ore mining process

Hydrometallurgy

This is a technique in the field of mining metallurgy, the extraction of metals from their ores. Hydrometallurgy involves the use of aqueous solutions to extract metals from ores, concentrates and secondary or residual materials.[1][2] Technologies complementary to hydrometallurgy: pyrometallurgy, steam metallurgy and molten salt electrometallurgy. Hydrometallurgy is usually divided into three main areas:

- Leaching

- Concentration and purification of the solution

- Recovery of metals or metal compounds

Leaching

Leaching involves the use of aqueous solutions to extract metal from metal-containing materials that are in contact with material containing the valuable metal.[3] The first examples come from Germany and Spain in the 17th century, where it was used for copper mining.[4]

In leach solution conditions are varied in terms of pH, redox potential, presence of chelating agents and temperature to optimize the rate, extent and selectivity of dissolution of the desired metal component in the aqueous phase. Through the use of chelating agents, it is possible to selectively extract certain metals. Such chelating agents are typically Schiff base amines.[5]

The five basic leach reactor configurations are: in-situ, heap, vat, tank, and autoclave.

Leaching in place

In situ leaching is also called “solution mining.” Initially, the process involves drilling holes into the ore deposit. Explosives or hydraulic fracturing are used to create open pathways within the sediment for solution to penetrate. The leach solution is pumped into the deposit where it comes into contact with the ore. The solution is then collected and processed. The Beverly Uranium Mine is an example of in situ leaching, as well as the Trojan Mine in Zimbabwe.[ citation needed

]

Heap leaching

In heap leaching processes, crushed (and sometimes agglomerated) ore is piled into a pile covered with an impervious layer. The leach solution is sprayed on top of the pile and allowed to trickle down through the pile. The dump design typically includes settling tanks that allow the "saturated" leach solution (i.e., the solution with dissolved valuable metals) to be pumped for further processing. An example is gold cyanidation, where pulverized ores are extracted with a solution of sodium cyanide, which in the presence of air dissolves the gold, leaving a non-precious residue.

Balloon model of the complex anion aurocyanide or dicyanoaurate (I), [Au(CN)2]−.[6]

Leaching VAT

VAT leaching involves contacting the material, which is usually crushed and classified, with a leaching solution in large vats.

Tank Leaching

Agitated tank, also called stirred tank leaching, involves contacting material that is typically crushed and classified with a leach solution in agitated tanks. Stirring can improve reaction kinetics by increasing mass transfer. Reservoirs often have a series reactor configuration.

Leaching in an autoclave

Autoclave reactors are used for reactions at higher temperatures, which can increase the reaction rate. Likewise, autoclaving allows the use of gaseous reagents in the system.

Hydrometallurgy

Details Category:

HYDROMETALLURGY

, processes of extracting metals from ores by leaching them with solvents followed by precipitation from solutions, in most cases in the metallic state and less often in the form of chemical compounds. In this case, precipitation is carried out by: 1) cementation, 2) electrolysis, 3) reagents (in the form of a chemical compound), 4) adsorption and 5) reduction on coal. Hydrometallurgy (wet extraction) is most important for obtaining the following metals: gold, silver, zinc and copper. In addition, hydrometallurgy is used in the extraction of lead, platinum, nickel and mercury. Peculiar processes, usually classified as chemical technology, but essentially hydrometallurgical, are used 1) in the production of aluminum oxide, which is then processed by electrolysis to produce pure aluminum, and 2) in the extraction of rare metals in the form of chemical compounds. Solvents are solutions of salts, acids and alkalis.

In table Table 1 shows the main reagents used in the practice of hydrometallurgy and the metals extracted by them.

Some metals (copper, platinum) undergo preparatory operations (sulfatizing roasting, chlorinating roasting) and may. converted into the form of compounds soluble in water. In this case, leaching is done with water. A unique hydrometallurgical extraction process is the amalgamation of gold, silver and platinum. In this case, the extracted metals form a dispersed system in liquid metal (mercury). The basis of this process is not dissolution, but wetting with the subsequent formation of chemical compounds and solid solutions that have low solubility in mercury.

