If your country house has an autonomous water supply system from a well, then the presence of a pump is a prerequisite.

And if the well is very deep, then you simply cannot do without such a device as a submersible centrifugal pump.

A submersible pump for wells is a device for pumping a certain volume of liquid to the desired level.

Submersible borehole pumps are divided into vibration and centrifugal. The uniqueness of devices of this type is considered to be partial or complete immersion in water.

There are the following types - horizontal single-stage, horizontal multi-stage, fecal, dredges

Distinctive features of hand and submersible pumps

There are manual and submersible. The main difference between a submersible pump and a manual one is that a manual one is used at a depth of no more than seven meters, while a submersible one can operate at a depth of 80m.

Hand pump

It will cost much less.

For your information: If your site is located in a place where the occurrence of aquifers exceeds eight meters, then you will not be able to cope without the help of a submersible unit.

Submersible pumps

They work automatically, but to operate a manual device requires physical strength.

Submersible borehole pumps are divided into vibration and centrifugal.

Vibration type

It has a fairly simple design and is much cheaper than a centrifugal device. They are used for wells located on sandy soil, where the passage of an aquifer vein is at a depth of fifty meters.

Operating principle

Concentrated electric current creates a magnetic field. The steel core attracts and lifts the rod towards the rubber diaphragm attached to it.

Due to this, the chamber enlarges, which reduces internal pressure. This causes the container to fill with liquid. Because coil with an alternating magnetic field, the polarity changes and the core is repelled in a different direction. The liquid that gets there flows into the pipe and the inlet valve closes.

They are mainly used in wells and open sources.

The correct choice of pumping equipment is the key to uninterrupted water supply from the well. The main function of this type of pump is to lift and supply water from an artesian well.

Note: What makes devices of this type unique is partial or complete immersion in water.

Centrifugal type

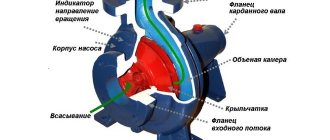

The design of the centrifugal unit is made up of the following components:

- housing with high corrosion resistance;

- high power electric motor;

- motor with thermal protection;

- motor shaft;

- self-lubricating bearings;

- the impeller is represented by two plates with holes and interconnecting blades;

- suction filter to prevent various contaminants from entering the unit.

To increase water pressure, multi-stage pumping systems can be used, where water flows from one pump to another and so on until the final one. By passing through all the devices, the required pressure is gained.

The main feature of centrifugal pumps is that liquid is supplied to it constantly.

Features of choice

When purchasing a submersible device, you need to consider some nuances:

- voltage in the electrical network;

- You need to know the volume of incoming liquid. This indicator should be higher than the performance of the device. That is, the water supply must exceed the pumping of the unit. Otherwise the pump may break;

- take into account the water level of the well, the pump must be completely covered with water to avoid overheating of the engine under load;

- know at least approximately the volume of water you need;

- the device must be close in diameter to the well pipe;

- determine the time of year when the pump will be used most.

This is interesting: Water pumps for wells: types and selection rules

Which pump to choose: tips

Among all water pumping devices, deep-well pumps are the most popular. They have a number of advantages over other units:

- quiet operation;

- there are no interruptions in the supply of water mass;

- easy and quick installation;

- water intake at great depths;

- narrow cylindrical body shape;

- protection against engine overheating;

- made of anti-corrosion materials.

Advice. In order to choose any pump, it is necessary to take into account the shape and depth of the well. Subsequently, you will not waste time, effort and money on installing additional equipment.

Connection diagram for a submersible pump

In order to choose the right submersible pump, the following data must be taken into account:

- water consumption at each water intake point and across the entire site in total;

- diameter and depth of the drilled well;

- geological data of the land (soil type, depth of groundwater, etc.);

- Availability of electricity sources on site.

The choice of pump directly depends on the depth of the well and the occurrence of groundwater. If the aquifer is located at a depth of 10 m or more, then it is worth choosing a deep pump. When purchasing a pump, choose a device with a power slightly higher than required: later you will be able to improve the water supply without having to replace the water pumping device.

Varieties

On the modern market, the well centrifugal pump is represented by three main modifications:

- submersible;

- semi-submersible;

- superficial.

Submersible models

A submersible centrifugal pump looks like a small-diameter gas-filled cylinder or cylinder - the cross-sectional size of some modern models does not exceed 100 mm. Installation of such equipment is carried out directly in the well.

Submersible centrifugal pumps

The cylindrical body of the unit houses a motor with a dry-type movable rotor. To start the equipment, no additional actions are required on the part of the foreman or site owner, nor does it require filling the pump housing with water.

A submersible pump is ideal for wells with a depth of 10 m or more - in fact, in this case it has no analogue or alternative. In addition, centrifugal submersible units are universal - they can be used for constructing sand or artesian wells, as well as for pumping and transporting oily and non-aggressive acidic liquids.

