Lesson plan:

Ferrous metallurgy

Non-ferrous metallurgy

Today, ferrous metallurgy plays an important role in the heavy industry of the Russian Federation. It is ferrous metals that hold the lead and are the main raw materials for the manufacture of various metal structures and products. This industry is important for the economy of any country, because the extracted raw materials are used to produce cast iron, various types and grades of steel, and rolled metal. This industry includes the beneficiation and extraction of ore materials, the extraction of non-metallic raw materials, and the installation of refractories.

Ferrous metallurgy

Ferrous metallurgy is an important industry, specializing in the production of ferrous metals. A wide range of products are used in various fields of activity. Russia ranks 5th in the production of steel and rolled metal (the main types of metallurgical products). The production of ferrous and non-ferrous metallurgy throughout the world is constantly increasing. This is due to the fact that the demand for products is rapidly increasing.

Companies that operate in the iron and steel industry are classified into several categories:

- Full cycle. Enterprises of this type carry out all stages of production, from the extraction of raw materials to the sale of finished products.

- Conversion. One of the stages is separated into a separate production. These may be subsidiaries of a large concern or plant.

- Small ones. This type represents metallurgical workshops, which are components of large complexes.

There are several regions producing ferrous metallurgy. Each of them has its own characteristics. In each of these regions there are enterprises that specialize in the extraction, processing of raw materials and production of ferrous metals.

Volumes and features of production

The total production is about 9.8%. The ferrous metallurgy industry includes more than 1.5 thousand organizations and enterprises. The dynamics of product exports is increasing every year. Metallurgical plants are traditionally located at a relatively short distance from the places where iron ore lies.

The production volumes of ferrous metallurgy products are quite large. There are more than 34 enterprises located in Russia. The largest plants are:

- Oskolsky;

- West Siberian;

- Novolipetsk;

- Cherepovetsky;

- Magnitogorsk.

Features of ferrous metallurgy production:

- consumption of large quantities of raw materials;

- high labor intensity of the process;

- high energy consumption;

- variety of products;

- high production costs.

Despite these difficulties, the industry is developing, because the demand for metal products is not decreasing. Russia produces metal that is not only used within the country, but is also exported.

Placement factors

Factories are located either in close proximity to sources of raw materials. The main factors for locating ferrous metallurgy enterprises are:

- proximity to factories where ferroalloys and electric steel are produced;

- availability of fuel and natural resources.

Most production sites are located in the Moscow region. Ferroalloys are produced in special furnaces or in factories using the electrothermal method.

Mining and processing companies are located near sources of raw materials. Coke and gas enterprises operate as part of full-cycle metallurgical concerns. Full cycle enterprises are based where there are fuel and raw materials resources, as well as sources of electrical energy.

Geography of ferrous metals metallurgy

Let us consider the geographic features of the ferrous metallurgy industries in Russia and the areas of development. Our country is well supplied with raw materials for ferrous metallurgy, but the distribution of deposits across the territory is uneven.

- The Russian Federation has large reserves of iron ore.

- In Yakutia, promising deposits are located in the Aldan province, as well as in the Olekmo-Amgun region.

- Deposits of chromium and manganese are insignificant. Manganese occurs in the Sverdlovsk and Kemerovo regions, and chromium occurs in the Perm region.

The dominant producer of steel and cast iron is the Ural Metallurgical Base, which has been operating since the 18th century.

Source

Impact of ferrous metallurgy on the environment

The main substances that enter the air and pollute it include products formed during the combustion of fuel. Iron oxide emissions also have a negative impact. Dust is generated as a result of loading and unloading, as well as during batch preparation. Gas formation and dust emission occur during the production of rolled metal and limestone roasting.

The trends and strategies for the development of the iron and steel industry are thought-provoking. The impact of this industry on the environment is enormous. It is necessary to develop effective measures to protect the environment and introduce technologies that would reduce the harmful impact on nature.

Industry development prospects

The demand for metal products is not decreasing. Metal today is used in various branches of human activity. Raw materials and finished metal products are used not only within the Russian Federation, but are also supplied to other countries. The industry will develop. Already, technological processes associated with the extraction and processing of raw materials are being modernized.

Source

In order to assess the market situation as accurately as possible for 2022 and the next two years, experts have put forward three forecast scenarios.

- Optimistic. The global pandemic will be stopped approximately by the end of 2022. First, world markets will recover, prices will stabilize, the Russian market will show a slight drop (about 5%), but after that it will continue to grow again.

- Pessimistic. If quarantine is forced to be extended, the market decline will become more severe and amount to 15%. A long production shutdown could even cause a financial crisis. And in this case, the market will begin to grow only in 2022.

- Base. This type of scenario is close to pessimistic. It also provides for a market decline of 10% by 2022, after which slow growth will begin.

