Principles of dimensional RCD

During dimensional processing, the usual mechanical cutters and abrasives act as a direct tool of influence. The key difference between this method is the energy source that powers the tool. An ultrasonic current generator operating at frequencies of 16–30 kHz acts in this capacity. It provokes vibrations of the same abrasive grains at an ultrasonic frequency, which ensures the characteristic quality of processing. Moreover, it should be noted that there are a variety of types of mechanical effects. This is not only the usual cutting and grinding elements, but also deformation of the structure while maintaining its volume. Moreover, ultrasonic sizing ensures minimal removal of workpiece particles even during cutting. The grains that impact the material punctuate microparticles that do not affect the design of the product. In essence, the destruction of the structure by extraction does not occur, but uncontrolled propagation of cracks may occur.

Ultrasonic cutting

Ultrasonic cutting is performed on special machines with reciprocating movement of the cutter in a vertical plane with ultrasonic frequency and very low amplitude. An abrasive suspension flows under the cutter. The cutter, as it were, hollows out the crystal from the plate. Several dozen crystals are cut simultaneously over the entire surface of the wafer.

Ultrasonic cutting is carried out on special machines with reciprocating movement of the cutter in a vertical plane with ultrasonic frequency and very low amplitude. An abrasive suspension flows under the cutter. The abrasive particles, under the influence of vibrations of the cutter (concentrator), seem to hollow out the crystal from the plate. Several dozen crystals are cut simultaneously over the entire surface of the wafer.

The advantage of ultrasonic cutting is that it can be used to produce crystals of semiconductor materials of any shape, with various recesses, recesses and grooves, which cannot be obtained with any mechanical cutting methods.

When ultrasonic cutting, it is very important that the workpiece is securely fastened to the table, since slight movement of the workpiece leads to cracking of the semiconductor material. Gluing the workpiece to a glass plate with quartz cement is quite reliable.

During the cutting process, the suspension is intensively mixed.

When producing thin plates of a small area, ultrasonic cutting and abrasive blowing provide greater productivity, but in the case of thick workpieces and plates of a large area, it is advisable to use sawing.

Germanium samples of complex and simple configurations obtained by ultrasonic cutting.

Subsequently, the plates are cut into rods, for which ultrasonic cutting machines, diamond discs, electric spark metal processing machines, or chemical etching using the photolithographic method are used.

Wafers into crystals are cut either on wire cutting machines or on ultrasonic cutting machines.

If necessary, for example, to control the concentration and mobility of charge carriers, shaped samples of the type shown in Fig. 1 are cut out of plane-parallel plates. 10.14. For this case, it is best to use ultrasonic cutting, the circuit diagram of which is shown in Fig. 11.1. The cutting tool, punch 3, has special cutouts at the end that correspond to the required shape of the sample.

This indicates that many factors are beyond your control when sawing with diamond blades. In experiments with ultrasonic cutting, it was found that it has approximately the same effect on the quality of pn junctions as sawing with a diamond blade.

The next operation is cutting the plates into elements. For this purpose, ultrasonic cutting machines, diamond discs, electric spark metal processing machines, or chemical etching using the photolithographic method are used.

We advise you to study - Power transformers - design and principle of operation

These punches are made from tool steel in accordance with the shape of the semiconductor samples being cut, including the shape of the shaped recesses. Using such punches, it is possible, using ultrasonic cutting, to produce samples of a very complex configuration with smooth side walls and sharp corners while strictly observing the specified dimensions.

In recent years, over 60,000 operations on the heart and blood vessels have been performed in surgical clinics and research institutes in our country. Soviet scientists have developed in clinical settings operations for transplanting various organs, bone homoplasty, ultrasonic cutting and welding of bones (V.I. Petrov et al., 1972), and the method of hyperbaric oxygenation. Scientists have also achieved significant success in other areas of clinical medicine.

| Nickel mask obtained by electroplating. |

When spraying through masks, glass substrates with linear dimensions from 25 to 250 mm are often used. In this case, the difference in expansion coefficients (for metals it is higher), especially when the substrate is heated, leads to the formation of a displacement of the sprayed pattern. For this reason, attempts have been made to use glass masks. The mechanical processing capabilities of glass are limited to sandblasting and ultrasonic cutting. In addition, chemical etching ensures acceptable resolution and sharp line edges on glass plates.