When considering the purchase of equipment such as submersible pumps for wells, it should be remembered that their installation and maintenance involve the need to shut down the system and remove the equipment from the well. It is recommended to hire specialists to diagnose and repair devices of this type.

Semi-submersible units

Semi-submersible centrifugal well electric pumps operate on the same principle as a classic deep-well pump (or centrifugal submersible unit). However, there are significant differences in the design and configuration of this type of equipment. The working unit of the unit or the engine is completely protected from moisture, while the working chamber is in direct contact with it. To ensure correct operation of the semi-submersible model, it is equipped with stabilizer fins. They hold the part of the housing in which the engine is located on the surface of the water; the working part of the installation is always in the water.

Compared to submersible analogues, semi-submersible ones have less power and larger dimensions , which does not prevent them from maintaining their market positions in the corresponding segment.

Surface equipment

A surface electric pump is relevant when the depth of a well or well does not exceed 10 m. As the name implies, a surface unit is installed directly above the well, and a submersible hose is used as a contact element. Designs of this type are easy to install and maintain; the hose can also be easily removed from the well pipeline for replacement or cleaning.

Installation of a surface centrifugal pump for a well

Despite the pronounced advantages of surface pumping equipment, it also has disadvantages:

- the chamber of an old modification of the pump, which is not equipped with a check valve, needs to be filled with liquid in a timely manner (done manually), otherwise the installation will not be able to pump out a sufficient amount of water;

- The power of the installation is inferior to submersible and semi-submersible analogues.

Selection options

- volume of daily water consumption;

- the exact depth of the well or well;

- speed of filling the well pipeline with water;

- productivity (speed and volume of pumping per unit of time);

- diameter of the main well pipe;

- quality and purity of water.

Selecting a well pump

The choice of pump for a well is made according to a set of indicators. There are scientific calculation methods, but a larger calculation can also be carried out.

The main indicators in the operation of the selected pump are:

- Pressure (pressure created), m of water column;

- Productivity, m3/hour.

The pressure characteristic consists of several components of the sum:

- The height (depth) of the well to the zero level of entry into the building;

- Resistance of the horizontal section of pipelines;

- Height to the upper water point;

- Minimum pressure in the home network;

- Power reserve – from 5 to 10%.

Moreover, the calculation should be carried out without taking into account the presence of a hydraulic accumulator at the station. It is designed to reduce the start-up frequency and smooth out pulsations. It is recommended to purchase and install a separate hydraulic accumulator of larger volume. The use of this device is mandatory for any type of pumping equipment.

Let's consider a special case - the well has a depth of 20 meters, the horizontal section is 8 meters long, the upper point of water intake (mixer) is located at a height of 2 meters. The minimum pressure for operating household equipment (washing machine, dishwasher, etc.) is from 1 to 1.5 kgf/cm2 (according to the product data sheet), that is, from 10 to 15 meters of water column.

The resistance of the horizontal section will be 8 x 0.3 = 2.4 meters. The final pressure is:

(20 + 2.4 + 2 + 15) x 1.1 = 43.34 meters (where 1.1 is the power reserve correction factor).

Next, the second value is determined - productivity. It is determined by the average water consumption per person per day - 200 liters. For a family of 4 people, the required volume of water will be 0.8 m3/day.

The constant period of water consumption is approximately 12 hours. The required pump capacity will be 800 l / 12 hours = 66.7 = 70 liters per hour. To account for peak loads, a correction factor of 1.25 should be applied. Then the final value will be 70 x 1.25 = 87.5 = 90 liters per hour (2.16 m3/day).

The calculated productivity value should not exceed the daily water limit of the well. Excess may cause clogging of the well and damage to the channels at its base.

The last stage of pump selection is selection according to the flow-pressure diagram. This diagram is present in the passport of each pump. Along the axes of pressure and flow (productivity) we mark the calculated values.

The intersection of points on the curve of the diagram will be real indicators of the operation of the unit under design conditions. The intersection point should be located in the middle part (middle third) of the graph.

Choosing a pump for a well is an important undertaking. Knowledge of the types of equipment and calculation methods allows you to select the necessary pump for a well without difficulty. You can involve specialists in the store in selecting a pump - as a rule, experienced managers know the selection methodology. At the same time, you can check your calculations - trust, but verify.

( , 1 today)

Installation features

When choosing a model, you need to take into account the fact that connecting a surface pump is somewhat different from installing a pump in a well.

Surface pump installation

The ease of use of surface models lies not only in the ease of fixing the unit and its connection, but also in the fact that you do not need to specifically select a location for this, since any convenient piece of land directly next to the well acts as it.

