Cast iron is an alloy of iron and carbon. One of the most widespread types is gray cast iron. The volume of carbon in its composition exceeds 2.14% and is contained in the range from 2.4 to 4.2%.

The material got its name from the color of the fracture, which is gray.

Essentially, it is cast iron interspersed with flake graphite. But, nevertheless, they continue to call him gray. By the way, the same color can be seen on the fracture of malleable cast iron. Metallurgists established a relationship between the volume of free carbon, but not on its form.

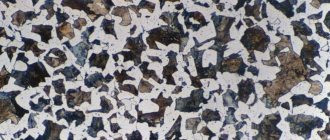

In gray cast iron, carbon takes the form of flake-like or plate-like inclusions as it cools. The difference between cast iron and steel is the volume of carbon. Carbon is absolutely completely dissolved in steel and is not contained in the form of inclusions; gray cast iron contains inclusions of carbon called graphite.

Main characteristics

Cast iron is widespread and in demand in the ferrous metallurgy. It is produced by reconstituting iron ore with the support of a carbon fuel (coke). During the reduction reaction, the resulting melt receives an additional portion of carbon.

It is the volume of carbon in a free state that determines the mechanical parameters of this cast iron. One of the properties that allows this material to be used not only as a conversion metal, but also as a casting metal is its fairly high casting qualities and low shrinkage when the casting solidifies. Gray cast iron has high fluidity, and this makes it possible to cast quite complex products.

There is also a limitation on the use of products made from this cast iron - it is due to the fact that this material has low bending strength and high fragility. But on the other hand, it is distinguished by high compressive strength.

This material is also resistant to wear. This allows it to be used in units operating under high friction conditions. In such conditions, the antifriction parameters of gray cast iron have a strong impact.

A large volume of carbon reduces the density of gray cast iron, which is from 6.8 to 7.3 tons per m3.

Carbon inclusions do not allow permanent connections to be made from gray cast iron workpieces by welding. But, nevertheless, welding technologies have been developed and used, which can be carried out subject to a number of conditions. This set includes preheating of workpieces and the use of specialized electrodes with a high carbon content. Smooth cooling of the seam, this is necessary to remove stress in the weld. But in any case, its structure is noticeably different from the main material.

Chemical composition and structure

The chemical composition of the alloy, in addition to iron and carbon, also includes some silicon content. The properties of the alloy depend on the cooling conditions, since the time of temperature change affects the formation of the internal structure of the material.

With slow cooling, large iron crystals are formed, and metal-carbon compounds acquire a pearlite base. Slow cooling causes an increase in the geometric dimensions of not only iron crystals, but also carbon inclusions, therefore, pearlite metal has high strength, but increased fragility.

Microstructure of gray cast iron

Under conditions of rapid cooling, carbon does not have time to form large graphite inclusions, so the alloy acquires a ferritic structure.

Ferritic gray cast iron is slightly less brittle than pearlitic.

By choosing a cooling mode for a cast workpiece, you can influence the final properties of the material in a certain way, depending on the requirements.

Marking

Metallurgical plants produce several grades of this material. Its marking is carried out as follows. The two letters at the beginning of the abbreviation indicate the type of cast iron, the marking of gray cast iron begins with SCH, the numbers located after the letters indicate the tensile strength

The following classification of gray cast iron is accepted:

- SCh10 - ferritic;

- SCh15, SCh18, SCh20 - ferrite-pearlite cast iron;

- starting from SCh25 - pearlitic cast iron.

Gray cast iron

Gray cast iron is widely used in mechanical engineering and is not a solid metal, but a porous metal sponge - an alloy of iron and graphite, the pores of which are filled with a loose non-metallic substance - graphite. Cast iron is very fragile. Its elongation at break is very low. It breaks into pieces with the blow.

The mechanical properties of gray cast iron depend on the properties of the metal base and mainly on the number, shape and size of graphite inclusions. The pearlite base provides the highest values of strength and wear resistance. Grades of gray cast iron according to GOST 1412-85 consist of the letters “SCh” and numbers corresponding to the minimum tensile strength Stv, MPa / 10. Cast iron SCh10 is ferritic; SCh15, SCh18, SCh20 are ferritic-pearlitic cast irons, starting from SCh25 - pearlitic cast irons.

Gray cast iron with flake graphite accounts for about 80% of the total production of iron castings.

Gray cast iron has high casting properties (it is characterized by a low crystallization temperature, fluidity in the liquid state, and low shrinkage) and therefore serves as the main material for casting. It is widely used in mechanical engineering for casting machine beds and mechanisms, pistons, and cylinders.

