08/30/2021 Author: VT-METALL

Issues discussed in the material:

- Types of fasteners for joining metal

- Recommendations for choosing fasteners for connecting metal products

- 6 ways to join metal products

- Areas of application of various methods of joining metal products

Today, the construction industry provides a wide selection of all kinds of fasteners and methods for combining various materials. But not everyone knows what methods of joining metal products there are, although this information can be very useful, because the areas where this is relevant are numerous and varied.

In our article, we presented an overview of the main methods by which metal parts are connected, indicating their key features. We also listed the main fasteners that are used for this purpose, so the information awaits you extremely useful.

Types of fasteners for joining metal

To connect products to each other, metal fasteners are used, available on the market in a wide range. Fasteners have different sizes, shapes and purposes. Most often, parts are connected with screws, bolts, nuts, self-tapping screws, screws, anchors, rivets, studs, washers, etc.

1. Bolt.

One of the ways to connect metal products is through bolts - rods with external threads and a four- or hexagonal head. The connection requires a nut or a hole with internal threads. The bolt resembles a screw in appearance; both fastening elements are widely used in mechanical engineering, construction, etc.

They differ in the way they work:

- the bolt passes through the elements to be connected and is fixed with a nut or wrench;

- the screw is screwed into the threaded part using a screwdriver or socket wrench.

Unlike the second, the first does not scroll inside the connected elements.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

2. Self-tapping screws.

Self-tapping screws are often used to connect wooden parts:

- fasteners with fine threads connect metal blanks of small thickness to wooden or plastic parts;

- self-tapping screws with large threads are designed for fixing wooden parts.

The sharp tip, made in the form of a drill, independently makes holes in the workpieces to be joined.

3. Nut.

Another way to connect metal parts is using nuts - fasteners with a hole and internal thread. Used in conjunction with bolts. Nuts vary in shape (hex, knurled round, square, T, finger lug, etc.) as well as strength.

4. Screw.

This fastener is a rod with an external thread, a conical tip and a head. The method of connecting metal to each other using screws is to screw the fastener into a finished hole or soft material (plastic, wood). This is the difference between them and self-tapping screws. They are less universal compared to the latter, as they have a smaller height and thread pitch. This type of fastener is in demand in construction and finishing works.

5. Anchor.

The anchor is attached to the supporting base and holds the desired element. The fastener has two parts:

- non-expandable, which is not directly involved in fixing structures;

- spacer (working), with variable dimensions.

In addition to the main parts, it may have a cuff - a border that prevents penetration into the base or fixed structure. Anchors are used for connecting metal products made from sheet materials, as well as for fastening heavy structures and foundations.

6. Rivets.

They are divided into two main types:

- Exhaust, consisting of an aluminum head and a galvanized steel rod. They are designed to permanently fix two or more metal elements. When working with them, mechanical tools are used.

- Threaded rivets are widely used in mechanical engineering and electronics. The shaft of this fastener is threaded, so the parts connected with it can be disassembled if necessary.

7. Hairpin.

This is a cylindrical rod without a head with threads along the entire length or only at the ends. This method of connecting metal products is used when there is no thread on the parts being fixed. Used in conjunction with a nut, or can be supplemented with a washer. The latter is a round plate placed under the nut and increases the strength of the fastening, preventing deformation of the workpieces being connected. This is achieved by increasing the pressing surface of the parts being fastened.

Pins are used to fasten any products and structures, including highly loaded ones. The advantage of this method of fastening metal elements is that its use does not require special skills.

Depending on the presence of threads, fasteners are divided into:

- metric, represented by screws, bolts, nuts and studs;

- non-metric (adapted), represented by nails, anchors, etc.

Depending on the area of use they are divided into:

- high-strength threaded fasteners;

- elements of mass use;

- products for shockless and/or unilateral fixation;

- fasteners intended for sealing products;

- parts intended for joining polymer composite materials, etc.

This is a conditional classification, since fasteners can simultaneously belong to several groups.

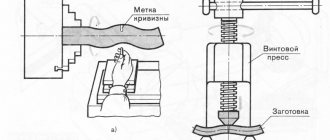

Application of riveting

Despite the fact that welding is actively used when connecting parts, riveting is not completely isolated from production. There is only one limitation that can become a problem when riveting: with this procedure it is only possible to make an overlap seam. But there is a possibility of a decrease in the strength of the structure, since the rivets become loose, and drilling holes creates additional problems.

Despite this, riveting is used in the production of airplanes and helicopters, as well as in the construction of bridges. This type of connection is more durable and safer for the structure. Another important factor is that metals are often used that do not weld well together.

At the same time, riveting is partially used in the production of various equipment. However, it is gradually being replaced by spot welding. Similar technology is used in the automotive industry, as well as in their repair.

As a result, these types of metal joining are still used because welding cannot yet cover all areas. However, the development of welding technologies today makes it possible to create integral structures, for example, bridges or airplanes. Probably, in a few years, welding will be able to completely replace other types of joints.