Installation diagram of a surface centrifugal pump for a well

Installation steps:

- determine the location of the equipment, level the site;

- install the pump in a position corresponding to the manufacturer’s recommendations and secure it with fasteners;

- connect the hose and check valves;

- before lowering the hose into the pipeline, make and check the connection to all communications;

- fill the pump chamber with water;

- check the functionality of the system and configure its operating parameters.

Scheme of installing a submersible pump in a well

Installation of submersible and semi-submersible pump

Despite the fact that the type of placement of a submersible and semi-submersible pump is different, their installation diagram is the same. The only difference is the need to place auxiliary support guides when installing the semi-submersible model and when placing the pump itself to prevent contact of the upper part of the housing (with the engine) with water.

Placement stages;

- inspect the pump itself, contacts and well for mechanical damage;

- install a check valve;

- connect the device to all necessary communications;

- attach a safety rope to the unit;

- perform immersion or installation in accordance with the manufacturer's recommendations;

- carry out a test run and configure the operating parameters of the installation.

Do-it-yourself selection, piping and installation of a pump in a well (video)

How to bring water from a well to a house with a deep-well pump?

Having purchased a suitable pump, you can begin arranging a water supply from a water source. This will require pipes through which water from the well will flow into the house. The diameter of the pipes should be 25–32 mm. Experts advise buying polymer products, as they do not corrode and are easy to bend. Further, during the work process, the pipes will be installed in the soil to a depth of 30–50 cm. To arrange water with your own hands, you will also need a septic tank. To make it easier to maintain, you will need to purchase a drainage pump.

Having prepared everything you need, you can start working. The algorithm of actions is as follows:

- First of all, you need to equip the pipe coming out of the well with a head;

- Next, you need to install the caisson. To do this, you will need to dig a hole next to the well and place a plastic container inside it;

- After this, you need to install the pump in the well. To do this, you need to pull a hose onto its nozzle and secure it securely with a metal clamp. After this, the hose, cable and safety rope are tied with electrical tape in increments of 1.2 m. Then the pump body is tied with a steel cable, and the unit itself is lowered into the water. During installation, the device should not swing, otherwise hitting the wall will cause pump malfunctions;

- Next, you need to connect the hose to the underground pipes. All joints must be treated with sealant and tied with FUM tape;

- Before burying dug trenches, the water supply should be checked. To do this, you need to start the engine for a while and observe the amount of water flowing from the pipes. If the pump performance does not decrease, you can dig trenches.

It is very important not to damage the unit while lowering it into the well. This must be done very slowly and carefully. Otherwise, an expensive repair of the device may be required, or a complete replacement of the deep-well pump.

Advantages and disadvantages

Let us list the main advantages of centrifugal pumps:

- High efficiency;

- Reliability in use;

- High pressure-flow properties make it possible to maintain high pressure in the water supply system with a large supply of liquid to the system;

- Possibility to install several working chambers in series or in parallel on one water supply system;

- If the operating mode of the hydraulic system changes, transient processes begin to gradually replace each other;

- The ability to smoothly regulate the power level allows you to start the device when the outlet valve or check valve is closed;

- The pumps can perform a self-priming function;

- Some device models can pump contaminated liquid containing up to 10% impurities;

- A gradual change in the functional characteristics of the device is carried out by changing the voltage in the operating network;

- Possibility of drawing a large volume of water;

- The relatively low cost of the device is ensured by the use of relatively inexpensive materials such as steel, polymers and cast iron in the development.

Disadvantages of centrifugal pumps:

- Surface models must be filled with liquid before starting;

- The phenomenon of cavitation may occur;

- Relatively low efficiency when interacting with viscous liquids;

A significant decrease in efficiency occurs with a small water supply and high pressure.

Principle of operation

A centrifugal pump is used to install a well or a well on private property or at a dacha. Such devices are distinguished from similar ones by their high performance, which allows them to be used for working in deep wells, or more precisely, for lifting water. The maximum depth from which water can rise reaches 15 m.

Centrifugal pump in water supply system

The scope of application of centrifugal pumps for wells is limited by the type of work required. A powerful device should be used only when it is necessary to lift water from great depths. Otherwise, the purchase will not be economically profitable, since centrifugal devices are quite expensive. If the well is shallow or the water level in it is high enough, it is worth purchasing a cheaper device.

The centrifugal pump consists of the following elements:

- impeller (maybe several);

- motor shaft;

- spiral channels;

- frame.

The operation of the device is based on the transfer of motion energy to the fluid, on the action of the centrifugal force generated due to the movement of the wheel located in the housing. The impeller is mounted on a special shaft, which is connected to the electric motor.

The impeller consists of two disks connected by blades. When the wheel is set in motion, water enters through the pipe. The pipe is protected by a mesh from debris and impurities.