According to experts, under such circumstances, large holdings that have a certain margin of safety and a wide range of products will have a great advantage.

Raw material base

Domestic metallurgy is developing thanks to the wealth of minerals that fill the bowels of the state.

Numerous deposits of coking coal fully satisfy the needs of metallurgists. Most Ural plants operate on coal supplied from the Kuznetsk coal basin (Kuzbass).

In terms of iron ore reserves, the Russian Federation is now in first place in the world. Its territory contains about 19% of the world's reserves of this mineral. Large deposits of iron ore are called an iron ore basin. The largest examples of them in the post-Soviet space are:

- Krivoy Rog iron ore basin;

- iron ore basin of the southern Urals;

- Kursk magnetic anomaly.

Experts develop iron ore deposits using open (quarry) and underground (mine) methods.

The feasibility of developing deposits of coal or ferruginous quartzite is determined by the depth of the deposits, transport accessibility of the deposit, as well as technological parameters.

Having considered the factors (not only raw materials) influencing the choice of location for metallurgical plants.

Non-ferrous metallurgy

Metals in which iron is not predominant are usually called non-ferrous. This category includes various alloys containing nickel, magnesium, aluminum, etc. The industry that includes the extraction and processing of non-ferrous metals and their alloys is called non-ferrous metallurgy. In terms of production size, it is one of the ten largest economic sectors in the country.

Non-ferrous metals are classified into the following types:

- lightweight (have a wide range of applications) - this includes aluminum, magnesium;

- heavy (used in the chemical and technical industries) - nickel, lead;

- noble alloys (used in jewelry) - platinum, gold;

- refractory (area of use: instrument making, mechanical engineering) – tungsten, tantalum;

- metals with a high level of radioactivity - polonium, radium, uranium (used in nuclear power plants, nuclear installations);

- dispersed metals - rubidium, germanium, gallium (used in lighting technology, vacuum technology);

- rare earths - scandium, lanthanum, lanthanides (fields of application include glass melting, nuclear energy, electronics, medicine).

Factors influencing the location of non-ferrous metallurgy enterprises: proximity to sources of raw materials, climatic conditions in the region, opportunities for development.

Volume and features of production

The volume of production of non-ferrous metallurgy products is increasing from year to year. The industry is actively developing, new technologies and processing methods are appearing. About 40% of nickel and 20% of aluminum are produced in Russia. On average, 70% of metals are exported. Therefore, this industry plays an important role in the Russian economy. The main feature of non-ferrous metallurgy is the high cost of obtaining and processing raw materials.

Rolled metal or rolled metal is a product made of metal that is subjected to special processing, during which it acquires the desired properties.

The main volume of transport supplies is carried out to non-CIS countries (90-95%). In terms of the amount of metal products produced in the country, non-ferrous metallurgy is clearly inferior to ferrous metals, but the price of non-ferrous metals is much higher. A positive result from the development of non-ferrous metallurgy will be if production enterprises are located near inexpensive sources of energy resources.

Placement factors

The energy factor is taken into account in the production of light non-ferrous metals. Their production uses a large amount of electricity. Often, non-ferrous metallurgy enterprises are located near hydroelectric power plants, which generate affordable electricity.

When determining the location of production sites, the raw material factor must also be taken into account. The environmental factor, despite the increased level of danger of enterprises, unfortunately, is practically not taken into account. The impact of non-ferrous metallurgy on the environment is an important problem that needs to be addressed comprehensively.

Geography of non-ferrous metallurgy

Metallurgy of non-ferrous metals is developing not only in our country. The richest reserves of non-ferrous ores are located in Chile, India, Peru, and Venezuela. To increase the efficiency of development, enterprises from different countries cooperate with each other. The aluminum industry plays a major role in non-ferrous metallurgy. A significant part of the ore of this metal is concentrated in the zone near the equator. But successful development of this industry is possible only in those countries where there are sources of affordable energy. Non-ferrous metallurgy development centers:

- Norway;

- Russia;

- USA;

- Canada.

These countries have enough reservoirs with powerful, productive hydroelectric power stations.

In countries such as France, Hungary, Austria, which have expensive energy and where aluminum smelting is a common type of industry, the production of this metal is gradually decreasing.

Impact of non-ferrous metallurgy on the environment

The first stage in the development of non-ferrous metallurgy was the Bronze Age. But in those days, this industry harmed the environment much less than it does today, because... Primitive but safe methods of extraction and processing of raw materials were used; there were no large enterprises that emit tons of harmful substances into the air.

Every year, about 3,000 tons of harmful substances are released into the atmosphere. Sources of harmful emissions in production are various types of furnaces (for smelting, roasting, induction, etc.), open storage areas and drying machines.

