Author:

Yulia Roshchina, specially for www.EquipNet.ru Photos from the sites nw-technology.ru, avek.ru, syntezndt.ru, mirndt.ru

The main task of any control system is to identify defects and determine the limits of strength and reliability. Defects can arise as a result of errors in design, production or operation: casting defects, fatigue failure, atmospheric corrosion, wear of mating parts, defects in coating, defects in permanent metal joints, and so on. In each specific case, special techniques are used to determine the degree of influence of the defect on the quality of the product: how much the reliability, performance characteristics will decrease, how the terms and operating conditions will change, or whether the defect is critical and the item cannot be allowed for use. There are two main groups of tests: destructive and non-destructive testing.

Problems of casting quality in foundry production

Let's consider common types of defects in foundry castings? Let's take shrinkage. What it is? The property of metals and alloys to reduce volume when cooled during solidification. The degree of shrinkage depends on the chemical composition of the steel - silicon and carbon content. If the concentration of these elements in the alloy is increased, the degree of shrinkage becomes less. Because the faster the heat is removed, the stronger the shrinkage. What defects are the result of casting errors:

- shrinkage cavities;

- cavities that are hidden inside the casting;

- alloys and underfills from metal flows that did not merge, but solidified during filling of the mold;

- misalignment due to incorrect alignment;

- hot cracks, warping, which occur due to crystallization or solidification of hot metal;

- cracks caused by excess amounts of sulfur, microimpurities, gases;

- defects in the structure, surface, contour and overall dimensions of the casting;

- discrepancy between the metal of the product and the specified chemical composition.

In order to ensure a low percentage of defects in products released for sale, implement casting quality management and alloy control.

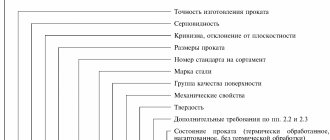

Incoming control of materials technological map

It is very important that the rolled metal meets all standard requirements. In accordance with GOST 24297-87, incoming control is carried out, the main tasks of which are control of documentation, storage conditions of products, shelf life, and compliance of metal quality indicators in accordance with standards. The main indicators of metal quality are:

- Chemical composition;

- Metal microstructure;

- Macrostructure of rolled metal;

- Dimensions and geometry of products;

- Metal surface quality.

To check rolled metal according to all requirements, incoming inspection is divided into several types of inspection , which are carried out simultaneously:

- Checking documentation - quality document, certificates, passports;

- Checking the condition of the surface - visual inspection, or sending a sample to a special laboratory;

- Checking the marking and packaging of rolled metal products;

- Checking geometric parameters;

- Checking the special properties of rolled metal (copper, brass, titanium);

- Checking the compliance of the metal grade and chemical composition, properties and structure.

Control methods and instruments in the quality management system of foundry production

When creating competitive products, various types of casting and alloy inspection instruments are used. Let us briefly consider the tasks aimed at assessing the quality characteristics of the metal.

In the foundry industry for smelting cast iron or in steelmaking when creating alloy steels, metals are analyzed for viscosity, composition of basic oxides and slag oxidation for the amount of SiO2, FeO, MnO, CaO. Basicity is found by testing electrical conductivity. To accurately represent the chemical composition, analysis of metal spectra is used. The objects of research are metals and alloys with bases (Fe, Al, Cu, Zn, Pb, Sn, Sb, Ni, Ti, Co, Mg). A variant of instruments for studying the quality of steel and cast iron is spectrometers.

The oxidation of the metal is determined by the color of the powder of the slag sample; impact strength – visimeter. Thermoelectric pyrometers and immersion thermocouples with sensors in contact with liquid metal monitor the temperature of alloys and metal.

After external inspection and selection of castings for control, the roughness of the workpiece is assessed using a profilometer, checking whether the product meets the prescribed requirements and standards. Deviations of the product from the stated dimensions are assessed and the area of defects is measured.

Castings intended to operate under pressure, such as valves, gate valves or pump housings, are checked for leaks. Non-destructive testing methods are used to search for hidden defects in workpieces. Sometimes spectral methods are the only possible way to check a product for defects without destroying its integrity.

Heat treatment control is performed by setting the temperature-time mode of the operation. For this purpose, thermocouples with potentiometers are used, which graphically demonstrate the heat treatment processes. The results are confirmed by testing mechanical properties or metallographic control of the microstructure.

3. INPUT METAL QUALITY CONTROL

(V.G. Shipsha

)

The main indicators of metal quality are: chemical composition; micro- and macrostructure; basic and technological properties; dimensions, geometry and surface quality of metal products. Requirements for the quality of metal and products made from it are specified in national standards, technical specifications of companies (enterprises) or separate agreements between the consumer and the supplier. The quality of the metal and reliable methods for determining its main indicators are the main ones in the technological production chain. The quality of metal products entering the enterprise is determined during incoming inspection (IC).