Differences from plasma processing technology

In terms of processing quality, ultrasonic and plasma methods have many similarities, providing the possibility of high-precision cutting. But there is also a significant difference between them in the principle of operation. Thus, if ultrasonic treatment involves intense impact on abrasive powder from a trimming tool with the energy support of an electric wave generator, then the plasma processing method uses ionized gas charged with ions and electrons as a working medium. That is, ultrasonic and plasma processing technologies equally require the support of a sufficiently powerful energy generator. In the first case, this is an ultrasonic electrical device, and in the second, high-temperature gas or isothermal installations capable of raising the temperature of the working environment to 16,000 °C. An important component of plasma processing is the use of electrodes and plasma-forming substances that provide high power to the cutter's guided arc.

Selection of metal cutting technology. Part 2

The main difference is that with laser cutting, the energy is concentrated at the focal point; if after the pulse you do not move the head or change the focal length, then no further cutting occurs. This makes it possible to change the cutting depth (laser engraving). Of course, a laser beam can equally successfully vaporize both metal and other materials, such as plastic, which results in the wide versatility of laser cutting. If you evaluate according to the template, then 1; 4; 10; eleven; and 12 points of this method are not implemented.

A technologist who is faced with a variety of orders for small series of parts of complex shapes from various materials, with high requirements for cleanliness and parallelism of the cut walls, will prefer to have a laser cutting machine in his arsenal.

In plasma cutting, the cutting tool is a stream of gas converted into plasma by an electric arc. The plasma flow cannot be stopped at a given point; it is very difficult to control the depth, so the metal is cut right through. On the other hand, thanks to this, plasma cutting gains an advantage in speed and thickness of the metal being cut (up to 160 mm).

An enterprise that is faced with the task of cutting large volumes of sheet metal, cutting thick strips or squares, or mass production of parts from rolled sheet metal will prefer to have plasma cutting installations. According to our template, plasma cutting is inferior to the ideal by only 4; 10; eleven; 12 point.

An additional advantage of this method is the availability of compact, portable devices. However, electricity consumption must be taken into account. If there are connection restrictions, and at the same time the plant has its own oxygen installation, then it is quite possible that gas cutting will be more effective.

Waterjet cutting, electrical discharge cutting, ultrasonic cutting.

The range of tasks arising in metalworking is very wide. In some cases, the metals and alloys being cut are very critical to the temperature in the cutting zone, for example, alloys with a high magnesium content, cerium, and low-melting alloys. Also a problem is cutting workpieces with a thickness of more than 160 mm made of hard alloys.

Waterjet cutting has been successfully used to solve these problems

In this technology, the metal is cut with a thin (0.5-1mm) jet of water mixed with abrasive powder (garnet mineral). A specially designed pump supplies water to the nozzle under pressure up to 4000 atm. The internal channel of the nozzle ensures the acceleration of water and abrasive to speeds three times higher than the speed of sound. The technology provides cutting of any metals up to 300 mm thick. In this case, no heating occurs, and metal vapors (sometimes poisonous!) do not enter the air. The disadvantage is the relatively low cutting speed.

Electrical discharge cutting is also used for cutting hard alloy workpieces larger than 150 mm.

. In essence, this is cutting with a spark, or an electric microarc. The technology copes with the greatest thickness of metal; the hardness of the alloy does not matter. The only method that allows you to cut at an angle. Hence the application - tool production, parts made of alloy and special steels.

Ultrasonic cutting

is based on the destruction of metal in an abrasive suspension under the influence of ultrasound. The method is believed to have good prospects, but is not currently widely used in industry.

The basis of the process of electrical discharge cutting of metals

is the impact on the part of spark discharges formed as a result of the flow of pulsed current with a frequency in the region of 240 kHz between the wire electrode and the part, located in close proximity to each other in a liquid dielectric medium.

