- Types and characteristics of deoxidizers

- Mild steel grades

- Advantages of quiet alloys

- Application areas of mild steel

- Differences between calm and semi-quiet steels

Calm steel contains a minimal amount of oxygen. In the classification according to the degree of deoxidation, it ranks first after boiling and semi-calm steels. Mild steel is obtained by enriching the original alloy with deoxidizing agents. They remove oxygen from the molten alloy, thereby improving its mechanical properties. The metal becomes denser, more resistant to heat and corrosion.

Which ordinary quality steel is considered boiling steel - Metalworker's Handbook

Steels are usually called alloys of iron and carbon containing up to 2.14% carbon. Depending on the chemical composition, carbon steels (GOST 380-71, GOST 1050-75) and alloy steels (GOST 4543-71, GOST 5632-72, GOST 14959-79) are distinguished.

In turn, carbon steels can be:

- low-carbon, i.e. containing less than 0.25% carbon;

- medium-carbon, carbon content is 0.25-0.60%;

- high-carbon, in which the carbon concentration exceeds 0.60%.

Alloy steels are divided into:

| Table of elements MS Word, 40Kb |

- low alloy content of alloying elements up to 2.5%;

- medium alloyed, they contain from 2.5 to 10% alloying elements;

- highly alloyed, which contain over 10% alloying elements.

Purpose

Structural, intended for the manufacture of construction and engineering products.

Tools, from which cutting, measuring, stamping and other tools are made. These steels contain more than 0.65% carbon.

With special physical properties, for example, with certain magnetic characteristics or a low coefficient of linear expansion: electrical steel, superinvar.

With special chemical properties, for example stainless, heat-resistant or heat-resistant steels.

Quality

Depending on the content of harmful impurities: sulfur and phosphorus, steel is divided into:

- Steel of ordinary quality, content up to 0.06% sulfur and up to 0.07% phosphorus.

- High-quality - up to 0.035% sulfur and phosphorus each separately.

- High quality - up to 0.025% sulfur and phosphorus.

- Particularly high quality, up to 0.025% phosphorus and up to 0.015% sulfur.

Degree of deoxidation

According to the degree of oxygen removal from steel, i.e. according to the degree of its deoxidation, there are:

- calm steel, i.e., completely deoxidized; such steels are designated by the letters “sp” at the end of the grade (sometimes the letters are omitted);

- boiling steels - slightly deoxidized; are marked with the letters “kp”;

- semi-quiet steels, occupying an intermediate position between the previous two; are designated by the letters "ps".

Ordinary quality steel is also divided into 3 groups based on supplies:

- Group A steel is supplied to consumers based on its mechanical properties (such steel may have a high sulfur or phosphorus content);

- steel group B - by chemical composition;

- steel group B - with guaranteed mechanical properties and chemical composition.

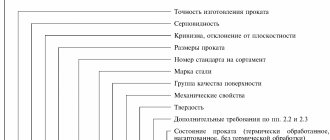

Depending on the standardized indicators (tensile strength, elongation, yield strength, cold bending), the steel of each group is divided into categories, which are designated by Arabic numerals.

Structural steels

Designated according to GOST 380-94 with the letters “St” and a conventional brand number (from 0 to 6) depending on the chemical composition and mechanical properties. The higher the carbon content and strength properties of the steel, the higher its number.

The letter “G” after the brand number indicates a high manganese content in the steel. The steel group is indicated before the grade, and group “A” is not included in the designation of the steel grade.

To indicate the category of steel, the number corresponding to the category is added to the brand designation at the end; the first category is usually not indicated.