Incoming control is control of the supplier’s products received by the consumer, intended for use in the manufacture, repair or operation of the product.

Incoming inspection of metal products is mandatory at companies (enterprises) that develop or manufacture industrial products, as well as repair them. This control is organized and carried out in accordance with GOST 24297–87, as well as with standards and other regulatory and technical documentation (NTD) of the enterprise.

ORGANIZATION OF INPUT QUALITY CONTROL OF METAL PRODUCTS

In accordance with GOST 24297–87, incoming inspection is carried out by an incoming inspection unit - the incoming inspection bureau (IBK), which is part of the enterprise's technical quality control (QC) service.

The main tasks of incoming control are:

- monitoring the availability of accompanying documentation for products;

- control of compliance of the quality and completeness of products with the requirements of design and regulatory technical documentation;

- accumulation of statistical data on the actual level of quality of the resulting products and development on this basis of proposals to improve the quality and, if necessary, revise the requirements of the technical documentation for products;

- periodic monitoring of compliance with the rules and shelf life of suppliers’ products.

Incoming inspection must be carried out in a specially designated room (area) equipped with the necessary means of control, testing and office equipment, as well as meeting occupational safety requirements.

Measuring instruments and testing equipment used during incoming inspection are selected in accordance with the requirements of the normative and technical documentation for controlled products and GOST 8.002–86. If metrological means and control methods differ from those specified in the technical documentation, then the consumer agrees on the technical characteristics of the means used and control methods with the supplier.

To ensure compliance with the requirements of GOST 24297, as well as the standards of the GOST R ISO 9000 series, the enterprise is developing its own technical documentation, taking into account the profile and characteristics of the products. For example, large enterprises are developing enterprise standards (STP) “Incoming inspection of metallic materials”, “Technological instructions (TI) for incoming inspection of metallic materials”, etc.

STP establishes the procedure for organizing, conducting and recording the results of incoming inspection of metal products used at the enterprise. TI determines the scope and types of incoming inspection in accordance with the list of metals and semi-finished products subject to inspection. The scope and types of incoming inspection are established in accordance with the normative and technical documentation and technical specifications for manufactured products.

Conducting the VC is entrusted to the BVK. Input control involves: a warehouse for purchased metal products or a consumer workshop (hereinafter referred to as the warehouse) and the central factory laboratory (CPL).

Incoming inspection of metal products includes the following checks:

- accompanying documentation certifying quality (certificate, passport);

- labeling, containers, packaging;

- geometric dimensions;

- surface conditions;

- special properties;

- grade of material (chemical composition), mechanical properties, structure.

A typical scheme for organizing a VC (Fig. 3.1) is as follows. Metal products received at the warehouse are accepted with accompanying documentation on the nomenclature and assortment

Rice. 3.1. Typical scheme for organizing incoming control

and quantity and no later than 10 days is transferred to incoming control. At the incoming inspection, checks are carried out on the first four points (see above) and samples are taken to confirm the metal grade, structure, mechanical and special properties. Sampling is carried out under the control of the BVK. Selected samples are transferred to the Central Laboratory. Based on the incoming inspection data, including the conclusions of the central laboratory, a conclusion is made about the compliance of the quality of metal products with the established requirements.

If the control results are positive, the accompanying documentation (certificate, passport) states

If any indicator does not meet the established requirements, twice the number of samples from a given batch of metal is subject to control. If unsatisfactory results are received again, the warehouse, BVK and the supply department draw up a defect report.

Rejected metal is marked with red “Reject” paint and stored in a reject isolator until a decision is made on disposal or return.

CONTROL OF GEOMETRIC DIMENSIONS AND SURFACE QUALITY

Control of geometric dimensions

The TI regulates the scope of control over the size of the assortment of metal products, which is, as a rule, 5% of one batch. Dimensions are controlled using measuring instruments that provide a measurement error equal to ½ the tolerance for the parameter being measured.

Depending on the type of assortment (rod, strip, sheet, etc.), the dimensions specified in the certificate are subject to control, while the technical specifications stipulate how and in what places measurements are taken.

For example, the thickness of strips and tapes should be measured at a distance of at least 50 mm from the end and at least 10 mm from the edge. Tapes with a width of 20 mm or less are measured in the middle. Measurements are made with a micrometer in accordance with GOST 6507–90 or GOST 4381–87.

The thickness of sheets and plates is measured at a distance of at least 115 mm from the corners and at least 25 mm from the edges of the sheet using a caliper (GOST 166–89).