Ultrasonic processing devices

Now it’s worth taking a closer look at the equipment that is used in the implementation of RCD. In large industries, for such purposes, machines are used that are equipped with a generator set to generate alternating current of ultrasonic frequency. The generated current is directed to the winding of the magnetic converter, which, in turn, creates an electromagnetic field for the working element of the installation. Ultrasonic machining begins when the machine punch begins to vibrate while in an electromagnetic field. The frequencies of this vibration are set by the generator based on the established parameters that are required in a particular case.

The punch is made of magnetostrictive material (an alloy of iron, nickel and cobalt), capable of changing in linear dimensions under the influence of a magnetic transducer. And at the final important stage, the punch acts on the abrasive powder through vibrations directed along the waveguide-capacitor. Moreover, the scale and power of processing may be different. The equipment considered is used for industrial metalworking with the formation of massive structures, but there are also compact devices with a similar principle of operation, on which high-precision engraving is performed.

Operating principle of installations for generating ultrasonic vibrations

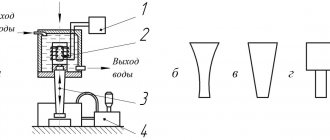

Ultrasonic installations used for dimensional processing of materials (Fig. 1) contain:

- electrical oscillation generator;

- acoustic transducer;

- ultrasonic oscillatory system, supply and removal system of coolant and suspension with abrasive.

Figure 1 – Diagram of the installation for ultrasonic dimensional processing (a) and diagram of the concentrators: exponential (b), conical (c) and stepped (d): 1 – generator; 2 – acoustic transducer; 3-ultrasonic oscillatory system; 4 – system for supplying coolant and suspension with abrasive

Ultrasonic generators are designed to convert electric current at industrial frequency (50 Hz) into high frequency current.

The acoustic transducer is designed to convert electrical high-frequency vibrations into mechanical ones. For dimensional processing purposes, magnetostrictive and piezoelectric transducers are predominantly used.

Magnetostrictive converters use the effect of longitudinal magnetostriction, which consists in changing the length of a core of ferromagnetic material placed in a magnetic field. The simplest magnetostrictive converter is a core made in the form of a rod or frame with an excitation winding. When an alternating electric current passes through the winding, an alternating magnetic field is induced in the core, and elastic deformations occur, causing longitudinal vibrations of the core.

To reduce losses due to Foucault currents, metal cores are assembled from stamped thin plates or wound from thin tape. Magnetostrictive converters are water-cooled. Their maximum electroacoustic efficiency in the frequency range 20...30 kHz is 50...70%. As the oscillation frequency increases, its value decreases.

Magnetostrictive converters are also made from ferrites. They have virtually no eddy current losses. Therefore, ferrite cores are made monolithic. To magnetize them, plates of ferrite permanent magnets are used, which are inserted or glued into the magnetic circuit of the converter. The electroacoustic efficiency of ferrite transducers reaches 80...85%. They do not require high supply voltage or forced water cooling.

Piezoelectric transducers use the piezoelectric effect, the essence of which is that in crystals with a certain type of lattices, under the influence of an electric current, internal voltages arise that are proportional to the electric field strength. As a result, the dimensions of the crystal change in accordance with the change in electric current.

All piezoelectric materials are divided into natural and artificial. Natural ones are quartz, seignette salt, tourmaline; artificial – ceramics of barium titanate TsTS-19 and lead titanate TsTS-23.

Quartz transducers are expensive and their sizes are limited. Piezoceramics are much cheaper and require lower exciting voltages.

The oscillatory system is designed to transmit vibrations occurring in the converter to the working units of the installation and, ultimately, to the surface being processed. The oscillatory system includes: a waveguide, a concentrator, and an instrument.

A waveguide is a rod or pipe of constant cross-section that connects an acoustic transducer to a concentrator.

The concentrator is designed to increase the amplitude of the mechanical vibrations of the instrument by ensuring resonance of the frequencies of the vibrator (magnetostrictive or piezoelectric) with the actuating instrument. The main forms of concentrators are presented in Figure 1 b, c, d.

