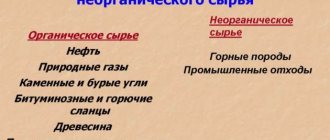

The concept of metallurgy: general methods for producing metals

Metallurgy is the science of industrial methods for producing metals. There are ferrous and non-ferrous metallurgy.

Ferrous metallurgy is the production of iron and its alloys (steel, cast iron, etc.).

Non-ferrous metallurgy is the production of other metals and their alloys.

Metal alloys are widely used. The most common iron alloys are cast iron and steel.

Cast iron is an iron alloy containing 2-4 wt. % carbon, as well as silicon, manganese and small amounts of sulfur and phosphorus.

Steel is an iron alloy containing 0.3-2 wt. % carbon and small impurities of other elements.

Alloy steels are alloys of iron with chromium, nickel, manganese, cobalt, vanadium, titanium and other metals. The addition of metals gives steel additional properties. Thus, the addition of chromium gives the alloy strength, and the addition of nickel gives the steel ductility.

Main stages of metallurgical processes:

- Enrichment of natural ore (purification, removal of impurities)

- Production of metal or its alloy.

- Metal machining

Most metals occur in nature in the form of compounds. The most common metal in the earth's crust is aluminum. Then iron, calcium, sodium and other metals.

| Finding metals in nature | ||

| Active metals - in the form of salts | Medium activity metals - in the form of oxides and sulfides | Low-active metals - in the form of simple substances |

| Sodium chloride NaCl | ||

Active metals (alkali and alkaline earth) cannot be obtained from compounds using classical “chemical” methods. Such metals in the form of ions are very weak oxidizing agents, and in their simple form they are very strong reducing agents, so it is very difficult to reduce them from cations to simple substances. The more active the metal, the more difficult it is to obtain it in its pure form - because it tends to react with other substances.

Such metals can be obtained, as a rule, by electrolysis of molten salts , or by displacement of other metals from salts under harsh conditions.

Sodium is produced industrially by electrolysis of molten sodium chloride with calcium chloride additives:

2NaCl = 2Na + Cl2

Potassium is obtained by passing sodium vapor through a melt of potassium chloride at 800°C:

KCl + Na = K↑ + NaCl

Lithium can be obtained by electrolysis of molten lithium chloride in a mixture with KCl or BaCl2 (these salts serve to lower the melting point of the mixture):

2LiCl = 2Li + Cl2

Cesium can be obtained by heating a mixture of cesium chloride and specially prepared calcium:

Ca + 2CsCl = 2Cs + CaCl2

Magnesium is obtained by electrolysis of molten carnallite or magnesium chloride with additions of sodium chloride at 720–750°C:

MgCl2 → Mg + Cl2

Calcium is obtained by electrolysis of molten calcium chloride with calcium fluoride additives:

CaCl2 → Ca + Cl2

Barium is obtained from the oxide by reduction with aluminum in vacuum at 1200 °C:

4BaO+ 2Al = 3Ba + Ba(AlO2)2

Aluminum is produced by electrolysis of a solution of aluminum oxide Al2O3 in cryolite Na3AlF6:

2Al2O3 → 4Al + 3O2

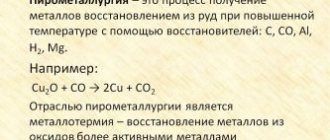

Low-active and inactive metals are reduced from oxides with carbon, carbon monoxide (II) CO or a more active metal. Metal sulfides are first fired.

3.2. Reduction of metals with coal

Pure metals can be obtained by reduction from oxides with carbon. In this case, only metal oxides located in the series of electrochemical activity after aluminum .

For example , iron is obtained by reduction from oxide with carbon:

2Fe2O3 + 6C → 2Fe + 6CO

ZnO + C → Zn + CO

Metal oxides, located in the series of electrochemical activity up to aluminum , react with coal to form metal carbides:

CaO + 3C → CaC2 + CO

Internal structure and physical properties of metals

Metals are simple substances whose atoms can only give up electrons. This feature of metals is due to the fact that at the outer level of these atoms there are few electrons (most often from 1 to 3) or the outer electrons are located far from the nucleus. The fewer electrons at the outer level of the atom and the further they are located from the nucleus, the more active the metal (the more pronounced its metallic properties).