Preparatory operations for the implementation of hydrometallurgical processes consist of grinding, roasting and removal of unwanted impurities through leaching or enrichment operations. Crushing and fine grinding are used with widely varying degrees of grinding. Gold and silver ores are crushed in the range of 28-150 mesh. 200 mesh grinding is sometimes used, and 325 mesh when cyanidating concentrates at McIntyre. In very rare cases, cyanidation is carried out after grinding on rollers to 1 cm (Shasta County, California). Leaching during the grinding process is used in Sec. arr. during cyanidation in ball mills. In some cases, up to 70% of the metal (or even more) contained in the ore is recovered. Pre-leaching roasting is used in hydrometallurgical zinc extraction; in the latter case, oxidative firing is carried out at a fairly high temperature. The same roasting is used for copper sulfide ores and sometimes for the extraction of gold by cyanidation or chlorination when there is a significant association of gold with tellurite minerals and, in more rare cases, with sulfides.

Reduction firing is carried out at low to moderate temperatures in a carbon monoxide atmosphere. It is used in preparation for leaching of oxidized and silicate copper ores with ammonium carbonate and for cyanidation of refractory oxidized silver ores.

Chlorination firing is carried out in a neutral atmosphere or in an atmosphere of chlorine in the presence of alkali (or alkaline earth) metal chlorides at a moderate temperature. As a result, it produces chlorides of copper, lead, zinc and silver. Applies to sulfide and, to a lesser extent, oxidized ores. Chlorinating roasting is used when extracting platinum from sulfide concentrates, and followed by leaching with a solution of table salt to a small extent when processing lead-silver ores. The furnaces used for firing are Bedge, Gereshoff, McDougall, Holt-Dern, Skinner and some others.

According to the conditions of the place where the extraction is carried out, the following division can be established: 1) leaching in underground workings, 2) leaching in heaps, 3) leaching during the grinding process, 4) leaching in special vats, 5) leaching during dewatering (filtration and thickening ), leaching in a flotation mat. Leaching in underground mines or in other conditions, depending on the nature of the occurrence of the leached mass, currently has very limited use as an independent technological process. The method is based on the ability of sulfide minerals forming an ore body to quickly oxidize and form soluble copper salts. In 1923, underground copper leaching was introduced by the Ohio Copper Company to Utah, where they began leaching a large ore body containing approximately 38 million tons of fractured quartzite copper ore with 0.3% copper. Leaching in heaps is represented by hydrometallurgy. the process is the most primitive in the technique of its implementation, and has a very long history; it is used to treat ore dumps accumulated on the surface of the earth. Leaching in special vats is usually carried out using one of the following two methods: 1) processing by mixing the pulp, which is a mixture of finely ground ore with a solution (agitation), 2) circulation of the solution under percolation conditions (percolation) through a layer of sandy part of the ore, relatively more coarsely crushed, than the solid part of the pulp (in the previous case). Factors that determine extraction in hydrometallurgical processes, as well as the conditions for their implementation. subdivided next. sample: 1) the composition of the mineral grains subjected to leaching, their size, crystallographic shape and surface condition, 2) the nature of the association of mineral grains with the host rock, 3) the conditions of diffusion in the solution of ions and molecules of substances that are solvents, 4) the concentration of the solution, used for leaching, 5) the relationship between the weight of the solution used during leaching and the weight of the ore, 6) the duration of contact, 7) the temperature at which leaching is carried out, aeration carried out by blowing air, 9) additional reagents, 10) regeneration of solutions. Solvent diffusion conditions are very important in the leaching process; its concentration in solution determines the intensity with which this process occurs. It is quite obvious that around the particles of the dissolving metal there is an adjacent layer of solution with a reduced concentration of substances consumed in the dissolution process. If the concentration of at least one of these substances falls below the optimal value, then the dissolution process slows down, and with a further decrease it stops. Replenishment of the content of reagents in the solution layer surrounding the metal particles occurs due to diffusion processes from the rest of the solution that is not in direct contact with the mineral particles interacting with the solvents.

