Diamond is undeniably popular in manufacturing industries. Until a certain period, it was considered an indispensable component of a cutting tool. With the development of scientific and technological progress, CBN appeared on the market of abrasive and cutting materials. CBN tools are not inferior in hardness and density to their competitors.

Features of the substance elbor

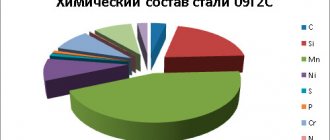

The graphite-like modification was obtained by heating boron and nitrogen in equal proportions at a temperature of 1700 - 1800°C and a pressure of 8 to 12 GPa in the presence of catalysts. The technology for producing the substance was developed at the Research Institute of Abrasives and Grinding during the existence of the Soviet Union. The work was carried out jointly with employees of Leningradsky. Domestic material received the abbreviation KNB. The chemical formula of the substance BN gives it three names – borazone.

Types of elbor, differing in color:

- Brands LKV60 and B5 have yellow transparent crystals of octahedral shape, synthesized in the Li-BN system.

- The LKV40 and LKV50 grades are formed in the presence of Mg and N and contain an excess of boron in the crystal lattice, which gives the substance a black-brown color.

Foreign analogues of borazone are usually designated cBN.

Advantages of elbor

The hardness of the material is almost as good as that of the popular natural mineral and is 3-4 times higher than that of silicon carbide and electrocorundum abrasives. CBN grains have increased wear resistance; during operation they retain their sharpness for a long time.

Oxidation of the granular surface of borazon begins at 1000-1200°C, for diamond at 600-700°C. Tools based on CBN can operate when critical temperatures arise during grinding in harsh conditions. The thermal and chemical resistance of the substance allows it to withstand temperature loads without premature wear of the abrasive grains.

Diamond is subject to rapid wear when grinding steels. Elbor has proven itself well in performing such tasks and does not lose its strength characteristics. The material is inert to almost all chemical elements. Along with a natural abrasive, it does not react with acids and alkalis.

Industrial production methods make it possible to obtain borazone with the necessary physical and technical properties, depending on the purpose.

Our main profiles for narrow band saw blades:

| Saw manufacturer | Disk profile | |

| Step 22 | ||

| Wood -Mizer (WM) summer, Cayman Silver, Ro-Ma, Armoth, Horns, Fenes, Krupp, Lynx, Alligator, Morse | 10/30-6.5 | 1 |

| Wood-Mizer (WM) summer reinforced | 13/29-6.5 | 16 |

| Wood-Mizer (WM) summer reinforced deep | 13/28-7.4 | 21 |

| Wood-Mizer (WM) winter | 9/29-5.5 | 19 |

| Wood-Mizer (WM) winter special | 7/29-5.5 | 25 |

| Wood-Mizer (WM) winter for frozen wood | 4/32-5.5 | 39 |

| Wood-Mizer (WM) winter experimental winter v.1 (based on No. 1 10/30) | 9/29-6.45 | 141 |

| Wood-Mizer (WM) winter experimental winter v.2 (based on No. 1 10/30) | 7/29-6.45 | 142 |

| Ripper | 10/30-6.3 | 123 |

| Lenox, Nook | 10/30-6.8 | 2 |

| Carl Rontgen CR-300, HWSM, Banholzer (old profile until 2020! New - No. 128) | 10/28-5.8 | 3 |