For example:

- St1kp2 - carbon steel of ordinary quality, boiling, grade No. 1, second category, supplied to consumers based on mechanical properties (group A);

- VSt5G - carbon steel of ordinary quality with a high manganese content, calm, grade No. 5, first category with guaranteed mechanical properties and chemical composition (group B);

- Vst0 - carbon steel of ordinary quality, grade number 0, group B, first category (steel grades St0 and Bst0 are not separated by degree of deoxidation).

| Steel designation | carbon |

| St0 | |

| St1 | 0,06-0,12% |

| St2 | 0,09-0,15% |

| St3 | 0,14-0,22% |

| St4 | 0,18-0,27% |

| St5 | 0,28-0,37% |

| St6 | 0,38-0,49% |

Unalloyed structural quality steels

In accordance with GOST 1050-88, these steels are marked with two-digit numbers showing the average carbon content in hundredths of a percent: 05; 08; 10; 25; 40, etc. So steel with a carbon content of 0.07-0.14% is designated 10, steel with a carbon content of 0.42-0.50% is designated 45, and steel with a carbon content of 0.57-0.65% is designated 60.

Moreover, for steels with C

For mild steels, letters are not added at the end of their names. For example, 08kp, 10ps, 15, 18kp, 20, etc.

The letter G in the steel grade indicates a high manganese content. For example: 14G, 18G, etc.

High-quality steels with improved properties, used for the production of boilers and high-pressure vessels, are designated according to GOST 5520-79 by adding the letter K at the end of the steel name: 15K, 18K, 22K.

Structural alloy steels

In accordance with GOST 4543-71, the names of such steels consist of numbers and letters. The first digits of the brand indicate the average carbon content in steel in hundredths of a percent.

The letters indicate the main alloying elements included in the steel.

The numbers after each letter indicate the approximate percentage content of the corresponding element, rounded to the nearest whole number; for an alloying element content of up to 1.5%, the number behind the corresponding letter is not indicated.

For example, steel of composition C 0.09-0.15%, Cr 0.4-0.7%, Ni 0.5-0.8% is called 12ХН, and steel of composition C 0.27-0.34%, Cr 2.3-2.7%, Mo 0.2-0.3%, V 0.06-0.12% - 30×3MF.

In order to show that steel has limited sulfur and phosphorus content (S

Particularly high-quality steels subjected to electroslag remelting, which ensures effective purification from sulfides and oxides, are designated by adding the letter Ш through a dash at the end of the name of the steel. For example: 12×2N4A, 15×2MA, 18ХГ-Ш, 20ХГНТР-Ш, etc.

Cast structural steels

In accordance with GOST 977-88, they are designated according to the same rules as high-quality and alloy steels. The only difference is that at the end of the names of casting steels the letter L is given, for example, 15L, 20G1FL, 35 KhGL, etc.

Construction steels

Construction steels according to GOST 27772-88 are designated by the letter C (construction) and numbers corresponding to the minimum yield strength of the steel. The letter K at the end of the name indicates steel with increased corrosion resistance, the letter T indicates heat-strengthened rolled steel, and the letter D indicates a high copper content. For example: S255, S345T, S 390K, S440D, etc.

Ball bearing steels

GOST 801-78 is marked with the letters “ШХ”, after which the chromium content is indicated in tenths of a percent. For steels subjected to electroslag remelting, the letter Ш is also added at the end of their names separated by a dash. For example: ShKh15, ShKh20SG, ShKh4-Sh.

Automatic steels

GOST 1414-75 begin with the letter A (automatic). If the steel is alloyed with lead, then its name begins with the letters AC. To reflect the content of other elements in steels, the same rules are used as for alloyed structural steels. For example: A20, A40G, AS14, AS38HGM

Tool steels

These steels, in accordance with GOST 1435-90, are divided into high-quality and high-quality.

High-quality steels are designated by the letter U (carbon) and a number indicating the average carbon content in the steel, in tenths of a percent. Thus, U7 steel contains 0.65-0.74% carbon, U10 steel - 0.95-1.04%, and U13 steel - 1.25-1.35%.

Advantages of quiet alloys

- homogeneous structure;

- low fragility;

- weldability;

- resistance to dynamic loads;

- lower content of impurities compared to steels that can boil.

The disadvantage of quiet alloys is their high price, justified by the addition of deoxidizing agents and the removal of the shrinkage cavity.