Technique for performing dimensional RCD

After installing the equipment and preparing the target material, an abrasive suspension is supplied to the operation area - that is, to the space between the surface of the product and the oscillating end. By the way, silicon or boron carbides are usually used as the abrasive itself. Automated lines use water for powder delivery and cooling. Direct ultrasonic processing of metals consists of two operations:

- Impact penetration of abrasive particles into the intended surface of the workpiece, as a result of which a network of microcracks is formed and microparticles of the product are punctured.

- Circulation of abrasive material in the processing zone - used grains are replaced by streams of new particles.

An important condition for the effectiveness of the entire process is to maintain a high pace in performing both procedures until the cycle is completed. Otherwise, the processing parameters change and the accuracy of the abrasive direction decreases.

Process characteristics

Processing parameters that are optimal for a specific task are pre-set. Both the configuration of the mechanical action and the properties of the workpiece material are taken into account. The average characteristics of ultrasonic treatment can be presented as follows:

- The frequency range of the current generator is from 16 to 30 kHz.

- The amplitude of vibration of the punch or its working tool - the lower spectrum at the beginning of the operation is from 2 to 10 microns, and the upper level can reach 60 microns.

- The saturation of the abrasive suspension is from 20 to 100 thousand grains per 1 cm3.

- The diameter of the abrasive elements is from 50 to 200 microns.

Varying these indicators allows you to perform not only individual high-precision linear processing, but also accurately form complex grooves and cuts. In many ways, working with complex geometric shapes has become possible thanks to the perfection of the characteristics of the punches, which can influence the abrasive composition in different models with a thin superstructure.

Deburring using RCD

This operation is based on increasing the cavitation and erosion activity of the acoustic field when introducing ultra-small particles from 1 micron into the abrasive flow. This size is comparable to the radius of impact of a shock sound wave, which makes it possible to destroy weak areas of burrs. The working process is organized in a special liquid medium with a glycerin mixture. A special equipment is also used as a container - a phytomixer, the glass of which contains suspended abrasives and a working part. As soon as an acoustic wave is applied to the working medium, the random movement of abrasive particles begins, which act on the surface of the workpiece. Fine grains of silicon carbide and electrocorundum in a mixture of water and glycerin provide effective removal of burrs up to 0.1 mm in size. That is, ultrasonic treatment ensures accurate and high-precision removal of microdefects that could remain even after traditional mechanical grinding. If we are talking about large burrs, then it makes sense to increase the intensity of the process by adding chemical elements like copper sulfate to the container.

Application of ultrasound in electric arc surfacing

In electric arc surfacing of metal surfaces, an important element of the process is droplet transfer of molten electrode metal.

The efficiency of droplet transfer of electrode metal and the productivity of surfacing noticeably increase when imparting transverse oscillatory movements to the melting electrode. Transverse vibrations of the electrode contribute to changes in the shape and structure of the deposited metal layer. It is known that during electric arc surfacing, the metal of the deposited layer consists of columnar crystals - dendrites, located perpendicular to the fusion line of the base metal. In this case, the austenitic grains of the base metal along the fusion line are the basis for growing dendrites, which is why the number and size of the latter are determined by the size and quantity of these grains. Therefore, the larger the grains of the base metal in the overheated area of the heat-affected zone, the more columnar crystals will occur in the structure of the deposited layer. By reducing the length of the liquid metal layer due to transverse vibrations, it is possible to reduce the stay of the electrode in the overheating zone. This reduces the grain size of the base metal in the fusion zone, and therefore contributes to the formation of a fine-grained structure of the deposited metal. It is known that a clear orientation of dendrites contributes to increased fragility of the deposited metal, while ultrasonic vibrations contribute to the creation of a strong, disoriented structure of the deposited layer. The diagram of the technological installation for surfacing with ultrasonic alloying metal powder additive in a protective gas environment is shown in Figure 6.