| Carl Rontgen CR-400 | 13/27-6.0 | 26 |

| Banholzer (Banso) (new, from 2022! Previously No. 3) | 10/30-6.5 | 128 |

| Simonds (old profile until 2022! New - No. 119) | 10/29-5.3 | 8 |

| Simonds (new profile from 2022! Previously No. 8) | 9/30-6.3 | 119 |

| Hakansson | 10/31-7.3 | 9 |

| Diamond | 10/30-5.5 | 14 |

| MFS (Uddeholm) summer | 10/30-6.1 | 18 |

| MFS (Uddeholm) winter | 8/30-6.1 | 28 |

| MFS (Uddeholm) summer | 12/30-6.1 | 29 |

| MFS (Uddeholm) winter for frozen wood | 4/32-6.1 | 30 |

| MFS (Uddeholm) winter for frozen wood | 7/29-6.1 | 31 |

| Bimetal Lenz | 10/30-6.5 | 33 |

| Bimetal Bahco (old profile until 2022! New - No. 108) | 10/30-6.3 | 34 |

| Bahco winter bimetal (old profile until 2022! New - No. 121) | 9/29-6.3 | 35 |

| Bahco winter bimetal for frozen wood (old profile until 2022! New - No. 122) | 4/32-6.3 | 36 |

| Bimetal Bahco (new profile from 2022! Previously No. 34) | 10/30-6.5 | 108 |

| Bahco winter bimetal (new winter profile from 2022! Previously No. 35) | 9/29-6.5 | 121 |

| Bimetal Bahco winter | 7/29-6.5 | 143 |

| Bahco winter bimetal for frozen wood (new winter profile from 2022! Previously No. 36) | 4/32-6.5 | 122 |

| Step 19 | ||

| Lenox, Simonds | 10/30 5.8 | 10 |

| Hakansson | 10/30-6.2 | 11 |

| MFS (Uddeholm) | 10/30-5.5 | 113 |

| Dakin Flathers | 11/30-5.8 | 136 |

| Step 25 | ||

| Hakansson, HWSM, Simonds | 10/30-8.4 | 12 |

| Lenox | 10/30-7.7 | 15 |

| MFS (Uddeholm) | 10/30-6.7 | 32 |

| MFS (Uddeholm) (new profile from 2022!) | 10/30-7.7 | 115 |

| MFS (Uddeholm) | 9/29-7.7 | 116 |

| Explanation of the value 9/29-5.5 : 9-front corner, 29-back corner, 5.5-depth. | ||

CBN tool

Borazon is used for the manufacture of individual elements and components of grinding machines, as well as as an independent tool for surface treatment. In terms of service life, CBN tools are superior to tools made from diamond and other abrasives. A characteristic feature of CBN is a softer grinding of surfaces.

Elbor circle

Borazon grinding wheels are produced in accordance with the requirements of GOST 24106-80. The document indicates the values of all quality indicators. Its tables for each brand indicate the following information:

- relative concentration of CBN;

- degree of hardness;

- maximum deviations of circle height;

- bore diameter;

- width height;

- graininess of the layer.

CBN circles are marked with these parameters indicated in turn. This makes it easier to select the required grinding wheel.

As information about the sizes and types of circles, you can use the information from GOST 17123 - 79. However, it must be taken into account that this document has lost force in the Russian Federation.

The marking of abrasive equipment must have the following designations:

- type, sizes;

- material;

- granularity of the abrasive layer;

- hardness;

- operating speed;

- CBN concentration;

- link used.

For circles with a diameter greater than 225 mm, the listed information is applied to the body. On a tool of smaller diameter there are indicators of primary importance. For products up to 50 mm in size, the use of labels is provided.

The body of the circle is made of metal or ceramics. The maximum speed directly depends on the material used. For a metal case it is 125 m/s, for a ceramic case 60 m/s, for a metal-ceramic case 80 m/s.

Before transportation, the grinding tool is wrapped in packaging material to protect the abrasive layer from damage, and placed in boxes with gaskets that protect it from moving inside.

The use of CBN wheels depending on the composition of the ligaments

The substance that transforms the abrasive grains of a grinding tool into a homogeneous dense mass is called a binder. For each type of processed material, its own type of connecting elements is used. These components determine what type of work the grinding equipment is intended for. There are three main types of ligaments.

- Organic. Equipment with such a binder is marked in the form of the letter “O”. This type of filler is used for the production of wheels intended for sharpening steel cutting tools, grinding guide frames, and flat grinding of hard-to-cut steels. Using a tool made of borazon on an organic bond, chip flutes are processed and grooves are cut.