Water is captured by the blades and, under the influence of centrifugal forces, moves to the periphery. As the speed increases, water enters the guide chamber and then passes into the pipeline. After space is cleared between the blades, the pressure decreases, and as a result, the next portion of water enters the device. This happens continuously throughout the operation of the mechanism.

Review of popular models

Before choosing a suitable device, you should familiarize yourself with the most popular pumps for wells:

- WILO SUB TWU 4 such a device is designed for the most practical homeowners. If we consider the technical characteristics of this device, we can come to the conclusion that its high cost is absolutely justified. This brand produces many high-quality devices. WILO brand pumps can perform almost any functional task assigned to them;

- Grundfos SQ are distinguished by their high cost and reliability. Such devices are endowed with the highest technical characteristics, but their cost is still a little overpriced. A significant argument for the manufacturer in the matter of pricing can be the additional options integrated into this well pump;

- Divertron (DAB) with integrated flow and pressure sensors, can operate in automatic mode. High-quality durable materials are used for the manufacture of devices, so the duration of their operational period remains quite high;

- "Belamos". Such devices are great for arranging garden plots. All its structural elements are made of stainless steel. The pump can draw water from a depth of up to 30 meters. Depending on the specific model, the power rating of the device can vary from 3 to 7.5 kW.

This is interesting: Centrifugal water pumps: design, principle of operation, operating rules

How does the pumping device depend on the depth of the well?

To select a pump, you need to look at the well’s passport data; all its parameters are indicated there. If you do not know the depth of the well, then you need to take measurements. Attach a weight to a dry (!!!) rope and lower it into the hole, remove the rope and use the wet mark to determine the distance from the surface of the earth to the water level in the well. By lowering the rope deeper, you can determine the depth of the well.

Well depth measurement

When purchasing a pump, be sure to read the instructions and product data sheet. These documents indicate the pump power depending on the depth of the well.

- 30-60 meters. In such conditions, pumps are installed directly into the well. During installation, 2-3 additional check valves are installed so that the raised water does not flow back. Centrifugal pumps equipped with thermal protection are installed in such wells. The device is inserted into the well using special equipment and secured with a cable to the surface of the earth.

- 10-20 meters. When water occurs at medium and shallow depths, you can use a surface rather than a deep pump. Such a device is installed far from the source, and water is drawn from it using a hose.

Connecting a submersible pump

Device operation and maintenance

Before purchasing, you need to familiarize yourself with the basic rules for using and maintaining the equipment:

- The unit should not be allowed to stand idle. If the pump is immersed in a working environment, it must function continuously;

- Monitoring the condition of the unit;

- Always follow the rules outlined in the installation instructions. The permissible lowering depth and operating rules for additional equipment must be observed.

It should also be taken into account that installation of such equipment is carried out independently only if you have the appropriate skills. Otherwise, it is better to trust the installation of equipment to sufficiently qualified specialists so that subsequent operation of the pump does not involve many problems.

What you need to know about the well

When choosing a pump for a well or well, you need to understand some of the subtleties:

- measure the depth (distance from the surface to the bottom). We do this with a line and sinker. The device must not be lowered to a length lower than 1 m from the bottom filter;

- determine the diameter. According to this indicator, the pump will be selected. There are narrow units that will not fit into the well if its diameter is less than 130–150 mm;

- Let's find out the well's flow rate. The value will not be constant, since this indicator changes over time. It shows how many m3 of water is supplied per hour. Before installing the pumping apparatus, only drillers will be able to determine the flow rate;

- the static level of the liquid, that is, at what depth it is located if it is not pumped out. The test can be done independently using a liquid-absorbing cord and sinker;

- water level with constant intake (dynamic level). Since accurate data can only be obtained with the pump installed, it must be remembered when installing the device that the level may vary.

Purpose of the pumps

- provision of water supply to private houses;

- drainage of sewage from a private house;

- connection to the fire safety system;

- watering the site;

- pressurizing the water supply system;

- functioning of fountains, aquariums;

- filling or clearing moisture from large containers (swimming pools, basements, wells);

- creation of a “field shower”;

- spilling drinks.

Criterias of choice

Centrifugal pumps, which are used in wells, differ in dimensions from their counterparts intended for wells. The latter are equipped with a special jacket for cooling the structure, so they have a large diameter. They are cheaper, but the performance is greater. The unit operating in a well is cooled by rising water during operation.

For wells, you need to choose pumps with a lower water intake, and for wells they are also suitable with an upper one; submersible devices have a fairly high liquid supply.

Amount of water consumed

The centrifugal unit must have enough pressure to provide the highest pressure if the water flow is close to the maximum. The pressure can be calculated using the following scheme:

- well depth + 30;

- increase the resulting number by 10%.