The conditions for the diffusion of ions and solvent molecules depend on the ore processing method. Let us first consider the general conditions of diffusion for the case of heterogeneous solid-liquid mixtures. The reaction rate for these cases of heterogeneous systems may be expressed by the formula

i.e., the amount of substance reacting per unit time (dx\dt) is proportional to the diffusion coefficient D, phase surface F and the decrease in solvent concentration; the latter is expressed as a fraction (S-C)/δ, where S is the concentration of the solution, C is the concentration of the layer over which the solvent diffuses around the particle, and δ is the thickness of the last layer. Outside the diffusion layer, the concentration of the solution is the same, but inside it it decreases in the direction of the dissolving particle. For the diffusion coefficient D of salts forming two ions in solution, Nernst gives the following equation

The speed of movement of cations u and anions v depends on the internal friction of the solution, which is determined by the viscosity of the pure solvent and the presence in it of substances that are in a dissolved state or form a dispersed system. According to Walden's law, the sum of ion velocities is inversely proportional to viscosity η

From the last two equations it is clear that the diffusion coefficient of the electrolyte and, consequently, the rate of reaction occurring in a heterogeneous system decreases according to the increase in internal friction of the solution. For non-electrolytes (for example, for oxygen during cyanidation), according to studies by Euler and Hedelius, the diffusion coefficient also depends on viscosity. Along with this, there is a drop in the concentration of gaseous substances dissolving in the solution. The molecular decrease in solubility is determined from the equation

where η0 and η denote solubility in water and in salt solution and η salt concentration. To an even greater extent than dissolved substances, the properties of the working solution are influenced by the finest particles of ore that are in suspension. The presence of a large number of particles suspended in the solution, most of which are so small that they pass through the pores of the filter, significantly increases the viscosity of the solution and has a greater effect on reducing the diffusion rate and solubility of gases than the presence of dissolved salts.

The concentration of the solution is determined by the composition of the ore being processed and the solvent used for this. The choice of solution concentration depends on the dissolution rate required for the process, on the grinding characteristics (determining the ratio of classes of crushed ore) and a number of other conditions for the implementation of the technological process. As a rule, increasing the concentration of a solution increases the dissolution rate to a certain limit. In the case of gold and silver recovery by cyanidation, this limit is reached at fairly low concentrations (from 0.25 to 0.4% NaCN). When leaching copper with sulfuric acid, increasing the concentration of the acid solution would have a greater effect if it did not interact with other components of the ore (dissolution of alkaline earth carbonates, iron, alumina, etc.). In the case of using acidic solutions of the sulfate salt of iron oxide for leaching copper, the concentration of the latter is above 1%, which reduces the use of current during deposition by electrolysis. When leaching calcined zinc concentrates, the transition to a solution of silicic acid and iron improves filtration and protects the anode from the formation of a crust on it. In table Table 2 shows the usual concentrations of solutions used for leaching.

Washing and filtration. At the end of leaching, the solution is separated from the solid part and the dissolved substance is washed from the latter. Sometimes the dewatering and washing stage is combined with leaching of the substance remaining undissolved. In the case of percolation of gold ores, medium and weak solutions and clean water are used for washing; in this case, the total amount of all solutions is in the range from 100 to 200% in relation to the material being processed. In the case of sequential percolation in several tanks, reduce the amount of solutions to 60% (Homstek). In the case of uniform passage of the solution through the percolated material, provided that the rate of diffusion and convection is not higher than the percolation rate, the metal content in the tailings after washing is determined by the formula

where a is the metal content in the solution after the operation preceding this washing, c is the metal content in the washing liquid, b and d are the corresponding volumes of solutions. The metal content in tailings after leaching is usually higher due to uneven percolation of the solution. The number of parts of wash water introduced into the process usually corresponds to losses: 1) with tailings when unloading into a dump, 2) due to leakage, 3) evaporation; otherwise, excess solutions accumulate at the plant. The separation of solutions from sludge is carried out at the initial stage by thickening. At the final stage, the separation of solutions and washing of sludge is carried out by: 1) decantation, 2) filtration, B) continuous countercurrent decantation and 4) repeated filtration with intermediate repulpation.