The diameters of rods and wires are measured in at least two places in two mutually perpendicular directions of the same section using a micrometer (wire) or a caliper (rod). Width and length are measured with a metal tape measure in accordance with GOST 7502–89 or a metal ruler in accordance with GOST 427–75.

Surface control

The quality of the metal surface is checked for compliance with the requirements of the normative and technical documentation for delivery visually without the use of magnifying devices (except for cases specifically stated). The recommended amount of inspection is 5% of the lot. In some cases (forgings, castings, etc.), 100% of the product is subjected to surface control.

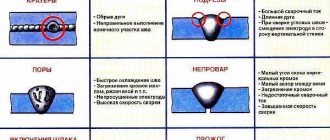

The most common characteristic surface defects of metal products are given in table. 3.1 and in Fig. 3.2.

Table 3.1

Surface defects of metal products

| Name of defect | Types, origin and brief description of the defect | The influence of a defect on the quality of a semi-finished product or finished product |

| Metallurgical defects | ||

| Captivity (Fig. 3.2, A ) | During pressure treatment, the walls of the bubbles and cavities of the ingots are compressed, stretched and partially widened. As the compression of the metal increases, the outer walls of the chambers become thin and break through. The delamination of metal thus formed, more or less parallel to the surface and extending onto it, is called a film | Removing film on semi-finished products, if their depth does not exceed the dimensional tolerances, does not affect the quality of the product. Films on the surface of the tubes lead to product rejection |

| Cracks (Fig. 3.2, c, d, f, g ) | Cracks on the surface, as well as internal cracks, are the result of stresses arising from uneven heating, strong hardening, burns during grinding and similar reasons. | Cracks that do not take the semi-finished product beyond the dimensional tolerances are classified as repairable defects. Cracks in the finished product cause rejection |

| Bubbles (Fig. 3.2, b ) | If the outer wall of the finished bubble is very thin, then when the metal is heated, the gases inside the bubble expand, bulge the outer wall and form a bubble on the surface | |

| Sinks | Holes on the surface of castings are the result of unsatisfactory molding, cutting out defects, and in products obtained by pressure processing, a consequence of opened bubbles, etc. | If the shell does not take the size of the product beyond the established tolerances, semi-finished products with surface shells are considered a correctable defect. In finished products, shells lead to rejection |

| Burrs and sunsets | A burr is a convexity along a rolled profile resulting from the extrusion of metal from a stream into the gap between the rolls. A burr is a burr rolled into metal during finishing rolling. Burrs are also found on stamped workpieces when the halves of the trimming die are displaced | Finished rods and rods of profile metal in the presence of a burr or decline are rejected |

| Ringiness | Ringing - herringbone-like dents and marks on the tubes, sometimes easily palpable by hand, are a consequence of the high friction force arising during the drawing process, accompanied by strong vibration | Ringiness on finished tubes leads to their rejection |

| White spots and stripes | White spots and stripes are defects found mainly on aluminum products. They are a consequence of metal contamination with electrolyte, the presence of non-metallic inclusions and sodium and calcium impurities | The defect sharply reduces the corrosion resistance of aluminum and aluminum products, and also spoils their appearance |

| sodium sickness | Sodium disease - inclusions of sodium compounds in aluminum | The defect renders aluminum products defective |

| Ripple | Ripples are dotted impressions of indentation on the surface of aluminum products caused by aluminum sticking to the rolling rolls. | |

| Chemical defects | ||

| Overtrawl | Overetch is characterized by a rough surface, revealing the crystalline structure of the metal. Severe overetching in thin-walled products leads to a significant reduction in the cross-section of the walls. Over-etching is a consequence of the high concentration of etching substances, as well as the long exposure of products in them | |

| Poor grass | Undergrasses are dark spots or uneven shade of the surface. Under-etching is a consequence of etching with solutions of weak acids and alkalis or exhaustion of the bath, short exposure in the bath, as well as contact of products with each other during etching | |

| Matte | It is the result of uneven etching caused by oil contamination during stamping, segregation heterogeneity, etc. | |

| Rough spots | Rough dark and white spots on light metal products indicate corrosion | |

| Mechanical defects | ||

| Risks and challenges | Risks (longitudinal scratches) arise on the internal and external surfaces as a result of poor polishing of the dies, the ingress of solid particles (sand, scale, metal shavings), the ingress of the same particles into the drawing point during broaching, with unsmooth surfaces of profiles, dies, etc. n. Seizures are obtained as a result of pressing at high temperatures or at high pressing speeds | Defects spoil the appearance, reduce the dimensional accuracy of manufactured products, and sometimes lead to defects |

| Flaws and tears | Fractures and tears are the result of metal rigidity, defects in the stamping tool (sharp corners) and improper installation of dies | Leads to product failure |