Thanks to its acquired qualities, mild steel is classified as a structural carbon alloy used in critical areas.

What kind of steel is called boiling steel?

Previously, we looked at the structure of steel (iron-carbon system), the deformation and destruction of metals, the influence of various impurities on its properties, etc.

In this publication we will consider types of steel according to the degree of deoxidation.

general information

So, steel is an alloy of Fe + C, (C – no more than 2%) + other elements. Steel is divided into carbon and alloy, taking into account the chemical.

composition, and based on application - structural and instrumental .

Special steels with specific characteristics are also produced for use in aggressive environments; such steels include heat-, corrosion-, and acid-resistant steels.

The quality of steel is determined by the production method and the amount of bad impurities and is divided into ordinary, high-quality, enhanced and high quality.

Chemical composition of ordinary quality steels

There is a typification based on the nature of solidification in the mold and the geometric shape of the ingot (mold shape). There are calm, semi-calm and boiling .

Carbon steel

Carbon steel is smelted without the addition of any alloying elements and is of ordinary and high quality.

Standard quality steels are usually divided into the following groups:

• group A – ensured by mechanical properties. Products made from steels of this group are used for subsequent welding, forging, etc. Moreover, the declared fur. properties may change. (St3, St5kp.).

• group B – steel is provided according to chemical requirements. composition. It is used for the manufacture of parts, during processing of which the mechanical characteristics determined by the composition may change.

Steel from group B is divided into 2 categories:

- 1st - the content of C, Si, Mn was established; limited content: S, P, N, As,

- 2nd - the amount of Cr, Ni, Cu is additionally limited.

• group B - ensured by mechanical characteristics and content of chemical elements. Used in the production of welded parts.

Divided into six categories.

Group B is designated as follows: steel grade, degree of deoxidation, category number.

They have the same composition as steel of category 2, group B.

Steel marking

Considering, as an example, the marking of steel St5ps (structural carbon steel of ordinary quality).

We determine that:

- this steel belongs to group A (since the category is indicated before the letters St (VSt1, VSt2), and only group A is not indicated).

- number 5 - determines the conditional number of the brand based on the chemical. composition and mechanical properties.

- ps is the degree of deoxidation.

If after the number defining the steel grade there is a letter G, then the steel contains a suspended amount of manganese. (St25G2S)

Degrees of steel deoxidation

There are 3 degrees of steel deoxidation.

The deoxidation process allows you to restore iron oxide and bind dissolved oxygen, thus reducing its harmful effects.

Boiling steel

Boiling steel is not completely deoxidized. During casting into molds, it boils due to the abundant release of gas, so it is the most contaminated with gases and inhomogeneous. T.

The mechanical properties of the ingot may differ, since the distribution of chemical elements throughout the ingot is not uniform.

The head part of the ingot contains the largest amount of carbon and various bad impurities (such as sulfur or phosphorus), which requires removal of part of the ingot (5% of the total mass).

The accumulation of sulfur in certain areas can cause a crystallization crack to appear along the seam. In these areas, steel is less resistant to aging and is most brittle at sub-zero temperatures. silicon in boiling steel does not exceed 0.07%.

So, we can say about boiling steel that it is quite brittle, has poor weldability and is most susceptible to corrosion. Therefore, in order to improve the characteristics of steel, it is deoxidized with silicon (0.12-0.3%), aluminum (up to 0.1%) or manganese (deoxidation is also possible with other chemical elements that dynamically react with oxygen).

Boiling steel is quite brittle, has poor weldability and is most susceptible to corrosion.

The deoxidation process allows you to restore iron oxide and bind dissolved oxygen, reduce its harmful effects, while maintaining a high temperature of the steel for a long time, which promotes maximum gas and slag removal, as well as obtaining a micro-grained structure due to the formation of crystallization areas. Due to the formation of these foci, the quality of steel improves.

