Content

- Main features of MP-3 electrodes

- Technical characteristics of electrodes

- Advantages of electrodes

- Features of welding with electrodes

- Application of electrodes for welding

- Catalog of electrodes for welding

MP-3 welding electrodes for manual arc welding are among the most popular on the modern market. The list of critical structures that they weld includes pipelines and pipe fittings, boilers and tanks, and almost the entire range of lifting and transport equipment. They are also widely used in everyday life, without causing any special difficulties in work for non-professional welders.

Designation

The letter “E” indicates that we are talking about electrodes intended for manual arc welding. The numbers “46” provide information about the value of tensile strength, which is measured in kgf/mm2. MP-3 is the brand of designated electrodes. “LUX” is a trade name assigned to its products by the manufacturer.

Next comes the cross-sectional diameter of the electrode. The letter “U” indicates that low-alloy steels with a low carbon content can be welded with these electrodes. The next letter “D” means that the electrode has a thick coating. The letter "E" refers to the designation of coated consumable electrodes, according to the international classification.

The number “43” is the value of tensile strength after the welding process is completed. “0” means that the elongation does not exceed 18 percent. (3) refers to the impact strength value of the deposited metal.

The letters “RC” stand for rutile-cellulose coating. One letter “P” will mean that the coating is purely rutile. The last two digits “11” indicate that welding with these electrodes can be carried out in all positions, excluding the movement of the electrode from top to bottom. The designation is applied to a tag glued to the packaging. This allows you to find out what characteristics the MP-3C electrode has and make the right choice.

Main features of MP-3

Electrodes for welding MP-3 are intended for joining parts mainly made of low-carbon (with a C content of up to 0.25%) and low-alloy steels. The tensile strength of such steels does not exceed 50 kgf/mm², that is, the tensile strength is 490 MPa. The rods are made from Sv-08 wire; the diameter range varies from 2 to 6 mm. The production of electrodes for welding is regulated by state standard 9466 and GOST 9467.

The products have a rutile coating (titanium dioxide), which ensures instant first and second ignition, and the weld pool is reliably protected from the harmful effects of nitrogen and oxygen. The main characteristics of the product are indicated in the labeling, for example: E46-MR-3-4-UD2, where

- E-46 – the type to which the electrode belongs;

- MP-3 – product grade (R – rutile coating);

- 4 – rod diameter;

- У – composition of the metal being welded (carbon steel);

- D2 – thick coating, second group.

The length of the MP-3 electrode depends on the diameter: with d=2...3 mm it is 350 mm, with d=4...6 mm – 450 mm. You can weld parts with a thickness from 3 to 20 mm.

Design and material of manufacture

In the center of the product there is a rod made of welding wire Sv-08, it is coated with a rutile-based coating.

Aluminosilicate or carbonate is added to it as additives. Additives increase the viscosity of the surfacing metal and protect against the appearance of cracks and pores in the weld material. Such electrodes have 3 modifications: MP 3 itself, MP 3s and MP 3m. Ilmenite was added to the coating of the MP-3m brand rods, and additives were added to the coating of the MP-3s electrodes to increase the degree of ionization . What is the difference between them: in terms of basic physical and mechanical characteristics, there is practically no difference between all three models. The differences appear during operation: MP-3s, thanks to ionizing additives in the coating, allows easy ignition of the arc on low-power household welding inverters.

They also reduce the amount of harmful substances released into the atmosphere, primarily manganese. With this composition it is easier to obtain a uniform seam on low-power welding machines.

The diameter of the wire is in the range of 2-6 mm, and the length is from 30 to 45 cm. The diameter of the electrode indicated in the marking is also determined from it.

If the rods were stored in a dry warehouse in their original packaging, there is no need for additional calcination . However, if for any reason the moisture content of the coating exceeds 1.5%, calcination will be required for 40 to 60 minutes at a temperature of about 170°C. It is unacceptable to work with wet electrodes: the coating loses its properties, and it is unlikely that a strong and durable seam will be obtained.

The coating is made on the basis of rutile, or titanium dioxide in powder form. It is mixed with a binder, and the rods are dipped into the resulting mass. The ends of the 20 mm rod are not covered with coating: one of them will be clamped in the holder, and the other will be used to ignite the electric arc. Next, the coated electrodes are dried at high temperature.