Every year, the non-ferrous metallurgy uses about 1200 million tons of fresh water. Wastewater is contaminated with minerals and photoreagents, which contain toxins.

The most powerful sources of pollution are large non-ferrous metallurgy plants, since they have a predominant open method of extracting raw materials and the soil suffers because of this.

Industry development prospects

The rate of increase in demand for metal products will be estimated at at least 3% per year (referring to the first option) and at least 5% per year (referring to the second option). Write about these options

- With a conservative development of events, the production of non-ferrous metals in 2022 will increase by 25.3%, and in 2030 - by 41.6%.

- Under the innovative scenario, the production of non-ferrous metals will increase by 28.5% this year alone, and by 49.7% in 2030.

In 2030, the implementation of major projects is being considered, including the modernization of factories, the development of new copper ore deposits, and the construction of zinc plants.

From ancient times to the present day, metal has been the main construction material. Recently, thanks to scientific and technological progress, the specific gravity of the metal has been reduced in many industries. But still, it plays an important role in the development of the economy of any country.

Criteria for choosing the location of metallurgical enterprises

The greatest economic effect is achieved when enterprises and interrelated industries are concentrated in one territory. This gives metallurgical plants significant savings on transportation costs.

It also greatly simplifies the organization of production management:

- Metallurgical plants, due to their technology, require large volumes of water resources. This makes it mandatory for them to be located near bodies of water.

- The environmental factor is also important. Metallurgical plants cannot be built near environmental protection zones. Their design must take into account the wind rose of each specific area.

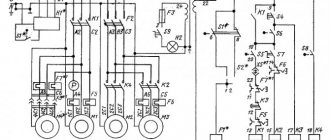

- Electrometallurgical plants require large amounts of electricity and scrap metal to operate. Such enterprises are usually built near powerful hydroelectric power stations.

Industrial zones with metallurgical plants should be located at a reasonable distance from residential areas. Under the influence of these factors, design institutes are developing new metallurgical enterprises that comply with all environmental protection standards.

Among the many factors for the location of ferrous metallurgy, a special place is occupied by its proximity or distance from large river and sea ports. Export deliveries are most feasible when products are shipped by sea, which is the cheapest. Proximity to the river system is one of the main requirements for the construction site of a metallurgical plant.

Ferrous metallurgy

Why is it legal for a plant to be located next to a body of water?

“For sure” is not a fact. We need evidence.

Evidence that industrial waste is being discharged in excess of the maximum permissible concentrations of harmful substances.

If there is such evidence, the enterprise will be fined and will also be forced to pay for the damage caused to aquatic biological resources and their habitat, and to residents.

I agree with the previous answer.

You should not be afraid of every enterprise near a body of water. You can think of anything about the fact that they dump waste into a pond. And there are many cities in which there is more than one enterprise near the river. Take cities on the banks of the Rybinsk Reservoir, for example, or on the banks of the Sheksna River. Cherepovets, Rybinsk, Uglich alone are worth a lot. The main thing is that waste discharge does not exceed the standards. And enterprises usually have cleaning systems.

If something very harmful was discharged in large quantities and would affect the quality of water and human health, such an enterprise would be immediately closed.

Why is it legal for a plant to be located next to a body of water?

I would focus not on whether the plant discharges water into the river or not (since the enterprise may be a closed cycle, may have local treatment facilities and most likely has them, etc.), but on the fact that the enterprise located next to the river. The fact is that any river, depending on its length, has its own water protection zone. For small rivers it is 50m, for long rivers - 100m, for large rivers - 200m. There are also SPZs (sanitary protection zones for enterprises), which range from 50m for warehouses and small farms to 1000m for brick factories, meat processing plants, etc.

Therefore, if there are any doubts, it is better to contact the administration. There should be master plans with designated SPZs, and they can also provide information on the enterprise itself.

Is it legal to have a business near a body of water?

If you didn't catch them dumping waste, then it's legal. Not caught, not a thief. You didn’t see them dumping waste, these are just your hypotheses. You will hardly be able to prove anything, probably everything looks beautiful on their papers.

And you can insure yourself - put a filter on the water. ideally, both the one you wash with and the one you drink. Definitely for the second one!

Legality of locating an enterprise near a body of water

Like in the cartoon: Children, why are you so dirty? We swam in the river! It's funny and makes me want to cry. But I agree - you can hardly prove anything to anyone if you don’t get caught dumping holidays. And I also agree with the advice.

Perhaps this is the only thing you can do in this situation.

Why is it legal for a plant to be located next to a body of water?

I think this is not only a problem for your home, but for half of our country. It’s been a long time since I’ve stopped expecting a miracle from anyone; I installed a Barrier flow filter at home. There used to be a jug, which was also a good thing. But for me the groove is more convenient.

Source