How to choose the right turning cutting tool

Turning cutting tools can machine virtually any type of surface. Depending on the holder used, it is possible to produce a part either cylindrical or with a shaped surface. When choosing a tool for metalworking, you should pay attention to many factors that determine their quality. Thus, reliable equipment cannot be cheap. If you choose between price and quality, it is better to bet on the latter aspect, but of course you have to pay for quality. But it should be understood that a good cutting unit will last much longer and will save money overall.

Particular attention should be paid to the material of the cutting part. Currently, the vast majority prefer to choose products made from hard alloys, which, along with wear resistance, allow you to work with almost any metal.

An important detail is the cutting edges. They must be durable, since durability during processing of the part depends on this. With rapid wear of the cutting edge, it is necessary to change equipment more often, and this leads to an increase in the cost of processing and, accordingly, the cost of the product.

Depending on the metal being processed, one or another type of hard alloy from which the cutting part is made and cutting modes are selected. High speed steel is only suitable for low speed work and soft materials. But products made of hard alloy, mineral ceramics or cubic boron nitride have a high level of wear resistance and allow you to work with a high level of productivity.

Turning tool accessories, service life

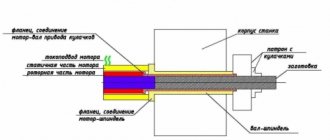

If you decide to purchase a turning tool, then you should think in advance about what additional equipment you need. The fact is that due to high operating speeds, even the most expensive equipment will not be able to work efficiently if the equipment lags behind, so it is necessary to acquire a holder. They help keep it in a fixed position, which has a positive effect on work results. If you need to make a precise cut, you must be sure that the tool will not slip - the holder will help ensure this. It is attached directly to the machine. Many holders have several holes at once, which will allow you to change attachments directly during operation, which will significantly speed up the process. You can also select holders with adjustable locking, allowing you to vary the supported turning tool within a given range. This again will allow you to save on equipment by buying one product instead of one.

About tools used for milling machines

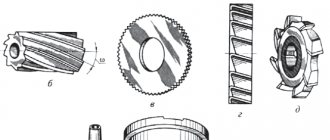

For milling, cutters are used as cutting devices, which come in various designs and have special teeth for processing the surface of parts.

All milling tools differ from each other in:

- the shape and appearance of the teeth;

- their direction and execution;

- their use and fastening.

In order to properly strengthen the cutter in the chuck of a milling machine, use its shank, which is attached to the teeth by welding or with various fasteners, for example:

- bolts;

- special wedges;

- screws.

Sometimes the cutter can be presented as a single unit with its cutting part. That’s what they usually call it – a solid cutter.

Important. Some modern CNC machines use only one-piece special end mills that have cylindrical and also conical shanks for more durable, quick fixation in the chuck of milling machines.

The following materials are most often used in the production of milling tools:

- metal ceramics;

- high-speed cutting steels;

- hard alloys with special diamond coatings to enhance hardness.

Why do we need metal turning tools, and what are they?

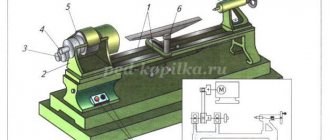

Today, metal turning tools are widely used in the production and manufacture of various parts and mechanisms when processing bodies of rotation. At the same time, the variety of technical solutions in the field of turning cutting tools is enormous. There are several groups:

- neutral, right or left (determine the cutting direction);

- according to material - from quick cutter or hard alloy;

- solid or composite, consisting of several elements.

The above classification demonstrates only a small part of the differences in design. And although they all differ from each other in functional purpose, they also have some common features.

How to choose the right turning cutting tool

Turning cutting tools can machine virtually any type of surface. Depending on the holder used, it is possible to produce a part either cylindrical or with a shaped surface. When choosing a tool for metalworking, you should pay attention to many factors that determine their quality. Thus, reliable equipment cannot be cheap. If you choose between price and quality, it is better to bet on the latter aspect, but of course you have to pay for quality. But it should be understood that a good cutting unit will last much longer and will save money overall.

Particular attention should be paid to the material of the cutting part. Currently, the vast majority prefer to choose products made from hard alloys, which, along with wear resistance, allow you to work with almost any metal.

An important detail is the cutting edges. They must be durable, since durability during processing of the part depends on this. With rapid wear of the cutting edge, it is necessary to change equipment more often, and this leads to an increase in the cost of processing and, accordingly, the cost of the product.