Task 8.1. Which metal is more active:

Name the chemical elements A, B, C, D.

Metals and non-metals in Mendeleev's Periodic Table of Chemical Elements (PSM) are separated by a line drawn from boron to astatine. Above this line in the main subgroups are non-metals (see lesson 3). The remaining chemical elements are metals.

Task 8.2. Which of the following elements are metals: silicon, lead, antimony, arsenic, selenium, chromium, polonium?

Question. How can we explain the fact that silicon is a non-metal, and lead is a metal, although they have the same number of outer electrons?

An essential feature of metal atoms is their large radius and the presence of valence electrons weakly bound to the nucleus. For such atoms, the ionization energy* is small.

* IONIZATION ENERGY is equal to the work spent on removing one external electron from an atom (to ionize an atom) that is in the ground energy state.

Some of the valence electrons of metals, breaking away from atoms, become “free”. “Free” electrons easily move between atoms and metal ions in the crystal, forming an “electron gas” (Fig. 28).

At a subsequent moment in time, any of the “free” electrons can be attracted by any cation, and any metal atom can give up an electron and turn into an ion (these processes are shown in Fig. 28 by dotted lines).

Thus, the internal structure of a metal is similar to a layer cake, where positively charged “layers” of metal atoms and ions alternate with electronic “layers” and are attracted to them. The best model of the internal structure of a metal is a stack of glass plates moistened with water: it is very difficult to tear one plate from another (strong metals), and it is very easy to move one plate relative to another (ductile metals) (Fig. 29).

Task 8.3. Make such a “model” of the metal and verify these properties.

A chemical bond carried out by “free” electrons is called a metallic bond .

“Free” electrons also provide such physical properties of metals as electrical and thermal conductivity, plasticity (malleability), as well as metallic luster.

Task 8.4. Find metal objects around the house.

By completing this task, you can easily find metal utensils in the kitchen: pots, pans, forks, spoons. Machine tools, airplanes, cars, diesel locomotives, and tools are made from metals and their alloys. Modern civilization is impossible without metals, since electrical wires are also made of metals - Cu and Al. Only metals are suitable for making antennas for radio and television receivers; the best mirrors are made from metals. In this case, not pure metals are often used, but their mixtures (solid solutions) - ALLOYS.

3.4. Reduction of metals with more active metals

More active metals displace less active metals from their oxides. The activity of metals can be roughly estimated from the electrochemical series of metals:

The reduction of metals from oxides by other metals is a common method for obtaining metals. Aluminum and magnesium are often used to restore metals. But alkali metals are not very suitable for this - they are too chemically active, which creates difficulties when working with them.

For example , cesium explodes in air.

Aluminothermy is the reduction of metals from oxides with aluminum.

For example : aluminum reduces copper (II) oxide from the oxide:

3CuO + 2Al = Al2O3 + 3Cu

Magneothermy is the reduction of metals from oxides with magnesium.

CuO + Mg = Cu + MgO

Iron can be displaced from the oxide using aluminum:

2Fe2O3 + 4Al → 4Fe + 2Al2O3

Aluminothermy produces a very pure metal, free of carbon impurities.

Active metals displace less active metals from solutions of their salts.

For example , when copper (Cu) is added to a solution of a salt of a less active metal - silver (AgNO3), a chemical reaction will occur:

2 AgNO 3 + Cu = Cu ( NO 3 )2 + 2 Ag

The copper will be covered with white silver crystals.