Precipitation of metals from solutions after leaching. After complete clarification (in special apparatus), the solutions are sent for the precipitation of metals from them; the latter is carried out by one of the following methods: 1) by simple cementation, 2) by cementation with the simultaneous release of hydrogen in order to create reducing environmental conditions, 3) by obtaining insoluble compounds, 4) by electrolytic means, 5) by decomposition by heating, 6) by adsorption, 7) restoration. The application of these principles to various metals and the nature of the reagents used are given in Table. 3.

Electrolytic deposition is a common deposition method in hydrometallurgy for copper and zinc; it makes it possible to regenerate the solvent simultaneously with precipitation. The conditions of electrolytic deposition are determined by the following factors: 1) voltage, 2) current density, 3) temperature, 4) concentration of the main components of the solution, 5) flow rate of the solution through the precipitation baths, 6) composition of the anodes and cathodes. The theoretical amount of metal deposited by the current is expressed by the formula

where I is the current strength, w is the atomic weight of the deposited metal and v is the valency of the metal. The use of current is determined by the ratio of the amount of actually deposited metal to the theoretical one. The current density determines the nature of the deposit. When copper is deposited from sulfuric acid solutions, the current density is 85–110 A/m2; when zinc is deposited from solutions with 3.5–7.5% sulfuric acid, it is 210–330 A/m2. In the case of the Tenton method (22-27% sulfuric acid) at a temperature of 60°C, a current density above 1000 A/m2 is used. The voltage depends on the composition of the solution, the distance between the electrodes and their composition. Under average copper deposition conditions, the voltage drop between adjacent electrodes is 2 V. For zinc electrolysis at the Trail plant, it is 3.9 V. The composition of the solutions determines the efficiency of the deposition process. The latter is very difficult in the presence of impurities: ferric sulfate (dissolves precipitated copper), arsenic, antimony and cobalt (reduce the use of current during zinc deposition). The nature of the resulting sediment worsens in the presence of suspended solids; in addition, copper deposits deteriorate with excess iron, zinc deposits - as a result of the presence of iron, vanadium, cobalt, nickel, arsenic and antimony. Additions of certain colloids (for example, gelatin) improve electrolysis conditions, promoting the formation of a dense deposit at high current densities. Purification of solutions is used to periodically remove impurities that impede the precipitation process or reduce the activity of solutions.

Precipitation by cementation with simultaneous release of hydrogen to create reducing environmental conditions is used for the precipitation of metals that dissolve in the presence of oxygen. In practice, this case has significant application for the precipitation of gold and silver from cyanide solutions. As a result of the decomposition of the complex salt, metallic gold is deposited and zinc is dissolved in the form of a cyanide complex. In this case, hydrogen is released at the cathode, polarizing its surface. The influence of polarization is largely eliminated by the creation of a loose lead deposit on the surface of zinc, which is easily achieved by leading it under the action of acetic acid salt [Pb(CH2CO2)2]. The complex anion, meeting the zinc surface, enters into the following cementation reaction:

On the surface of the other element of the pair, which is usually lead, the reduction of hydrogen occurs as a result of the dissolution of zinc in cyanide and alkali, since the reduction potential of the latter is much lower than that of sodium (or another metal that forms a complex salt).