The resulting number will indicate the size of the water column - the pressure of your well or well. Without knowing this value, choosing the right model will be difficult. How much water you need per day is calculated as follows: the standard per person is multiplied by the number of people in the family. We get the volume of water consumed per day. Let's assume it will be 0.8 m3 of water, add the need for irrigation, approximately 1 m3 per day.

When understanding the models, pay attention to submersible pumps, the characteristics of which indicate that the flow is 200 m3 per 1 hour of operation.

This indicator is typical for centrifugal cantilever units. These include model 1K150-125-315 (output 200 m3/hour), model 1K150-125-315a (output 200 m3/hour). The small gap between the sealing ring and the similar wheel belt limits the pumped fluid from the high pressure area. This achieves a high efficiency of the unit. They can be used to provide water to holiday villages.

Pay attention to the diameter

The diameter of a well pump is usually given in inches, usually 4 inches (outer diameter) is approximately 10 mm. The unit must be selected with a diameter approximately 10 mm smaller.

It is equally important to take into account water contamination. If the unit operates in sandy soil, sand particles may enter the pump and damage it. You need to choose the appropriate model.

Armed with this knowledge, we set out to choose a submersible centrifugal pump.

Pump design: purpose and principle of operation, design diagram

Selection of pumping equipment for a well

Sealed centrifugal pump with shielded motor

When choosing a model, the main parameters will be pressure and flow. Pressure determines the height to which water will be supplied, expressed in meters of water column. Supply is the amount of water that this model can supply.

In order to choose the right centrifugal pump, you need to consider a number of characteristics:

- power;

- noise level;

- water consumption (depends on the needs of the buyer), to supply water to a family of 2-4 people, an option with a capacity of 50-60 l/min is suitable; if you need to water the plants on the site or fill the pool with water, you need to choose a more powerful model;

- water pressure;

- well depth - the maximum height of the water column must exceed the depth by at least 10%.

- the diameter of the casing installed in the drilled well;

- price;

- guarantees;

- the ability to repair the model: availability of necessary spare parts in stores, location of repair shops, etc.

Currently, you can find models on sale from both domestic manufacturers and well-known brands: Makita, Calpeda, Bosch, Wilo, Stiga, etc. The products presented may differ significantly both in price and quality, as well as in technical characteristics, so it is quite possible find a suitable model.

About water supply and its pressure

When planning to choose a liquid pump, you need to look at its parameters. All characteristics are important, but one of the key ones is the water flow rate. It is necessary to calculate how many cubic meters of water the home owner spends per hour to find out which option is suitable.

The next, no less important characteristic is pressure. It indicates with what force the unit will supply water. This parameter is calculated according to how far the water source is from the house. The pressure is lost under the influence of height and forks in the pipeline, so it is better to provide a small margin when calculating.

Calculation of required functional characteristics

It must be understood that in the process of selecting a suitable pumping installation, many control parameters must be taken into account. The external characteristics of a device may not always matter, but this data should not be neglected either. First of all, you need to determine the appropriate pressure. For this purpose, it is necessary to summarize the sufficient height of rising liquid, as well as the distance from the well to the living space.

To be on the safe side, another 20 meters are added to the resulting coefficient. As a result, you can get a number corresponding to the required pressure indicator pumped by the well pump. You should not worry if you end up with a number of about 50-70 m. This figure is considered the minimum for a conventional borehole centrifugal pump.

The performance of the device must be taken into account. This indicator depends on the number of people living in the house, as well as the planned water consumption. For a family of 3 people and a small garden, it is enough to install a submersible pump that takes about 3 cubic meters of water per hour. This figure will have to be increased if more water needs to be extracted. Pressure and performance level are the main functional characteristics that must be taken into account when selecting centrifugal well units. Other indicators are determined on a residual basis.

Types of pumping equipment for pumping liquid media from wells

The main purpose of deep-well pumps is to pump out a liquid medium from an underground source and its further transportation through a pipeline system under a certain pressure. Hydraulic machines of this type are equipped with various systems, which, in particular, include autonomous water supply and drainage systems, irrigation systems, etc.

Depending on the scope of application, deep-well pumps can be classified as:

- devices for industrial use, which, due to their high power, are capable of lifting the liquid they pump from a depth of up to 1000 meters (such equipment is large in size and is used in various industries);

- submersible pumps for domestic use, used to ensure the efficient operation of autonomous water supply systems in country houses and cottages, as well as for the operation of irrigation systems (submersible pumps of this type are compact in size and have fairly high power).

Connection diagram for a submersible well pump

According to the installation diagram in the well, rod and rodless submersible pumps are distinguished. Devices of the second type, in particular, include pumping units with electric centrifugal pumps (ECP).

A rod pump is a hydraulic machine, the drive motor of which is located on the surface of the earth, outside the well, while only its intake part is immersed in the pumped liquid medium. The rods present in the design of such a device are designed to transmit the thrust created by the drive electric motor to the intake part.