When adding iron (Fe) to a solution of copper salt (CuSO4), a pink coating of copper metal appeared on the iron nail:

CuSO 4 + Fe = FeSO 4 + Cu

When zinc is added to a solution of lead(II) nitrate, a layer of metallic lead forms on the zinc:

Pb(NO3)2 + Zn = Pb + Zn (NO3)2

How metal is made

Ore is a mixture of iron and oxygen compounds - iron oxides. Iron is extracted from ore at high temperatures. To do this, it is heated with a reducing agent - a substance that can take oxygen away from iron. The most accessible, perhaps the only possible reducing agent in ancient times was firewood. But firewood produces too little heat, since it contains a lot of water; Even in dry wood, the content of the combustible element (carbon) is low. There is also hydrogen in firewood, but it is associated with oxygen, which is part of the wood, and therefore cannot take oxygen away from iron oxides.

However, already in ancient times, people noticed that with a small amount of air during the combustion process, firewood becomes charred, turning into charcoal, consisting of carbon and hydrogen. When burning one kilogram of charcoal, three to four times more heat is released than when burning one kilogram of firewood. When burned, it gives a high temperature at which the reduction of iron oxides occurs. Carbon, combining with oxygen, turns into dioxide (carbon dioxide) and leaves almost pure metal.

Establishing who first proposed smelting metal on charcoal is probably as difficult as identifying the author of the first application for the invention of a wheel, bow, or boat. It is also impossible to establish in which country metal smelting on charcoal was first carried out. However, it is known that the ancient civilizations of Egypt, China, and India used these materials. Moreover, charcoal is still used today.

Tree trunks, cleared of branches, were placed either in a hole (pit method) or in a cone-shaped pile with a diameter of 3–4 to 10–12 meters and a height of 3–7 meters (fire method). Passages were left in the pile for air and flue gases to escape. The lower part of the vertical heap was compacted with clay, and the entire surface of the heap was covered with earth. The firewood in the middle of the pile was lit through a special kindling hole. The smoke escaped into a channel left in the center of the heap, or, in more advanced heap designs, through a pipe specially constructed in the center of the heap. The campfire method existed in Russia and, for example, in Sweden, which was the largest exporter of charcoal until the twentieth century.

In the pit method, the pit was usually placed on a slope to allow the resin formed during the charcoaling process to drain.

The art of the charcoal burner was to manipulate the opening and closing of the air supply holes to allow as little wood as possible to burn in the pile so that the remainder, under the influence of the released heat, was subjected to dry distillation - releasing water, bound oxygen and turning into charcoal . The pit method produced coal of low quality, small and low-strength. And branches and small wood were used for its production. When using the fire method, selected wood was used, mainly coniferous. Over time, charcoal became increasingly used for blacksmithing and iron smelting. And in turn, more and more of it was needed.

The higher the temperature in the device for the production of iron or cast iron, the faster the process goes. Even the ancient craftsmen mastered the importance of blowing to improve fuel combustion processes, so they began to use bellows to supply air. More blast, more air, higher temperature, more metal. The larger the installation, the higher its productivity. This is the main direction in which the development of units for the production of iron, and then cast iron, took place.

The first craftsmen produced 2–5 kilograms of metal per day with great difficulty. Centuries passed, more and more metal was required, furnaces grew both in width and height, consuming more and more ore, air and wood. The productivity of the units was already in the hundreds of kilograms and even tons.

Several centuries ago, devices were created for smelting iron from ores, which are still used today - these are blast furnaces. The name itself comes from the ancient Russian verb “dmati” - to blow, and clearly characterizes the technological process of metal production.

A blast furnace is a hollow structure made up of two truncated cones. Coal and ore were loaded into the blast furnace from above, and air was blown in from below. The coal burned at the bottom of the blast furnace, releasing heat and turning into carbon dioxide (carbon dioxide). A little higher, carbon dioxide met with new portions of charcoal and turned into monoxide or “carbon monoxide,” as it is colloquially called. And already on the next tier, carbon monoxide reduced iron oxides and turned back into carbon dioxide. The ore was disappearing. Instead, liquid metal and slag were formed. They seeped through the layer of materials and collected at the bottom of the unit.