- Ceramic. Denoted by the letter "K" or Latin "V". CBN wheels on this bond are used for grinding high-precision parts made of steels and alloys. They are used for round internal and flat processing of products with threads and teeth, holes, tracks of small-sized precision bearings.

- Metal . It is marked in the form of the letter “M”. Suitable for fine pitch thread grinding and fine honing of steels. Tools with this type of binding can be used for processing wooden, stone, ceramic and composite surfaces.

Borazon wheels can be used to level the surface of hot and cooled metals. They are suitable for finishing products. Grinding with tools of any type of bond is carried out with dry cooling or using liquids. Water, special emulsions and industrial oil are used as a coolant.

Advantages of CBN wheels

The octahedral structure of the material allows for gentle processing and brings polished surfaces to a mirror state.

Advantages:

- The structure of borazone is second only to diamond in hardness.

- The cost of equipment made from CBN is lower than that of circles made from natural minerals.

- High level of wear resistance due to long-term preservation of the sharpness of the grains.

- Resistance to high thermal loads.

- Ability to grind alloy steels with complex chemical composition.

The listed advantages contribute to increasing demand for this tool in industry, machine tool and mechanical engineering.

CBN cutter

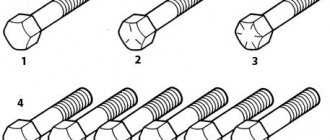

This tool is designed for removing surface layers from parts. The shape of the cutter can be straight or radial. The sharpening angles of the leading and trailing edges are also different.

CBN cutters are available in lengths from 40 to 125 mm in increments of 20 to 80 mm or more. The size of the working part of the cutting element determines the diameter of the base; it has dimensions from 10 to 40 mm. The thickness of the inner core of the cutter is from 6 to 12 mm. Massive cutters are produced for rough processing and correction of the shape of the part. Technical characteristics are described in GOST R 50302-92 or GOST 13297-67.

Applications and advantages of CBN cutters

This tool is designed for cutting, making passes during milling, turning parts, grinding on lathes and boring machines, CNC equipment and built into automatic lines.

The shape of the cutting edges and the type of cutter depend on the purpose, type of machine and the material being processed. The properties of borazone cutters must be taken into account when choosing an effective method of application. The demand for CBN cutters and inserts provides the following advantages:

- preservation of sharpness during operation;

- self-sharpening ability of grains;

- high cutting ability;

- resistance to thermal loads, no burns to the workpiece;

- convenient removal of removed chips;

- The surface finish quality exceeds the accuracy class of diamond cutters.

Thanks to these advantages, when working with a tool made of borazone, it becomes possible to select an accelerated operation mode. This significantly increases labor productivity.

Qualitative characteristics of CBN cutters:

- The strength of the crystals and complete inertness to iron allows the cutters to be used for fine finishing and semi-finish turning and boring of parts made of hardened steels with increased hardness and cast irons.

- The high wear resistance of borazon makes it possible to process parts that require maintaining geometric accuracy.

- CBN tools polish and grind threads, teeth, hard alloys, heat-resistant steels, glass, and silicon. The cutters are used for processing ceramics, marble, granite, and precious stones.

It is not recommended to process metals with low hardness using borazone tools. During the grinding process of soft alloys, surface deformation may occur.

Main characteristics of CBN elements

- The first can be called the type of circle according to the above-mentioned GOST 17123.

- The second characteristic is the outer diameter. Depending on the type, it can be up to 10 mm, from 100 to 200 mm, from 30 to 135 mm, etc. The maximum value of the outer diameter of the CBN circle is 500 mm.

- The third parameter is grain size.

- The fourth parameter is the degree of hardness.

The remaining parameters relate to the minimum time periods of durability (in minutes) and operating time (in square meters). The maximum value of the roughness parameter (in micrometers) is also important. It must comply with GOST 2789 standards.

CBN wheels can work with both dry and coolant. These data are also indicated in GOST 24106-80 for each type. The coolant can be:

- industrial oil (pure or with the addition of sulforesol);

- special emulsion;

- aqueous solutions of sodium nitrite or other solutions.