Downhole sucker rod pumps

The drive motor of rodless pumps is located in the same housing with the intake mechanism and is immersed in the pumped liquid medium along with it. Such submersible devices are most widespread, as they are more convenient to install and operate.

Submersible pumping equipment is also divided into various types according to design and operating principle. Thus, depending on these parameters, deep-well pumps are distinguished between centrifugal and vortex, or vibration, types.

A submersible centrifugal pump is a device whose main working body is a wheel with blades mounted on a shaft rotating by an electric motor. When such a wheel (impeller) rotates, the pumped liquid located in the inner chamber, under the influence of the centrifugal force exerted on it, is thrown towards the walls of the chamber, which helps push the liquid medium into the pressure pipe. At the same time, a vacuum of air is created in the central part of the chamber, due to which a new portion of the pumped liquid is sucked from the pipe located in the well.

Downhole submersible pump "Dzhileks"

In order to prevent solid inclusions contained in the pumped liquid from entering the inside of the centrifugal submersible pump, such devices should be used in conjunction with coarse filters installed on the supply pipe. The most significant disadvantage of centrifugal pumps, which can be operated year-round, is their rather high cost when compared with the price of vortex-type equipment.

Vortex (or vibration) deep-well pumps are used in cases where water needs to be pumped out from a shallow well. The principle of operation of devices of this type is that high-frequency vibrations are created in their internal part, which drive a mechanical piston. The latter ensures the suction of the pumped medium from the supply pipe.

Vortex type borehole pump design

The most significant advantages of the pumps under consideration include:

- compact dimensions;

- low cost (compared to the price of centrifugal pumps);

- minimal power consumption.

Among the disadvantages of vortex-type submersible pumps are usually:

- destruction of the well walls from vibrations (the vibration impact of a vortex pump on the well walls can be minimized by putting rubber rings on its body);

- low power;

- rather low performance of pumping liquid medium.

Vibration pump for well “Malysh”

The best models of submersible pumps, according to the editors

As it turned out earlier, with the help of deep pumps it is possible to pump water from the deepest sources without loss of pressure. However, not all users are well versed in this type of technology. Our editors are ready to provide information about the existing most optimal models with excellent performance qualities and more.

Pump Grundfos SQ 2-85

A submersible well pump that develops high power and is capable of creating maximum pressure force. This unit can be installed horizontally and vertically. The design of the pump is intended to transport liquid exclusively in its pure form without the presence of impurities and metals.

| Power, W | Productivity, m³/hour | Device weight, kg | Head, m | Water temperature tolerance, ºС |

| 1650 | 3 | 6,2 | 109 | 35 |

Pump JILEX Poplar 3D 70/60

The pump is designed for pumping drinking water. Used for artesian springs. Such units are not recommended for use in overhead wells intended for watering gardens.

| Power, W | Productivity, m³/hour | Immersion depth, m | Head, m | Filter, mm |

| 900 | 4,2 | 80 | 60 | 1,5 |

Pump PATRIOT SP 3250S

This pump can only be operated in a vertical installation. The declared analogue is also intended for use only in conditions of perfectly clean wells.

| Power, W | Productivity, m³/hour | Weight, kg | Immersion depth | Security options |

| 750 | 1,92 | 11,2 | 80 | From dry running |

Pump BELAMOS TF3-40

Model with good performance and low noise level. The device copes with the transportation of perfectly clean water. The unit is installed in a strictly vertical position and has built-in overheating protection.

| Power, W | Productivity, m³/hour | Head, m | Immersion depth, m | Weight, kg |

| 550 | 2,7 | 42 | 80 | 9,4 |

Pump CALIBR NPTS 1.2/50

Standard submersible device, the body of which is made of stainless steel. The unit is intended for shallow wells, as it has rather weak characteristics and, accordingly, a minimum immersion depth.

| Power, W | Productivity, m³/hour | Head, m | Immersion depth, m | Pump type |

| 370 | 1,2 | 50 | 5 | Centrifugal |

Deep well pumps - design and principle of operation of submersible well pumps

In order to effectively solve problems such as pumping from great depths and supplying water to an autonomous water supply system, it is necessary to understand the design of a submersible pump for a well.

The use of such pumps makes it possible to pump water from wells whose depth reaches 80 meters.

Types of pumping equipment for pumping liquid media from wells

The main purpose of deep-well pumps is to pump out a liquid medium from an underground source and its further transportation through a pipeline system under a certain pressure.

Depending on the scope of application, deep-well pumps can be classified as:

- devices for industrial use, which, due to their high power, are capable of lifting the liquid they pump from a depth of up to 1000 meters (such equipment is large in size and is used in various industries);

- submersible pumps for domestic use, used to ensure the efficient operation of autonomous water supply systems in country houses and cottages, as well as for the operation of irrigation systems (submersible pumps of this type are compact in size and have fairly high power).