In the old days, the temperature in blast furnaces was not high enough, and therefore the metal did not melt, but settled to the bottom of the furnace in the form of a spongy mass. Kritsa was extracted and forged in a hot state, squeezing light non-metallic inclusions from the depths to the surface. However, metallurgy was possible only on a small scale of production, in our modern understanding. Today, blast furnaces produce only liquid metal – cast iron, which is used to make a variety of castings. However, most of the cast iron is processed in steelmaking units: converters, open hearths, in which, by removing carbon, silicon, manganese, and sulfur from the cast iron, strong and elastic steel is obtained.

Cast iron contains up to 3% carbon, and steel only 0.3%.

The most common steel is 3, our main structural material is the same cast iron, but in which there is 0.3% carbon. This is the steel from which cars, fittings, strips, etc. are made.

For hundreds of years, ferrous metals were produced using charcoal. To obtain one ton of metal, from two to four tons of such coal were consumed.

And to prepare a ton of charcoal, 10 - 12 cubic meters of forest were required. Ironworks were built, and the ax began to walk through the neighboring forests. At the end of the 16th century. Queen Elizabeth of England was forced to ban the use of forests for coal production. After 25 - 30 years, iron smelting was stopped almost throughout England. And in the 18th century. The Russian Empress Elizabeth, by a special decree, prohibited the construction of iron factories within a radius of 200 miles around Moscow.

But what about Elizabeth? In ancient Egypt, under Pharaoh Ramses II, more than 1,000 copper smelting furnaces operated. Charcoal was used, which was burned from palm trees. And then (about 300 years later) copper smelting production practically ended. Palm trees were cut down and they switched to imported copper.

SHARE INTERESTING INFORMATION

Alloys

Metals easily form alloys - materials that have metallic properties and consist of two or more chemical elements (simple substances), at least one of which is a metal. Many metal alloys have a single metal as the base with small additions of other components. In principle, it is difficult to draw a clear boundary between metals and alloys, since even the purest metals contain “trace” impurities of other chemical elements.

All the items listed above - machines, airplanes, cars, frying pans, forks, spoons, jewelry - are made from alloys. Impurity metals (alloying components) very often change the properties of the base metal for the better, from a human point of view. For example, both iron and aluminum are fairly soft metals. But when combined with each other or with other components, they turn into steel, duralumin and other durable structural materials. Let's look at the properties of the most common alloys.

Steel is an alloy of iron and carbon, containing up to 2% of the latter. Alloy steels also contain other chemical elements - chromium, vanadium, nickel. There are far more steels produced than any other metals and alloys, and it is difficult to list all of their possible uses. Low-carbon steel (less than 0.25% carbon) is consumed in large quantities as a structural material, and steel with a higher carbon content (more than 0.55%) is used to make cutting tools: razor blades, drills, etc.

Iron forms the basis of cast iron . Cast iron is an alloy of iron with 2–4% carbon. Silicon is also an important component of cast iron. A wide variety of very useful products can be cast from cast iron, such as manhole covers, pipeline fittings, engine cylinder blocks, etc.

Bronze is an alloy of copper, usually with tin as the main alloying component, and also with aluminum, silicon, beryllium, lead and other elements, excluding zinc. Tin bronzes were known and widely used in ancient times. Most antique bronzes contain 75-90% copper and 25-10% tin, which makes them look similar to gold, but they are more refractory. This is a very durable alloy. Weapons were made from it until they learned how to produce iron alloys. An entire era in human history is associated with the use of bronze: the Bronze Age.

Brass is an alloy of copper with Zn, Al, Mg. These are non-ferrous alloys with a low melting point and are easy to process: cut, weld and solder.

Cupronickel is an alloy of copper and nickel, sometimes with the addition of iron and manganese. In terms of external characteristics, cupronickel is similar to silver, but has greater mechanical strength. The alloy is widely used for making tableware and inexpensive jewelry. Most modern silver-colored coins are made from cupronickel (usually 75% copper and 25% nickel with minor additions of manganese).

Duralumin , or duralumin, is an aluminum-based alloy with the addition of alloying elements - copper, manganese, magnesium and iron. It is characterized by its steel strength and resistance to possible overloads. It is the main structural material in aviation and astronautics.