Liquation is the formation of a heterogeneous chemical structure of steel that occurs at the moment of crystallization. I distinguish two types of liquation: intracrystalline and dendritic. This phenomenon was first discovered by Russian metallurgists N.V. Kalakutsky and A.S. Lavrov in 1866.

Calm steel

The steel obtained as a result of deoxidation is called calm steel. silicon in mild steel is at least 0.12%, and the presence of non-metallic inclusions and slag is minimal.

Mild steel ingots have a dense, homogeneous structure, and, accordingly, improved mechanical properties.

Mild steel is excellent for welding and also has better resistance to impact loads. Is more homogeneous.

It is suitable for the construction of supporting metal structures (due to its resistance to brittle fracture) that are subject to heavy loads.

Mild steel is excellent for welding and also has better impact resistance and is more uniform.

Semi-quiet steel

Semi-quiet steel is intermediate in quality indicators.

It is semi-deoxidized and crystallizes without boiling, releasing a sufficient amount of gas and having fewer bubbles than boiling steel. Therefore, semi-quiet steel has average quality indicators (as close as possible to calm steel), and sometimes replaces calm steel.

The cost of semi-quiet steel is slightly lower than that of calm steel, and the yield of high-quality rolled products from such ingots is 8-10% better.

The quality indicators of semi-quiet became closer to calm.

Semi-quiet steel hardens without boiling, but with the release of a large amount of gas. In such an ingot the content of bubbles is less than in a boiling ingot, but more than in a calm one.

Since the production of boiling steel is cheaper than calm and semi-quiet steel, it is widely used for the production of the least critical rolled metal products, such as wire rod, strip, angle, and hardware.

Comex

Steel is a metal alloy of iron and carbon, necessary for the production of semi-finished products and products by plastic deformation in cold and hot states. To change the properties of a material, various elements can be added to its composition. Thus, with an increase in the amount of carbon, the strength of steel increases. If it is more than 2.14% in the alloy, we get cast iron.

How is semi-quenched steel produced? How is it different?

Steel is selected taking into account the conditions of its use. For example, if it is necessary to make power springs or shock absorbers for a car, a material with excellent elasticity characteristics is used.

The main properties by which steel differs:

Semi-quiet steel can be obtained through special smelting, which involves incomplete deoxidation of the material (whereas boiling steel requires complete deoxidation). This type of steel acquires hardness without boiling, so there are far fewer bubbles in its composition. In terms of quality, the semi-calm type is intermediate between steel of the calm and boiling type.

There are several grades of semi-quiet steel, including carbon material, manufactured to specified standards. Less common are low-alloy semi-calm grades.

High-quality semi-quiet steel is in high demand; it is used for the production of various building elements and the manufacture of rolled metal products. Detailed information about the material and its characteristics can be found on the supplier’s website.

Which ordinary quality steel is classified as boiling steel?

Steel is an alloy of two elements: iron, carbon, and alloying impurities that are added to the metal to give it the desired properties.

St3 is a structural carbon steel of ordinary quality, widely used in all areas of industrial production. It is the most commonly used metal for load-bearing building structures.

Sheets, profiles, pipes, I-beams and other rolled metal products are made from this alloy.

Chemical composition

Steel grades differ in composition, which determines the mechanical characteristics, scope and weldability of the material.

The small amount of alloying elements and high ductility of St3 make it the most common alloy used in construction. Not a single construction site can do without rolled steel from St3.

The chemical composition of the material includes the following elements:

- iron – 97%;

- carbon – 0.14-0.22%;

- nickel, copper, chromium – each no more than 0.3%;

- manganese - 0.4-0.65%;

- silicon - 0.05-0.17%;

- arsenic less than 0.08%;

- sulfur no more than 0.05;

- phosphorus less than 0.04%.

Carbon determines the hardness, strength, ductility, weldability, and physical and mechanical properties of steel. Sulfur and phosphorus are harmful impurities.

Alloying elements in the structure of this alloy that affect its characteristics are manganese, chromium, copper and nickel.

