Home / Boiler automation

Back

Published: 06/11/2019

Reading time: 2 min

1

5266

Modern heating boilers are equipped with electrical devices for ease of use and increased functionality. One of these is a water flow sensor for a gas boiler. The three best models, possible malfunctions and methods of application are discussed further in the article.

- 1 Where used 1.1 For gas boilers

- 1.2 For pumps

Where are they used?

Flow sensors are used in devices where control of the water supply system to an apartment or private house is necessary. By installing this type of equipment on a gas boiler, you can significantly reduce your monthly payment, and the heat generator will also become much safer to use.

For gas boilers

There is a water flow regulator in all boilers (Buderus and other models). Thanks to the device, the heat generator can work as a device for heating a home and heating water.

The gas boiler water pressure sensor is mounted on the pipeline. Once installed, it begins to respond to flow as soon as the hot tap is opened.

The regulator transmits a signal to a special board installed inside the boiler. After this, the circulation pump automatically starts and the pressure in the gas injectors decreases. As a result, the water circulation valve closes. After this, the water heating nozzles turn on, and the liquid begins to warm up in the heat exchanger. After closing the valve, the mounted sensor for the gas boiler records this action and transmits the corresponding signal to the board.

For pumps

In many private houses, an autonomous water supply system is installed. This is necessary if there is often low pressure on the site and the owner wants his yard to be independent of the centralized water supply. The equipment is installed so that the water pressure in the house always remains at a high level.

The system includes:

- special pump;

- a tank where water is poured;

- control system.

You can connect various household appliances to the pump, for example, dishwashers or washing machines. In this case, the regulator is necessary for timely activation of the pump, ensuring a stable water supply.

And it doesn’t matter whether the wash has started, the tap is open in the kitchen, or water is draining from the toilet tank - the regulator performs the same functions for any type of household equipment connected to the system.

Also, the owners of the living space in question often connect the sensor in question to automatic watering in the country or in a private house. Here the device not only performs the opening function, it regulates the amount of water that should be consumed at a time.

This function is very useful if dosed watering is used so as not to over-moisten the soil. For stable operation, the flow regulator is mounted to the central pipeline, and it transmits all information to the system control panel.

Areas of use

In domestic conditions, water flow sensors have found their use mainly in devices that require constant monitoring of the life support systems of the house and compliance with a certain mode of their operation. By controlling the water supply, motion sensors can significantly reduce the cost of maintaining a home and make life much more comfortable and safer.

For gas boiler

The main place for using water flow sensors in modern homes are gas boilers. Modern gas boilers equipped with such sensors combine the functions of a water heater and a heating boiler.

The water flow sensor installed on the tap water supply pipeline reacts to the start of water movement when the hot water tap is opened.

The sensor sends a signal to the boiler control board, and the electronics turns off the heating circulation pump, extinguishes the gas heating nozzles, and closes the water circulation valve in the heating system. And then the board turns on the nozzles for heating running water and the process of heating water begins in the heat exchanger. When the tap is closed, the sensor detects that the water movement has stopped, which is signaled to the control board.

For pump

Many modern households are equipped with autonomous water supply systems. Such systems allow you to have a level of comfort in a private house comparable to apartments, but at the same time not depend on a centralized water supply.

The system, consisting of a pump, a water tank and a control system, allows you to service all the systems necessary for comfortable living - automatic washing machines, dishwashers, hot water and a toilet.

The role of the water flow sensor is that when any of the devices connected to the water supply system is turned on or water selection begins, the sensor turns on the pump and the water supply automatically starts. It doesn’t matter whether the laundry starts, the kitchen faucet opens, or the toilet cistern flushes.

Another option for using water flow sensors is automatic irrigation systems. Here, in addition to the opening function, the flow sensor controls the amount of water used for irrigation. This function is necessary to control dosed watering and avoid waterlogging of the soil. A sensor installed on the central pipeline supplies information to the system control panel.

Today, two types of water flow sensors are most widely used: a Hall sensor and a reed switch relay.

A flowing water sensor, based on the operating principle of a Hall sensor (also called a flow meter), is a small turbine on which a magnet is mounted. When the turbine rotates, the magnet creates a magnetic field and, like a turbine in a hydroelectric power station, generates small electrical impulses that are sent to the boiler control board. The turbine rotation speed depends on the water supply speed; the higher the flow, the clearer the pulses. Thus, thanks to the Hall sensor, it is possible not only to signal the flow of water, but also the speed of water supply.

The reed water flow sensor is a sensor based on the principles of a magnet. Fundamentally, this sensor looks like this - inside a chamber made of composite material there is a magnetic float; when water pressure increases, the float moves around the chamber and affects the reed switch.

The reed switch, which is nothing more than two magnetic plates in a chamber without air, opens under the influence of the magnetic field of the float, and the control board switches the boiler to hot water supply mode.