| Wrinkles and folds | They are most often found on the bodies of drawn products and represent vertically located thickenings caused by metal compression. These defects result from uneven thickness of the workpiece or clearance between dies and insufficient preheating of the workpiece | They spoil the appearance and lead to defective finished products. |

| Chernoviny | Unpolished areas of products with scale remaining at the bottom | The defect contributes to rapid wear of the product, spoils the appearance and interferes with work with a certain accuracy |

| Snatches | Recesses obtained during processing with an abrasive tool | They shorten the service life of the product and spoil the appearance of the surface. Snatches on the cutting part of the tool reduce the quality of its work |

| Grooves | Grooves - lines visible to the naked eye and running in the direction of rough grinding on finished products (tools) | Grooves spoil the appearance, reduce corrosion resistance, and in some devices and tools affect proper operation |

| Peeling of metallic or non-metallic coatings | Peeling of metallic and non-metallic coatings is the result of poor adhesion to the base metal | |

| Nicks (Fig. 3.2, d ) | ||

Rice. 3.2. Surface defects of metal products: a

) captivity;

b

) bubbles on the surface;

c

) cracks due to strong hardening;

d

) crack caused by grinding burn;

e

) nicks;

f

) hardening cracks;

g

) grinding cracks;

( f

and

g

- revealed by magnetic powder)

If it is necessary to control the inner surface of pipes, samples are cut from them, cut along the generatrix and the presence of defects is checked.

In all cases, when defects are detected (including traces of corrosion), samples are taken from the locations of these defects and sent to the Central Laboratory to determine the nature of the defect and the depth of its occurrence. Based on the conclusion of the central laboratory, a decision is made on the suitability of a given batch of metal.

CONTROL OF CHEMICAL COMPOSITION AND MECHANICAL PROPERTIES

This control is carried out in the central laboratory on specially selected samples from each batch of metal with a conclusion drawn up in the prescribed form.

Chemical composition control

This type of control is carried out to establish compliance of the qualitative and quantitative chemical composition of metal products with the standards stated in the certificate.

The sampling rate for monitoring the chemical composition is established in the technical specifications and is usually:

- for sheets and slabs - from one control sheet, batch slab;

- for tapes, strips, wire - from one control roll of the batch;

- for bars and profiles that are individually stamped by the supplier - from one bar, profile, batch;

- for rods and profiles marked on a tag - from 2, 3 and 5 rods, profiles for batches of less than 30 pcs., from 30 to 50 pcs. and over 50 pieces respectively.

Selected samples are sent to the central laboratory, where the chemical composition is monitored using chemicals.

and/or

spectral

analysis methods.

Chemical methods of analysis, which are based on the chemical reactions of analyte substances in solutions, include mainly gravimetric, titrimetric and colorimetric analyses. These methods are described in the relevant GOSTs. It should be noted that chemical analysis is labor-intensive, not universal, and does not have high sensitivity (especially at low concentrations of the elements being determined).

Spectral analysis is a physical method for qualitative and quantitative determination of the composition of a substance from its spectra

.

For express and marking analysis of the chemical composition of steels, cast irons and non-ferrous alloys, spectrographs (ISP-30, DFS-13, DFS-8) and quantometers (DFS-41, DFS-51, MFS-4, “Papuas-4”) are widely used. , the basis of which is the generally accepted scheme of emission spectral analysis. When performing an analysis, a pulsed electric discharge is excited between two electrodes, one of which is the sample being analyzed. Radiation from the atoms of the elements that make up the sample, excited in the discharge, passes through a polychromator with a concave diffraction grating and is decomposed into a spectrum. Each chemical element has its own set of spectral lines, the intensity of which depends on the concentration of the element in the sample.

In qualitative analysis, the resulting spectrum is interpreted using tables and atlases of the spectra of elements. For quantitative analysis of a sample, one or more analytical lines of each analyzed element are selected from the spectrum.

Intensity ( J

) spectral line of length l is related to the concentration (

c

) of the element in the sample by the dependence:

J(l) = a

×

сb

,

where a

and

b

are values depending on the analysis conditions.

Modern instruments for spectral analysis, as a rule, are combined with a computer, which allows fully automated analysis of spectra.

In addition to the indicated devices, enterprises use steeloscopes (Fig. 3.3) of the “Spectrum” type for quick visual qualitative and comparative quantitative analysis of ferrous and non-ferrous alloys in the visible region of the spectrum. The portable version of the steeloscope (SLV) allows such analysis to be carried out in workshops, warehouses, and on large parts without destroying the surface.