Figure 6 – Diagram of a technological installation for surfacing with ultrasound and metal powder additive: 1 – device for transmitting ultrasonic vibrations to the electrode; 2 – waveguide-hub; 3 – electrode wire; 4 – body of the surfacing head; 5 – current conductor; 6 – device for supplying a gas-powder mixture; 7 – welded surface

The installation works as follows. Device 1 transmits longitudinal ultrasonic vibrations from the generator through the waveguide-hub 2 to the current guide 5 installed in the surfacing head. In the guide tube of the current guide 5, transverse vibrations are excited, which are transmitted to the surfacing wire 3. Vibrations of the electrode wire cause the dispersion of droplets of the electrode melt into small particles, which, having received oscillatory movements, enter the weld pool and, becoming additional crystallization centers, contribute to the formation of a homogeneous structure.

A comparative analysis of the resulting structures shows that the grain size, density and quality of the layer deposited using ultrasonic vibrations is significantly greater than that of the layer deposited without ultrasound. Moreover, when surfacing with ultrasonic vibrations there is practically no interface between the layers: coating-base, which characterizes their high adhesion and a smooth gradient of properties. Ultrasonic vibrations actively promote the processes of nucleation and formation of crystals, prevent their growth and increase the homogeneity of the structure.

When an alloying powder is introduced into the melt, the particles of which, under the influence of ultrasound, are in suspension, wetted by the melt and, evenly distributed in its volume, become additional crystallization centers, and upon solidification, this metal suspension is fixed, forming a composite alloy during crystallization with various properties: antifriction, abrasive, wear-resistant, corrosion-resistant and others. This achieves an increase in the productivity of the electric arc surfacing process and an increase in the wear resistance of the deposited layer by 1.5–1.7 times.

The deposited layer is of high quality, without metallurgical defects and with higher hardness. This surfacing method makes it possible to reduce the temperature gradient across the cross-section of the deposited layer and increase the crystallization rate, which reduces residual stresses both in the deposited layer and in the adhesion zone of the coating to the base.

Cleaning parts using RCD

The surfaces of working metal workpieces may contain various types of coatings and contaminants that cannot be removed by traditional abrasive cleaning for one reason or another. In this case, the technology of cavitation ultrasonic treatment in a liquid environment is also used, but with a number of differences from the previous method:

- The frequency range will vary from 18 to 35 kHz.

- Organic solvents such as freon and ethyl alcohol are used as a liquid medium.

- To maintain a stable cavitation process and reliable fixation of the workpiece, it is necessary to set the resonant operating mode of the phytomixer, the liquid column in which will correspond to half the length of the ultrasonic wave.

Physical properties and features of ultrasound propagation

Ultrasonic vibrations are elastic vibrations of a material medium with a frequency exceeding the limit of audibility (15–20 kHz).

Ultrasonic vibrations can propagate in any elastic media: liquid, solid, gaseous. There are three types of ultrasonic waves - longitudinal, transverse and surface. In solids, waves of all three types can propagate; in liquid and gaseous bodies, only longitudinal waves of rarefaction and compression can propagate. Ultrasound in gases, and in particular in air, propagates with high attenuation. Liquids and solids are good conductors and exhibit much less attenuation. For example, in water the attenuation of ultrasound is 1000 times less than in air.

The short length of ultrasonic waves is the basis for considering their propagation by methods of geometric acoustics. Physically, this leads to a ray propagation pattern. This leads to such properties of ultrasound as the possibility of geometric reflection and refraction, as well as sound focusing.

The next important feature of ultrasound is the ability to obtain high intensity even with relatively small vibration amplitudes. Ultrasonic waves of high intensity are accompanied by a number of effects that can only be described by the laws of nonlinear acoustics.

An important feature of ultrasound is the ability to concentrate energy at relatively small vibration amplitudes, since the energy flux density is proportional to the square of the frequency. Ultrasonic waves of high intensity are accompanied by a number of effects. Thus, the propagation of ultrasonic waves in gases and liquids is accompanied by the movement of the medium, which is called acoustic flow.

Important phenomena of acoustic flow include cavitation, which consists of the growth in an ultrasonic field of bubbles from existing submicroscopic nuclei of gas or vapor in a liquid, which begin to pulsate at the frequency of ultrasound and collapse in the positive pressure phase. When gas bubbles collapse, high pressures arise, on the order of thousands of atmospheres, and spherical shock waves are formed. Acoustic microflows arise near the pulsating bubbles.