Surface pumps for water wells

The second type of well pumps is surface pumps. They are located near the wellhead (in a caisson) or in a private house. Water is sucked through a submersible hose (sleeve, pipe) placed in the aquifer of the well.

Most surface pumps are centrifugal type units. The electric motors are cooled by a fan built into the casing. The dimensions of the pumps are such that it is impossible to place several subsequent discharge chambers - therefore the pumps are limited in suction depth to 10 meters.

Manual surface pumps

The hand pump is the simplest member of the family. Using a manual drive lever, a translational movement is applied to the piston in the working chamber equipped with a valve system. Alternating opening of the valves ensures the supply of water at the outlet of the pump column.

The described unit is a rarity and is used very rarely - during a temporary lack of electricity.

Surface self-priming centrifugal pumps

Self-priming pumps are equipped with a check valve at the outlet; the working chamber must be constantly filled with water. The operation of the device is based on the centrifugal principle. The device has simple controls, without automatic protection.

Pumps of this type create a pressure of up to 10 meters and are designed for filling containers, watering, etc. The disadvantage is manual control, high noise level, lack of interlocks and automatic protection.

Surface pumping stations for water

The pumping station is an optimized self-priming pump. It is equipped on the basis of a hydraulic accumulator and has a built-in check valve. The station is equipped with a pressure monitoring system in the system as a whole. According to the sensor readings, the pump turns on (when the pressure drops below the set value) and turns off (when the set pressure is reached).

Stations are the main type of surface equipment for wells; they create pressure up to 10 - 12 meters. The disadvantage of operation is the increased noise level, so it is advantageous to place the station in a caisson.

Ejector and injection pumping stations

Pumps of this type are special pumping station configurations. They are equipped with small diameter pipes laid externally (ejector) or internally (injector).

Water in small-diameter bypasses moves at a higher speed, and at the exit from the ejector (injector) it accelerates the main flow of water.

Design features of deep-well pumps

The design of a deep-well pump and its design features are largely determined by the principle of operation and the type of drive electric motor of this hydraulic machine. When using such pumps, the pumped liquid medium is collected through a special pipe placed in the shaft of the serviced well or in a well. An electric cable placed in a protective sheath is responsible for powering the drive motor, located at a certain depth.

In the design of a centrifugal type well pump, two main parts can be distinguished:

- drive motor, which can be built-in or external;

- directly the pumping part of the equipment.

Design of a centrifugal well pump

If the pump drive motor is built-in, it is usually located at the bottom of the device. Water intake when using pumps of this type can be carried out both through the upper and lower parts of their housing. In this case, preference is given to collecting the pumped liquid through the lower part of the housing, as this allows you to clean the deep part of the well from silt and sand accumulating in it. Submersible pumping devices, which is very convenient, are cooled by the liquid medium in which they are placed. This allows you to protect such devices from overheating, which can quickly render them unusable. Centrifugal-type deep-well pumps, although more complex in design than vibration devices, are characterized by higher reliability, productivity and a longer service life.

The pump suspension must withstand a load exceeding the weight of the pump by 5–10 times

The main design elements of vortex submersible pumps are a housing, a special glass, a drive motor and a vibrator. The vibrator in these devices is the most complex structural element, consisting of an armature, a rubber shock absorber and adjusting washers. The necessary conditions for drawing fluid from a well, carried out by a vibration pump, are created by its rubber shock absorber, which compresses and decompresses during operation of such a device.

A mandatory element of equipping submersible pumping equipment is a coarse filter that protects the inside of such devices from the ingress of solid impurities contained in the pumped medium. To ensure more efficient operation of submersible pumping equipment and ensure its protection from negative factors, various sensors are used that automatically stop the pump when emergency situations arise (the content of silt and sand in the pumped liquid is too high, the water level in the well decreases, etc.).

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

Pump cleaning and repair

If it is necessary to disassemble the pump, do not forget that the device does not have a filter. A mesh that catches large particles is attached to the outside. You may be able to remove a large clog yourself.

Cleaning is carried out in several stages:

- The protective mesh is removed.

- The cable channel is removed.

- The engine is disconnected from the pump part, then the couplings are removed.

- The disassembled pump is laid horizontally.

- The shaft is turned with a socket wrench.

- Water pressure is supplied, which will remove parts that interfere with the operation of the device.

- We rinse the pump well and reassemble.

Classification

These devices are classified according to technical characteristics and features of use into normal-priming and self-priming. They can be with either single-stage or multi-stage equipment.

Self-priming devices can be used in liquids with a high content of gases. Their main feature is the ability to start working without liquid, while normal-absorbing ones can only work when the suction pipe is filled with water.