At the time of reduction, hydrogen binds oxygen if the latter is present in the solution, and its excess is released on the surface of the zinc. The release of hydrogen as a result of the dissolution reaction (within certain limits) is of great importance, since it binds oxygen supplied with solutions or absorbed by them during the deposition process (especially in extractors), and this prevents the dissolution of gold (which would be possible in the presence of oxygen), as well as oxidation of zinc filings. According to the hydrogen reduction reaction on the anode surface, zinc dissolves, causing it to pass into solution in the form of a complex or first in the form of a zinc cation, which then passes into the cyanide complex ion according to the formulas:

Sludge processing and melting. Further processing of the product obtained as a result of sedimentation is carried out in various ways depending on the composition of the sediment. A detailed description of these methods is given in articles on the metallurgy of the corresponding metals. A summary of the main sludge treatment methods is given in Table. 4.

Source: Martens. Technical encyclopedia. Add. volume - 1936

- < Back

- Forward >

Concentration and purification of the solution

After leaching, the leach liquor usually must be concentrated with metal ions to be recovered. In addition, removal of unwanted metal ions is sometimes required.[1]

- Precipitation is the selective removal of a target metal compound or the removal of a major impurity by precipitation of one of its compounds. Copper is precipitated as sulfide to purify nickel leaching products.

- Cementation is the conversion of a metal ion into a metal through an oxidation-reduction reaction. Typical applications include adding scrap metal to a copper ion solution. The iron dissolves and metallic copper is deposited.

- Solvent extraction

- Ion exchange

- Gas reduction. Treatment of a solution of nickel and ammonia with hydrogen produces metallic nickel in powder form.

- Electrowinning is especially selective if the electrolysis process used to separate the precious metals is expensive. Gold can be galvanized from its solutions.

Solvent extraction

Solvent extraction is a mixture of an extractant and a diluent used to extract a metal from one phase to another. In solvent extraction, the mixture is often called "organic" because the main component (diluent) is some type of oil.

PLS (saturated leach solution) is mixed until emulsified with the removed organic matter and allowed to separate.[ citation needed

] The metal will be replaced by PLS with the organic they modified.[

clarification needed

] The resulting streams will be loaded organic and raffinate.

In electrolytic separation, the loaded organics are then emulsified with the depleted electrolyte and allowed to separate. The metal will be replaced by organics and electrolyte. The resulting streams will be organic-free and electrolyte-rich. The organic stream is recycled through the solvent extraction process while the aqueous streams are cycled through the leaching and electrochemical recovery[ clarification needed

] processes respectively.[

citation needed

]

Ion exchange

Chelating agents, natural zeolite, activated carbon, resins and liquid organics impregnated with chelating agents, are used to exchange cations or anions with the solution.[ citation needed

] Selectivity and recovery depend on the reagents used and the contaminants present.

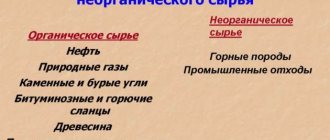

Methods of obtaining and mining

Mining and processing takes place in natural mines. Then the consumable raw materials are delivered to the foundry, where they are processed into the final material. Methods of obtaining:

- Powder. In the manufacture of alloys, powders are used - a mixture of the main components of the alloy in accordance with GOST. Using special equipment, the powder is compressed and given a certain shape. After this, the consumable material is sintered in an industrial furnace.

- Foundry method. All components of the future alloy are first melted and then mixed. The mixture should harden.

Natural springs

The largest amount of metals is found in the earth's crust. Their compounds can be found in various foods, water, air, and chemicals.

Natural compounds

Natural compounds:

- sulfides - cinnabar, zinc blende, sulfur pyrites;

- chlorides - rock salt, sylvinite;

- sulfates - gypsum, Glauber's salt;

- carbonates - magnesite, dolomite, limestone, marble, chalk;

- oxides - red, magnetic, brown iron ore;

- nitrates - Chilean saltpeter.

Ore mining (Photo: Instagram / dikomnw)

Extraction methods

There are two ways to mine metal ores:

- Open. It involves the development of a huge quarry that goes deeper towards the center. From its depths, ore is transported to the top using mining dump trucks, where it undergoes further processing. The average depth of the quarries is 300 meters. Large excavators, dredgers, and quarry equipment are used for development. The quarry method of extracting metal ore is used only if, after testing the soil, more than 57% ore is found in it. The main disadvantage of the quarry is the shallow depth of development.