Ultrasonic phenomena in the cavitation field are used in the production of emulsions, aeration of liquids, cleaning surfaces from contamination, degreasing and etching, ultrasonic dispersion, acoustic emulsification, etc.

The main parameters of ultrasonic vibrations are:

- wavelength λ – the distance between two adjacent points that are in the same phase;

- amplitude of oscillations A – the greatest displacement of the oscillating point from the equilibrium position;

- oscillation frequency f – number of oscillations per unit time;

- oscillation period T – time of propagation of wave motion over a distance equal to the wavelength;

- average speed of oscillatory movements V;

- speed of propagation of sound waves C.

Ultrasound-assisted diamond drilling

The method involves the use of a rotating diamond tool, which is driven by ultrasonic vibrations. The energy costs for the processing process exceed the amount of resources required with traditional methods of mechanical action, reaching 2000 J/mm3. This power allows drilling with a diameter of up to 25 mm at a speed of 0.5 mm/min. Also, ultrasonic processing of materials by drilling requires the use of coolant in large volumes up to 5 l/min. Liquid flows also wash away fine powder formed during the destruction of the abrasive from the surfaces of the equipment and workpiece.

Monitoring the implementation of RCD

The technological process is under the control of the operator, who monitors the parameters of the influencing vibrations. In particular, this applies to the amplitude of vibrations, the speed of sound, and the intensity of the current supply. Using this data, control of the working environment and the impact of abrasive material on the workpiece is ensured. This feature is especially important for ultrasonic processing of tools, when several operating modes of equipment can be used in one technological process. The most advanced control methods involve the participation of automatic means of changing processing parameters based on readings from sensors that record product parameters.

Benefits of Ultrasound Technology

The use of RCD technology provides a number of advantages, which manifest themselves to varying degrees depending on the specific method of its implementation:

- The productivity of the processing process increases several times.

- The wear of the tool used for the ultrasonic processing method is reduced by 8-10 times compared to conventional machining methods.

- When drilling, processing parameters in depth and diameter increase.

- The accuracy of mechanical action increases.

Ultrasonic welding

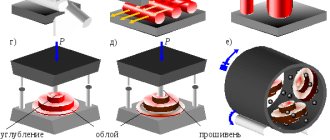

During ultrasonic welding, the surfaces to be joined are pressed with a small pressure Pst and are subjected to shear at an ultrasonic frequency relative to each other (Fig. 4). As a result of the action of shear deformations in microvolumes of the contact zone, plastic deformation occurs, crushing of brittle oxide films on rubbing surfaces and the formation of common crystals that firmly connect the welded products.

Figure 4 – Ultrasonic welding diagram: 1 – converter; 2 – concentrator; 3 – tool; 4 – connected products; 5 – traverse; 6 – tip; 7 – support

To connect plastics with metals, as well as welding products made of hard plastics, circuits with longitudinal torsional or torsional vibrations have been used (Fig. 5). Static pressure Pst is applied normally to the surface of the materials being joined, and dynamic pressure F has two components, one of which F' coincides with the vector Pst, and the other component F" is tangential (Fig. 5 a, b).

Diagrams of devices for implementing longitudinal-torsional vibrations are presented in Figure 1. 31 c, d. In the magnetostrictive transducer 1, windows are made on the side surface of the emitter along a helical line. They house the excitation winding (Fig. 5c). During operation of such devices, both torsional and longitudinal vibrations are created. The advantage of these devices is their small size and high converter efficiency.

Excitation of torsional-longitudinal vibrations is possible when using a design in which the torque arises due to the attachment of a tool with a spiral thread (Fig. 5 d). A special feature of this device is its versatility. When removing a threaded tool, only normal vibrations are excited in the workpiece being welded.

To increase the power of torsional vibrations, two or more transducers connected to a waveguide can be used (Fig. 5e, f).

The design of the welding head with torsional vibrations (Fig. 5g) uses both ends of the transducer. A waveguide with curved ends performs longitudinal vibrations. Both ends of the transducer are connected to a waveguide-tool, which performs torsional vibrations. In this case, static pressure is applied at the central point of the waveguide - the instrument that performs torsional vibrations.