Gray cast iron is very prone to cracking during welding, and special attention must be paid to combating cracks during welding.

Often during the welding process, cast iron bleaches, which gives it high hardness and brittleness in the welding zone and makes it completely unsuitable for machining after welding.

There are varieties of cast iron that are almost completely impossible to weld, for example the so-called burnt gray cast iron, which has been exposed to prolonged exposure to high temperatures, acids, steam, etc.

The influence of chemical properties on the structure and physical and mechanical properties of gray cast iron. The influence of the main elements on the graphitization of cast iron:

Carbon. Increasing the carbon content of gray cast iron generally leads to a decrease in strength, elastic modulus and hardness and an increase in ductility and cyclic toughness. The lower limit of carbon content in cast iron with increased strength is limited by a decrease in the casting properties of cast iron. Typically, the carbon content in gray cast iron ranges from 2.4-4.2%.

Silicon, from the point of view of its influence on the graphitization of gray cast iron, is an analogue of carbon. However, its effect on mechanical properties is fundamentally different from the effect of carbon. Silicon forms a solid solution with ferrite and increases the hardness and strength of ferrite, while simultaneously reducing its viscosity. The total (graphitizing and alloying) effect of silicon can significantly change the mechanical properties of gray cast iron. Typically, an increase in silicon content is associated with an increase in the size of graphite inclusions and an increase in the proportion of ferrite in the matrix; the strength of gray cast iron decreases. With a high silicon content, the ductility of gray cast iron decreases due to the formation of silicoferrite. The hardness of gray cast iron with increasing silicon content first decreases due to graphitization, and then increases due to the formation of silicoferrite.

The influence of carbon and silicon on the mechanical properties of gray cast iron is usually considered together. In the simplest case, the total content of carbon and silicon is taken into account; a more accurate method is to determine the carbon equivalent or the degree of eutecticity.

Sulfur. By weakening the grain boundaries, Fe-FeS eutectic reduces the strength and ductility of cast iron. On the other hand, sulfur promotes perlitization of the structure and can increase the strength and hardness of ferritic or ferritic-pearlitic gray cast iron. In addition, sulfur increases the wear resistance of cast iron.

Manganese inhibits graphitization, alloys ferrite, promotes the crushing of pearlite and sometimes the formation of free carbides. The effect of manganese on the mechanical properties of cast iron is shown in Fig. 38. Manganese, interacting with sulfur, neutralizes its harmful effects, therefore the choice of the amount of manganese should be linked to the sulfur content. When smelting low-sulfur cast iron, the manganese content should be reduced.

Phosphorus alloys ferrite, promotes the crushing of eutectic grains and the formation of phosphide eutectic inclusions. With increasing phosphorus content, the hardness and wear resistance of cast iron increases.

Chromium. As the chromium content increases, the strength and hardness of cast iron castings increases; The increase in strength occurs faster in modified cast iron. Chromium inhibits graphitization and is an active carbide-forming element. In Fig. Figure 40 shows the change in hardness in castings with different wall thicknesses with changes in chromium content. The increase in hardness in thin sections with increasing chromium content occurs more intensively than in thick sections.

Nickel has a beneficial effect on equalizing the mechanical properties of cast iron in castings with different wall thicknesses. In cast iron with a nickel content of slightly more than 3%, the strength remains almost unchanged with wall thicknesses from 22 to 88 mm. Each percentage of nickel increases the hardness of gray cast iron by approximately 10 HB. With increasing nickel content, the corrosion resistance of cast iron increases, especially in alkaline environments; machinability improves and, in addition, tightness increases, since with high eutecticity graphite takes on a favorable shape and the grain size decreases.

Molybdenum is an intense carbide-forming element and inhibits graphitization. The strength and hardness of cast iron increases with increasing molybdenum content. With increasing molybdenum content, the strength of cast iron increases linearly: 1% Mo increases the strength by approximately 1 kg/mm2 at any degree of eutecticity from 0.8 to 1.0. In this case, the impact strength does not decrease, but even increases slightly. Molybdenum increases the strength of cast iron at elevated temperatures. Maximum strength is achieved at a content of 1.9% Mo, then a drop in properties occurs due to the formation of ledeburite. The increase in hardness due to increased homogeneity is not accompanied by a deterioration in machinability. Molybdenum also increases the wear resistance of cast iron and its growth resistance.