More common types of device data include:

- Horizontal single-stage : for liquid substances with a chemical composition similar to water;

- Horizontal multi-stage : the ability to create high pressure with a small water supply;

- Fecal : for pumping water containing polluting particles;

- Sand dredger or dredger ; works with industrial waste liquid.

conclusions

Submersible water pumps are very powerful devices for lifting water. They are used for various purposes, at different depths. This is a very important, and in some cases, irreplaceable unit in cases where it is necessary to ensure water supply in dachas and houses on the ground. In addition, pumps are used for irrigation or to get rid of accumulated sewage from flooded cellars and basements, ditches and pits.

The different types of existing submersible pumps allow users to choose exactly the device that will perform the important and necessary work , which requires the use of pumps.

Installing these units does not pose any particular difficulties, but this process cannot be taken lightly. A very important point is that it is necessary to approach the integrity and serviceability of the entire structure extremely carefully and responsibly. Each piece of equipment should be inspected before installation to avoid all the unpleasant consequences that may result from improper installation.

Submersible pumps are very useful mechanisms that bring real benefits in the absence of a centralized water supply , as well as in other situations requiring the intervention of pumps. Before purchasing such equipment, you should familiarize yourself in detail with all its characteristics specified in the instructions in order to select the right device. This must be done carefully, since there is always the possibility of purchasing a unit that will not meet the required work requirements.

There is a very wide range of such devices on the domestic market, so it will not be difficult for the user to choose the right pump for his needs. The price range can also be called relatively small, so a user with average earnings can purchase such equipment.

Advantages and disadvantages

The well pump, like other models, has its disadvantages and advantages.

The popularity of using a centrifugal unit compared to other tools for pumping water is explained by the following advantages:

- centrifugal pump is a compact device, lightweight, has a small diameter, which allows it to be used even in very narrow wells;

- the process of installation, repair and dismantling is easy; these operations can be carried out on your own without the involvement of specialists;

- a submersible centrifugal pump can be installed at any depth, even in an artesian well;

- rapid rise of water from depth due to high productivity;

- the unit operates silently, which does not create inconvenience during operation;

- the mechanism has a high degree of reliability and durability;

- water flows continuously due to the fact that the design of the unit eliminates water hammer;

- a centrifugal mechanism can be used to collect water even from a sand well, in which mechanical impurities usually form; even with high-quality maintenance, the water obtained from such a source will contain a minimal amount of sand.

Centrifugal mechanisms have disadvantages, although there are not many of them. For example, they are very sensitive to the presence of solid particles in the liquid, which can cause a malfunction. Like other units, the pump requires periodic inspection and, if necessary, repair. To do this, you have to dismantle it, take out the device, and after inspection, lower it back into place.

Installation stages

Coupled pumps

The connection process does not present any particular difficulties, so you can handle it yourself if you wish. The main requirement is to observe safety precautions when working.

Installing a submersible pump on your own is difficult, but possible. Here's how to proceed:

- the well should be cleaned;

- Use a brass fitting to connect the water-raising pipe and the centrifugal apparatus;

- Use a driven brass fitting to connect the head to the other end of the pipe;

- Use a cable coupling to connect the cable and the unit.

To prevent water from escaping, the system should be equipped with a check valve, connected to the pipe with a small flexible reinforced hose.

Preparatory work: drilling a well and pumping it. It is advisable to entrust this stage to the masters. If this is not possible, you will have to purify the water from mechanical impurities using water-lifting units. You should not use a pump for this procedure. Then check the permeability in order to find out the maximum depth for installing the device.

The next step is to secure the pump. To do this, use a safety rope and heads. Fastening is done using clamps. For long and safe operation, it is worth checking the reliability of the cable insulation. One of its edges is attached to the head, the second to the device itself.

It is best to use pipes made of metal or polypropylene. The electric motor, as usually indicated in the instructions, needs to be filled with water. Place a sealing ring and a cap on one end of the pipe. The entire structure is carefully lowered into the well.

Every two to three meters the cable must be attached to the pipe with clamps.

When installing a centrifugal pump, it is worth remembering several rules:

- the best option is to secure the mechanism to a reinforced cable or stainless steel cable;

- to protect against debris it is worth erecting a head;

- the pump pipe must be selected so that its diameter is smaller than the diameter of the well - this will prevent the pipe from changing its shape when starting the mechanism.

Tips for use

When using it, you should follow some tips:

- It is recommended to constantly monitor the condition of the caisson;

- Downtime should not be allowed; regular use is required when installing equipment;

- installation of equipment must be carried out in accordance with the instructions.

Centrifugal well pumps are designed to obtain water from wells more than 10 m deep. With their help, you can install a water supply system in a private house that is not connected to a centralized network. The market offers models of both domestic and foreign brands, varying in price. Based on water consumption and depth, choosing the optimal model for your site will not be difficult.