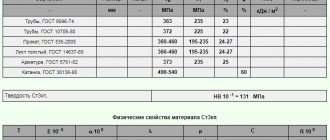

Physical and mechanical properties

St3 steel is the most used grade of metal used in construction and mechanical engineering. Low price combined with physical and mechanical properties that determined the popularity of this material.

Let us list the mechanical indicators of St3:

- yield strength 205-255 MPa;

- temporary tensile strength 370-490 MPa;

- relative elongation 22-26%;

- impact strength at temperature:

- 20 0C is 108 J/cm2;

- 20 0C equals 49 J/cm2;

- hardness HB 10-1: 131 MPa.

Strength indicators: yield strength and relative elongation depend on the thickness and shape of the rolled product. The greater the thickness of the rolled metal, the lower the value of the indicator; the lowest indicators are for pipes, the highest indicators are for sheets with a thickness of 5-10 mm.

The density of St3 is 7850 kg/m3. The alloy is a highly weldable material.

Marking St3

Low-carbon steels are classified according to their composition and degree of dispersion. Deoxidation is the process of removing oxygen, which is a harmful impurity, from the melt. It worsens the mechanical and other properties of the material.

According to the degree of deoxidation, the alloy is of three types:

- calm is designated “sp”;

- semi-calm – marked “ps”;

- boiling - “kp”.

Let's decipher the St3Gps material. The letters "St" stand for steel. The number “3” is the percentage of carbon; the higher the number, the greater the percentage of carbon contained in the metal. The letter G is written if the percentage of manganese content is 0.8% or more. PS – semi-calm.

Varieties of St3 alloy

Mild steel is deoxidized using manganese, silicon and aluminum. This is an expensive and high quality material. Due to its homogeneous structure, a calm metal is more ductile and more corrosion resistant. It is used for the manufacture of load-bearing critical structures, machine components, mechanisms that operate at low temperatures and dynamic loads.

Semi-quiet steel is deoxidized by manganese and aluminum. The strength and ductility indicators of this material are close to that of steel, but are inferior to it. It is used in the construction of load-bearing metal structures, where the requirements for strength indicators are lower than for structures made of solid metal. The advantage of this alloy is that it is cheaper.

Boiling steel is the cheapest and is deoxidized only by manganese. When this melt is poured into slabs, active boiling occurs - the gases contained in the alloy are released. In different parts of the ingot it may have heterogeneous properties. Boiling metal is brittle, difficult to weld and susceptible to corrosion. It is used for the manufacture of structures that do not have high requirements.

Application of St3

Mild steel is used to produce: sheets, angles, channels, reinforcement, I-beams and other rolled metal products, which are used for the manufacture of:

- pipeline fittings, pipes, fittings;

- overhead cranes, load-bearing railway metal structures, building frames, intra-shop metal structures, railway and road bridges;

- tanks for storing water and petroleum products, railway cars, tanks for transporting petroleum products;

- car bodies, ship hulls;

- other critical structures used in all industries operating at low ambient temperatures, under conditions of dynamic alternating loads.

Semi-quiet steel is used for the same metal structures and parts as calm steel, but on the condition that these products will not operate at temperatures below -10 0C.

Boiling steel. It is used for lightly loaded, secondary, unloaded metal structures that operate under constant loads. Fences, grounding, brackets, sheet cladding, and other elements of buildings and metal structures are made from it.

Which ordinary quality steel is considered boiling steel?

Boiling steel is low-oxidation steel that intensively releases gases in the mold during solidification. Gases formed: up to 90% CO, carbon dioxide, nitrogen, hydrogen, methane. Strong deoxidizing agents such as aluminum and titanium are not used in the production of this metal.

The main feature of a boiling steel ingot is the absence of a concentrated shrinkage cavity. The structure of the ingot depends on the intensity and boiling period of the melt. In the hardened state it has 5 zones:

- outer dense crust;

- accumulation of honeycomb bubbles having an elongated shape;

- intermediate zone between cellular and secondary bubbles;

- accumulation of deep (secondary) air bubbles;

- the core of the ingot is the zone of deep bubbles.