Spectral analysis of metals is carried out according to GOST standards, namely:

- steels - GOST 18895–81;

- titanium alloys - GOST 23902–79;

- aluminum alloys - GOST 7727–75;

- magnesium alloys - GOST 7728–79;

- copper - GOST 9717.1–82, GOST 9717.2–82, GOST 9717.2–83;

- copper-zinc alloys - GOST 9716.0–79, GOST 9716.1–79, GOST 9716.2–79, GOST 9716.3–79;

- tin-free bronzes - GOST 20068.0–79, GOST 20068.1–79, GOST 20068.2–79, GOST 20068.3–79.

X-ray spectral analysis. Compared to optical spectra, X-ray characteristic spectra contain fewer lines, which simplifies their interpretation. This advantage is driving the increasing use of X-ray analysis in factory laboratories.

The characteristic X-ray spectrum of a sample can be obtained either by placing it on the anode of an X-ray tube and irradiating it with an electron beam with an energy of 3–50 KeV (emission method), or by placing the sample outside the tube and irradiating it with sufficiently hard X-rays emanating from the tube (fluorescence method).

The fluorescent method is more preferable because:

- has a higher sensitivity (up to 0.0005%);

- more efficient and technologically advanced (there is no need to make the tube dismountable and pump it out to maintain the vacuum);

- the sample is not heated.

Fluorescent X-ray spectrometers used in industry to control the chemical composition of steels and alloys (Spark-1-2M, Lab-X3000, ED 2000, MDX 1000) are equipped with a computer, which allows you to automate the process of processing spectra and increase efficiency (Fig. 3.4).

The results of control of the chemical composition of the metal are documented in the accompanying documentation and registered in the incoming control passport.

Rice. 3.3. Optical design of the steeloscope: 1

— light source (electric arc between the electrodes that serve as the samples under study);

2

- capacitor;

3

- gap;

4

- rotary prism;

5

- lens;

6

and

7

- prisms that decompose light into a spectrum;

8

— eyepiece

Rice. 3.4. Functional diagram of a fluorescent X-ray spectrometer: RT - X-ray tube; A - analyzer; D - detector

During the incoming inspection of imported materials, the grade of the material is determined in accordance with the certificate of chemical composition.

Mechanical properties control

This type of control is carried out at the Central Plant in accordance with the requirements of STP and TI. The content and scope of control of the mechanical properties of metal products arriving at the enterprise are determined by the grade of metal, delivery condition and purpose in accordance with the normative and technical documentation.

As a rule, mechanical properties are controlled by testing: uniaxial tension, hardness, impact strength (see Chapter 2). The shape and dimensions of test samples must comply with the requirements of GOST 1497–84 and GOST 9454–78.

For tensile testing of round, square and hexagonal metal, 2 samples, 60 mm long from either end of the rolled product, are taken from each batch.

For tensile testing of wire supplied in coils for the manufacture of springs, a sample 600 mm long is taken from one coil of each batch, and for wire with a diameter of 0.9 mm, one sample 1500 mm long is taken at a distance of at least 1 m from the end of the coil.

For tensile testing of rolled sheets, two samples 250 mm long and 50 mm wide are taken from one sheet along the rolling direction, and from sheets of aluminum and magnesium alloys - across the rolling direction. For tapes and strips, a sample 400 mm long is taken from one roll of each batch at a distance of at least 1 m from the end of the roll.

To test the impact strength of sheets, strips with a thickness of at least 11 mm, from pipes with a wall thickness of at least 14 mm, rods with a diameter of at least 16 mm, 2 samples measuring 11 × 11 × 60 are taken from either end next to the tensile test sample mm for the production of samples measuring 10×10×55 mm. From rolled products with a thickness of up to 10 mm, 2 samples are taken to make samples measuring 5 × 10 × 55 mm. To test impact strength at sub-zero temperatures, 3 samples are taken.

If results are obtained that do not comply with the certificate, the test is repeated on twice the number of samples. If repeated tests yield negative results on at least one sample, then the entire batch of metal is rejected. The results of the mechanical properties of the metal are reflected in the incoming inspection passport with test tables attached.

Spectral instruments for casting analysis

Modern spectral instruments have a number of advantages that are fundamentally different from previous cheap steeloscopes, capable only of quantitative analysis of the content of impurities in metal by visually assessing the intensity of spectrum lines. For quantitative atomic emission analysis of cast iron castings, photoelectric spectral analysis is used. Most often, impurity and alloying elements other than carbon are analyzed to control casting. However, a number of instruments have been developed to accurately determine the quantitative content of carbon, phosphorus and sulfur. presents two modifications of spectral instruments for metal quality analysis and casting control. These include:

- X-ray fluorescence spectrometer. Instruments of this type perform quantitative analysis of the content of chemical substances in metals. The action is based on the radiation of the X-ray tube and the excitation of the atoms of the substance provided for research. The X-ray fluorescence operating principle is used in the design of portable hand-held XRF metal analyzers.

