; for three years there have been no complaints from customers.”

Alexander Pashutin, Nizhny Novgorod.

“I am building a house, and to strengthen the screed, the architectural engineer who oversaw the project recommended buying fiberglass. According to him, plastic reinforcement is not afraid of water and has the same coefficient of expansion as concrete, so cracks are completely eliminated. I looked for information on the Internet, read reviews, and decided not to chase the cheapness, but to buy from a truly trusted manufacturer. Therefore, I ordered the products through a Galen factory dealer. It is really light, quite durable, but it breaks, so it won’t make crooked structures. At the same time, I asked the curator why the foundation was reinforced with steel and not composite. To which he offered to compare the basic characteristics of both materials himself and draw conclusions. The mesh was quickly installed under the screed and carefully poured. A month later we checked it – the screed turned out great, no complaints.”

Mark, Moscow region.

“I often come across negative reviews about composite reinforcement from those who have not even worked with it. I usually recommend using it for foundations for small, lightweight buildings. The material does not rust, is not afraid of dampness, is easy to cut and install, and there is no need to worry about proper pouring, forming a concrete pad and other protective measures.”

Valentin Shevchenko, Ufa.

“I used fiberglass for the foundation for a small brick bathhouse. Although the building is small, changes have been noticeable in six months - multiple cracks have appeared on the lower part of the concrete strip, apparently the building has already begun to sag, because the door opens with force. I shouldn’t have been fooled by advertising, now I’ll sew up the gaps with metal strips or corners, and I’ll try to strengthen the structure with beams.”

Yakov Kuprin, Krasnodar.

Application in construction

Plastic reinforcement is used in the same way as steel. With their help they build:

- bridges;

- walls and floors;

- different types of foundations;

- fencing.

The composite is used in the production of sleepers, since concrete disintegrates under intense vibration. With its help, docks, berths, and various coastal barriers are erected. I equip shafts with such fittings and secure insulation and cladding materials.

It is not uncommon for polymer rods to replace steel parts during the construction of a frame or wooden building.

Working with different types of plastic fittings is much easier and more convenient. The process does not require large financial expenditures when compared with metal structures.

There is practically no similar material in the world. Its positive qualities allow it to expand its scope of application. It meets all the requirements of the construction process.

The linear expansion of concrete when using plastic and steel reinforcement occurs in the same way. Thanks to this, there is no risk of cracks and other deformations while pouring the solution.

Knitting features

You need to find out how to knit plastic reinforcement for the foundation in order to carry out the procedure correctly. A high-quality and reliable foundation is the guarantee that the house will last a long time. Therefore, reinforcement of the base is an important stage of construction.

Most often, strip foundations are used for buildings. For this purpose, the knitting of plastic reinforcement is carried out with some special features. This procedure helps to make the structure uniform and durable. The rods are tied at their intersections. This is done with wire or special means.

The wire is bent in the middle, after which it is put on a hook, applied to the reinforcement and tightened. This is quite difficult, so a plastic tie will help make the job easier.

Plastic shut-off valves are considered an important element of the reinforcing system. It helps to more firmly attach individual rods to each other.

Fasteners are popular among builders. These are embedded parts that create a protective layer of a certain thickness in concrete.

Such clamps are made of polyethylene. They are poured under high pressure. They provide reliable fastening of reinforcing bars, frames and allow you to obtain a strong concrete or reinforced concrete structure. Clamps are used in horizontal and vertical surfaces, and they are also used to create formwork.

Tips for choosing

Nowadays the number of manufacturers of composite reinforcement has increased, so low-quality products are found. Therefore, when choosing a material, you need to pay attention to the following nuances:

- Color. If the rods are good, then in the entire batch they are the same color. If some elements have a different color, then there was a temperature violation during production.

- Cracks and delaminations. They shouldn't exist. These defects are easy to notice on the cut.

- Fiber breaks. Because of them, the characteristics of the material are reduced. They are visible to the naked eye.

- Uneven winding. This indicates the use of old equipment and a loss of continuity.

Over time, they plan to introduce strict requirements for plastic fittings. This material can replace steel. But in order not to end up with a low-quality product, you should carefully study the characteristics.

Advantages and disadvantages

List of quality properties of composite products:

| Advantages | Flaws |

| Light weight | Insufficient tensile and tensile strength |

| Do not conduct electricity | Temperature range: from -15 to +120 °C |

| Resistant to corrosion, rotting | Excessive plasticity of the material, due to which the frame bends and moves during concrete pouring |

| Inert to moisture, solvents, chemically aggressive substances | Plastic clamps are used to secure the crosshair areas |

| Easy to install | It is impossible to form angular and curved structures |

| Easy to transport | Unknown actual lifespan |

| Not environmentally friendly material | |

| High price |

Manufacturers recommend using polymer reinforcement in the same areas as metal reinforcement (foundation, monolithic walls made of heavy concrete, etc.). However, the feasibility of such a solution is questionable. The use of products in the following areas is justified:

- Construction of walls, support pillars, partitions.

- Construction of roads, sidewalks, pedestrian paths.

- Strengthening screeds, decks, bridges.

- Production of shaped products.

- Formation of frames for greenhouses, hangars, extensions.