Depending on the metal being processed, one or another type of carbide is selected from which the cutting part of the metal turning tool is made, and cutting modes. High speed steel is only suitable for low speed work and soft materials. But products made of hard alloy, mineral ceramics or cubic boron nitride have a high level of wear resistance and allow you to work with a high level of productivity.

Turning tool accessories, service life

If you decide to purchase a turning tool, then you should think in advance about what additional equipment you need. The fact is that due to high operating speeds, even the most expensive equipment will not be able to work efficiently if the equipment lags behind, so it is necessary to acquire a holder. They help keep it in a fixed position, which has a positive effect on work results. If you need to make a precise cut, you must be sure that the turning cutting tool will not slip - this will help ensure the holder. It is attached directly to the machine. Many holders have several holes at once, which will allow you to change attachments directly during operation, which will significantly speed up the process. You can also select holders with adjustable locking, allowing you to vary the supported turning tool within a given range. This again will allow you to save on equipment by buying one product instead of one.

Techniques for making tools for working with metal

First of all, the tool must meet high requirements that allow you to work with strong and durable material. Tools for metal processing are made using the following methods:

- burning;

- hardening;

- forging using a press;

- grinding;

- hot stamping of hardened steel;

- induction hardening;

- metallization.

Such methods are necessary to give the working surface of the tool additional strength. The resulting equipment must have excellent cutting properties, as well as increased strength.

Main types of instruments

All equipment for metal processing is divided into several main groups, according to the method of influence:

- Pipe cutters. This is a group of equipment that is designed for cutting pipes of various thicknesses and diameters.

- Cross mixer - necessary for creating grooves in metal workpieces.

- Drill stand. There is a drill in it and it is possible to fix the workpiece.

- A die is used to cut external threads. A die holder is made for them.

- Goniometer. This is a measuring device, an analogue of the well-known protractor.

- A soldering iron is used to join metal parts.

- Hand hacksaw for metal. Designed for cutting metal, both sheet metal and small pipes.

- Metal scissors. Designed for cutting sheets that are not too strong.

- Vise - necessary for fixing the workpiece.

- Milling cutters. They work with different surfaces and can be cylindrical, end, disk, end, or conical.

All tools are used in industry and in everyday life. Many of them are used in combination.

Where can I buy metal turning tools?

The best prices for goods and we guarantee their quality. If you are going to buy a turning cutting tool, then you should pay attention to the following factors:

- price;

- reputation of the manufacturer;

- quality;

- range.

On our website you can purchase turning tools from the most famous manufacturers. We guarantee a high level of product reliability. Another convenient advantage is the fact that we deliver to the consumer’s warehouse. We offer a wide selection of turning cutting tools with an optimal price-quality ratio.

About the principles of milling

When milling, using the teeth of a cutter, chips are removed from the surfaces they grind, and they are removed from the cutting zone by special grooves along the cutter itself. Therefore, the location of the teeth relative to each other is of particular importance. Correct geometric relative position affects:

- cutting speed;

- quality of processed surfaces;

- wear resistance of the cutter;

- saving energy costs;

- price of finished products.

Attention. Each type of intended workpiece, be it wood, stone, metal, plexiglass, for example, requires a certain type of milling device.

Thread processing tool

Modern tools for turning and thread processing are of the following types:

- tap (needed to create threads on internal nuts and pipes);

- die (creates a screw thread on bolts and studs);

- die (a die of increased dimensions, looking like a system of cutters);

- plate (width and depth are important).

The difference will be in the diameter and type of threaded connections created. The available options are metric or inch, the first is universal, the second is used when creating plumbing elements. In some countries there are no metric threads at all. Also, when choosing, look at the direction of the cut - it can be left or right; there are universal products.

Parting and grooving tools

When grooving, it is important to achieve optimal performance. The requirements are no less high than for cutting, so tools for cutting and grooving are presented in the following categories:

- plates (must be strong, elastic, have optimal dimensions);

- mandrels (allow for correct boring);

- cutters (main cutting elements);

- holders (needed for the operation of the machine, there are different types).

Deep grooves are more difficult to work with than shallow ones, but using a quality tool will significantly improve the quality of the final result.

Possible schemes of action - in 1 or 2 passes, standard set of tools. We recommend: Working with a brick cutting machine