Recommendations for choosing fasteners for connecting metal products

Various methods of joining metal products are used in a wide variety of industries and production: from the creation of electronic devices to construction. After treatment with special compounds that increase their strength and anti-corrosion properties, fasteners are suitable for use in aggressive environments, in conditions of high humidity.

The service life of the finished product or structure also depends on the fasteners used, so when choosing them you should pay attention to the following:

- the strength of the fastener must be higher than the strength of the workpieces being connected;

- high tightness, regardless of the object at which one or another fastener and/or method of connecting metal products is used;

- high-quality materials, thanks to which high reliability and safety of the finished structure is achieved;

- the type and diameter of fasteners are selected in accordance with the expected nature of the impact (transverse or longitudinal, static or dynamic).

Welded connection of metal structures

Welding is a method of permanently joining metal elements by melting the edges of these elements together with filler material, forming a weld pool, followed by its solidification and crystallization. Technologically, welding is a well-studied process, therefore, there are no difficulties when calculating and designing metal structures with welded joints, taking into account defects in which residual stresses are concentrated.

Features of welding include the following:

- At the welding site, where thermal effects occur, the properties of metals and alloys change, and residual stresses and deformations arise.

- When welding, the cross-section and area of metal parts, workpieces, and structures do not change; there are no cracks or gaps where corrosion may occur.

- Labor and material costs when connecting metal structures are reduced.

After welding work, the seams must be “reworked” - compliance with the requirements of GOST 11533, 5264, 8713, 11534 and a number of other standards must be ensured. Tests of strength and other mechanical properties are performed in accordance with GOST 6996.

The quality of welded joints is checked by the manufacturer using various methods - visual and instrumental testing, ultrasonic testing. All checks are carried out before painting or anti-corrosion treatment.

For building metal structures (elements of buildings and structures, bridges, etc.) electric arc and electroslag welding are used. Manual, semi-automatic and automatic electric arc welding is possible. Consumable electrode welding is most often used. Carbon, low-alloy steel alloys are welded with fluxes with a high content of silicon and manganese to isolate the welding zone from oxygen and nitrogen from the air.

Welded joints can be butt, tee, or overlap. If parts and structural elements are not subject to special requirements for endurance, then lap seams are allowed.

The shape of the edges of the welded products can be either with or without a bevel. The shape of the bevel, its angle, bluntness and gap are determined based on the thickness of the rolled metal.

Residual stresses are of great importance for the strength, reliability and load-bearing capacity of metal structures with welded joints. They invariably appear during welding due to the influence of different forces on the weld metal and the areas near it.

Areas of application of various methods of joining metal products

Various methods of fixing metal elements are used in different areas of industry, as well as in everyday life. They are used in furniture production, construction, heavy industry, etc.

Keyed and splined fasteners are common in the areas of creating power tools, equipment, and mechanical engineering. Without interference joints it is impossible to produce gear shafts and worm wheels. Soldering is necessary for working on electronic equipment that requires high precision. Rivets are used to connect thin sheet metals.

As technological progress develops, new ways of joining metal products appear. Modern life is impossible without various machines and mechanisms. In order for them to last longer, reliable fasteners are needed. The quality of fasteners also determines the shape of the finished product, the quality of its work, the risks of accidents and emergency situations in production, etc.

In the article we talked about the types and methods of connecting metal products and parts. Before purchasing any fastener, you should inspect it for defects. Parts deformed during operation can be used for the outer contours of metal workpieces. Thus, savings on consumables are possible, but without compromising the quality of the finished product.

Bonding of metal structures

Bonding is effective for those metals that are quite difficult to weld. This is most often titanium or magnesium. However, in the process of gluing metals a number of difficulties arise:

- The need for spot preparation of the bonded surface;

- Adjustment for overlap gluing;

- Relatively low joint strength;

- Impossibility of breaking work.

Combined types of connections are also used. Among them, riveted-glued and adhesive-welding joints are distinguished. They provide additional strength.

Static rigid bonding of metals

Applicable in structures that are not subject to dynamic deformation. The mixtures used for such gluing form a very hard and durable seam that can withstand heavy loads. In fact, two parts after such gluing form a monolithic structure that is very resistant to shear rupture. In this case, glue such as PURAFLEX 9155 or Maple-812 is used.

The disadvantage of a rigid connection of parts is the fragility of the seam, therefore those structures that are subject to deformation require deformation gluing and the choice of a different adhesive.

Rigid bonding is most widely used in construction and machine tool production.

Preparing surfaces for gluing

Bonding materials with different linear expansion coefficients

Different coefficients of linear expansion of materials lead to the fact that during heating and cooling, the adhesive joint experiences significant load deformation. It would be logical to reason that the seam itself should be quite elastic. Such materials are best glued together with a polyurethane-based mixture. In principle, no difference is visible when gluing materials with different coefficients of expansion and deformation bonding. The main difference is that in the first case the adhesive joint must withstand higher temperatures.