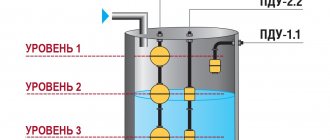

Reed water level sensor:

Water flow meter:

Sensor types

Today, the most popular and advanced water flow devices are reed switch relays and Hall sensors.

Description:

- A flow meter or Hall sensor is a small turbine with a magnet. As soon as the turbine begins to rotate, the magnet creates a field and generates electrical pulses that are transmitted to the boiler board (for example, Ferroli).

- The reed switch regulator also uses magnetism. A float magnet is installed inside the chamber. As soon as the water pressure increases, the float moves and begins to act on the reed switch (several magnetic plates that move apart under the influence of the float).

Installation

Considering that most water flow sensors are structurally included in the devices, their installation is required only in case of replacement due to failure. However, there are situations when the water flow sensor must be installed separately, for example, when there is a need to increase the water supply pressure.

After all, situations often occur when there is insufficient pressure in the central water supply system, and in order to turn on the gas boiler in hot water supply mode, it is necessary to create good pressure. In this case, an additional circulation pump is installed, equipped with a water flow sensor.

In this case, the sensor is installed after the pump, so when the water starts moving, the sensor turns on the pump and the water pressure increases.

Flow sensor malfunctions

Common malfunctions that may occur during operation:

- The DHW mode does not start, the equipment is unstable. To make sure that it is the regulator that has failed, you need to take a multimeter and measure the resistance. If it is approximately 2.5 kOhm, then according to the table this indicator should be achieved when heated to 60 degrees. But if the device is cold, then the problem is definitely in the water flow sensor. The regulator will “say” that the water is already heated and additional temperature is not needed. To fix the problem, you will have to completely replace the failed sensor. But we must not forget that it has direct contact with water and before removal it is necessary to drain all the water from the boiler (Baksi or other companies) and shut off its supply.

- If error No. 201 appears on the indicator, this means that there is a break or damage to the wires that are connected to the regulator. For the regulator to work normally, you need to restore its original position.

- Error No. 202 - short circuit. In this case, you need to check the device itself or the wires that are connected to it.

Varieties of the model range

Based on the type of execution, the units are classified into fitting and relay units, and they are also classified according to the operating pressure indicator.

Relay devices are installed on pumps that do not have high power. As a rule, relay sensors serve as a rational addition to single-chamber devices. Experts warn that this class of devices exhibits low conductivity. On the specialized market there are models characterized by vertical placement of plates. The upper limit of their working pressure is 5 Pa. Representatives of the P48 series are often introduced into protective systems; they minimize the likelihood of leaks and attract attention with their stability and reliable operation.

Relay water flow sensor for boiler

In-line devices that functionally complement pumps have become widespread. They can be distinguished by the characteristic horizontal placement of the plates; in samples with advanced technology, two valves can be seen. Here, too, the maximum pressure in the system should not exceed 5 Pa, but the protection class differs from the previous version - P58. The level of passage of the unit is directly dependent on the dimensions of the fitting.

If we consider the device’s triggering mechanism, we can use one of two scenarios:

- a model operating on the principle of a Hall sensor - it sends signals both about the presence of water flow and about the parameters of its supply (that is, speed),

- Reed switch sensors operate on the principle of a magnet - their body contains a magnetic float, which, in proportion to the increase in liquid pressure, moves along the internal cavity, thereby influencing the location of the reed switch.

Low pressure devices are rational for installation on pumps whose power does not exceed 4 kW. Camera parameters have a direct impact on the device's passability. The profile market is filled with two float models of sensors for pumps. A wide range of products and reasonable prices contribute to their widespread use.

The design of high-pressure devices has a single elongated fitting, in which the plates are placed in a horizontal direction. It is recommended to use such samples in tandem with centrifugal pumps. Protection class P70 is provided here, the maximum pressure mark is at 6 Pa.

Top 3 best sensors

Based on user reviews, there are three best devices that you should pay attention to when purchasing:

- Regulator for the Grundfos UPA 120 pump. The equipment turns on automatically, but can be started as needed. Used in a private house or apartment where an independent water supply system is installed. The sensor will begin to function when the flow of incoming liquid is as stable as possible (range - 90-120 liters per hour). The purpose of the installation is to avoid idling of the heat generator installed in the house.

- Genyo – Lowara Genyo 8A. The water supply system is controlled based on the actual fluid flow. Automatically monitors pressure during operation.

- Sensor 1.028570. Can work with Immergas double-circuit boilers. Compatible with models: Mini 24 3 E, Victrix 26, Major Eolo 24 4E | 28 4E. The Hall sensor will ensure a stable outlet water temperature.

Design and principle of operation

A water flow sensor is a device that monitors the pressure inside the water supply system; it is connected to the pump via pipes.