After drying, finished products are painted blue and markings are applied to the coating. Decoding MP-3 means:

- M – rutile coating;

- P – high quality seam;

- 3 - model number in the manufacturer’s lineup

The rod material, in addition to iron, contains additives in the following percentages:

- Manganese 0.66;

- Silicon 0.1;

- Carbon 0.1;

- Phosphorus 0.03;

- Sulfur 0.019.

Finished products are packaged in boxes sealed with polymer film to maintain low humidity levels . Shipment in cardboard boxes and packs of technical paper is allowed.

Advantages of MP-3

Welding with MP-3 electrodes with rutile coating is considered the most environmentally friendly and safe in terms of the release of toxic compounds into the air, so work can be performed in closed, poorly ventilated rooms. Among other advantages:

- good first and re-ignition;

- stable burning of the electric arc (arc – medium, short or extremely short);

- unhindered separation of slag crust;

- low percentage of spattered metal;

- the ability to weld parts of large thickness;

- high-quality, durable, intergranular corrosion-resistant seam.

Like any others, rutile-coated electrodes of the MP-3 brand must be stored in a dry room at a temperature not lower than +15 °C. The permissible moisture content in the coating is 1%. If this indicator is exceeded, the electrode requires calcination for an hour at a temperature of 150-180 °C.

general information

Welding elements of the MP-3 brand are suitable for joining workpieces made of carbon and low-carbon steels. They can be welded in close contact or leave a small gap. In the latter case, experts recommend choosing the welding mode very carefully and using less than the rated current to avoid the formation of defects or cracks in the metal.

Additive materials produced under this brand are advantageous in that during their use a minimal amount of substances is released, so there is no doubt about their safety. They are indispensable for welding carried out in particularly difficult conditions, since they are the least demanding on the cleanliness of the surface, which may have rust stains or moisture, but this does not greatly affect the quality of welding.

Welding work is carried out using conventional transformers that maintain a minimum voltage of 50 V. MP-3 welding material can also be used for mounting parts of medium or large thickness. The metal can be easily welded throughout the entire recess, ensuring high strength of the joint created. Based on the technological conditions of welding work, when working with these electrodes, it is not necessary to create a large arc to obtain a temperature sufficient to set the metal with the electrode .

As part of the preparatory stage, the electrodes must be dried and calcined, which only has a positive effect on their working properties. Electrodes of this brand can be used in combination with transformers that support operation with direct and alternating current. Filler material can be worked in any position due to the fact that, regardless of the operating conditions, they can provide a high quality connection.

At the end of welding, it is necessary to perform the final operation - remove slag from the metal. This is done very easily, so the quality of the connection remains consistently high. The coating of the electrode directly affects its inherent advantages. The welding material has a special chemical composition, thanks to which it is possible to maintain a stable arc when working in any plane. Due to the stability of the arc, the quality of welding is consistently high, regardless of the influence of extraneous factors.

Features of MP-3 welding

Parts can be welded using either alternating or direct current of reverse polarity. When using a transformer, the open circuit voltage must be 65 (+/-5) Volts. Welding is possible with both long and short seams.

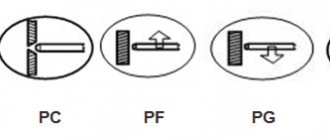

To perform RDS, any spatial positions are acceptable except for vertical descent.

- Standard bottom (horizontal) position. Parts of large and medium thickness are welded in this way. The diameter of the MP-3 electrode is, as a rule, at least 6 mm. The rod is positioned at an acute angle to the seam plane in the direction of welding. Cook on a medium and short arc at high currents.

- Welding “in a boat” - fillet welds are welded in the lower position (angles 30 °, 45 °, 60 °), welding is performed on the shortest possible arc with a vertically located rod. With a “symmetrical boat” (the electrode conditionally divides the right angle of the connection into two 45% each), they usually cook at higher currents. “Asymmetrical boat” implies that the rod divides the angle into 60° and 30°; in this case, sagging and undercutting of the weld are more likely.

An electrode of this brand is also used to weld a horizontal seam on a vertical plane, a vertical seam in an upward position, and a seam in a ceiling position.

Let us note once again that the rod must be at an acute angle to the surface, since a different position may result in increased release of slag and its entry into the weld pool.