- Closed. It involves the development of mines that can go down to a depth of several hundred meters. Applicable when less than 57% of useful ores were found on the surface after inspection. Externally, the mine resembles a well, which branches out to the sides at great depths. The main disadvantage is the danger for workers (frequent collapses, gas explosions, great health hazards).

One of the modern methods of mining metal ore is SGS. It is a hydromechanical method of ore mining, which involves the creation of a deep shaft equipped with a pipeline with a hydraulic monitor. A stream of water under high pressure is fed into the pipeline. With its help, rocks are broken off and float to the top of the mine. The effectiveness of this method is low, but it is completely safe for people.

Mine (Photo: Instagram / subcities)

rich mines

Rich iron mines:

- Bakchar iron ore deposit.

- Abakan iron ore deposit.

- Abagaskoe iron ore deposit.

- Kursk magnetic anomaly.

The richest deposits of aluminum ores are located in

- Hungary;

- France;

- India;

- South Africa;

- Kazakhstan;

- Russia;

- Yugoslavia;

- Kola Peninsula;

- Siberia.

Rich deposits of copper ore are located in the USA, Sweden, Canada, Russia, Finland, and South Africa.

Copper ore (Photo: Instagram / alex_tango1910)

Hydrometallurgy

A technique that is based on chemical reactions. They occur in various solutions. The most common materials obtained in this way are nickel, zinc, and gold.

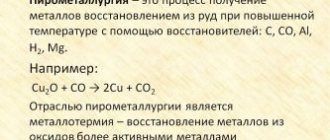

Pyrometallurgy

Metal is extracted from consumable raw materials under the influence of high temperatures. To carry out this method, furnaces and smelters are used. This method produces cast iron, lead, steel, nickel, copper, chromium

For the production of active metals it is important to use reducing agents

Electrometallurgy

Involves processing consumable raw materials with electric current. The current strength varies depending on the predominant components in the ore. With the help of electrometallurgy, various metals are obtained - alkaline earth, alkaline. The main ones are aluminum and magnesium.

- Using metals. This process is called metallothermy.

- With the help of hydrogen. Using this technique, it is possible to obtain a material with the least amount of foreign inclusions.

- Using carbon or carbon monoxide. This technique is called carbothermy.

Metal recovery

Metal recovery is the final stage of the hydrometallurgical process. Metals suitable for sale as raw materials are often produced directly from the metal extraction stage. However, sometimes further refining is required if ultra-high purity metals are to be obtained. The main types of metal reduction processes are electrolysis, gas reduction and precipitation. For example, the main target of hydrometallurgy is copper, which is usually obtained by electrolysis. Cu2+ ions are reduced at moderate potentials, leaving behind other contaminant metals such as Fe2+ and Zn2+.

Electrolysis

Electrowinning and electrorefining, respectively, involve the extraction and purification of metals using metal electrodeposition at the cathode, or metal dissolution or competitive oxidation reaction at the anode.

Precipitation

Precipitation in hydrometallurgy involves the chemical precipitation of either metals and their compounds or contaminants from aqueous solutions. Precipitation will continue when, through reagent addition, evaporation, pH change or temperature manipulation, any particular species exceeds its solubility limit.

Description

These are chemical processes occurring in metallurgical units at high (800-2000°C) temperatures. Therefore, pyrometallurgy is sometimes called “high temperature chemistry.” Often chemical reactions are accompanied by a change in the aggregate state of the reacting substances: melting, sublimation, evaporation of the resulting metals or their compounds. In such processes, interactions can occur between solid, liquid (melts) and gaseous phases in any combination.

Pyrometallurgical processes are the processes of agglomeration of metallurgical raw materials, smelting of charge materials, production of alloys, and refining of metals. In particular, this is roasting, blast furnace smelting, open-hearth smelting, smelting in converters, arc and induction furnaces. Pyrometallurgy is the basis for the production of cast iron, steel, lead, copper, zinc, etc.