- Atomic emission spectrometer. The work is based on the study of the emission spectra of free atoms and ions in a gaseous medium using plasma as a light source, for example, the plasma of an electric spark or arc. The device analyzes the composition of metals and alloys and the presence of impurities in them. A representative of the class of atomic emission spectrometers is Iskroline-300, operating in the spectral range of 174-930 nm.

Testing the quantitative composition of carbon in cast iron can also be carried out using expensive and laboratory-based infrared absorption, coulometric or gas volumetric methods.

Spectral instruments for assessing the quality of castings have a number of advantages:

- stabilized discharge source;

- spectrum controlled by an electronic detector;

- computer processing of results using modern programs;

- study of the spectrum in the vacuum-ultraviolet and ultraviolet regions of the spectrum;

- accuracy of readings according to GOST requirements with a tenfold margin according to standards;

- the lower limit of detection of chemical elements is 0.0001%.

Non-destructive testing methods

If destructive testing methods are applied only to control samples to determine general mechanical properties, then non-destructive testing serves for mass control of product quality. The operation of non-destructive testing devices is based on the principles of changing the properties of an object in the presence of defects. These are ultrasonic flaw detection and thickness testing , radiography , magnetic particle and capillary testing , eddy current testing , optical-visual testing and others. For example, ultrasonic flaw detection equipment measures the difference in the transmission of ultrasound depending on the thickness and density of the metal. Thickness gauges 26MG, 26MG-XT, 26XTDL, 36DLPLUS, produced by Panametrics, are used to determine the remaining wall thickness of pipes, boilers and other structures subject to wear. 36 DL PLUS is a modern digital pulse-echo portable contact thickness gauge that allows you to measure the thickness of even objects that can only be approached from one side. It is used in energy and mechanical engineering to measure the wall thickness of pipelines, pressure vessels, boilers and other objects.

One of the common methods of non-destructive testing is eddy current . It is based on measuring eddy current disturbances when an electric current is injected into a sample. Even the slightest crack or cavity in the metal, pitting corrosion or thinning is immediately detected in a change in eddy currents. Modern eddy current flaw detectors are used to monitor the landing flanges of wheel disks, a number of fasteners of aircraft structures, detect cracks near fastening holes, as well as display C-scans of fastening holes, and monitor multilayer corrosion in the automotive, aviation and aerospace industries. Eddy current inspection equipment includes instruments from Zetec, which allow a wide range of inspections of various aircraft structures, engine components and wheels. For example, MIZ®-21SR is a multi-mode eddy current flaw detector and bond tester. It is a lightweight, portable instrument that uses two eddy current flaw detection techniques to detect non-bonding, delamination and density anomalies. In addition, MIZ®-21SR has functions for measuring conductivity and thickness of coatings. All information is displayed on the display with high resolution and image clarity.

Problems of casting control and production features

The demand for premium quality castings with special surface properties is constantly growing. These include:

- high density;

- homogeneity of the material;

- absence of cuts and increased local stresses concentrated in one place.

In these cases, it is not enough to perform a quality check by simply determining the structure of the material and confirming the properties. Sometimes it is necessary to know the operating parameters:

- stress corrosion;

- tightness;

- resistance to alternating loads.

To confirm operational capabilities, the performance of products is assessed under conditions close to actual ones. To obtain a reliable result, laboratory conditions are required, the presence of:

- test bench;

- load simulator;

- identical operating conditions to the working environment;

- compliance with temperature conditions.

To confirm the quality of premium-segment castings, statistical methods of quality management are needed that identify defects in current production in order to eliminate them. A way to improve quality control is spectral analysis methods. Optical and X-ray spectrometers, quality analyzers, are used for express analysis of the chemical composition and determination of metal grades.

Destructive testing methods

Destructive testing serves to quantify the maximum load on an object, after which destruction occurs. The tests can be of a different nature: static loads allow you to accurately measure the force on the sample and describe in detail the deformation process. Dynamic tests are used to determine the toughness or brittleness of a material: these are various types of impacts during which inertial forces arise in parts of the sample and the testing machine. Fatigue tests are repeated loads of small force, up to destruction. Hardness tests measure the force with which a harder body (such as a diamond hammer tip) is driven into the surface of a specimen. Wear and abrasion tests determine changes in the surface properties of a material under prolonged exposure to friction. Comprehensive tests make it possible to describe the basic structural and technological properties of the material and regulate the maximum permissible loads for the product.

To determine the characteristics of mechanical strength, tensile testing machines . For example, WEB 600, manufactured by TIME Group Inc.: it is capable of developing a force of 600 kN. Technological testing machines, such as IA 5073-100, IH 5133, IH 5092, produced domestically, are used for testing wire twisting, sheet metal extrusion, wire bending, and so on.