In high-quality ingots, the outer crust is so dense and thick that when heated and rolling, the accumulation of honeycomb bubbles does not open.

“Clogged” – a type of boiling steel

In terms of the degree of suppression of gas evolution during melt solidification, the material is between boiling and semi-calm steels. The difference between this technology is the closing of the ingot from above after casting by mechanical or chemical means.

- In mechanical capping, the ingot is closed with a heavy cast iron lid.

- Chemical plugging is achieved by adding aluminum or ferrosilicon additives to the top of the mold. This leads to accelerated hardening of the upper part of the ingot, which is cut off and sent to waste.

This technique allows you to reduce the time of gas release and reduce the number of air bubbles inside the ingot.

Main characteristics

Boiling steels are characterized by heterogeneity of structure and chemical composition, which leads to a decrease in some operational characteristics. The strength of the metal is reduced due to air bubbles brewed during rolling, which during rolling or stamping can lead to delamination of the material.

Properties of boiling steel

- Problematic weldability due to pronounced uneven distribution of phosphorus and sulfur throughout the thickness of the product, which negatively affects the properties of the metal. Zones with a high sulfur content cause the appearance of crystallization cracks in and around the seam.

- The metal is prone to aging in the area near the weld, which leads to its embrittlement at subzero temperatures.

- Higher susceptibility to corrosion compared to mild and semi-mild steels.

Application areas of boiling steel

These metal products have certain restrictions on areas of use. It is not allowed for the manufacture of:

- fastening elements for boilers operating under pressure;

- structures and equipment planned for operation at temperatures below -20°C

- devices operated under dynamic, alternating, pulsating loads;

- equipment and structures in contact with aggressive, explosive and fire hazardous environments, compressed and liquefied gases.

Boiling steel ingots are used to produce strips, sheets, thin slabs, wire, rods, strips, and pipes intended for the manufacture of ordinary products.

What grades of carbon steel can be classified as boiling steel?

For the manufacture of this type of alloy the following are used:

- carbon steels of ordinary quality - boiling alloys are manufactured in accordance with GOST 380-2005, designation - “kp”;

- high-quality and high-quality steels - regulated by GOST 1050-88, letter designation - “kp”.

Steels with a carbon content of more than 0.15% are usually used in production.

Carbon steels of ordinary quality have long been a product of mass production, which has made their cost affordable. According to GOST 380-2005, their composition, in addition to iron and carbon, may include a certain amount of non-metallic inclusions, as well as impurities that worsen the quality characteristics of such steels.

Thick plates are produced, as a rule, from structural carbon steel of ordinary quality

Requirements GOST 380-2005

You can familiarize yourself with the GOST requirements for carbon steels of ordinary quality by downloading the document in pdf format from the link below.

GOST 380-2005 specifies all the requirements for the characteristics that carbon structural steels of ordinary quality must have. Such steels are used primarily for the production of:

- hardware products;

- products obtained by stamping and forging;

- metal in sheets of various thicknesses;

- long products;

- blanks obtained by casting and rolling;

- broadband rental;

- shaped rolled products;

- metal tapes and wires of various diameters;

- products obtained after metal processing on rolling crimping equipment (slabs, blooms, etc.);

- metal ingots.

From the production of long products to the production of nuts

Steel that is completely deoxidized during the production process has lower composition heterogeneity. Semi-quiet type material is cheaper. High-quality rolled products are produced from steel: hexagons, angles, strips, circles, sheets, etc. These are popular types of products used in construction, mechanical engineering, machine tool building, furniture manufacturing, etc.

Semi-quiet steel is used in the production of billets for rolled pipes. Due to its high strength, the material is used to produce load-bearing welded structures that can withstand significant intense loads. Another area of application is the production of fasteners.