Copper has a dual effect on gray cast iron: it promotes graphitization during solidification and the formation of pearlite during the eutectoid transformation. With increasing copper content, fluidity increases and shrinkage decreases. As the copper content increases, the elastic modulus of cast iron, strength and hardness increase.

There is an increase in the elastic modulus from 13,000 to 20,000 kg/mm2; the bending strength is from 35 to 67 kg/mm2; the hardness is from 137 to 20 HB, and at 2.6% Cu it remains uniform over the entire cross-section of the castings.

Cuprous cast iron is processed better than unalloyed cast iron. The addition of copper to cast iron alloyed with carbide-forming elements (chromium, molybdenum, vanadium) reduces its hardness and improves machinability, and can also increase strength by reducing the embrittlement effect of carbides. Due to the positive effect of copper on the formation of thin-lamellar pearlite, the corrosion resistance of cuprous cast iron increases in many environments.

An increase in the tensile strength of cuprous cast iron occurs regardless of its eutecticity; the increase in hardness depends on eutecticity (at low eutecticity, hardness increases more rapidly).

Tin content up to 0.1% increases the hardness, as well as the strength and elastic modulus of gray cast iron. However, simultaneously with an increase in hardness, the tendency of cast iron to whiten increases. Therefore, to avoid bleaching, the tin content should not exceed 0.05-0.08%.

It is recommended to use tin as an alloying element instead of chromium to eliminate large variations in hardness across different sections of castings.

Tin significantly reduces the growth of cast iron and the formation of scale.

Antimony in gray cast iron prevents the release of free ferrite, similar to tin, but more effectively. The effect of antimony is detected at its content of 0.015%, and additives of 0.03-0.08% Sb provide effective alloying of cast iron. The strength of cast iron increases up to approximately 0.1% Sb until a pure pearlitic structure is achieved, and as the antimony content increases further, the strength decreases. Antimony only affects the crystallization of the metal base of cast iron, without changing either the shape or distribution of graphite inclusions. The impact strength of cast iron decreases when alloyed with antimony.

With increasing antimony content, the sensitivity of cast iron to wall thickness decreases noticeably. The effect of antimony on mechanical properties is given in table. 26.

Boron increases the strength of cast iron by promoting the release of crushed carbides. With extremely small additions, boron apparently has a graphitizing effect on cast iron and slightly increases deflection and impact strength; at high boron contents, the strength increases and the ductility and toughness of cast iron decreases.

With a selected ratio of boron and silicon in a wide range of wall thicknesses and eutecticity of cast iron, a peculiar half-structure is obtained with a uniformly distributed cementite network on a pearlite basis. Depending on the amount of introduced boron, it is possible to obtain a hardness of up to 260 HB. Gray cast iron with a thin cementite mesh is easy to process. Complex additions of boron and aluminum have a similar effect on the properties of cast iron. By alloying with boron, the wear resistance of cast iron can be significantly increased without fear of reducing its machinability.

The most widely used is complex alloying with the introduction of several elements into cast iron simultaneously.

Welding of cast iron is used to correct various casting defects, in repair work when restoring worn and destroyed machine parts, as well as in the manufacture of combined machine parts from cast iron and from cast iron in combination with other alloys.

The main methods of welding cast iron are: gas, electric arc and electric contact spot, used to connect cast iron parts with copper, bronze and brass parts.

Service properties of gray cast iron. Wear resistance is determined by the rate of metal loss, expressed in weight or linear measurements.

The main types of wear are classified as follows: abrasive, dry friction, friction with lubricant, erosion-cavitation.

The wear resistance of gray cast iron depends primarily on its structure and hardness. The smaller the total amount of graphite and the size of the graphite inclusions, the greater the wear resistance of cast iron. The presence of ferrite in the structure is useful only with a relatively soft counterbody, at low pressures and speeds, under conditions of rolling friction with continuous one-way rotation, as well as with possible distortions of the rubbing pair during the running-in process. In most cases, the pearlite structure has significant advantages, especially in sliding friction and reciprocating motion.

In the vast majority of cases, wear resistance is directly dependent on the hardness of cast iron and increases with increasing hardness of the latter. Parts operating under conditions of impact and abrasive wear should have especially high hardness.

The wear resistance of gray cast iron can be significantly increased through the use of alloying (Fig. 50).

Tightness is assessed by leakage rate, pressure drop, or boundary parameters (wall thickness, pressure) at which a leak is detected.

Tightness requirements apply to cast iron parts operating under liquid or gas pressure. The fluid pressure can be equal to atmospheric pressure (crankcases, open tanks). Castings of pumps and compressors, pipelines, fittings, brake pneumatics, hydraulic drives, etc. must have high tightness.