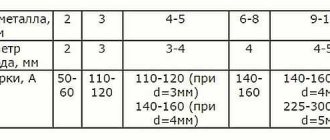

Recommended current values

The operating current depends on the diameter of the selected electrode and the welding position. Recommendations for selection are summarized in a table, current strength is given in amperes

| Diameter, mm | Vertical seam, amperage | Lower position, current strength | Ceiling position, current strength |

| 3 | 90-110 | 100-140 | 100-120 |

| 4 | 140-180 | 160-220 | 140-180 |

| 5 | 150-200 | 180-260 | Not applicable |

| 6 | Not applicable | 300-360 | Not applicable |

It is important to remember that these are indicative values. For specific parts, a test weld is made, and the current intensity is adjusted depending on its results . You should start with the minimum values, since rutile electrodes do not like excessive current values.

If the test seam shows insufficient penetration, the current should be gradually increased in 5 ampere steps until satisfactory results are obtained. At elevated operating current values, the spattering of the metal increases and the stability of the arc decreases. Burn-throughs may occur on thin workpieces.

Application of MP-3 electrodes

Electrodes make it possible to weld parts of mechanisms and structures of a wide range of equipment.

- Mills of various types (sheet rolling, section rolling, crimping, etc.).

- Cranes, elevators, conveyors, escalators, winches and other lifting and transport equipment.

- Gas, oil pipelines, oil storage tanks.

- Containers, tanks for transportation of dangerous goods.

- Steam boilers and other boiler equipment.

Electrodes are also used to weld metal building structures, including reinforcement and other embedded elements for reinforced concrete products.

Leading domestic manufacturers

On the market of welding consumables, there are products of varying quality, unfortunately, not always the best. To avoid problems, it is recommended to purchase electrodes produced only by manufacturers who are generally recognized leaders in this industry segment. Let's name just a few brands.

- First of all, this is the Magnitogorsk Electrode Plant (abbreviated as MEZ). Highly qualified employees of the specialized laboratory included in its structure developed the “MP-3 Lux” brand. These products are distinguished by improved technical characteristics in relation to the metal of the formed seam. They have been successfully certified by HAKC experts for use in technical devices of the following groups: CK, PTO, OXHBP, OTOG, NGDO, MO, KO, GDO and GO.

- There are also no complaints about MP-3 brand electrodes produced at the production facilities of the Losinoostrovsky Electrode Plant operating in Moscow. The recognition of these products is ensured by the dark blue and white colors of the branded packaging.

- Among the leading domestic manufacturers is the Welding Materials Plant from the city of Sudislavl, (abbreviated SЗCM), operating in the Kostroma region. RF. The high quality of the MP-3 electrodes he produces is evidenced by the fact that they were supplied to such industrial giants as Norilsk Nickel and some other companies of the same profile. The boxes with these products must have the CЗCM logo.

Among the foreign enterprises specializing in the production of welding consumables, it is worth highlighting the Swedish company ESAB, headquartered in Gothenburg. It was founded in 1904 and is rightfully considered today the leader in the global electrode market.

Advantages and disadvantages

The advantages of the MP brand are mainly associated with the use of rutile coating.

- When welding with alternating current, the stability of the arc is the same as when welding with direct current.

- Ease of arc ignition. Repeated ignition will not force the welder to strain. MP electrodes are suitable for both welding and tack welding.

- Spatter percentage is extremely low . It approaches the same figure when welding in inert gas.

- The rutile coating prevents the ingress of slag and various oxides into it. The seam turns out smooth , without visible transitions, in good presentation.

- Coating with rutile provides the seam with good impact strength and high fatigue strength.

- The properties of the seam are not affected by the wet surface of the materials being welded.

- The presence of rust and other contaminants is not an obstacle to welding work . It is possible to weld surfaces coated with a thin primer.

- It is possible to perform high-quality welding with electrodes whose diameter is larger than recommended.

- A short-term change in arc length does not affect the quality of the seam.

- released during welding with rutile electrodes are not toxic.

The disadvantages are few and far between.

- The increased fluidity of the weld pool does not make it possible to obtain a high-quality weld in a vertical spatial position with the “top-down” direction

- Increased consumption of filler material compared to other similar welding materials.

- High requirements for setting the welding current - deviations will contribute to the formation of pores.

- When carrying out welding work, the rod should be held at an acute angle . Welding at right angles will contribute to the formation of a large amount of slag and its inevitable entry into the weld area.