Standard circuit of a water flow sensor:

- relay;

- set of plates;

- There is a wide chamber inside the device;

- a small float, which is placed inside a stationary flask;

- outlet feed channel;

- Most models are equipped with an adjustment valve installed at the outlet.

The principle of operation of the sensor: when there is no liquid flow, it automatically pauses the pumping station and does not allow dry running, and when water appears, it starts the device.

Device selection criteria

Before purchasing a sensor, experts recommend studying the following parameters:

- level of electricity consumption;

- maximum pressure;

- priority method of installing the boiler, pump, and sensor itself;

- weight range of attachments that will not damage the performance of the boiler;

- requirements for the quality of the water passed through;

- device performance.

The markings of components usually indicate the models and full characteristics of the equipment in tandem with which a particular device will fully function. The cost of products is influenced by factors such as housing material, type of fixation, weight, power consumption and operating pressure.

Strengths of the units:

- simple installation - installation can be done by yourself;

- the ability to coordinate all parameters of the flow of water or working fluid;

- the ability to automatically turn off the pump in the event of an emergency;

- rich assortment and flexible price range.

What does a water flow sensor look like for a boiler?

When choosing, it should be taken into account that if the springs are weakened, the correct operation of the unit will be called into question. Not every heating system can incorporate such a component; here you need to delve into the specification.

Running self-test

The Navien boiler self-diagnosis system operates constantly and does not require a separate startup.

The probability of a failure of one or another node exists at any time, so the sensors send signals about the status of certain elements 24/7, never stopping.

If the sensor stops working for any reason, the corresponding error code immediately lights up on the display. This is an important function that helps maintain performance and timely troubleshooting .

Application area

Water flow sensors are usually found in devices where it is necessary to constantly monitor the life support system and observe a certain operating mode.

Most often, water flow sensors are used in boilers operating on gas. Modern gas boilers equipped with such sensors are used for both heating and water heating.

The device, which is located on the tap water supply pipeline, when water enters, sends a signal to the boiler control board and the operation of the circulation pump stops. Then the board turns on the nozzles responsible for heating the running water, and the water in the heat exchanger begins to heat up. When the tap closes, the sensor notifies that the water supply has been stopped.

Most households are equipped with autonomous water supply systems, thanks to which you can have the most comfortable conditions.

The function of the water flow sensor is that when you turn on any of the devices connected to the water supply system, the sensor turns on the pump and water begins to flow.

DIY repair

You can fix some problems yourself. The main thing is to follow our recommendations.

Water heater does not turn on

First of all, check if there is voltage in the network. You can check this with a screwdriver with an indicator: it should light up on “Phase”, but not on “Zero” and “Earth”. If the cable insulation is damaged, it is not recommended to carry out repairs. It is better to replace the element immediately, but make sure that the new cable matches the old one in terms of parameters.

A short circuit or lack of grounding leads to permanent shutdown of the RCD. A breakdown of the heating element on the body also leads to similar consequences. In this case, the element is diagnosed and replaced.

The RCD machine could break. To confirm your guesses, press RESET on the instrument panel. Is the light on? This means food is being served. Then press TEST and RESET again. If the indicator lights up again, the RCD is working normally.

Boiler does not heat water

Check the tightness of the contacts between the plug and the socket. If everything is in order and the voltage is supplied normally, you need to check the heating element. Do you have a storage type of boiler? Then drain the water from it first. A volume of water of 50-80 liters can be removed through the tap. It is better to drain 100 liters or more using a valve.

Remove the housing from the wall. Now you need to pull out the flange to which the heating element is attached. In Ariston 80 liter models, the flange is secured with only one bolt. In other cases, you will have to unscrew 5 bolts.

Disassembly is done like this:

- Rotate the flange along the axis.

- Take it out of the tank.

- Heater diagnostics are carried out with a multimeter. Read more in the article: “Replacing the heating element in a water heater.”

- If the multimeter needle moves, the part is working. Is it standing still? You need to install a new one.

Have you noticed that the water takes longer to heat up than usual? This does not mean that the heater is broken. Perhaps the reason is scale: over time it grows in a thick layer and interferes with normal heat transfer. Clean the element with special means.

Lack of heat may indicate a broken thermostat. Perform a reset on the boiler panel. If the appliance cannot be restarted, the thermostat is faulty.

A tester will help diagnose the breakdown more accurately:

- Set the multimeter to the maximum position.

- Attach the probes to the contacts of the thermostat (located next to the heating element).

- Does the arrow on the screen move? The device is working.

There is another option:

- Heat the thermostat with a lighter.

- Set the multimeter to "minimum".

- Place the probes on the contacts.

- If the arrow moves away from zero, then the part is functioning normally.

If there is a malfunction, the thermostat needs to be replaced. Disconnect the wiring from the part and pull it out of the hole.

Installation is carried out in reverse order.