When choosing steel, you need to focus on its operating conditions, including temperature conditions and the level of load applied. Buy the material from a large supplier who will offer a wide selection of steel grades and help you make your choice.

Source

Which ordinary quality steel is considered boiling steel?

Boiling steel is low-oxidation steel that intensively releases gases in the mold during solidification. Gases formed: up to 90% CO, carbon dioxide, nitrogen, hydrogen, methane. Strong deoxidizing agents such as aluminum and titanium are not used in the production of this metal.

The main feature of a boiling steel ingot is the absence of a concentrated shrinkage cavity. The structure of the ingot depends on the intensity and boiling period of the melt. In the hardened state it has 5 zones:

- outer dense crust;

- accumulation of honeycomb bubbles having an elongated shape;

- intermediate zone between cellular and secondary bubbles;

- accumulation of deep (secondary) air bubbles;

- the core of the ingot is the zone of deep bubbles.

In high-quality ingots, the outer crust is so dense and thick that when heated and rolling, the accumulation of honeycomb bubbles does not open.

Valid elements

The regulatory document (GOST) also regulates the chemical composition of carbon steels of ordinary quality. such an element as silicon in steels with different degrees of deoxidation can vary within the following limits:

- boiling – up to 0.05%;

- semi-quiet (St1ps, St2ps, St3ps, etc.) – 0.05–0.15%;

- calm – 0.15–0.3%.

Mild steel grades

If you want to know which ordinary quality steel is considered mild steel, read the markings. For mild steel, grades are designated by conventional numbers depending on the chemical composition. The designation includes letters and numbers. For example, the St1sp brand means:

- structural carbon steel of ordinary quality - St;

- conditional brand number - 1;

- degree of deoxidation - SP (calm).

Requirements for metal quality are set out in GOST 380-2005.

Types of steels and their hot-dip galvanizing

The metallurgical industry is able to produce steel of the most varied composition; all of them can be conditionally divided into six types according to the types of impurities, which determine the main purpose of the steel. The main impurities are carbon, phosphorus, sulfur, silicon, manganese, as well as a combination of impurities a number of refractory metals, including chromium, nickel and some others.

These six types are:

- Carbon steels, that is, steels in which carbon is the main alloying element, are steels with a carbon content of less than 2.14%. Its presence does not exclude the existence of some elements in steels in even large quantities (manganese, silicon), but these elements play in this case a rather subordinate role - at some concentration they improve the mechanical and some other properties, in other cases they slightly worsen them.

- Steels with high silicon content. The element silicon in a concentration of up to 0.4% is a useful element because it affects the quality of steels (mainly their strength properties). But there are steels with a higher content – up to 2%. These are the so-called spring steels, used for the manufacture of springs and springs.

- Steels with high manganese content (over 1%). These are the so-called “ductile” steels. The usual manganese content in “carbon” steels is 0.4-0.6%, but these steels with a high manganese content have their own area of use.

- Automatic steels – these steels contain a high percentage of sulfur. Sulfur in steel is a harmful element because it leads to increased brittleness at elevated temperatures, but its content of about 0.2% improves the processing of steels on milling machines, so such steels are used for the manufacture of fasteners for non-critical purposes.

- Electrical steels containing high levels of phosphorus. These steels have a low coefficient of thermal expansion or special magnetic properties, therefore they are used in the electrical industry.

- Stainless steels. Typically contain high levels of nickel and chromium. Used as materials used in highly corrosive environments.

Ordinary quality steel

Ordinary quality steels are produced in accordance with GOST 380–2005. They are usually smelted in large open-hearth furnaces and oxygen converters. They are designated by the letters “St” and numbers from 0 to 6, for example: St0, St1, St6.

The letters “St” mean “Steel”, the numbers are the conventional number of the steel grade depending on its chemical composition.

At the end of the brand designation there are the letters “kp”, “ps”, “sp”, which indicate the method of deoxidation: “kp” - boiling, “ps” - semi-calm, “sp” - calm.