There are several methods for determining the hardness of a metal: according to Vickers, when a tetrahedral diamond pyramid is pressed into the surface under a load of 5, 10, 20, 30, 50 and 100 kgf. Then the print is measured along the diagonals of the square, and the hardness number is determined from the table. Machines for determining hardness - hardness testers . For example, IT 5010 is a machine for determining Vickers hardness.

When testing hardness using the Rockwell method, the sample is smoothly loaded to 98 N (10 kgf). Then an additional load is given to a maximum value of 490 N (50 kgf) - 1373 N (140 kgf). After reaching it, the number of hardness units of the sample is displayed on the device indicator scale. One of the most common Rockwell hardness testers is the TR 5006 M. Among the machines designed for fatigue testing is the MUI-6000 (supplied by North-West Technologies).

Iskroline series equipment for foundry production

Qualitative and quantitative analysis of metals using spectral instruments is performed by analyzing the absorption spectrum. Metal images have a spectrum, which is a set of characteristic lines by which elements are identified. Quantitative analysis is assessed by the intensity of the spectral lines. In this way, the percentage of a chemical element in the test sample is determined. Spark analyzers are used in foundry production:

- desktop express analyzer "Iskroline 100";

- laboratory device "Iskroline 300".

These devices belong to spectrometers based on atomic emission spectral analysis. The main advantages of Iskroline devices:

- work in an extended spectral range, which determines the number of chemical elements;

- low detection limits;

- convenience and efficiency of work;

- quantitative analysis of metals and alloys;

- simultaneous determination of up to 70 elements with spectral lines in the range of 167 – 460 nm, including carbon, phosphorus and sulfur with a spectral line resolution of 0.02 – 0.04 nm;

- determination of microimpurities and dissolved gases takes no more than a minute.

Samples of, for example, aluminum alloys are taken from melts or final products. The classic approach to sampling in foundries is to take a sample from a bath of molten metal using a test spoon and placing the metal in a special copper mold (Die Mold). Made of copper, the mold provides rapid cooling and helps obtain homogeneous samples, which is a good way to avoid erroneous results, since the crystalline fine-grained structure guarantees accurate, reproducible results.

In addition, laboratory-grade analytical devices “Iskroline 300” and the desktop spectrometer “Iskroline 100” are included in the State Register of Measuring Instruments of Russia, Belarus and Kazakhstan, which confirms the level of performance of the analytical device and is perfectly suitable for standard equipment for foundries.

X-ray control

This method is usually used for flaw detection of large welded metal structures exposed to the corrosive effects of the atmosphere: pipelines, supports and load-bearing and any other metal structures. X-ray machines can be stationary (cable and monoblock type), portable, or mounted on crawlers. Crawler is a self-propelled, remote-controlled robot carrying an autonomous X-ray complex. It is intended for quality control of welded joints of pipelines. Such a device, upon command from the outside, moves in the pipeline, stops and takes an x-ray. The crawler exposure device operates completely independently. Some X-ray machines require exposure and development of special film, while others reflect information directly in digital form.

Among the X-ray inspection equipment, it is necessary to mention the products of Sintez NDT CJSC, which is part of the UNITEST group of enterprises. Stationary devices of the Vityaz series are manufactured as a monoblock, with a glass X-ray tube. Their cost is relatively low. The “Bastion” series are cable-type devices; they use a metal-ceramic tube, which ensures reliability and a long service life, but they are more expensive. As a rule, stationary devices are used to control materials or finished products; they differ from portable devices in their high stability of current and voltage parameters and a minimum of ripple. Portable X-ray machines of the RPD series, from the same manufacturer, also provide options for working in harsh climatic conditions, in the Far North. In this case, the power and control unit is mounted in a metal case, protection category is IP65. Panoramic X-ray tubes of the SXT series are installed on the crawlers. They provide the highest possible rigidity of the radiation spectrum with high efficiency; the devices are powered by a crawler battery. The SHT equipment is equipped with a system of forced air cooling of the anodes by fans.

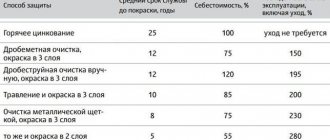

Today there is no one universal method that would allow one to measure all the properties of a metal product at once. Therefore, quality control methods are used in a complex: at the stages of development and manufacturing - destructive, during operation - various non-destructive ones. The choice of a specific control method depends not only on the specifics and purpose of the metal structure, but also on numerous external factors, which are certainly taken into account by specialists.

Incoming quality control of incoming metal products

Market economics moves the economy towards rationalization and control.

As you know, one of the main factors influencing the sale of a product is its quality, which largely depends on the raw materials from which the product itself is made.

In this regard, the issue of incoming quality control of rolled metal entering the enterprise is particularly acute.