The main factor determining the tightness of castings is the presence of shells and microporosity. The main role is played by “transit”, i.e. interconnected microporosity.

Application of gray cast iron in machine tool industry. The first class of castings includes base, body and other parts of high strength or wear resistance. Cast iron in the thickest areas of castings, which mainly determine the strength and rigidity of parts, should have a tensile strength of about 25-30 kg/mm and an elastic modulus of about (1.15-1.35) 104. Depending depending on specific wall thicknesses, to ensure this given strength in castings, the following grades of gray cast iron are recommended for preferential use: SCh 21-40, SCh 28-48, SCh 32-52.

Parts belonging to the first class are parts that carry high loads: brackets, gears. Parts that are subject to requirements for stability of geometric shape and subject to wear during sliding friction in conditions of high contamination of the lubricant, as well as during rolling friction: beds with sliding guides of screw-cutting lathes, turrets, horizontal boring, milling and other machines, as well as coordinate boring, grinding with insufficient protection of guides; beds of jig boring, thread grinding, grinding machines with rolling guides; sliders, cross members, overhead guides; scraping and testing plates and rulers. Parts that are subject to requirements for tightness at pressures above 80 kg/cm: parts of hydraulic and pneumatic equipment - cylinders, pump housings, spools.

First-class castings operating under conditions of wear of working surfaces (guides) are subject to additional requirements in terms of hardness and microstructure. The hardness of the guides at a depth of 3/4 of the machining allowance must be at least 180 HB. For heavy castings weighing more than 7000 kg or with a guide thickness of more than 100 mm, the hardness can be reduced to 170 HB. The same reduction in hardness is allowed if the sliding guides are well protected from contamination (they do not come out of contact with the guides of the mating parts).

The microstructure of castings weighing up to 4000 kg with a guide thickness of up to 60 mm should consist of fine-plate highly dispersed perlite in an amount of at least 98% and small graphite platelets ranging in size from 10 to 125 microns, graphite inclusions, isolated or in the form of colonies with a low degree of isolation. When the weight of castings is from 4000 to 10,000 kg or when the thickness of cast guides is from 60 to 100 mm, the perlite content must be at least 95%. For particularly heavy machine castings over 10,000 kg or with a guide thickness of more than 100 mm, perlite can be from medium-lamellar to fine-lamellar with a content in the structure of more than 90%, and graphite with a size of 10 to 250 microns.

For the most critical parts of the first class: base, body and other parts of high strength and high wear resistance of precision machines, i.e. machines of increased, high and especially high precision, it is preferable to use cast iron grade SCh 32-52.

High strength properties and hardness of working surfaces are achieved by alloying cast iron with nickel, chromium and molybdenum.

The second class of castings includes base and body parts with increased strength or wear resistance. To ensure the necessary strength and rigidity, the cast iron in the castings (in the areas that dominate the section thickness) must have a tensile strength of about 20-25 kg/mm3. Depending on the wall thickness of the castings, to ensure such strength, it is recommended to use the following grades of gray cast iron: SCh 15-32, SCh 21-40 and SCh 28-48.

Castings of the second class are parts that are subject to requirements for stability of geometric shape and do not suffer from wear: beds and slides with overhead guides of turret, screw-cutting lathes, etc.

The use of gray cast iron and other types of cast iron is discussed in more detail in the article the use of cast iron.

Composition of gray cast iron and its structure

The parameters and properties of the alloy directly depend on the cooling mode; the fact is that it is during cooling that the structure of the material is formed.

During the process of slow cooling, considerable iron crystals are formed, and the combination of metal and carbon becomes pearlitic. During such cooling, not only the size of metal crystals increases, but also carbon inclusions. This combination leads to the fact that pearlite material has not only high strength, but also increased fragility.

Assessment of the structure of the MF determines:

- the size of graphite inclusions, measured in micrometers (μM), their distribution, quantity (in%), the type of structure of the metal base and, if pearlite is present, its dispersion.

According to the structure of the metal base, gray cast irons are divided into:

- pearlite - the structure contains pearlite and graphite;

- ferrite-pearlite - ferrite, pearlite and graphite;

- ferritic - the structure consists of ferrite and graphite.

Which base will be depends on the cooling rate after hardening.

To designate parts of the microstructure of cast iron of this type, the terminology defined in GOST 3443-87 is used, for example, flake graphite is designated by the letters PG. Carbon is included in the material in the following forms.