In pyrometallurgy, carbon reduction is often used - in cases where the metals being reduced do not form stable carbides, in addition to those mentioned above, such metals include germanium, cadmium, tin and others. In cases where stable carbides are formed by reduced metals, metallothermy is often used instead of reduction with carbon.

Pyrometallurgy is the main and most ancient field of metallurgy. From ancient times until the end of the 19th century, metal production was based almost exclusively on pyrometallurgical processes. At the turn of the 19th and 20th centuries, another major branch of metallurgy, hydrometallurgy, acquired industrial importance. However, pyrometallurgy continues to maintain a dominant position both in terms of production scale and variety of processes.

At the beginning of the 20th century, along with flame heating methods, different types of electric heating (arc, induction, etc.) began to be used in metallurgy; Around the same time, electrolysis of molten chemical compounds was introduced into industry (production of aluminum and other non-ferrous metals).

In the 2nd half of the 20th century, plasma melting of metals, zone melting and electric fire melting became widespread. Metallurgical processes based on the use of electric current are classified as an independent field of pyrometallurgy - electrometallurgy.

Recommendations

- ^ a b

Brent Hiskey "Metallurgy, a Review" in Kirk-Othmer Encyclopedia of Chemical Technology, 2000, Wiley-VCH, Weinheim. Doi:10.1002 / 0471238961.1921182208091911.a01 - F. Habashi "Recent Trends in Mining Metallurgy" Journal of Mining and Metallurgy, Section B: Metallurgy, 2009, Vol. 45, pp. 1-13. doi:10.2298/JMMB0901001H

- Um, Namil (July 2022). Hydrometallurgical Process for Extracting Rare Earth Elements from Waste: Basic Application of Acid Leaching with Designed Scheme

. INTEC. pp. 41–60. ISBN 978-953-51-3402-2. - Habashi, Fathi (2005). "A Brief History of Hydrometallurgy". Hydrometallurgy

.

79

(1–2): 15–22. doi:10.1016/j.hydromet.2004.01.008. - Tasker, Peter A.; Tong, Christine S.; Westra, Arjan N. (2007). "Co-extraction of cations and anions in the extraction of non-ferrous metals." Coordination Chemistry Reviews

.

251

(13–14): 1868–1877. doi:10.1016/j.ccr.2007.03.014. - Greenwood, N.N.; & Earnshaw, A. (1997). Chemistry of the Elements (2nd ed.), Oxford: Butterworth-Heinemann. ISBN 0-7506-3365-4.

Corrosion

Corrosion is a process of spontaneous destruction of alloys and metals that occurs under the influence of the environment. Rust begins to appear when exposed to oxygen, water, sulfur oxides, and carbon.

Types of corrosion:

- atmospheric.

- electrolytic;

- gas;

- lifting;

- biological.

It is impossible to imagine human life without metals. They are used in various fields of activity. The process of mining metal ore to make homogeneous materials or alloys has remained virtually unchanged for hundreds of years. New equipment and technology appeared, but the essence of the process remained the same.

Hydrometallurgical copper production technology

Copper ore may also contain gold

This method is not widely used because it can result in the loss of precious metals contained in the copper ore.

Its use is justified when the rock is poor - it contains less than 0.3% of red metal.

How to obtain copper using the hydrometallurgical method?

First, the rock is crushed to a fine fraction. Then it is placed in an alkaline composition. The most commonly used solutions are sulfuric acid or ammonia. During the reaction, copper is replaced by iron.

Cementation of copper with iron

The solutions of copper salts remaining after leaching undergo further processing - cementation:

- iron wire, sheets or other scraps are placed in the solution;

- during a chemical reaction, iron displaces copper;

- As a result, the metal is released in the form of a fine powder, in which the copper content reaches 70%. Further purification occurs by electrolysis using a cathode plate.