For these purposes, the enterprise must maintain a special control and accounting log.

But the work of monitoring incoming products does not end with maintaining this journal.

Let's look at the list of necessary work on incoming quality control of incoming rolled metal:

1. The first stage of verification is checking the accompanying documentation for the goods received.

Particular attention must be paid to the compliance of materials and shipping documents with them. The results of the inspection must be recorded in the log book.

2. The second step is checking the geometry. Sheet steel is checked for deflection and wave. Round steel is tested not only for bending, but also for spiral and ovality.

3. The next step is to check the geometric dimensions using a special measuring tool. The following measurements are made:

— measurements of strips in thickness and width;

- measurements of the square in size and shape;

— upon receipt of hexagons, the edges are measured;

- pipe according to wall thickness and outer diameter.

4. Next comes the stage of checking the surface condition.

Particular attention is paid to casting, namely the presence of shrinkage cavities, the presence of gas porosity, non-metallic inclusions, the presence of cracks (the examination is carried out using optical instruments), as well as checking for the presence of segregation (inconsistency of the chemical composition in certain zones).

After checking for casting, it is necessary to check the quality of the rolled product, namely for the presence of surface marks, for the presence of hairs, films and for the presence of sunsets.

We recommend that you pay additional attention to the appearance of defects such as flakes in medium-carbon and medium-alloy steel grades.

Flocks are thin, sinuous cracks that appear in the center of round steel.

Such defects arise with an increased content of hydrogen, which fills the voids and turns into molecular hydrogen; powerful pressure arises, which leads to the destruction of the metal.

5. The next stage of incoming quality control of incoming rolled metal products is the application of special markings according to steel grades (a designation system approved at the enterprise).

First of all, on rolled sheets, steel markings are placed along the perimeter of the sheet; on round rolled products, the designation is placed along the end.

6. The last step is to check the chemical composition of the products, this is carried out before cutting the workpiece, by spectral analysis (usually an SL-13 steeloscope is used).

It is timely control over the received products that allows you to avoid unnecessary costs for the production of obviously defective products.

Equipment incoming inspection form

In construction, incoming inspection of installed equipment plays an important role. An incoming inspection is a study of the quality characteristics of a product received by the customer for its further use. The results of the examination are displayed in the report. The document is drawn up and approved within 3 days after inspection of the arrived products. The act is signed by all members of the commission. The essence of the survey is to identify information about the condition of the product and compare it with the parameters of regulatory documents.

Surface defects of metal products

Metallurgical defects:

- Films – delamination of material parallel to the surface. At shallow depths, they can be removed without reducing the quality of the sample.

- Cracks - formed under excessive load from heat or mechanical impact. Small cracks may be present on semi-finished products (if their size is not larger than that established by standards). There should be no cracks in the finished product.

- Bubbles are protrusions of the outer wall that form during strong heating. They should not even be in semi-finished products.

- Sinkholes - formed at the site of bubbles from high pressure during processing. There may be shells on the workpiece (if their size is not larger than that established by the standards); on the finished product, the presence of a defect may cause it to be sent for scrap.

- Burrs - occur when metal is processed incorrectly. If there is a defect on the rods and rods, they are sent to scrap.

- Ringiness – herringbone-shaped dents formed from vibration when metal is drawn.

- White spots - usually appear on aluminum products when the surface is contaminated with electrolyte. If such a defect exists, it greatly reduces the resistance of the semi-finished product to rust formation.

- Ripples also occur on the aluminum surface when material sticks to the rolling shafts.

Chemical defects:

- Overetching is characterized by roughness that is formed when the metal is improperly etched. With thin walls, the defect significantly reduces the cross-section of the product.

- Undergrasses are dark spots on the surface or uneven color of the metal. It is formed when metal is etched with weak substances, the procedure is insufficiently long, or when the workpieces touch each other while in the etching bath.

- Dullness – occurs when etching is of poor quality, when the etching composition acts unevenly on the surface.

- Spots that are rough to the touch form on light metals and indicate corrosion.

Mechanical defects:

- Risks are scratches that form due to poor-quality polishing or when foreign inclusions enter during processing.

- Seizing – occurs during pressing with very high heat or at high pressing speed.

- Tears - appear on hard metal and when using low-quality stamping equipment.

- Folds and wrinkles are formed when the thickness of the semi-finished product is unequal, when a gap occurs or when the workpiece is poorly heated.

- Rough marks – occur due to poor grinding. A product with such a defect will wear out faster.

- Snatches are depressions that are formed when using abrasive products. They also make the product less durable.

- Grooves are lines that worsen the appearance of the product and impair resistance to corrosion.

If any defects are detected, damaged samples are selected and sent to the laboratory for analysis. Only after this is a decision made whether to write off the batch or not.