Carbon steels of ordinary quality contain C ≤ 0.49% and are produced in three varieties depending on the deoxidation technology: boiling with C ≤ 0.27% (St1kp, St2kp, St3kp and St4kp); semi-quiet (St1ps, St2ps, St3ps, St4ps, St5ps and St6ps); calm (St1sp, St2sp, St3sp, St4sp, St5sp and St6sp).

These steels also include steels St3Gps, St3Gsp, St5Gps with Mn = 0.8–1.10% (in steel St5Gps Mn = 0.8–1.20% is allowed). These steels have increased strength compared to the strength of steels St3ps, St3sp and St5ps.

In St0 steel, only the carbon content is limited (no more than 0.23%), sulfur, phosphorus, there are no special requirements for the technology of its smelting, only the temporary resistance is standardized (σв ≥ 300 MPa).

Table 5.1. Chemical composition of carbon steels of ordinary quality according to GOST 380-2005

| steel grade | Mass fraction, % | ||

| C | Mn | Si | |

| St0 | ≤0,23 | – | – |

| St1kp | 0,06-0,12 | 0,25-0,5 | ≤0,05 |

| St1sp | 0,06-0,12 | 0,25-0,5 | 0,15-0,3 |

| St2kp | 0,09-0,15 | 0,25-0,5 | ≤0,05 |

| St2sp | 0,09-0,15 | 0,25-0,5 | 0,15-0,3 |

| St3kp | 0,14-0,22 | 0,3-0,6 | ≤0,05 |

| St3sp | 0,14-0,22 | 0,4-0,65 | 0,15-0,3 |

| St4kp | 0,18-0,27 | 0,4-0,65 | ≤0,05 |

| St4sp | 0,18-0,27 | 0,4-0,7 | 0,15-0,3 |

| St5kp | 0,28-0,37 | 0,4-0,7 | 0,05-0,17 |

| St5sp | 0,28-0,37 | 0,5-0,8 | 0,15-0,35 |

| St6ps | 0,38-0,49 | 0,5-0,8 | 0,05-0,15 |

| St6sp | 0,38-0,49 | 0,5-0,8 | 0,15-0,30 |

In ordinary quality steels, the impurity content is standardized at a higher level than for steels of other groups: S ≤ 0.05%, P ≤ 0.04%, As ≤ 0.08%. In steels smelted from Kerch ore, As ≤ 0.15%, N ≤ 0.010% are allowed; in steels smelted in arc furnaces, N ≤ 0.012%.

For hot-rolled steels, the cooling rate decreases as the diameter (thickness) of the rolled product increases from 10 to 100 mm. A decrease in the cooling rate leads to the formation of coarser ferrite-pearlite structures and a decrease in σт and δ.

Chemical composition

Steel grades differ in composition, which determines the mechanical characteristics, scope and weldability of the material.

The small amount of alloying elements and high ductility of St3 make it the most common alloy used in construction. Not a single construction site can do without rolled steel from St3.

The chemical composition of the material includes the following elements:

- iron – 97%;

- carbon – 0.14-0.22%;

- nickel, copper, chromium – each no more than 0.3%;

- manganese - 0.4-0.65%;

- silicon - 0.05-0.17%;

- arsenic less than 0.08%;

- sulfur no more than 0.05;

- phosphorus less than 0.04%.

Carbon determines the hardness, strength, ductility, weldability, and physical and mechanical properties of steel. Sulfur and phosphorus are harmful impurities.

Alloying elements in the structure of this alloy that affect its characteristics are manganese, chromium, copper and nickel.

Mild steel grades

Full deoxidation alloys are divided into the following groups:

- mild carbon steels of ordinary quality - regulated by GOST 380-2005, designated “sp”;

- high-quality and high-quality - produced in accordance with GOST 1050-88, they do not have a letter index according to this standard;

- All alloy and low-alloy steels are usually made calm and do not have a letter index.

Attention! Steels produced by continuous casting are completely deoxidized during the process.