Figure 5 – Schemes: welding (a), action of forces (b) and structures (c–g) with longitudinal-torsional and torsional vibrations of the waveguide : 1 – converter with winding; 2, 3, 4 – waveguides

Ultrasound can be used to weld almost all metals and alloys used in industry. Ductile metals with similar tensile strength values are best welded. It is preferable to use ultrasonic welding to join metals with low electrical resistance and high thermal conductivity, the welding of which is difficult with other methods.

Ultrasonic welding can be used to join non-metallic materials, such as various plastics and ceramics. Welding of non-metallic materials with metals is possible.

Ultrasonic welding can be used to weld a large number of thermoplastic plastics. Welding of thermoplastic plastics occurs in a viscous-fluid state at a temperature above the softening temperature, but below the decomposition temperature, at low static pressure. Since plastic has low thermal conductivity, it reaches a viscous-fluid state only in a thin surface layer. Therefore, welding is carried out in a fraction of a second. Polymer materials are welded not only at small thicknesses, but also at thicknesses exceeding 10 mm.

Using ultrasonic vibrations, you can weld methyl methacrylate, polyethylene, vinyl plastic, vinyl chloride, nylon, nylon, fluoroplastic. Ultrasonic welding can also be used to join dissimilar plastics.

One of the significant advantages of ultrasonic welding is the absence of heating significant volumes to melting temperatures and the accompanying changes in physical and chemical properties. This allows us to obtain welded joints with stable electrical and thermal conductivity, corrosion resistance, and mechanical properties. The structure of the welding zone mainly corresponds to the structure of the material being welded. The strength of the connection is almost equal to or exceeds the strength of the base metal.

Static forces in ultrasonic welding are much less than those used in cold welding. As a result, the deformations of the samples are insignificant and amount to 5-10% instead of 60-80

% for cold pressure welding. Therefore, ultrasonic welding can be used to join parts of very small thicknesses.

Along with its advantages, ultrasonic welding has a number of disadvantages, the main ones being the following:

- Difficulty in welding materials thicker than 2.5 mm. With the same thickness of the parts being welded, high-quality welding is obtained with thicknesses of no more than 2–2.5 mm.

- Insufficiently satisfactory reproducibility of joint strength indicators under all the same conditions.

For economic reasons, ultrasonic welding is used to join only certain metals. The feasibility of using ultrasonic welding is primarily related to the strength characteristics of the resulting joints. For example, ultrasonic welding of copper provides a joint strength that is 2 times higher compared to electric contact welding, while energy consumption is 10 times less.

Weld metals with a thickness of no more than (mm): aluminum - 3, copper - 2, steel - 1.3, brass - 1. Metals molybdenum, cobalt, tantalum, tungsten, beryllium with a thickness of 0.5–0.75 mm can only be welded under certain conditions.

Brittle and refractory metals, such as beryllium bronze, solid electrolytic copper, and some grades of spring steel, are difficult to weld.

Ultrasonic welding occupies a large place in radio electronics (ultrasonic microwelding). She has a number

advantages over other types of welding in the manufacture of semiconductor devices and microcircuits. Ultrasonic microwelding makes it possible to obtain joints of homogeneous and dissimilar materials used in microelectronics. Ultrasonic welding is used to join wire (10 μm diameter) and tape (70–100 μm thickness) leads of gold, aluminum, and other metals in a wide variety of semiconductor devices and integrated circuits.

Ultrasonic microwelding is used in the vacuum and electrical industries. A large group of connections consists of various electrical leads to products, connections of copper parts, contacts, relays, and collectors.

Disadvantages of technology

A number of disadvantages have so far hampered the widespread use of this method. They are mainly related to the technological complexity of organizing the process. In addition, ultrasonic processing of parts requires additional operations, including the delivery of abrasive material to the working area and the connection of water cooling equipment. These factors can also increase the cost of work. When servicing industrial processes, energy costs also increase. Additional resources are required not only to ensure the function of the main units, but also to operate the safety systems and current collectors that transmit electrical signals.