- lamellar rectilinear, it is designated PGF1;

- plate vortex - PGF2;

- needle-shaped - PGF3;

- nest-shaped -PGF4.

Of primary importance for acquiring the required parameters of an iron casting is its structure, which is why when making blanks, careful implementation of the technology of melting and pouring raw materials is required. To obtain the required parameters of gray cast iron and eliminate defects, a modification operation is used.

The composition of SP, depending on its brand, may include the following substances:

The base is Fe (iron), the rest:

- C (carbon) - 2.9-3.7%;

- Si (silicon) -1.2-2.6%;

- Mn (manganese) - 0.5-1.1;

- P (phosphorus) no more than 0.2-0.3%;

- S (sulfur) no more than 0.12-0.15%.

It is permissible to alloy gray cast iron using substances such as Cr, Ni, Cu, and some other elements.

Silicon in the composition increases the graphitization of carbon. Manganese, although it makes graphitization difficult, improves its mechanical properties.

The chemical composition of SP is defined in GOST 1412-85. Gray cast iron is produced in many countries around the world; in the USA, A48-30B is considered an analogue of this material, in Britain BS 200 or 220, in China GB HT 20, in the European Union EN-JL1030 FG20.

Malleable cast iron

In the structure of malleable cast iron, graphite has a flaky shape. This type of graphite is called annealed carbon. Compared to gray cast iron, ductile cast iron has higher strength, ductility and toughness. It got its name because it has increased plasticity. Cast iron is not subject to forging in the truest sense of the word.

The process of producing castings from malleable iron includes two stages: the production of shaped castings from white cast iron and annealing of the resulting castings for the purpose of graphitization of cementite. During annealing, white cast iron cementite decomposes to form flake-shaped graphite. As a result, brittle and hard castings become ductile and softer. Depending on the conditions and annealing mode, the structure of cast iron can have a ferritic (F), pearlitic (P) and ferrite-pearlite metal base. The most widely used is ductile ferritic ductile iron. Annealing of malleable cast iron is a very lengthy process, taking 70-80 hours. However, it can be accelerated by hardening white cast iron castings before graphitization, as well as modifying cast iron with aluminum, boron, bismuth or titanium. There are other ways to speed up the annealing process. The use of these methods allows you to reduce the annealing time to 35-40 hours.

Table 2. Malleable cast irons, their main properties and applications

| Brand | NV | Properties and Application |

| CC 35-10 CC37-12 | 160 | Ferritic cast irons are used for the production of parts, operated under high dynamic and static loads (cases, gearboxes, hubs, hooks, brackets, rear axles, brackets) |

| CC 30-6 CC 33-8 | 160 | For the manufacture of less critical parts (clamps, nuts, valves, parts of agricultural machines, mufflers, flanges, couplings, brake parts, pedals, wrenches, pads, brackets) |

| CC 45-7 | 203 | Malleable cast irons of pearlitic class grades have high strength, moderate ductility and good anti-friction properties. They are used to produce cardan shaft forks, gears, worm wheels, pistons, bearings, links and rollers of conveyor chains, bushings, clutches, brake pads, crankshafts |

| CC 50-5 | 226 | |

| CC 55-4 | 236 | |

| CC 60-3 | 264 | |

| CC 65-3 | 264 | |

| CC 70-2 | 280 | |

| CC 80-1.5 | 314 |

According to GOST 1215-79, malleable cast iron is marked according to the same principle as high-strength cast iron. For example, the grade of cast iron KCH 33-8 means that this cast iron has a tensile strength σв = 32.4 N/mm2 (33 kgf/mm2) and elongation δ = 8%.

Ductile iron castings can be obtained with a cross-section of up to 55 mm. With a larger cross-section, lamellar graphite is formed in the core of the castings and the cast iron becomes unsuitable for annealing. In mechanical engineering, high-strength cast iron is more often used, which is obtained using less complex and cheaper technological processes than the production processes of malleable cast iron.

The main properties of malleable cast iron and its application are given in Table 2.

Standards

| Name | Code | Standards |

| Castings with special properties (iron and steel) | B83 | KSt 81-033:2009 |

| Cast iron | AT 11 | GOST 1412-85 |

| Pipes made of ferrous metals and alloys, cast and connecting parts for them | B61 | GOST 5525-88, GOST 9583-75 |

| Iron castings (gray and ductile iron) | B81 | OST 108.962.01-85, OST 24.207.01-90, OST 23.4.258-86, OST 23.4.117-84, TU 26-0401-725-86, TU 1-812-0072-94 |